Battery liquid leakage detecting equipment and method

A technology of detection equipment and detection method, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problems of high leakage detection rate and low efficiency, and achieve the leakage detection rate Low, high detection efficiency, good quality inspection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further elaborated below with reference to the drawings.

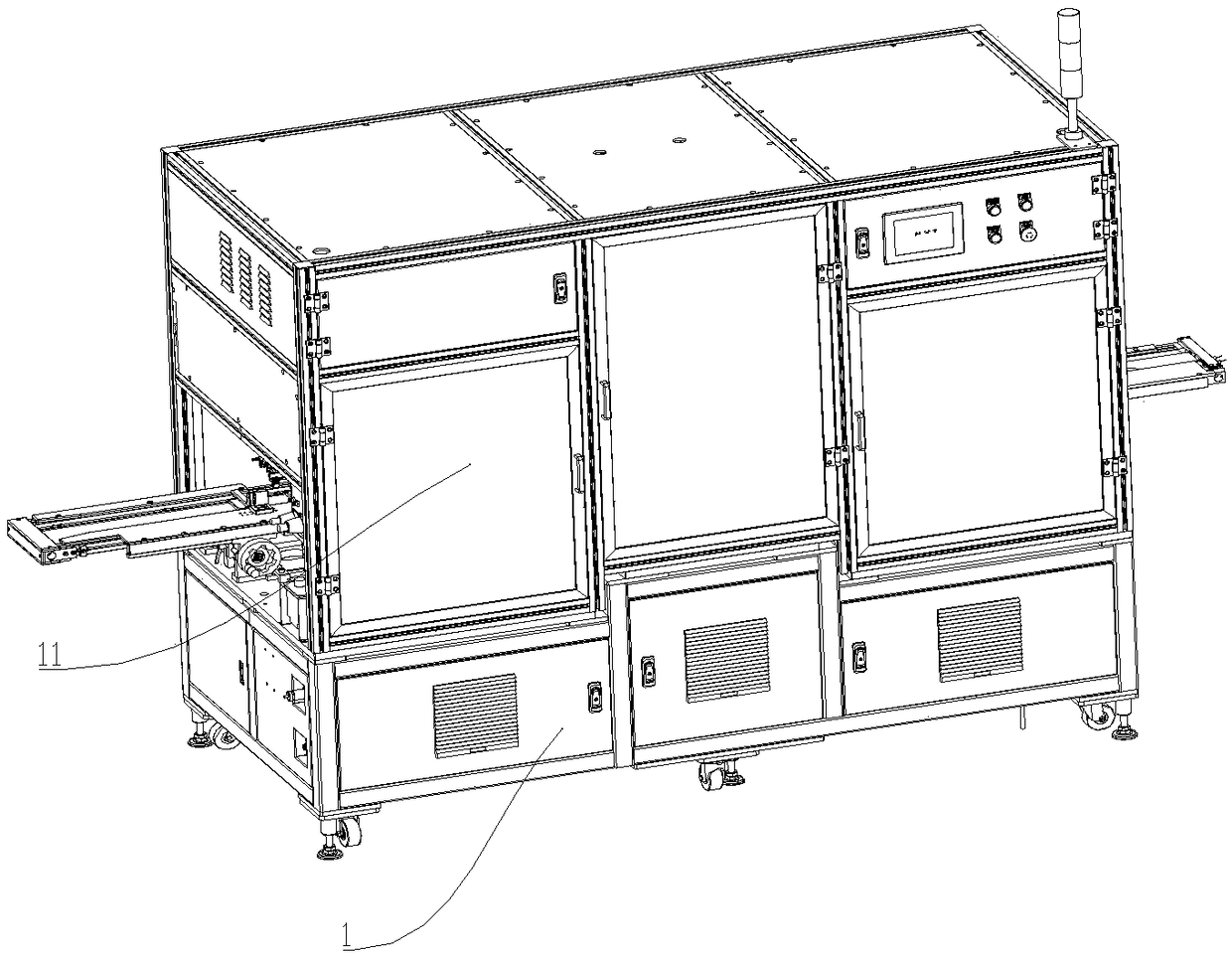

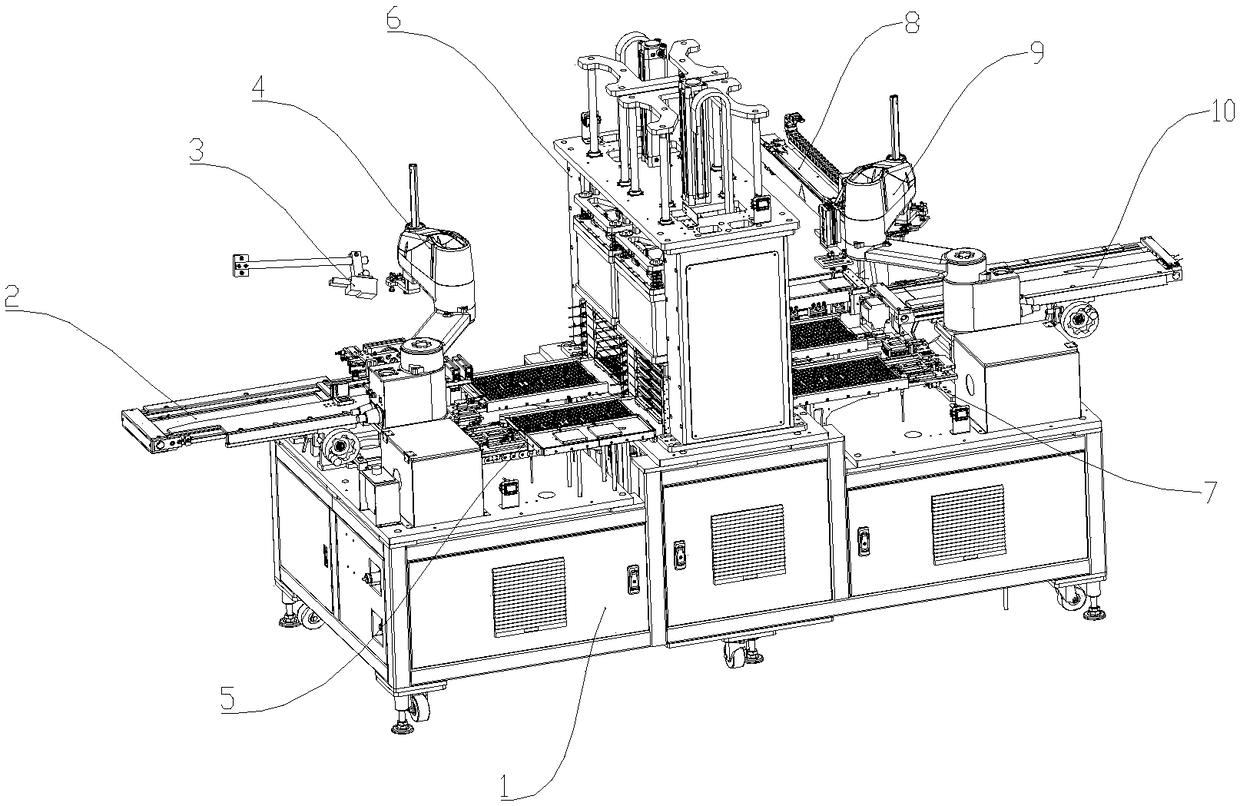

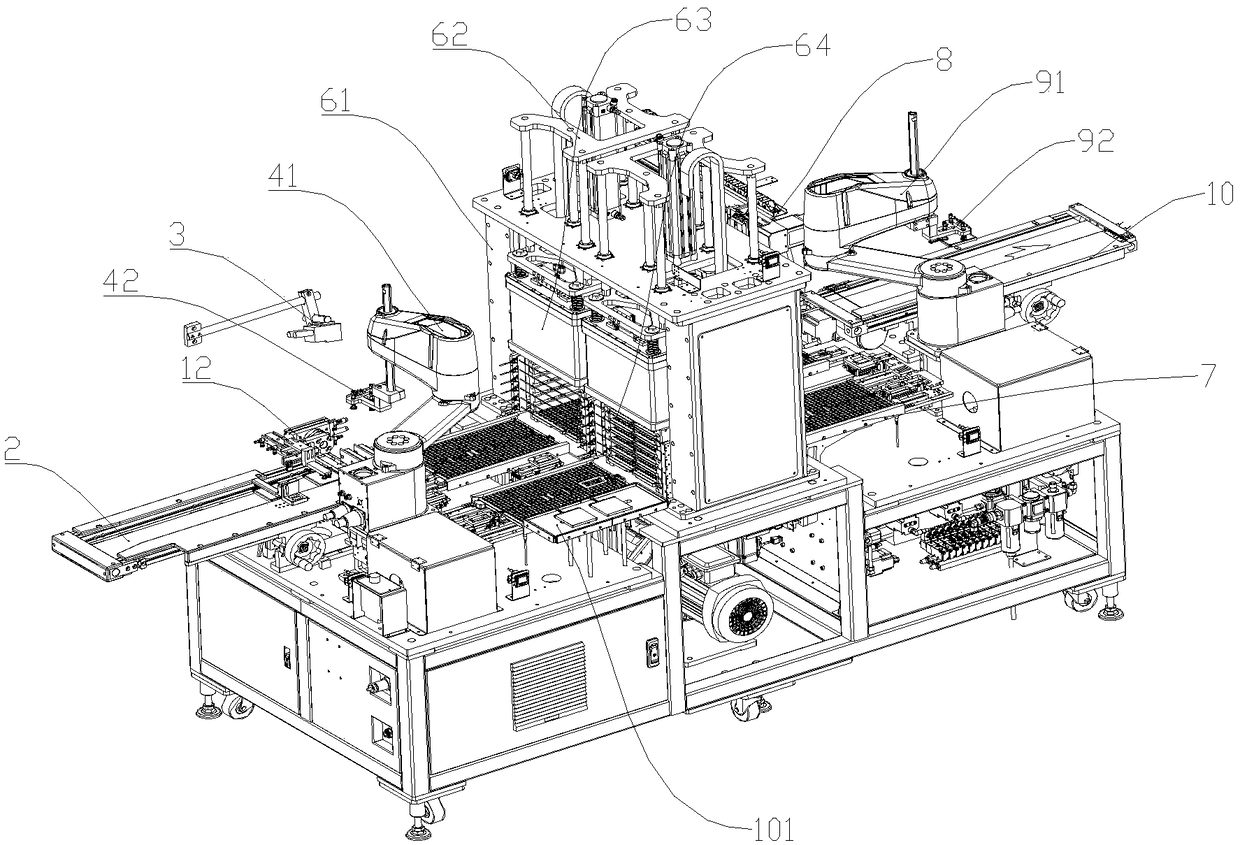

[0036] The embodiment of the present invention discloses a battery leakage detection equipment, which at least includes: a rack 1, an industrial computer (not shown in the figure, which is an industrial controller, such as a PLC, provided on the rack 1, MCU, etc.), a detection mechanism 6 is provided on the top table of the frame 1, a first tray push-pull mechanism 5 is provided on the front side of the detection mechanism 6, and a second tray push-pull mechanism 7 is provided on the rear side. The feeding end of the first tray push-pull mechanism 5 is provided with a first reclaiming mechanism 4, and the discharge end of the second feeding pan push-pull mechanism 7 is provided with a second reclaiming mechanism 9. Wherein, under the control of the industrial computer, the first reclaiming mechanism 4 is used to take out the battery 200 to be tested at the previous station and transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com