Prediction of residual service life of gas turbine bearings based on support vector regression

A technology of support vector regression and life prediction, which is applied in computer parts, computer-aided design, special data processing applications, etc., can solve problems such as easy to fall into misunderstandings, complex model establishment, poor model interpretability, etc., to achieve efficient prediction, improve The effect of forecast accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

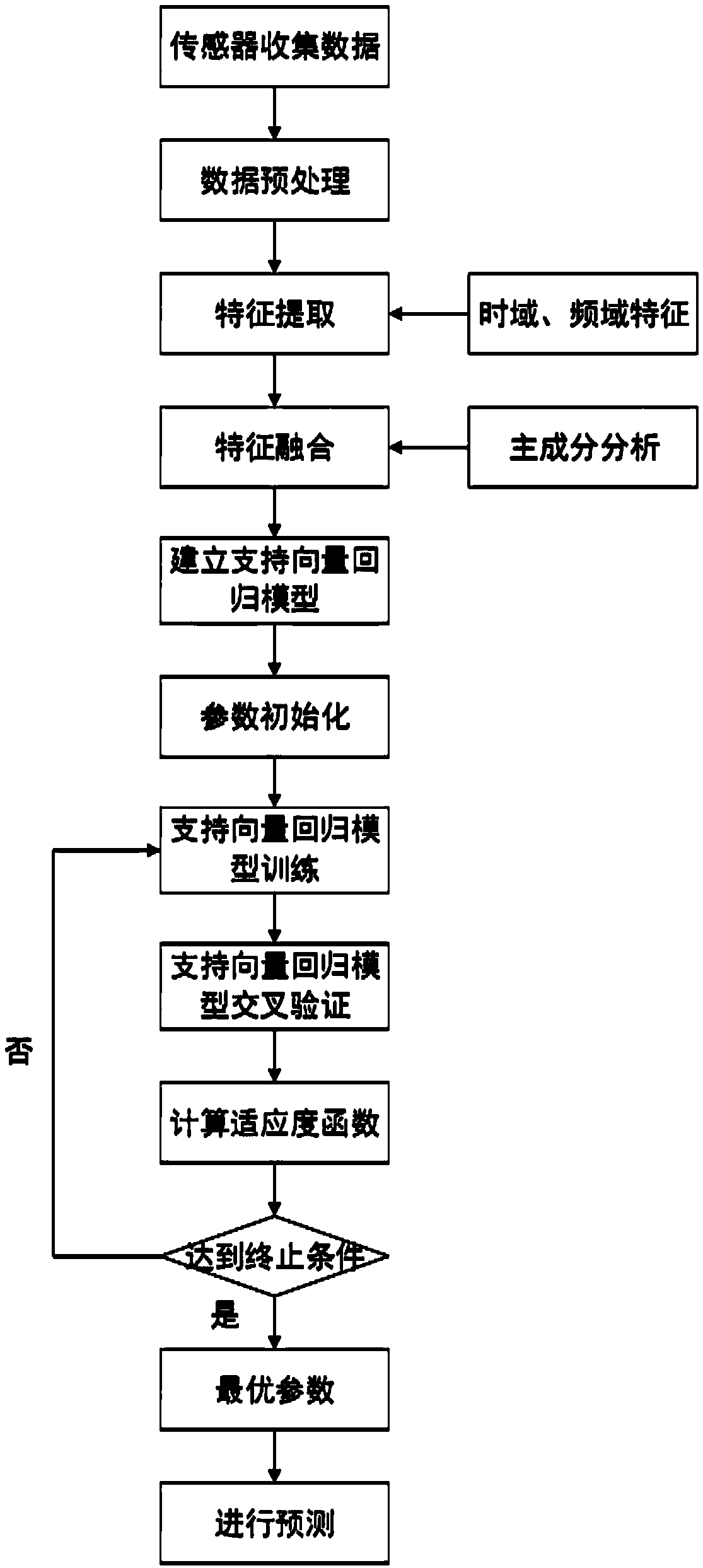

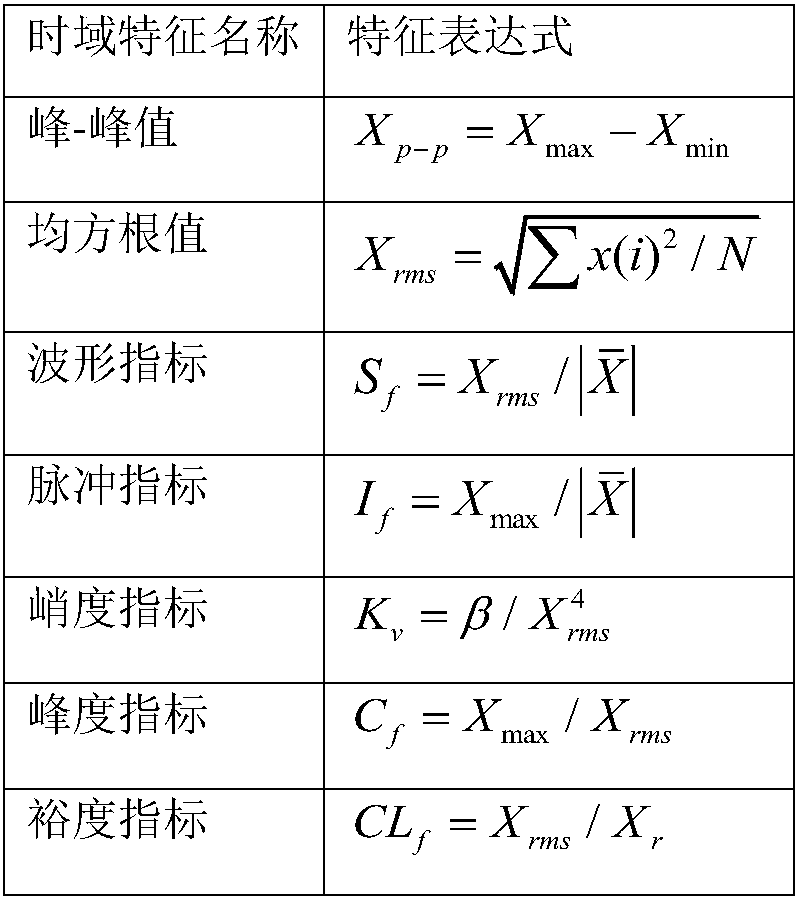

[0026] Such as figure 1 As shown, it is a method for predicting the remaining service life of gas turbine bearings based on support vector regression involved in this embodiment, and its specific steps include:

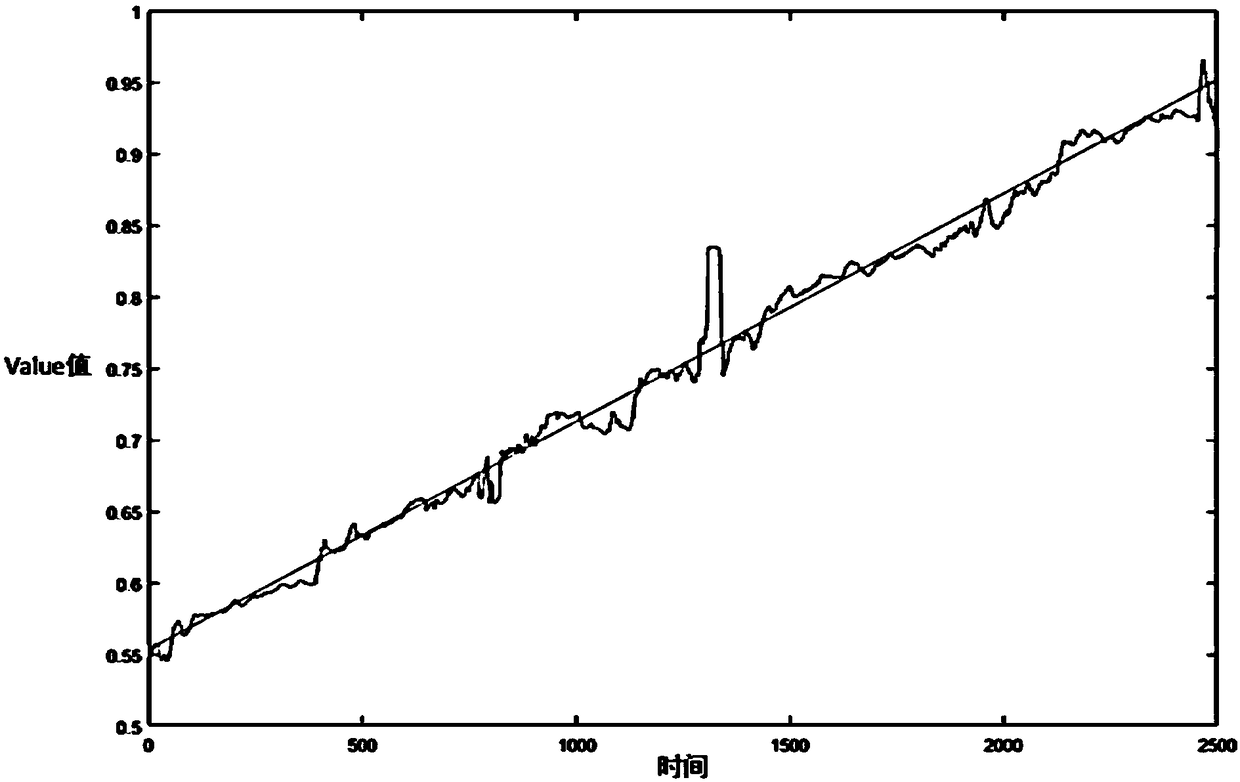

[0027] Step 1) Use the acceleration sensor to collect the acceleration vibration signal of the gas turbine bearing from normal operation to complete degradation, including the vibration acceleration in the horizontal direction of the bearing and the vibration acceleration in the vertical direction of the bearing. The data unit of the bearing acceleration is the gravitational acceleration g. With the continuous degradation of the bearing, the amplitude of the vibration signal of the bearing gradually increases until the vibration acceleration exceeds 20g, and the bearing is completely degraded.

[0028] The data collection is completed by the acceleration sensors arranged on both sides of the bearing. The acceleration sensor detects the acceleration vibration signal of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com