PU adhesive for soft lens leather and preparation method thereof

An adhesive, soft mirror technology, applied in the direction of adhesive, adhesive type, polyurea/polyurethane adhesive, etc., to achieve the effect of low crystallinity, simple process and soft hand feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

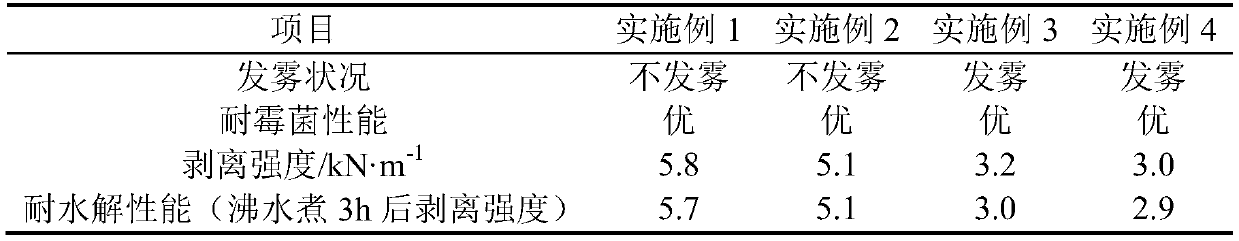

Examples

Embodiment 1

[0028]Example 1: Weigh 300g of polymethylpropylene adipate diol in a reaction flask, distill under reduced pressure at 110°C to remove water below 300ppm, add 0.2g of antioxidant BHT and 0.003g of phosphoric acid at the same time and stir well . Then add 71g of isocyanate (XDI) and stir evenly in the reaction flask to make it react at 70-80°C for 2h, then add 20.3g of methylpropanediol chain extender and organic solvent N,N-dimethylformamide to it. Carry out capping, continue to stir for 1 hour, and then wrap the material. This is the main ingredient, and the solid content is 60%. Add organic solvent butanone to another reaction bottle, then add 110g XDI and 17g glycerin to react at 70-80°C for 2 hours, cool and discharge, and prepare a curing agent with an NCO content of 10% and a solid content of 80%.

Embodiment 2

[0029] Example 2: Weigh 300g of polymethylpropylene sebacate diol in a reaction flask, distill under reduced pressure at 110°C to remove water below 300ppm, add 0.2g of antioxidant BHT and 0.003g of phosphoric acid at the same time and stir well . Then add 71g of isocyanate (XDI) and stir evenly in the reaction flask to make it react at 70-80°C for 2h, then add 20.3g of methylpropanediol chain extender and organic solvent N,N-dimethylformamide to it. Carry out capping, continue to stir for 1 hour, and then wrap the material. This is the main ingredient, and the solid content is 60%. Add the organic solvent dimethyl carbonate in another reaction bottle, then add 110g XDI and 25g trimethylolpropane, react at 70-80°C for 2h, add the organic solvent, cool and discharge, and prepare a solid NCO content of 10%. 80% curing agent.

Embodiment 3

[0030] Example 3: Weigh 300g of polyneopentyl glycol adipate diol in a reaction flask, distill under reduced pressure at 110°C to remove water below 300ppm, add 0.2g of antioxidant BHT and 0.003g of phosphoric acid at the same time and stir thoroughly uniform. Then add 71g of isocyanate (XDI) and stir evenly in the reaction flask to make it react at 70-80°C for 2h, then add 20.3g of methylpropanediol chain extender and organic solvent N,N-dimethylformamide to it. Carry out capping, continue to stir for 1 hour, and then wrap the material. This is the main ingredient, and the solid content is 60%. Add organic solvent acetone to another reaction flask, then add 110g XDI and 19g diethylenetriamine, react at 70-80°C for 2h, add organic solvent, cool and discharge, and prepare NCO content of 10%, solid content of 80% curing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com