Method for cleaning aluminum frame for hollow glass

A cleaning method and technology for aluminum frame, applied in the direction of cleaning method using liquid, cleaning method using gas flow, cleaning method and utensils, etc., can solve problems such as damage to aluminum frame, reduction of service life, accumulation of dust and cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

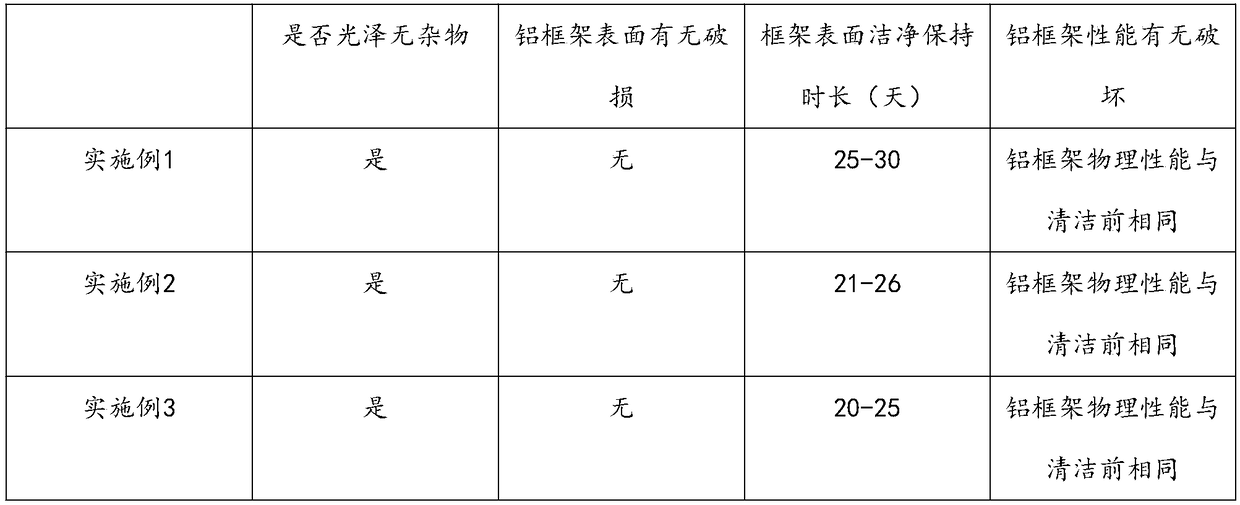

Examples

Embodiment 1

[0027] A method for cleaning an aluminum frame for insulating glass, characterized in that it comprises the following steps,

[0028] Step 1. Initial cleaning: erect the aluminum frame and then fix it, use a 1400-1800W blowing device to blow hot air for 20-25 minutes;

[0029] Step 2. Clean again: After the hot air is blown, use a medium-pressure blower to blow the surface of the aluminum frame for 10-15 minutes;

[0030] Step 3, soaking treatment: put the glass into the soaking pool and soak for 25-30 minutes, and stir the soaking liquid in the soaking pool with a stirring device when soaking;

[0031] Step 4, carry out blowing treatment: use a 1400-1800W blowing device to blow hot air on the soaked aluminum frame, and blow it for 20-25 minutes;

[0032] Step 5. Soak again: Put the aluminum frame into the soaking pool again for 15-20 minutes;

[0033] Step 6. Continue blowing treatment: Rinse the soaked aluminum frame with deionized water for 3-5 minutes, then use a 1000-14...

Embodiment 2

[0043] A method for cleaning an aluminum frame for insulating glass, characterized in that it comprises the following steps,

[0044] Step 1. Initial cleaning: erect the aluminum frame and then fix it, use a 1400-1800W blowing device to blow hot air for 20-25 minutes;

[0045] Step 2. Clean again: After the hot air is blown, use a medium-pressure blower to blow the surface of the aluminum frame for 10-15 minutes;

[0046] Step 3, soaking treatment: put the glass into the soaking pool and soak for 25-30 minutes, and stir the soaking liquid in the soaking pool with a stirring device when soaking;

[0047] Step 4, carry out blowing treatment: use a 1400-1800W blowing device to blow hot air on the soaked aluminum frame, and blow it for 20-25 minutes;

[0048] The stirring speed of described stirring equipment is 180r / min;

[0049] The soaking solution is made of the following materials by weight,

[0050] 5-9 parts of anionic polyacrylamide, 5-9 parts of non-ionic polyacrylamid...

Embodiment 3

[0057] A method for cleaning an aluminum frame for insulating glass, characterized in that it comprises the following steps,

[0058] Step 1. Initial cleaning: erect the aluminum frame and then fix it, and blow the surface of the aluminum frame with a medium-pressure blower for 10-15 minutes;

[0059] Step 2. Cleaning again: After blowing with the medium-pressure blower, use a 1000-1400W blowing device to blow hot air. After blowing for 20-25 minutes, continue to blow the surface of the aluminum frame with a medium-pressure blower for 10-15 minutes;

[0060] Step 3, soaking treatment: put the aluminum frame into the soaking pool for 25-30 minutes;

[0061] Step 4, carry out blowing treatment: use a 1000-1400W blowing device to blow hot air on the soaked aluminum frame, and blow it for 10-15 minutes;

[0062] The stirring rate of the stirring equipment is 180R / min;

[0063] The soaking solution is made of the following materials by weight,

[0064] 5-9 parts of anionic polya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com