Injection molded body, injection molding method, and injection molding die

A technology of injection molding and molding method, which is applied in the field of guide parts formed by injection molding, can solve the problems of "drawing, high elongation of resin, etc., and achieve the effect of suppressing manufacturing cost and high quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

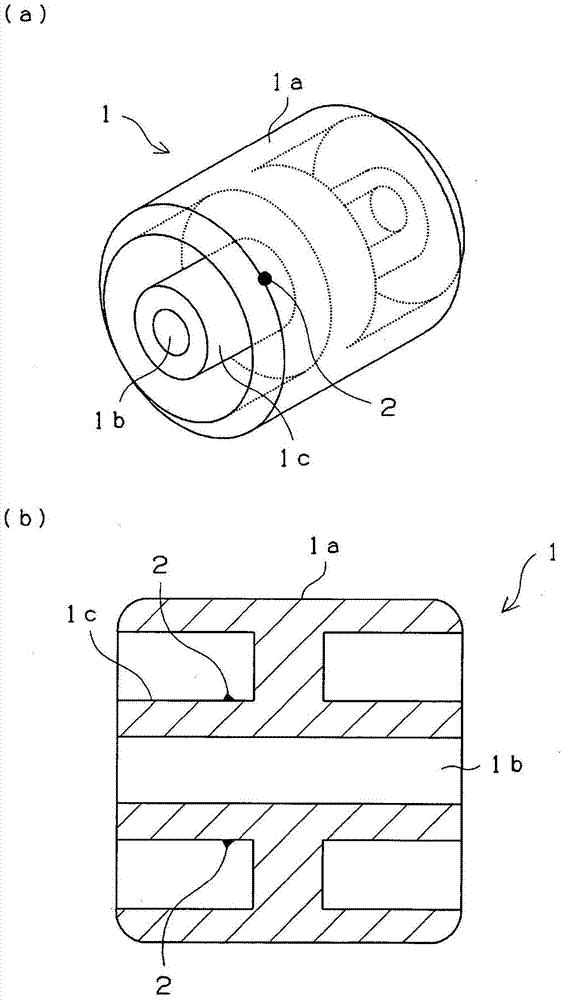

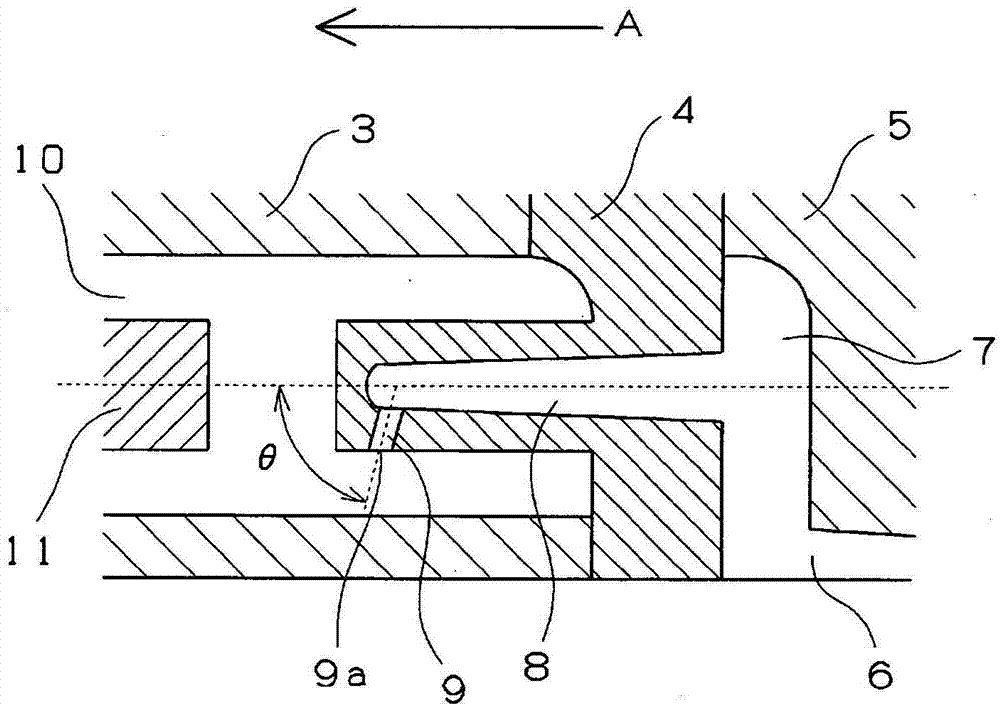

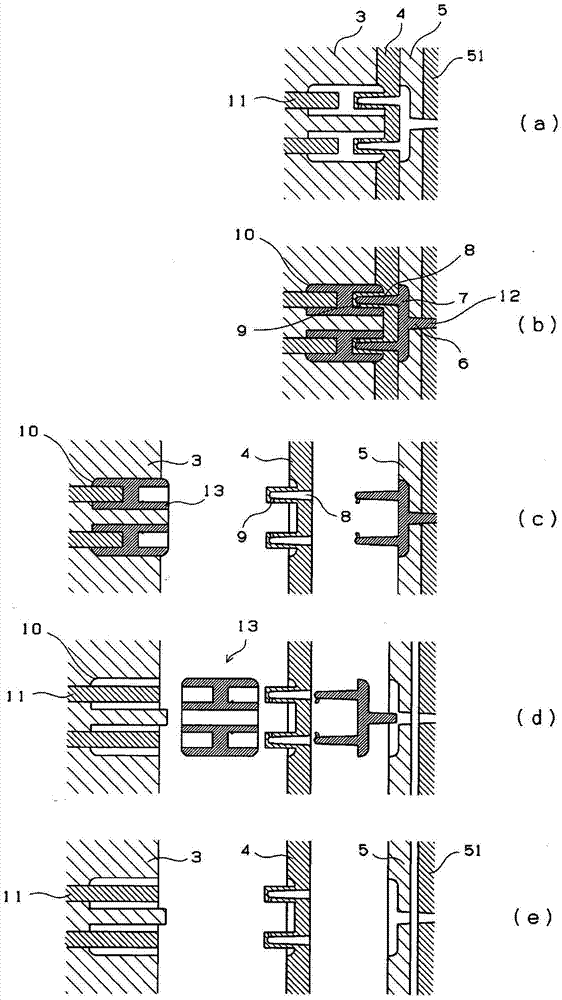

[0055] use figure 2 injection molding tooling, in accordance with image 3 The injection molding method of the present invention manufactures an injection-molded body of synthetic resin, that is, an ejection roller of an electrophotographic device. The shape of the eject roller is figure 1 The shape shown has an outer diameter of 10 mm, an inner diameter of 8 mm, a bearing hole diameter of 3 mm, an outer diameter of the bearing portion of 5 mm, and a total length of 13 mm. In addition, the mouth diameter of the gate of the injection molding mold was 0.8 mm, and the inclination angle θ of the pinhole gate relative to the axis of the second sprue was 45°. The synthetic resin used was PFA manufactured by NTN Precision Plastic Co., Ltd.: Vieri FE5000 (tensile elongation at break: 380%).

[0056] The discharge roller manufactured under this condition has the following characteristics: figure 1 As shown in the gate mark, even if a molten fluororesin with a tensile failure elong...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com