Cleaning appliance, cleaning method, and liquid supply device

A technology for cleaning liquids and utensils, applied to devices for coating liquids on surfaces, cleaning methods and utensils, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

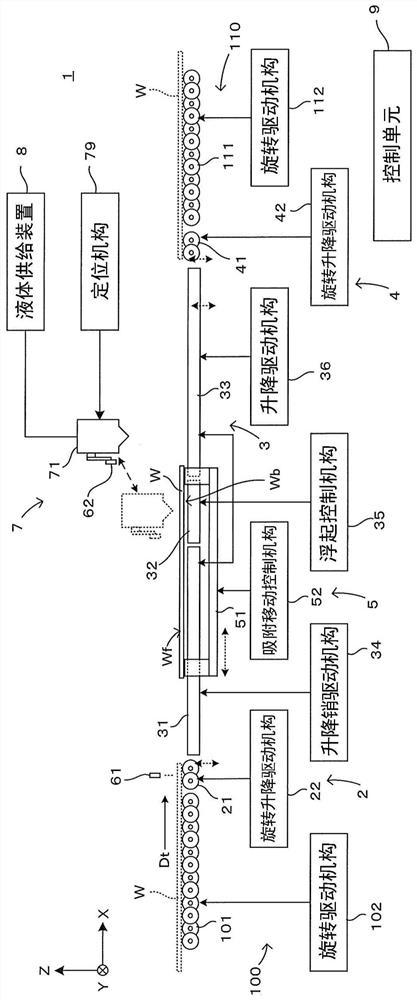

[0038] figure 1 It is a figure which schematically shows the whole structure of the coating apparatus provided with the liquid supply apparatus which concerns on one Embodiment of this invention. This coating device 1 is a slit coater for coating a coating liquid on an upper surface Wf of a substrate W obtained from figure 1 It is carried in a horizontal position with the left-hand side facing the right-hand side. In addition, in each of the following figures, in order to clarify the arrangement relationship of each part of the device, the conveyance direction of the substrate W is referred to as "X direction". figure 1 The horizontal direction from the left-hand side to the right-hand side is called "+X direction", and the opposite direction is called "-X direction". In addition, in the horizontal direction Y perpendicular to the X direction, the front side of the device is referred to as "−Y direction", and the rear side of the device is referred to as "+Y direction". In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com