Method for eliminating printing drawing filaments, FDM printing device, storage medium and processor

A wire drawing and printer technology, applied in the field of 3D printing, can solve the problems of nozzle material wire drawing and retraction action can not play a good effect, so as to increase the complexity and eliminate the effect of wire drawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

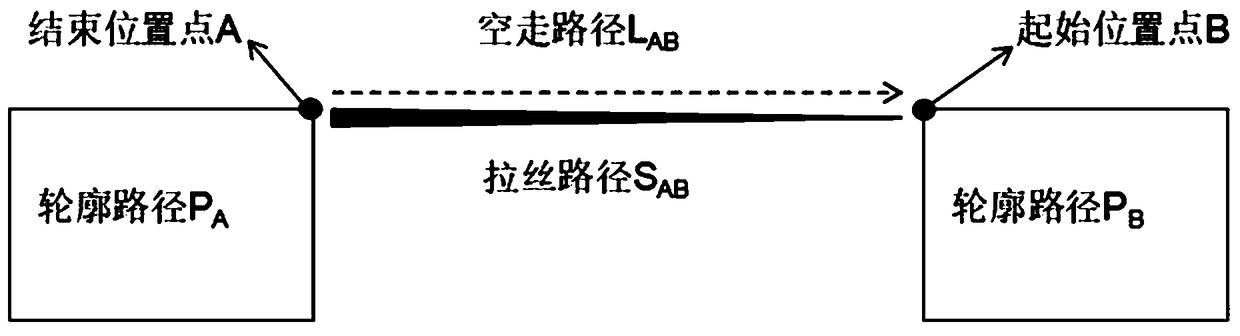

[0028] In this embodiment, a method for eliminating printing stringing, when the printer nozzle moves from the contour path P A The end position A jumps to another contour path P B When the starting position B of , perform the following steps:

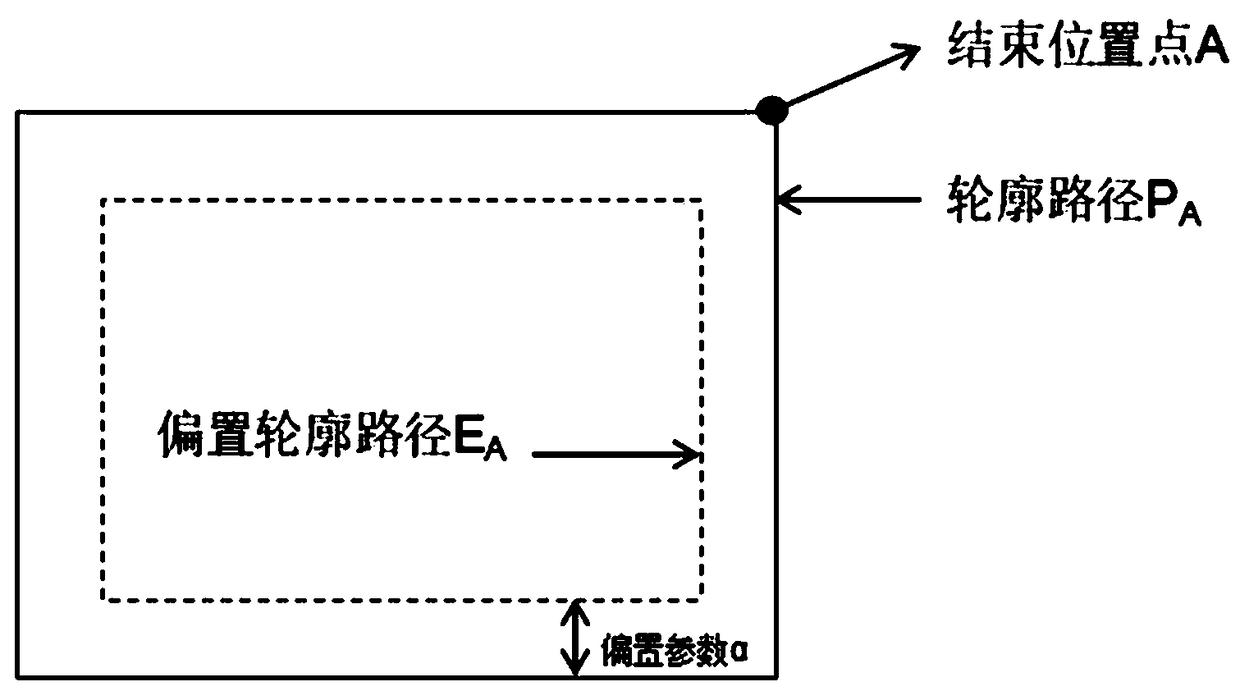

[0029] Step 1. The nozzle of the printer starts from point A and moves along a specific path with a minimum length of D, and performs an action of eliminating wire drawing; wherein, the specific path is the contour path P A The offset contour path E obtained after reducing the offset with parameter α A ,Such as figure 2 shown. The minimum length of the wire disappearing path is calculated as follows: D=L AB × R D , where L AB is the idling path length between the end position A and the start position B, R D is the disappearance coefficient.

[0030] Step 2. After performing the thread removal action, the printer nozzle jumps from the current position to the start position B to continue printing.

[0031] Before executing step...

Embodiment 2

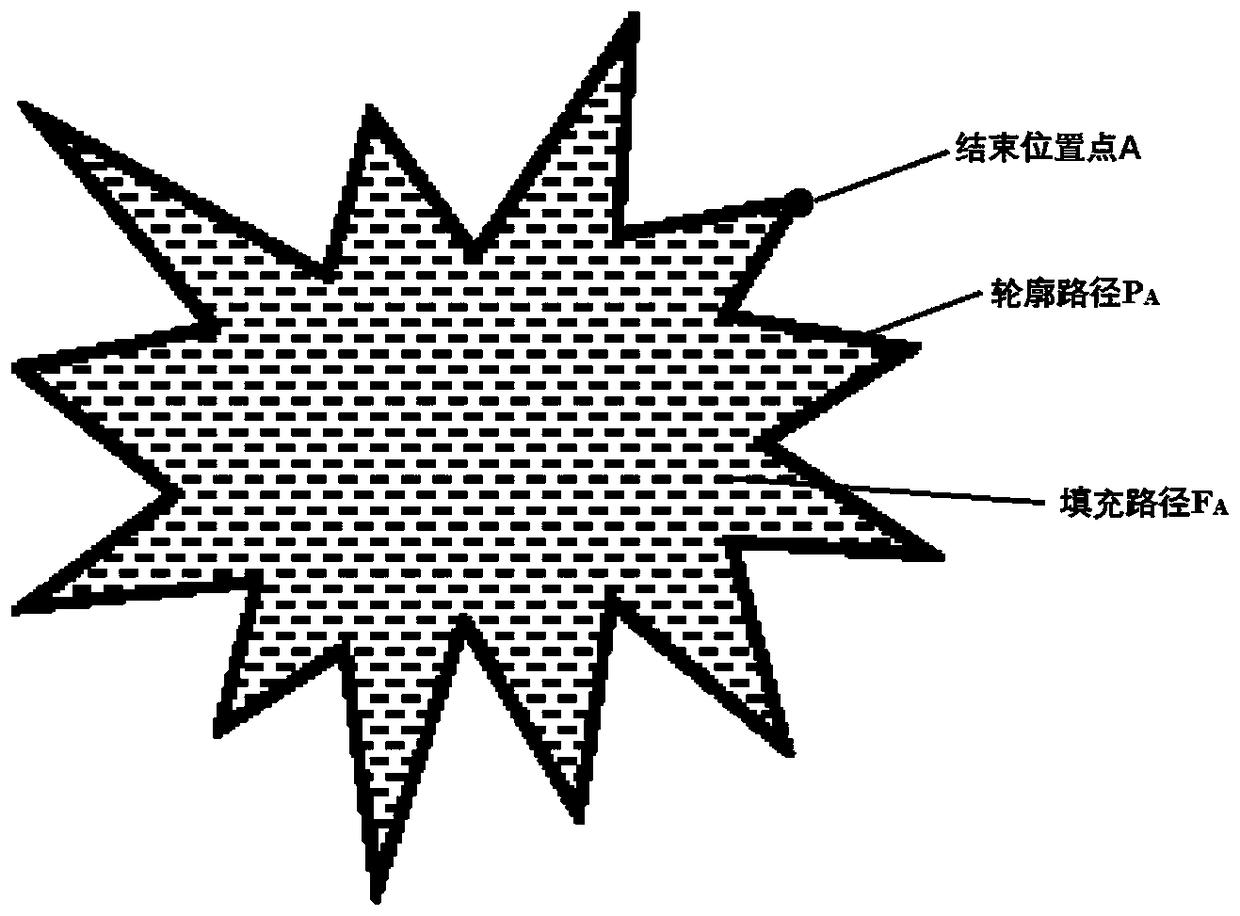

[0036] In this embodiment, a method for eliminating printing stringing, when the printer nozzle moves from the contour path P A The end position A jumps to another contour path P B When the starting position B of , perform the following steps:

[0037] Step 1. Starting from point A, the printer nozzle moves a thread elimination path with a minimum length of D in a specific area, and performs an action of eliminating thread drawing; wherein, the specific area is the contour path P A The fill path F within A ,Such as image 3 shown. The minimum length of the wire disappearing path is calculated as follows: D=L AB × R D , where L AB is the idling path length between the end position A and the start position B, R D is the disappearance coefficient.

[0038] Step 2. After performing the thread removal action, the printer nozzle jumps from the current position to the start position B to continue printing.

[0039] Before executing step 1, it should be ensured that the origin...

Embodiment 3

[0044] Yet another embodiment of the present invention also provides an FDM printing device, which adopts the method for eliminating printing stringing as described in Embodiment 1 or Embodiment 2 during printing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com