Frame structure formwork, assembled and spliced frame structure formwork and stereo frame structure formwork thereof

A frame structure and frame formwork technology, applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connector, building structure, etc., can solve the problems of low construction efficiency, high cost, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

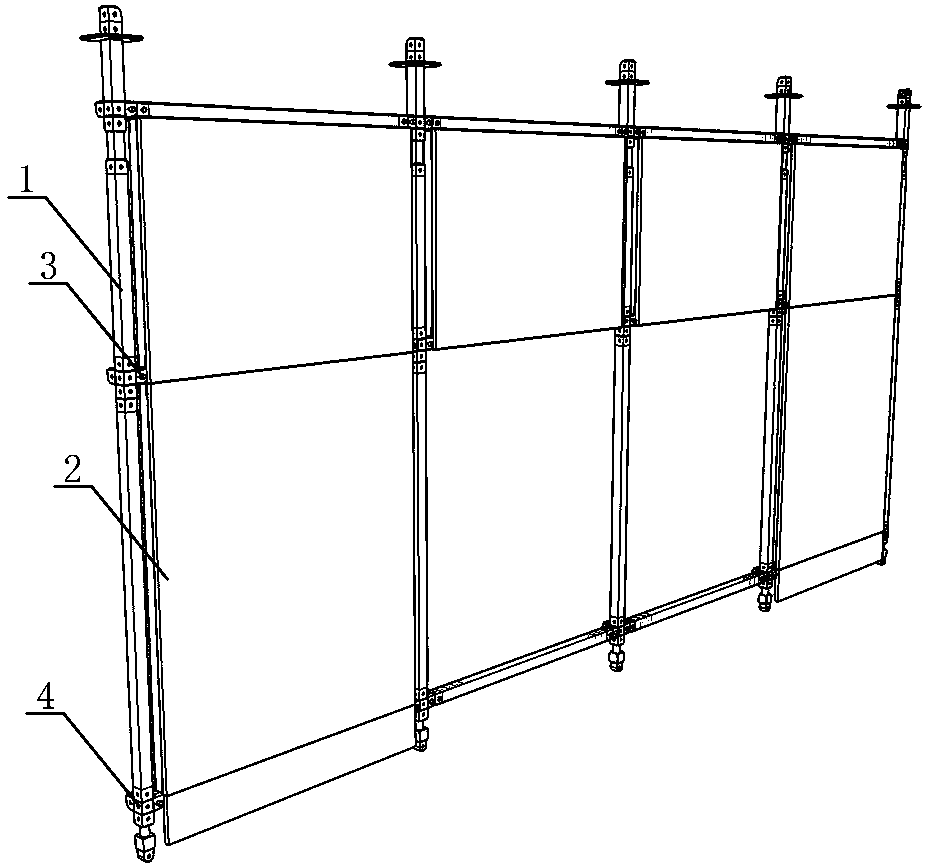

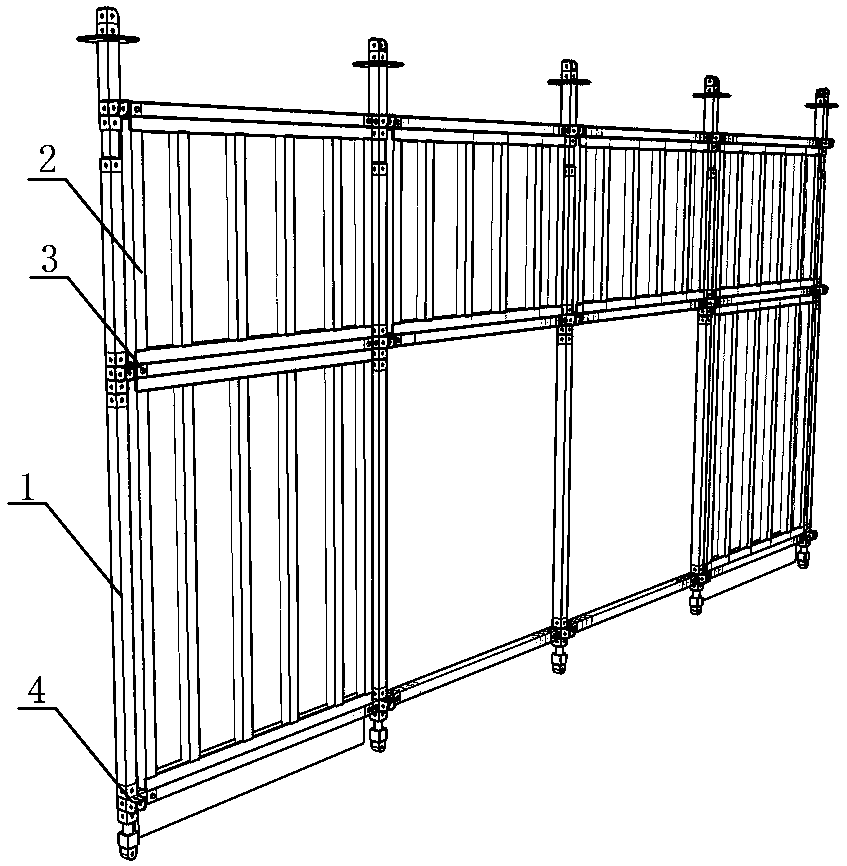

[0039] Embodiment one sees figure 1 , figure 2 As shown in the frame mold, the frame mold is composed of a frame mold 1 and a plate mold 2; the plate mold is detachably embedded in the frame opening of the frame mold. In this example, the frame molding is a facade frame molding.

[0040] see image 3 As shown, the frame mold 1 is a rectangular frame formed by two pairs of parallel main pipes connected vertically with shape joints; in this example, the frame mold 1 is a facade frame mold, which consists of a pair of vertical main pipes and a A rectangular frame formed by connecting horizontal main pipes with geometric nodes.

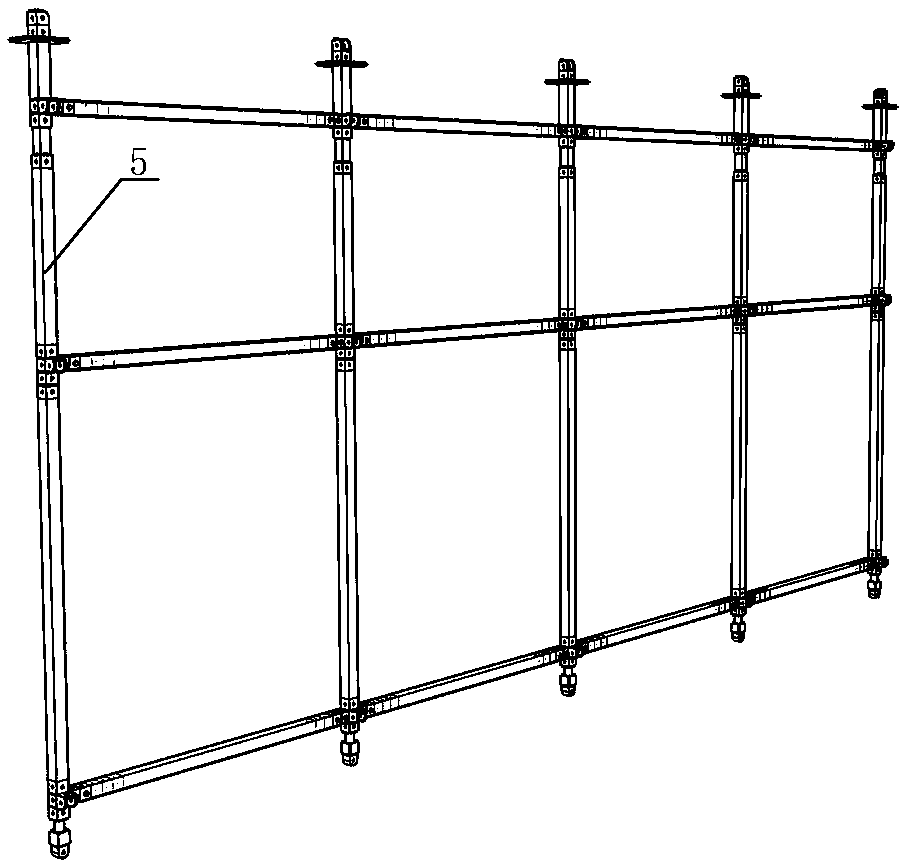

[0041] see Figure 4 As shown, the upper and lower ends of the vertical main pipe are inserted with vertical pin tubes 51; The external joint of the surface frame molding; the vertical pin tube inserted and fixed in the vertical main pipe forms the height adjustment pipe of the vertical main pipe; the frame molding forms a height-adjustable mold fra...

Embodiment 2

[0045] Embodiment two see Image 6 As shown, different from Embodiment 1, the frame mold in this example is a plane frame mold;

[0046] see Figure 7 As shown, the frame mold 1 is a planar frame mold, which is a rectangular frame formed by connecting a pair of vertical and horizontal main pipes and a pair of horizontal and horizontal main pipes by joints.

[0047] see Figure 8 As shown, the two ends of the horizontal main pipe are inserted with horizontal pin tubes 52; the horizontal pin tubes are correspondingly connected to the horizontal pipe joints of the shape joints; other horizontal pipe joints of the shape joints form the plane frame mold An external joint; a horizontal pin pipe inserted and fixed in the horizontal main pipe forms a length adjustment pipe of the horizontal main pipe; the frame mold forms a mold frame with adjustable length or width.

[0048] see Figure 9 As shown, the formwork 2 is a planar formwork; the outer surface of the formwork is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com