A compression and recovery air pump

A technology for compressing air and air pumps, which is applied to pumps, piston pumps, and liquid variable displacement machinery, etc. It can solve the problems of no compressed air and low efficiency of electric energy conversion to air energy, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

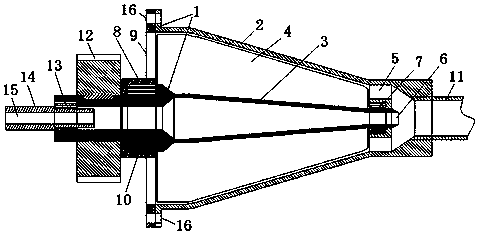

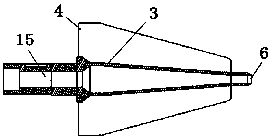

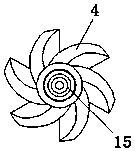

[0024] refer to Figure 1-Figure 7 , the compression and recovery air pump 1 of the present embodiment includes a pump casing 2 and a pump core 3, the pump core 3 includes a mandrel, the mandrel is a hollow mandrel, the front end is a return air inlet 15, and the rear end It is the return air exhaust port 6, and the mandrel is provided with a turbine blade 4; the pump housing 2 includes a housing and a cover plate 8, and the cover plate 8 is fixedly connected with the housing, and the cover plate 8 is A compressed air inlet 9 is provided, and the rear end of the housing is provided with a compressed air exhaust port 5 and an air pipe I11. The rear end of the pump core 3 is assembled and connected to the housing through a bearing I7, and the compressed air The exhaust port 5 and the return air exhaust port 6 communicate with the air delivery pipe I11, the front end of the pump core is assembled and connected with the cover plate 8 through the bearing II10, and the front end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com