Method for cleaning corrugated board

A corrugated board, cleaning technology, applied in the cleaning method using tools, the cleaning method using liquid, the cleaning method using gas flow, etc., can solve the problems of falling ash and trouble, and achieve the effect of low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

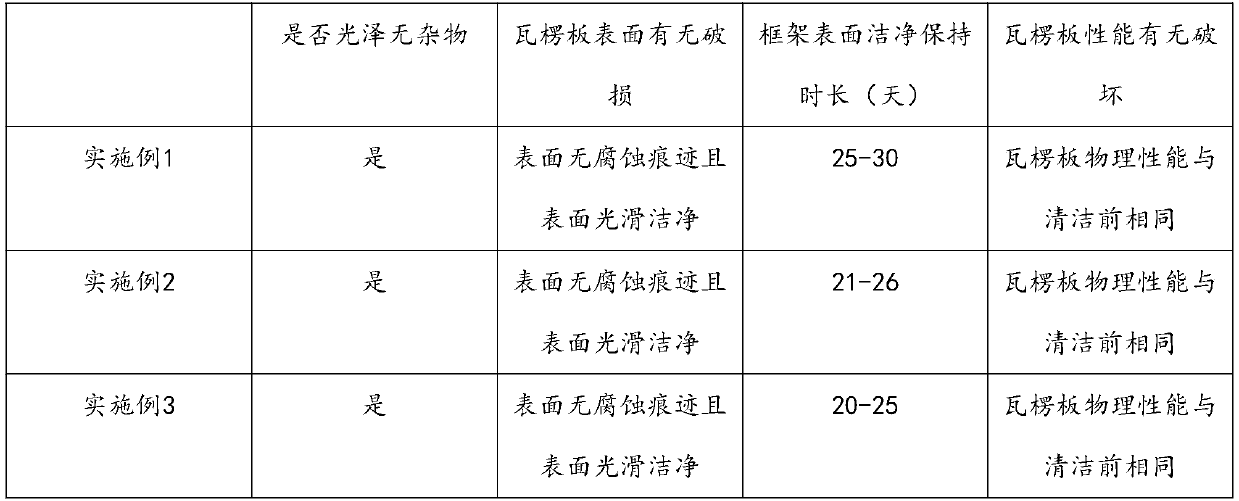

Embodiment 1

[0032] A cleaning method for corrugated board, characterized in that: comprising the following steps,

[0033] Step 1. Initial blowing: put the corrugated board vertically, and use a medium-pressure fan to blow the surface of the corrugated board 1-2 times;

[0034] Step 2. Preliminary cleaning: rinse the surface of the corrugated board with columnar water 2-3 times after blowing;

[0035] Step 3, blow air again: After showering, let it stand for 4-7 minutes, wait for the water droplets to fall naturally, and then use a 1900-2200W fan to blow air evenly for 17-21 minutes;

[0036] Step 4. Clean up again:

[0037] ⅠSpray the cleaning solution evenly on the blown corrugated board, and then let it stand for 40-45 minutes;

[0038] Ⅱ After standing still, take out the corrugated board, and take out the wet towel soaked in the cleaning solution, and evenly wipe the surface of the corrugated board with a wet towel for 1-2 times;

[0039] Step 5. Rinse: Rinse the surface of the co...

Embodiment 2

[0052] A cleaning method for corrugated board, characterized in that: comprising the following steps,

[0053] Step 1. Initial blowing: put the corrugated board vertically, and use a medium-pressure fan to blow the surface of the corrugated board 1-2 times;

[0054] Step 2. Preliminary cleaning: rinse the surface of the corrugated board with columnar water 2-3 times after blowing;

[0055] Step 3. Clean up again:

[0056] Ⅰ After showering, let it stand for 4-7 minutes until the water drops fall naturally;

[0057] ⅡSpray the cleaning solution evenly on the corrugated board after standing, and then let it stand for 40-45 minutes;

[0058] Ⅲ After standing still, take out the corrugated board, and take out the wet towel soaked in the cleaning solution, and evenly wipe the surface of the corrugated board with a wet towel for 1-2 times;

[0059] Step 5. Rinse: Rinse the surface of the corrugated board with columnar water, and wipe it with a towel or brush while rinsing, for a ...

Embodiment 3

[0071] A cleaning method for corrugated board, characterized in that: comprising the following steps,

[0072] Step 1. Initial blowing: put the corrugated board vertically, and use a medium-pressure fan to blow the surface of the corrugated board 1-2 times;

[0073] Step 2. Preliminary cleaning: rinse the surface of the corrugated board with columnar water 2-3 times after blowing;

[0074] Step 3, blow air again: After showering, let it stand for 4-7 minutes, wait for the water droplets to fall naturally, and then use a 1900-2200W fan to blow air evenly for 17-21 minutes;

[0075] Step 4. Clean up again:

[0076] ⅠSpray the cleaning solution evenly on the blown corrugated board, and then let it stand for 40-45 minutes;

[0077] Ⅱ After standing still, take out the corrugated board, and take out the wet towel soaked in the cleaning solution, and evenly wipe the surface of the corrugated board with a wet towel for 1-2 times;

[0078] Step 5. Rinse: Rinse the surface of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com