An improved back suction valve for hot melting adhesives

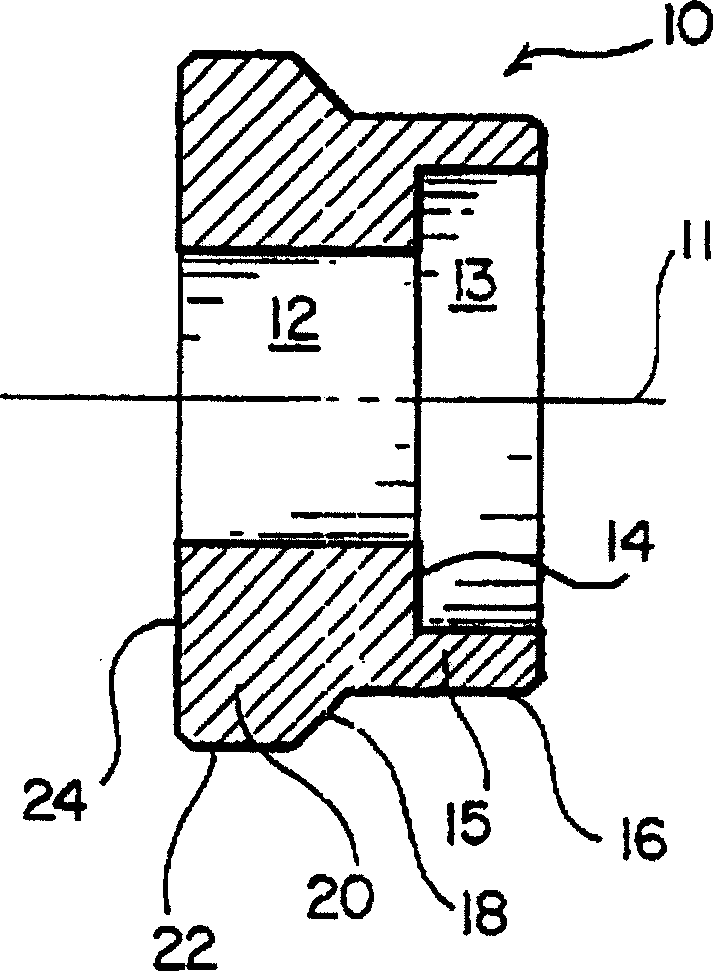

A technology of valves and valve components, applied in the direction of valves, lift valves, valve devices, etc. to prevent dripping from nozzles, and can solve the problems of long stroke of suck back valve 10, slow valve speed, shortening the service life of seals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

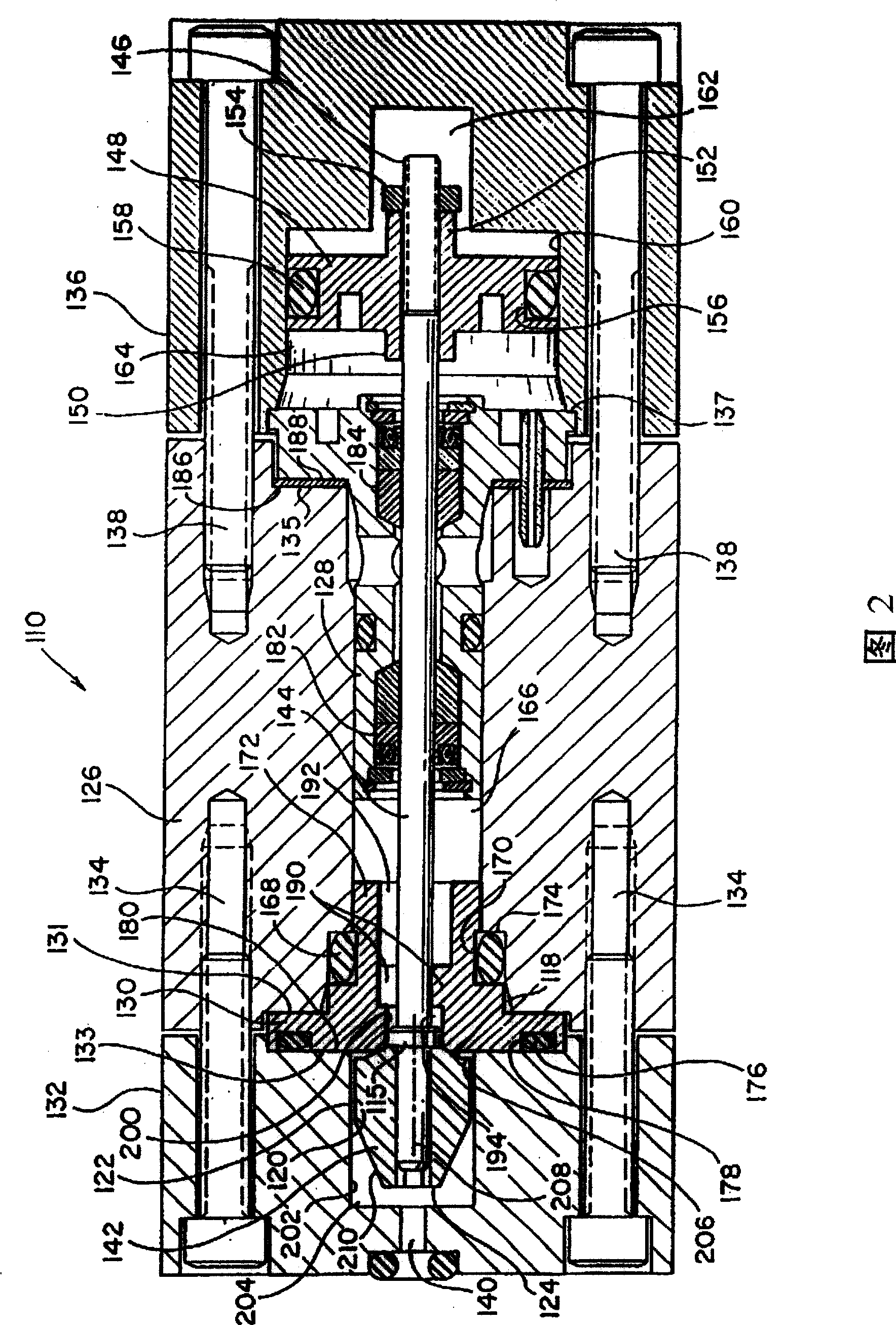

[0020] Referring now to the drawings, and in particular to FIG. 2 therein, there is illustrated and generally designated by reference numeral 110 a first embodiment of a novel and improved suckback valve assembly constructed in accordance with the principles and teachings of the present invention. It is worth noting that in the detailed description of the suckback valve of the present invention, those parts corresponding to those of the suckback valve of the prior art will be indicated with similar reference numerals, so that it may be easier to compare the valve of the present invention with the existing Valves of the present invention are compared, however, reference numerals representative of valve components of the present invention will be within the 100 series.

[0021] Accordingly, it will be seen that the suckback valve assembly 110 includes a body member 126 with a sealing cartridge assembly 128 disposed within a first end of the body member 126 and a valve seat member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com