Two-dimensional metalloporphyrin-based cof material and thin film preparation method and application

A porphyrin-based, metal-based technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of little research on photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]Preparation of Cup-DHNDA-COF:

[0032]5, 10, 15, 20- Tetracene Copper (CutApp) (88.2 mg, 0.12 mmol), 2,6-dihydroxy-1,5-Dialdehyde (58.6 mg) , 0.24 mmol), 0.6 ml of 36% acetic acid, dichlorobenzene (3 ml), n-butanol (3 ml) is added to an autoclave having a polytetrafluoroethylene liner, and the ultrasonic dispersion is seal seal in an oven. , 120 ° C reacted 3D. It is then naturally cooled to room temperature, centrifuged, and then N, N-dimethylformamide, tetrahydrofuran, acetone were washed away, and the precursor and oligomer without reactions were washed away. It was then dried in vacuo at 80 ° C for 12 h to give 116.2 mg of purple solids (the theoretical yield was 138.2 mg), and the yield was 84.1%.

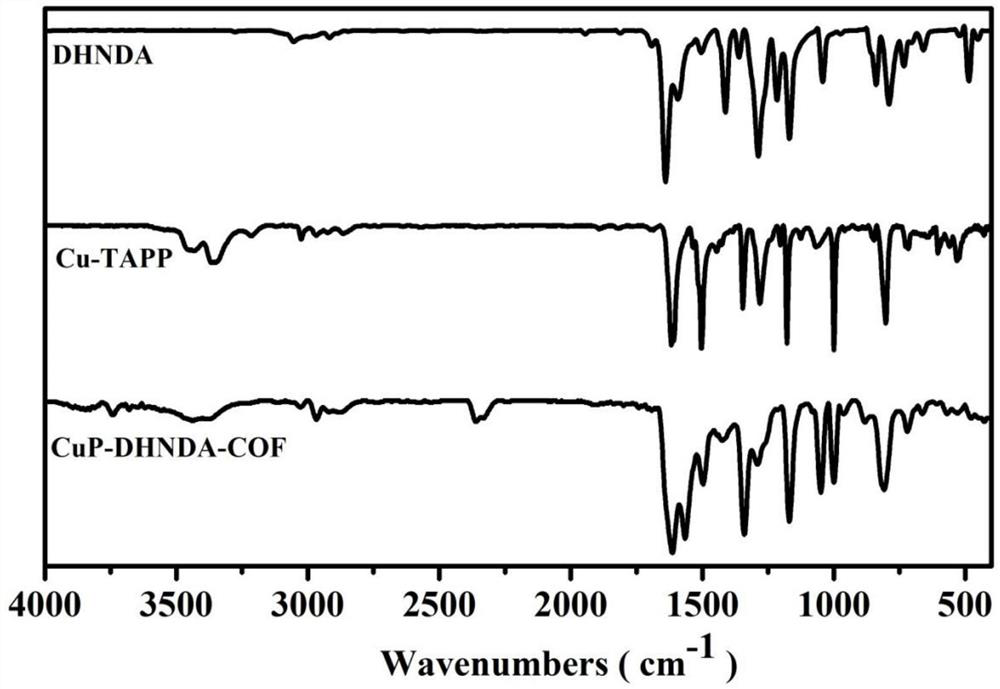

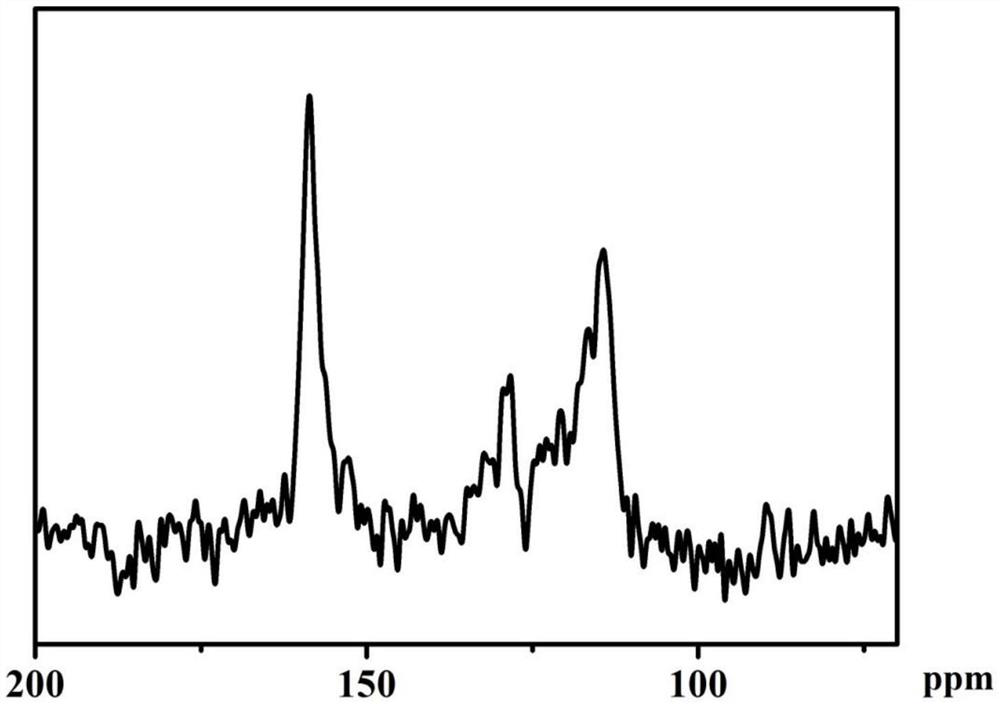

[0033]Such asfigure 1 Description, product Cup-DHNDA-COF at 1586CM-1There is a strong absorption, a telescopic vibration peak formed by imine c = n, and the aldehyde group C = O (1658cm) is in the raw material.-1) And amino n-h (3289cm-1The peak is strongly attenuated, which proves ...

Embodiment 2

[0041]Light-degraded methylene blue experiment: In order to further explore the performance of synthetic CUP-DHNDA-COF material, a series of experiments were designed to verify its efficiency of catalytic degradation of methylene blue.

[0042]10 mg of catalyst (CUP-DHNDA-COF) was taken into a methylene blue aqueous solution of 20 mg (10 mg / L), and the mixture was placed in the ultrasonic cleaning instrument to completely disperse the catalyst in the methylene blue water solution. According to the above operation, the test tube of the above-mentioned reaction liquid is prepared, and the number 1, 2, 3, 4, 5, 6.1 is prepared, and the methylene blue water solution and the catalyst were added to the catalyst, and the ultraviolet visible absorbance value, 2-6 test tube The ultraviolet visible absorbance value of the No. 2 was measured after 1 hour in the dark conditions. The visible light irradiation reaction was 15 minutes after testing the No. 3 test tube absorbance, visible light irra...

Embodiment 3

[0045]Preparation of Cup-DHnda-COF film: After the ITO glass was used, the reaction was first reacted with 2,6-dihydroxy-1,5-diehyldenaphthalene, and then washed, placed in 5, 10, 15, The 20-tetra-(4-aminophenyl) porphyrin copper solution is then reacted, then the washed, then placed in the previous 2,6-dihydroxy-1,5-dialldyl naphthalene solution, so repeated 50 The time, washed, dry, and measure the SEM to find a dense film.

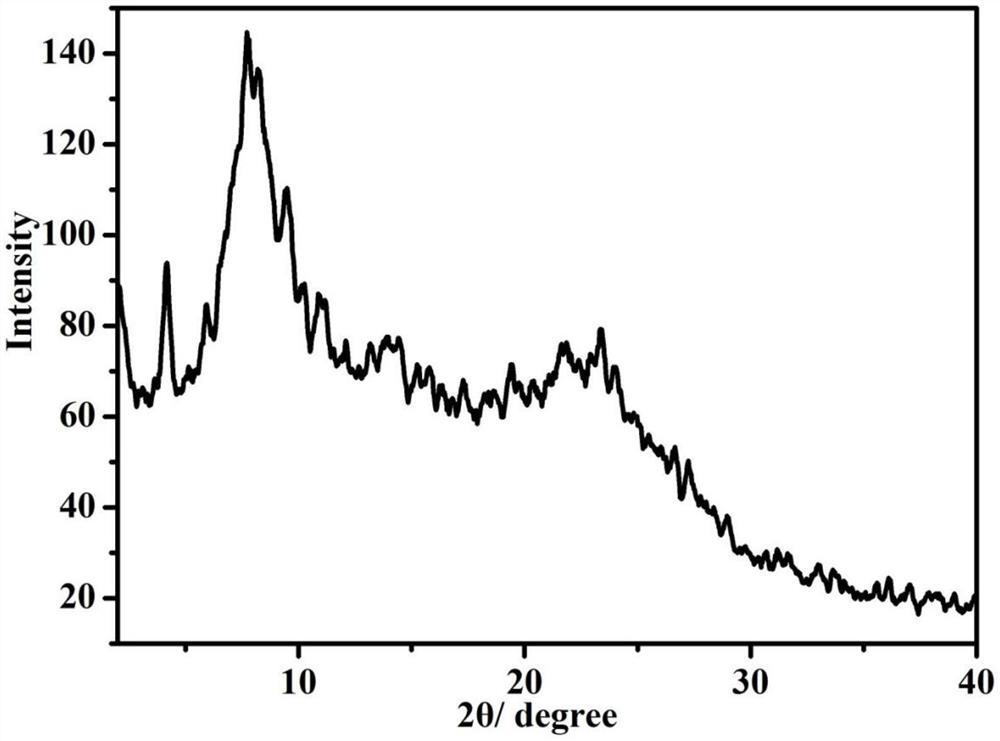

[0046]Such asFigure 9 As shown, the XRD of the Cup-DHNDA-COF film and the powder has a similar shape, and the peak position is consistent, indicating the synthetic Cup-DHNDA-COF film having the same frame structure as the powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com