Patents

Literature

35 results about "Coupling (piping)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A coupling (or coupler) (used in piping or plumbing) is a very short length of pipe or tube, with a socket at one or both ends that allows two pipes or tubes to be joined, welded (steel), brazed or soldered (copper, brass etc.) together.

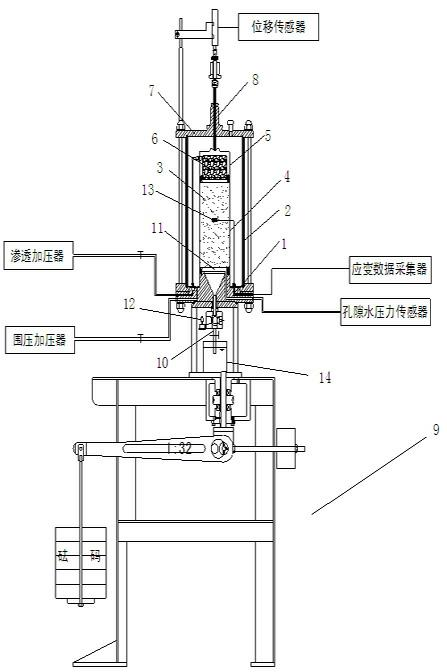

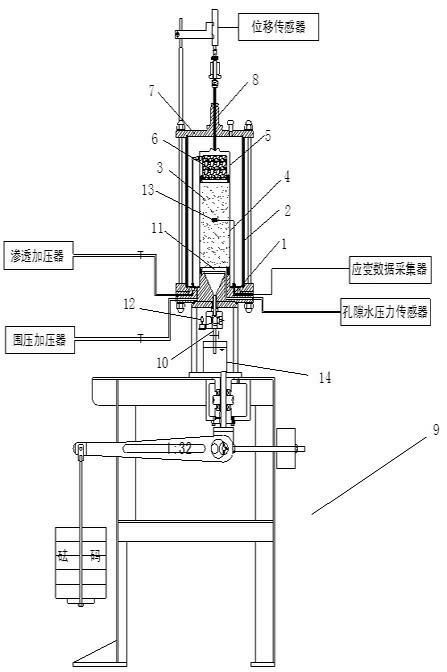

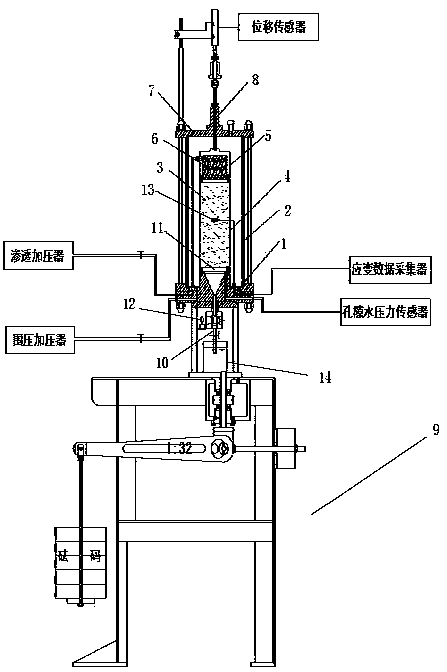

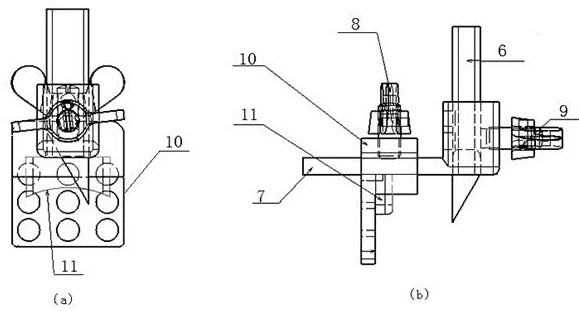

Piping test device of seepage corrosion stress coupling

The invention relates to a piping test device of seepage corrosion stress coupling, wherein a leakage groove is arranged in the base, a pressure chamber is installed on the upper part of the base and a top cover is installed on the upper part of the pressure chamber; one end of the water outlet tube is connected with the bottom outlet of the base and the other end is extended into a measuring pot; a sample is installed in the pressure chamber on the base; a porous steel plate is installed between the sample and the base; a shrinkable tube is closely wrapped on the outside of the sample and a cover cap is arranged at the top part of the sample; a scree filter layer is filled in the cover cap; one end of the axial pressurizing rod is penetrated through the top cover to contact with the cover cap and the other end is connected with an axial pressurizer; a photoelectric sensor is installed on the body of the water outlet tube; a resistance strain gage is installed on the shrinkable tube. The invention researches a piping development process of the soil body under a complex stress state from the seepage corrosion stress coupling aspect, provides a new aspect for the comprehensive understanding of the soil body piping developmental mechanism and also provides an important theoretical basis and a technical support for the prediction and the effective treatment of the dam piping dangerous case.

Owner:HOHAI UNIV

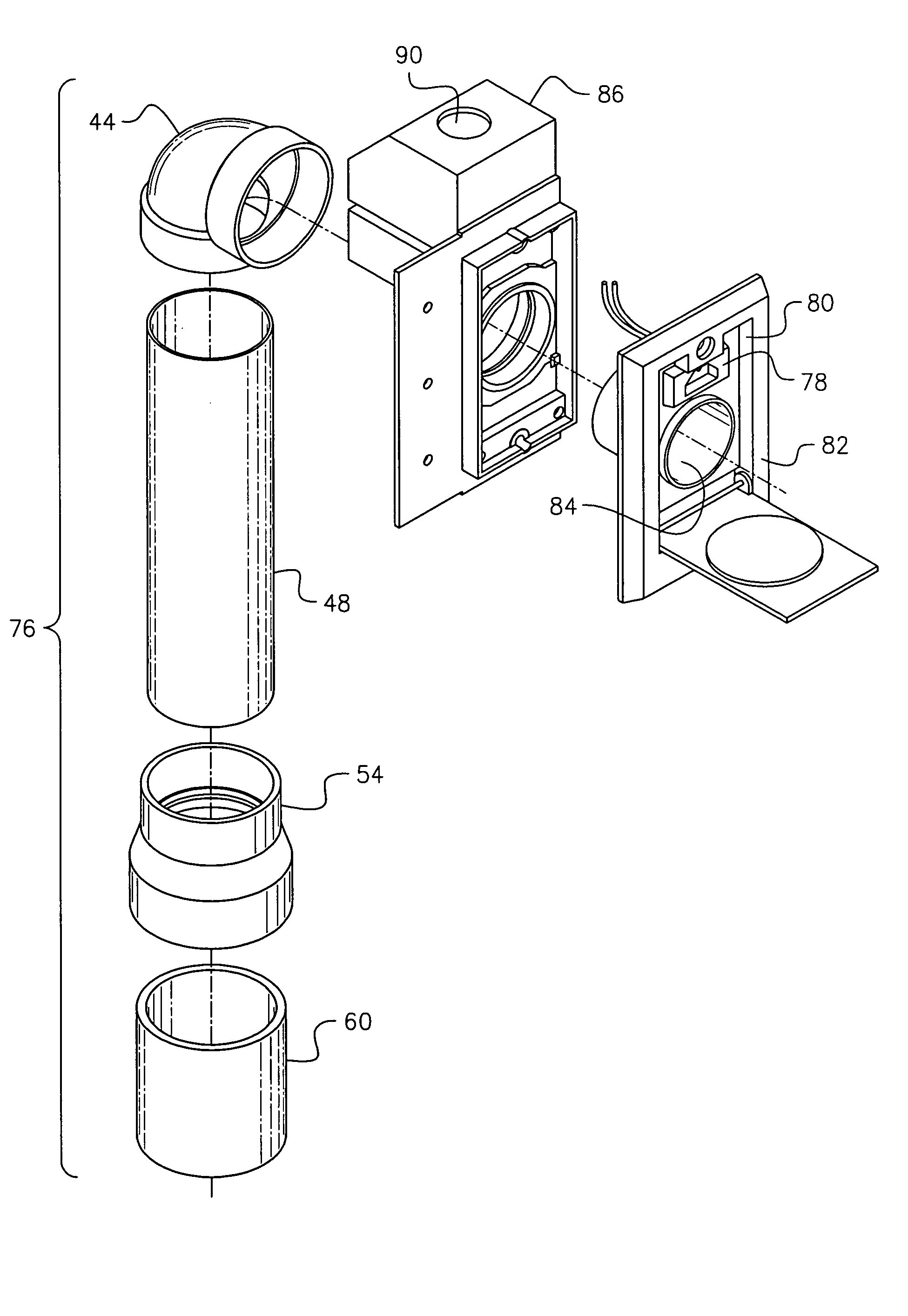

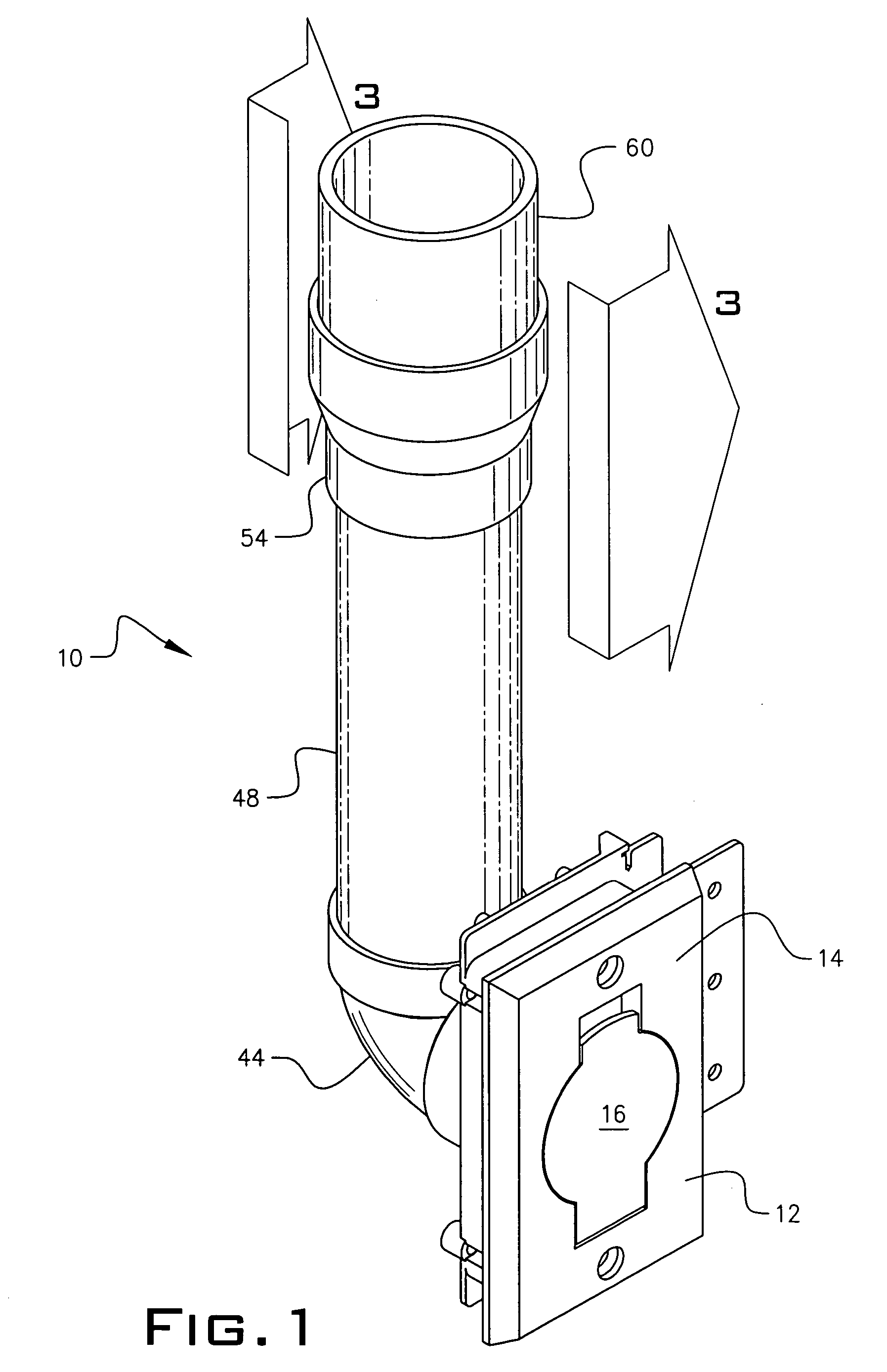

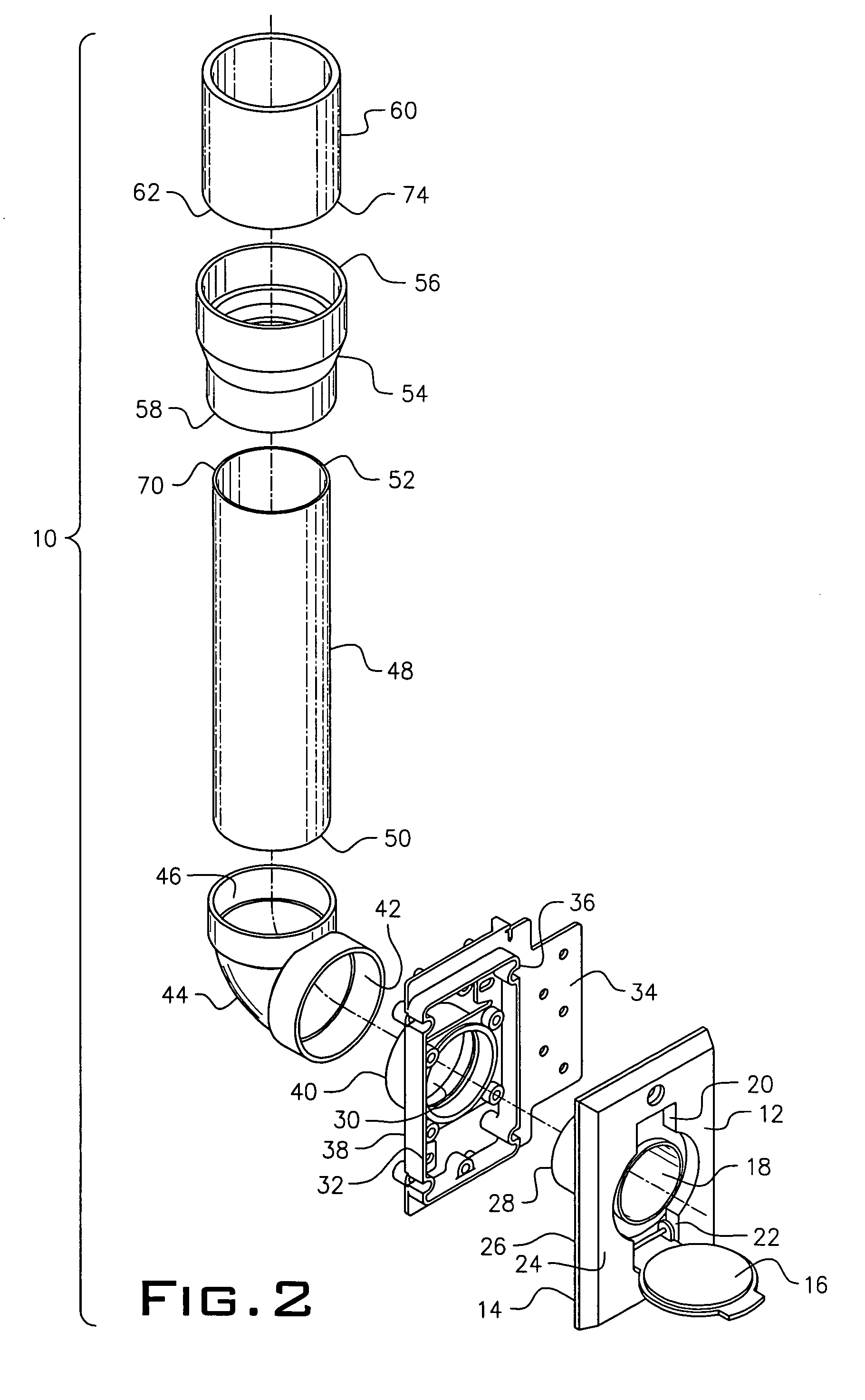

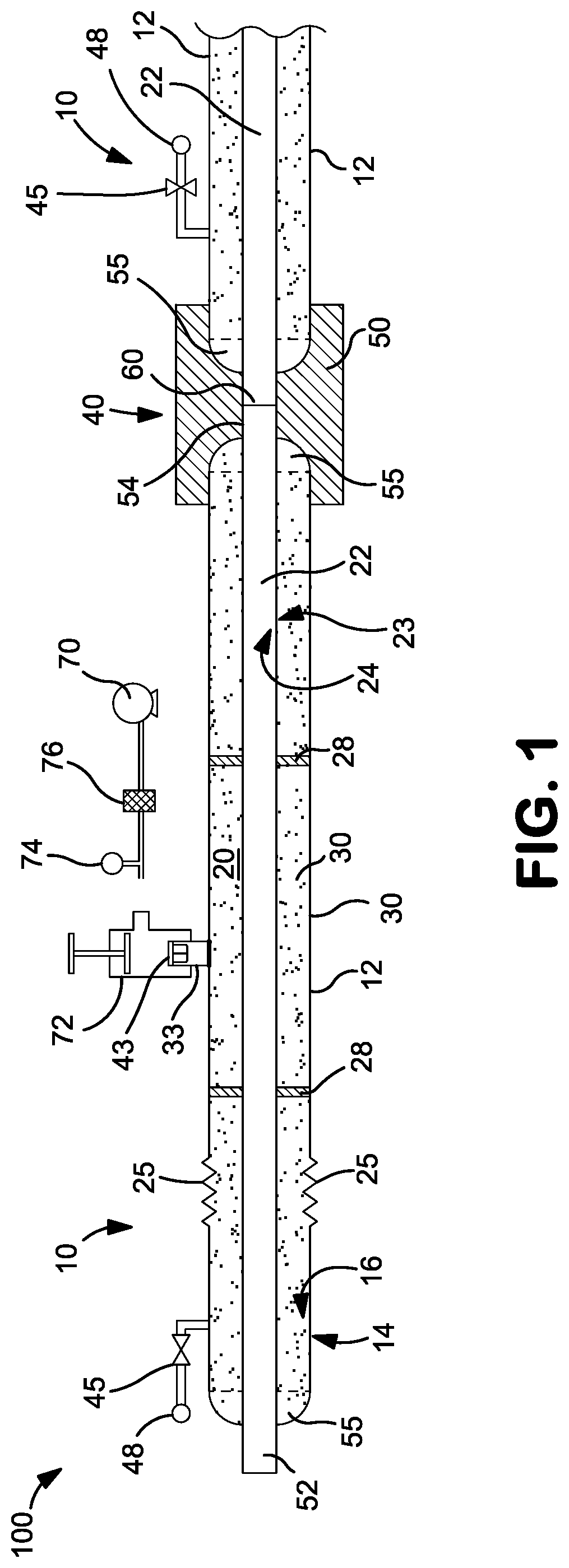

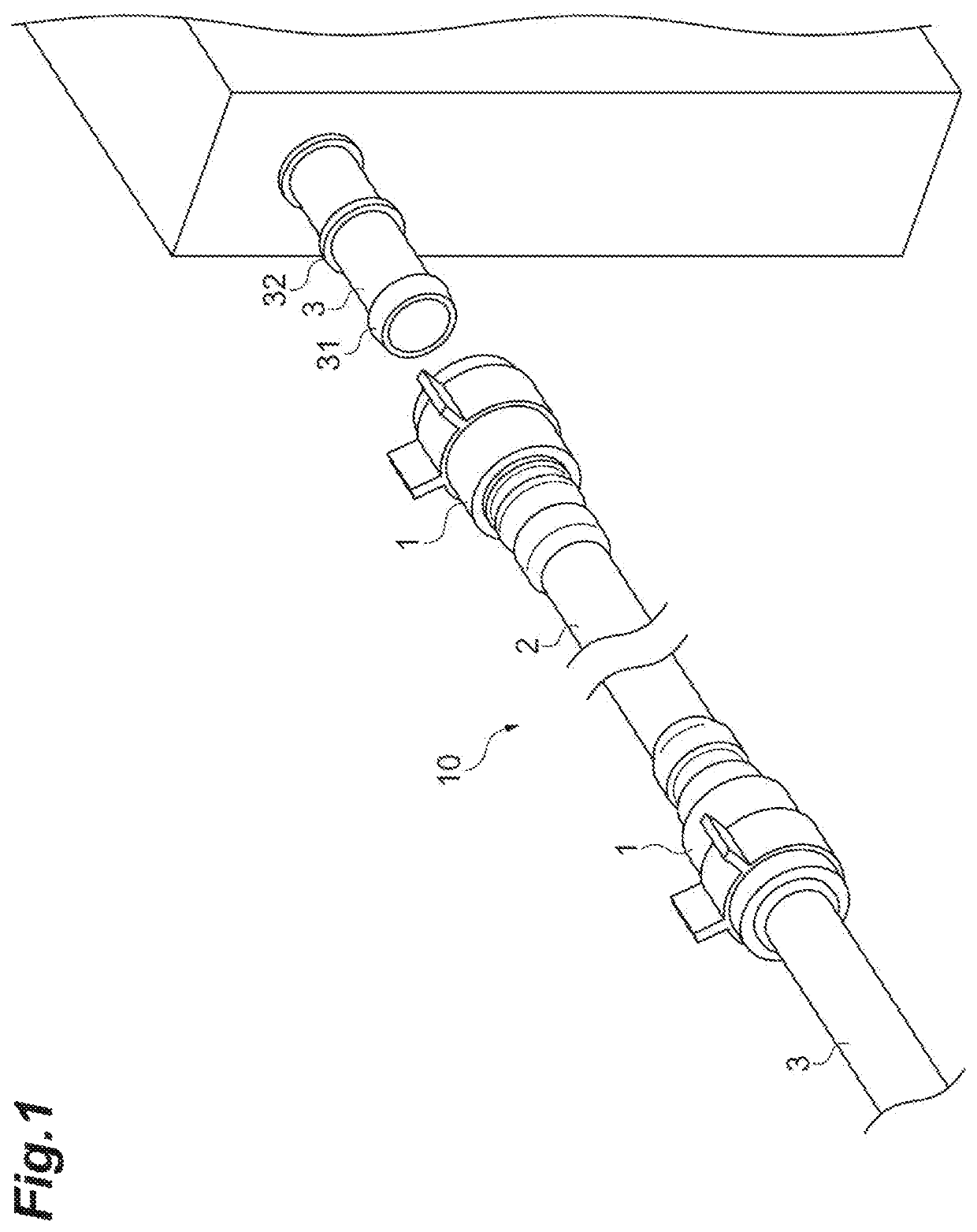

Pipe coupler for in-wall central vacuuming system

An in-wall central vacuuming system has a central receptacle and a vacuum pump for drawing dirt and dust into a network of piping and into the receptacle. The system includes a series of ports strategically located around an interior environment of a residential or commercial building. The series of ports permit a flexible tubular hose to be connected thereto. Each port includes an interior wall mounting plate positioned behind the port and has axially aligned circular openings for receiving the flexible tubular hose. An elbow positioned within the wall attaches to a rearwardly extending tubular portion of the mounting frame and attaches to an odd sized first pipe section. A coupler member attaches the odd sized first pipe section to a universally available second pipe section which is used to create a network of piping for the system.

Owner:AMBROSE ROGER A

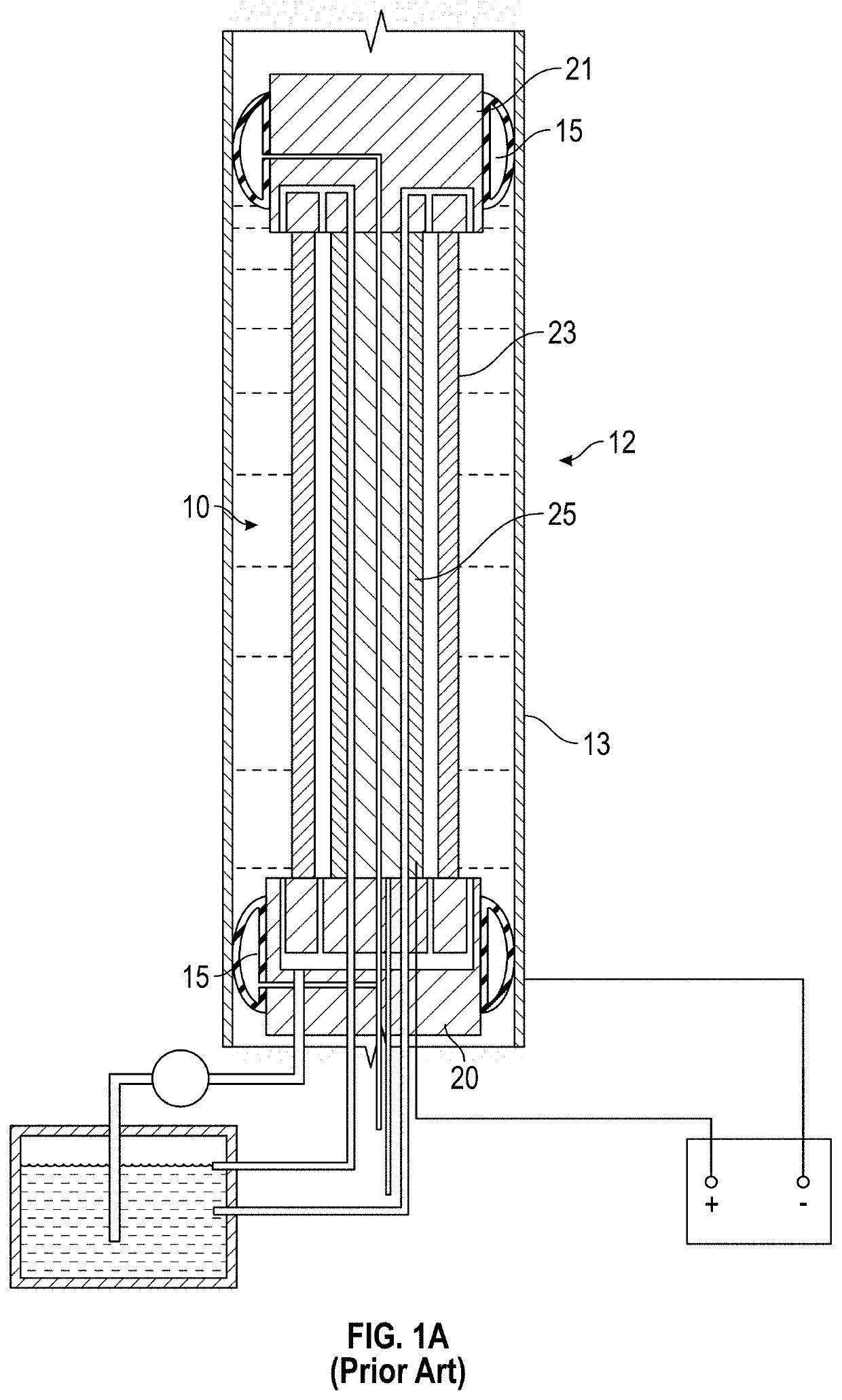

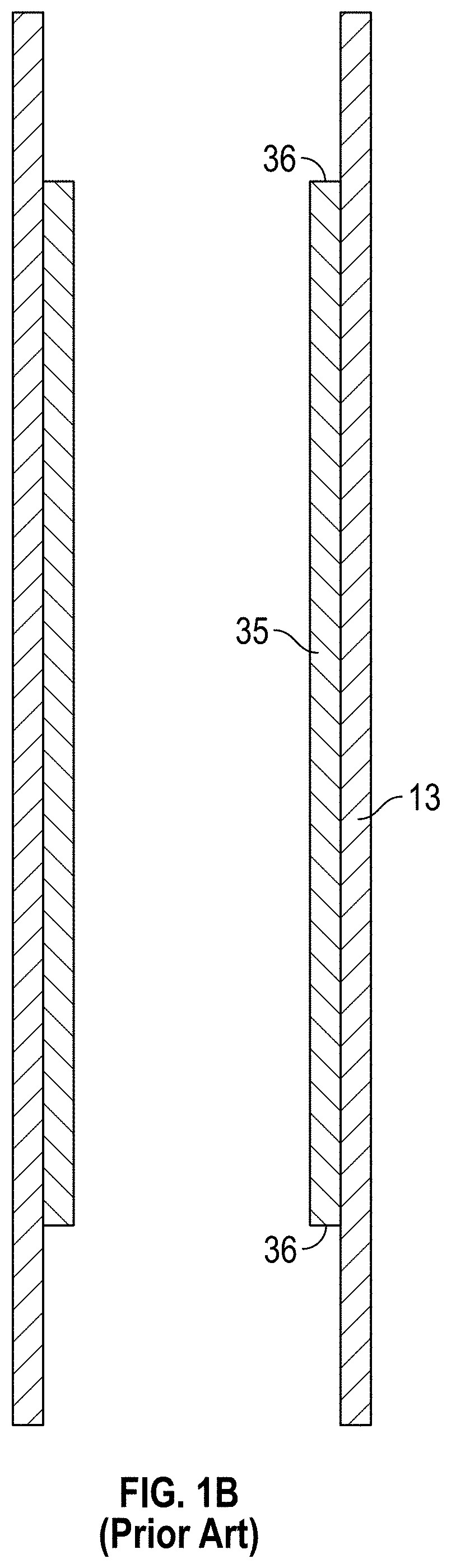

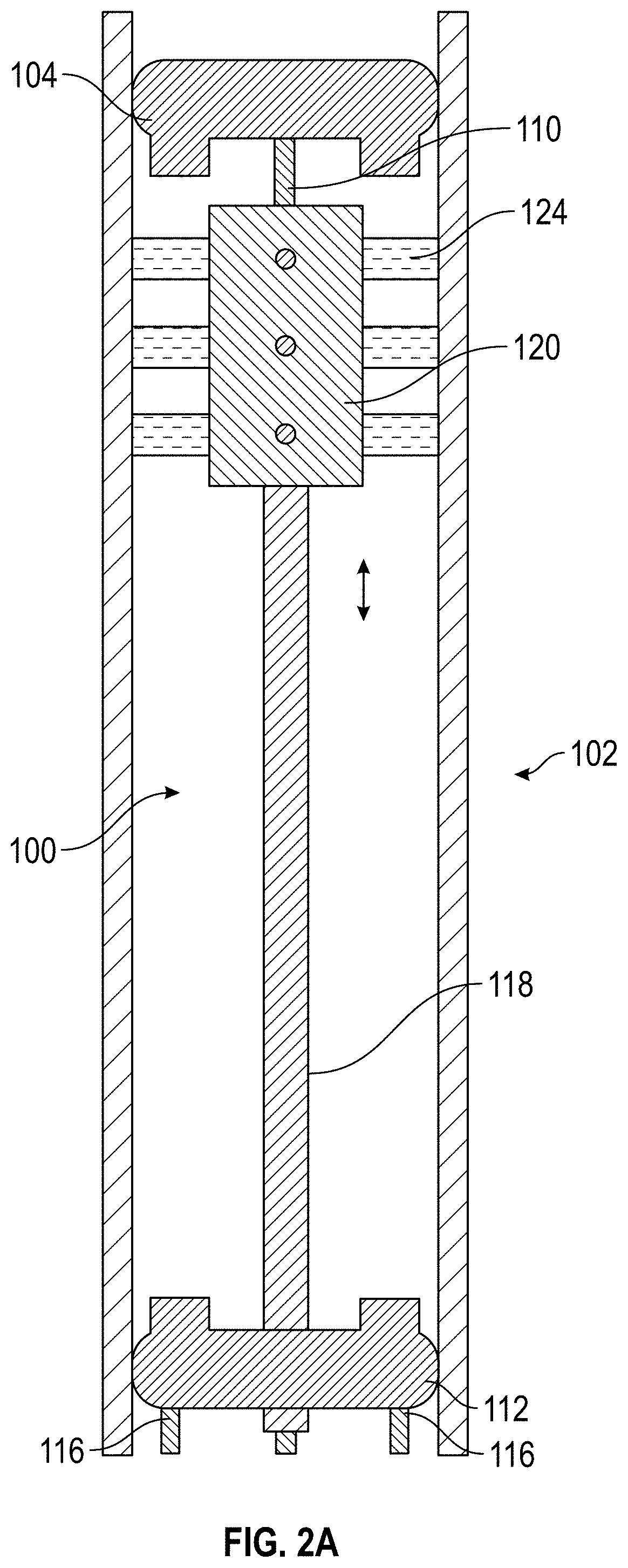

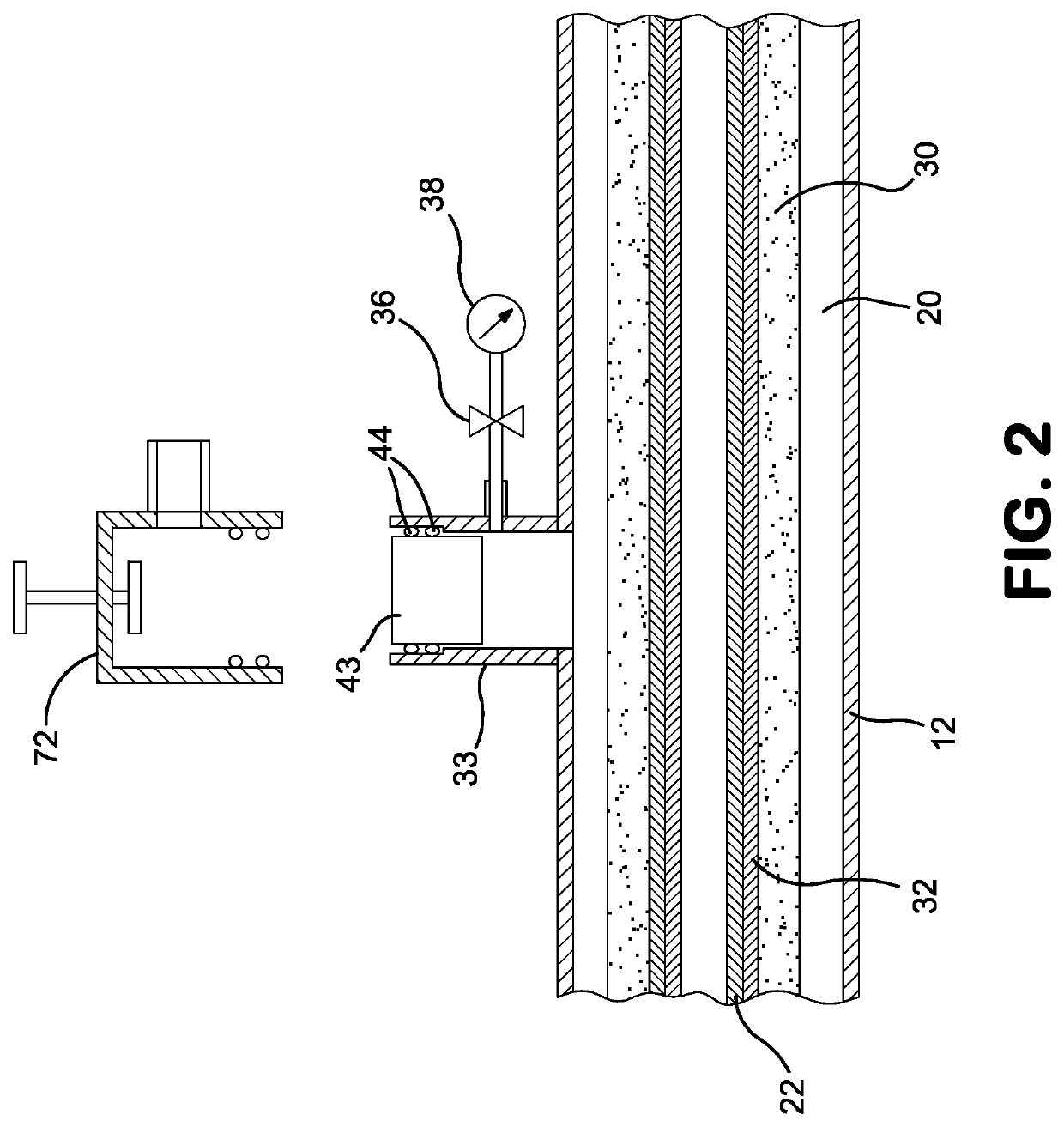

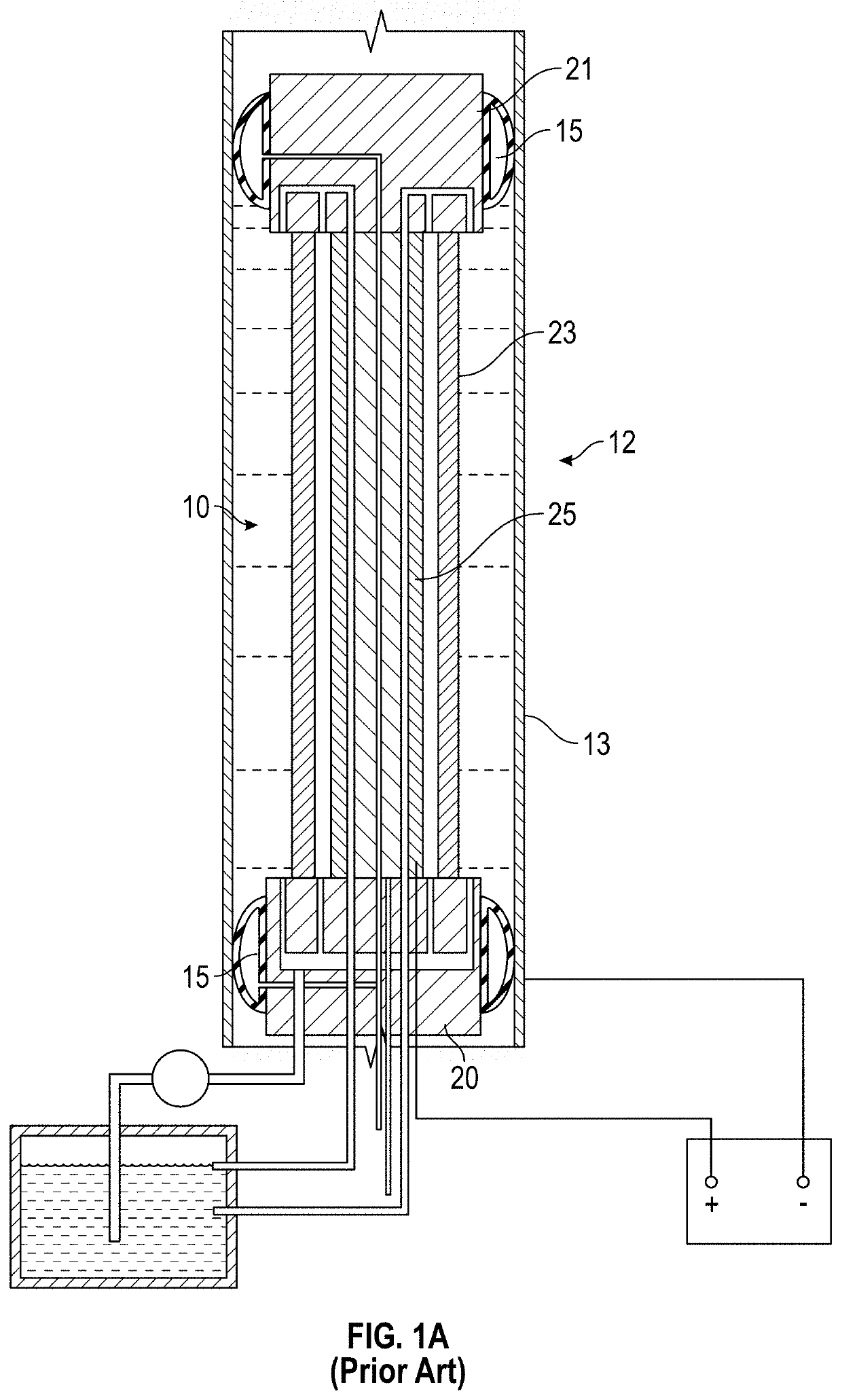

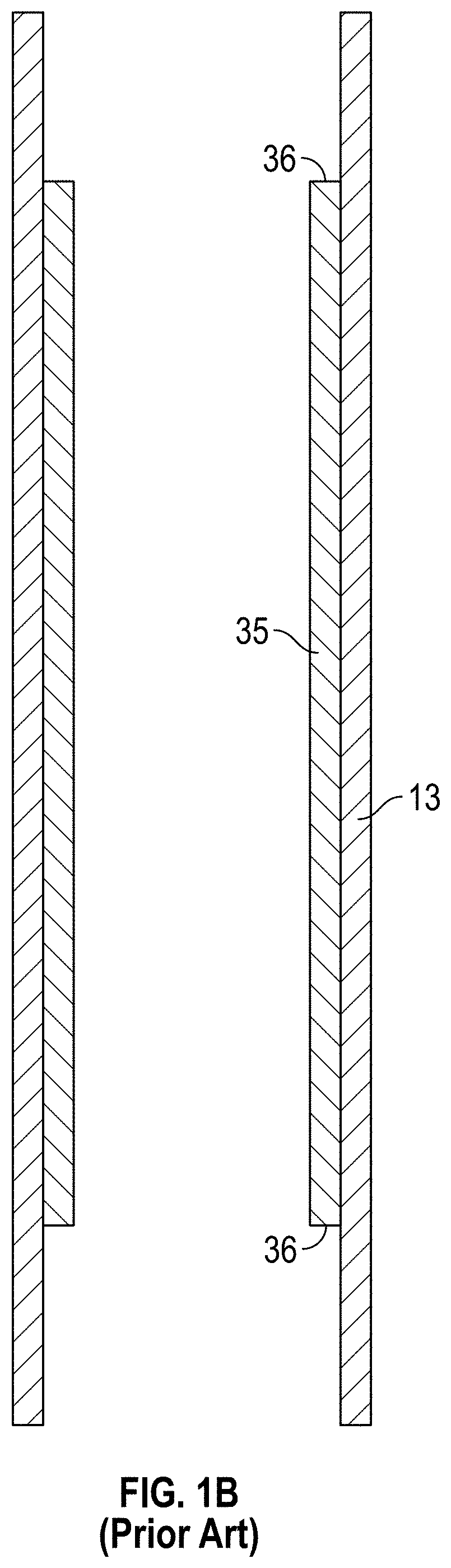

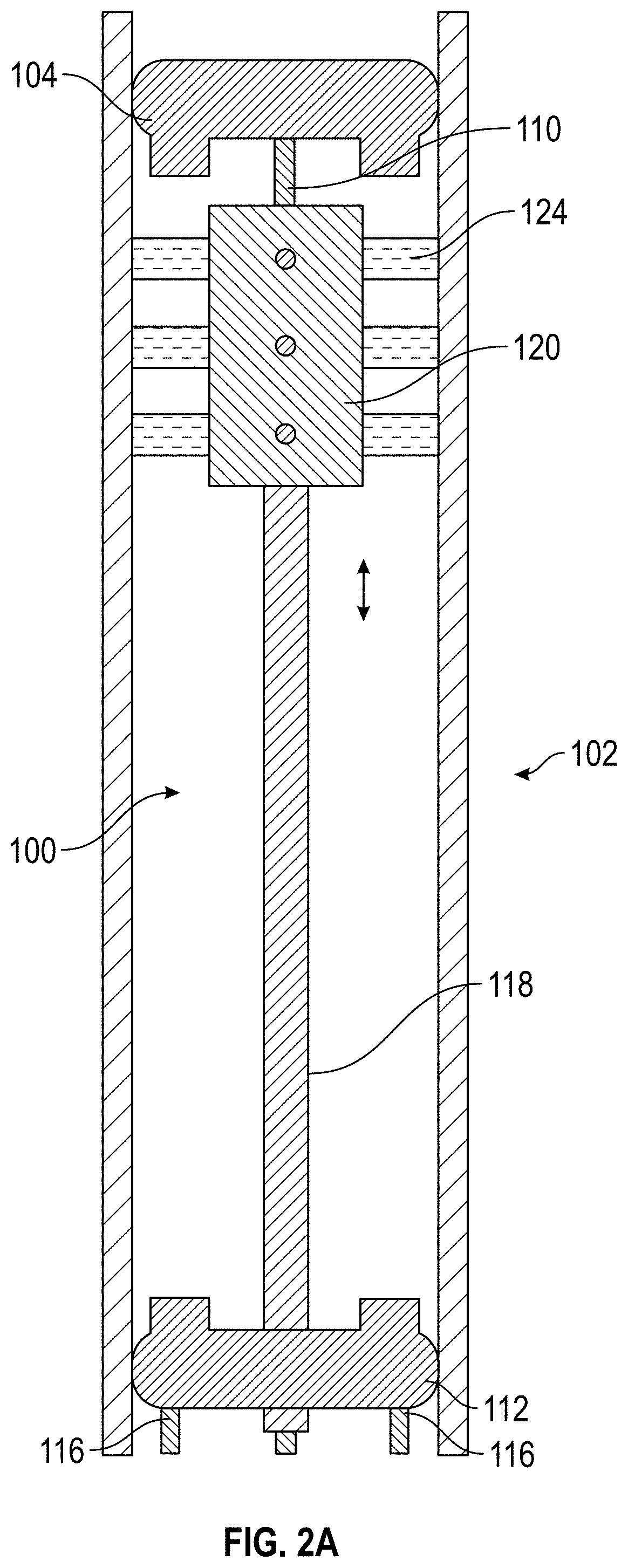

Apparatus and method for in-situ electrosleeving and in-situ electropolishing internal walls of metallic conduits

ActiveUS20210292930A1Avoid disintegrationReduce deposition thicknessSealing devicesCurrent conducting devicesStraight tubeMetallic materials

An apparatus and system for in-situ electropolishing and / or for in-situ electroforming a structural or functional reinforcement layer such as a sleeve of a selected metallic material on the internal surfaces of metallic tubular conduits are described. The apparatus and system can be employed on straight tubes, tube joints to different diameter tubes or face plates, tube elbows and other complex shapes encountered in piping systems. The apparatus includes components which can be independently manipulated and assembled on or near a degraded site and, after secured in place, form an electrolytic cell within the workpiece. The apparatus contains counter-electrodes which can be moved relative to the workpiece surface during the electroplating and / or electropolishing operation to provide flexibility in selecting and employing electropolishing process parameters and electroplating process parameters to design and optimize the surface roughness as well as the size, shape and properties of the electrodeposited reinforcing layer(s).

Owner:INTEGRAN TECH

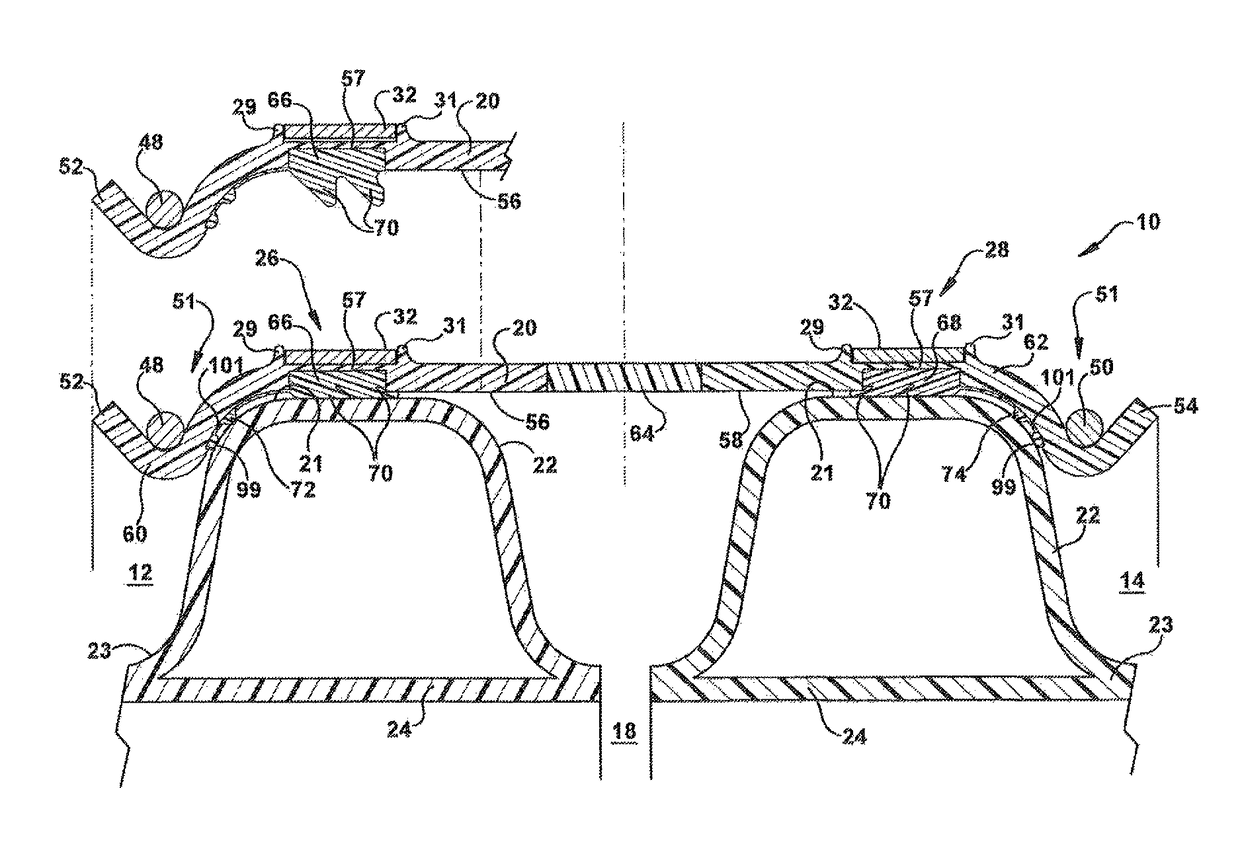

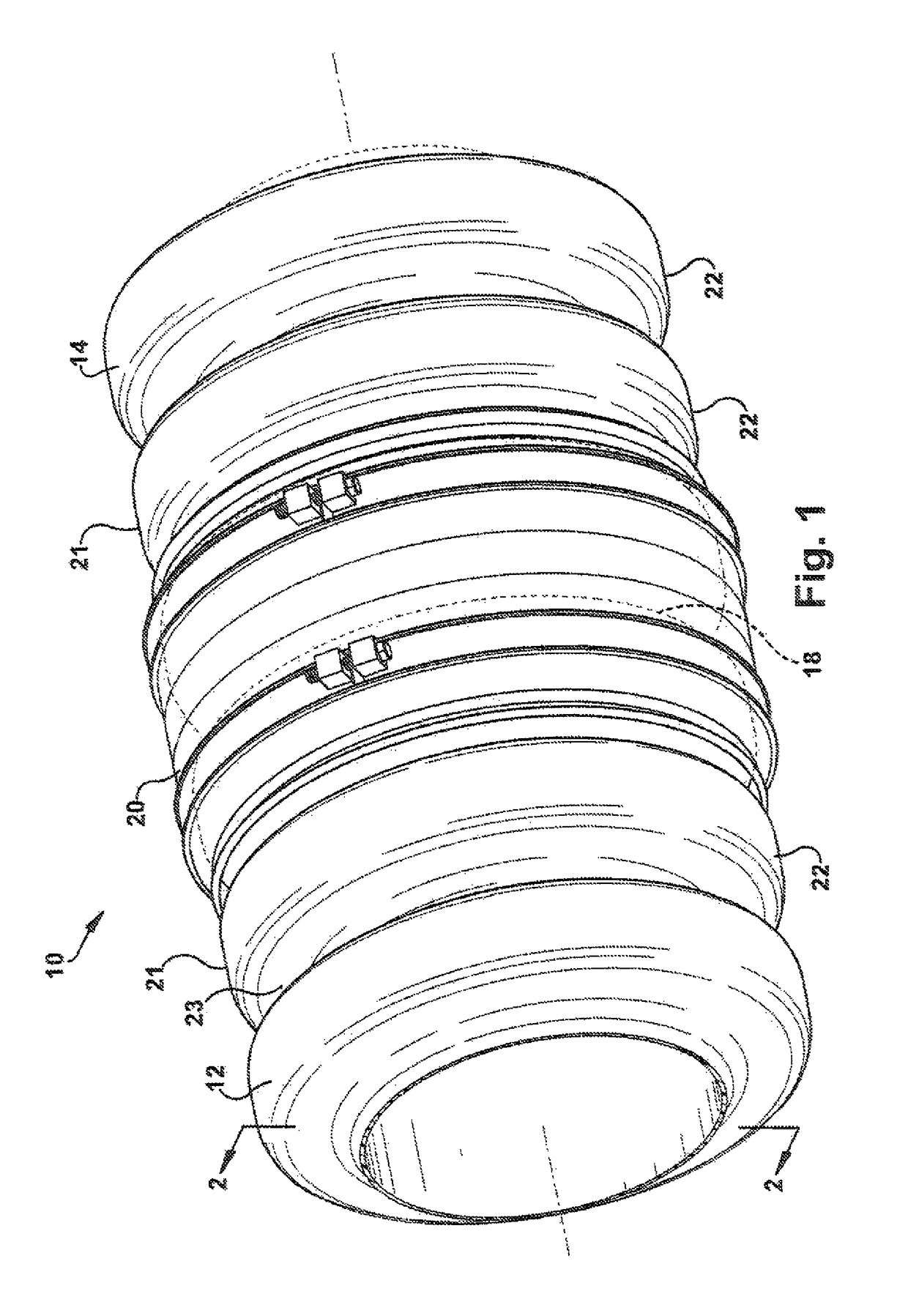

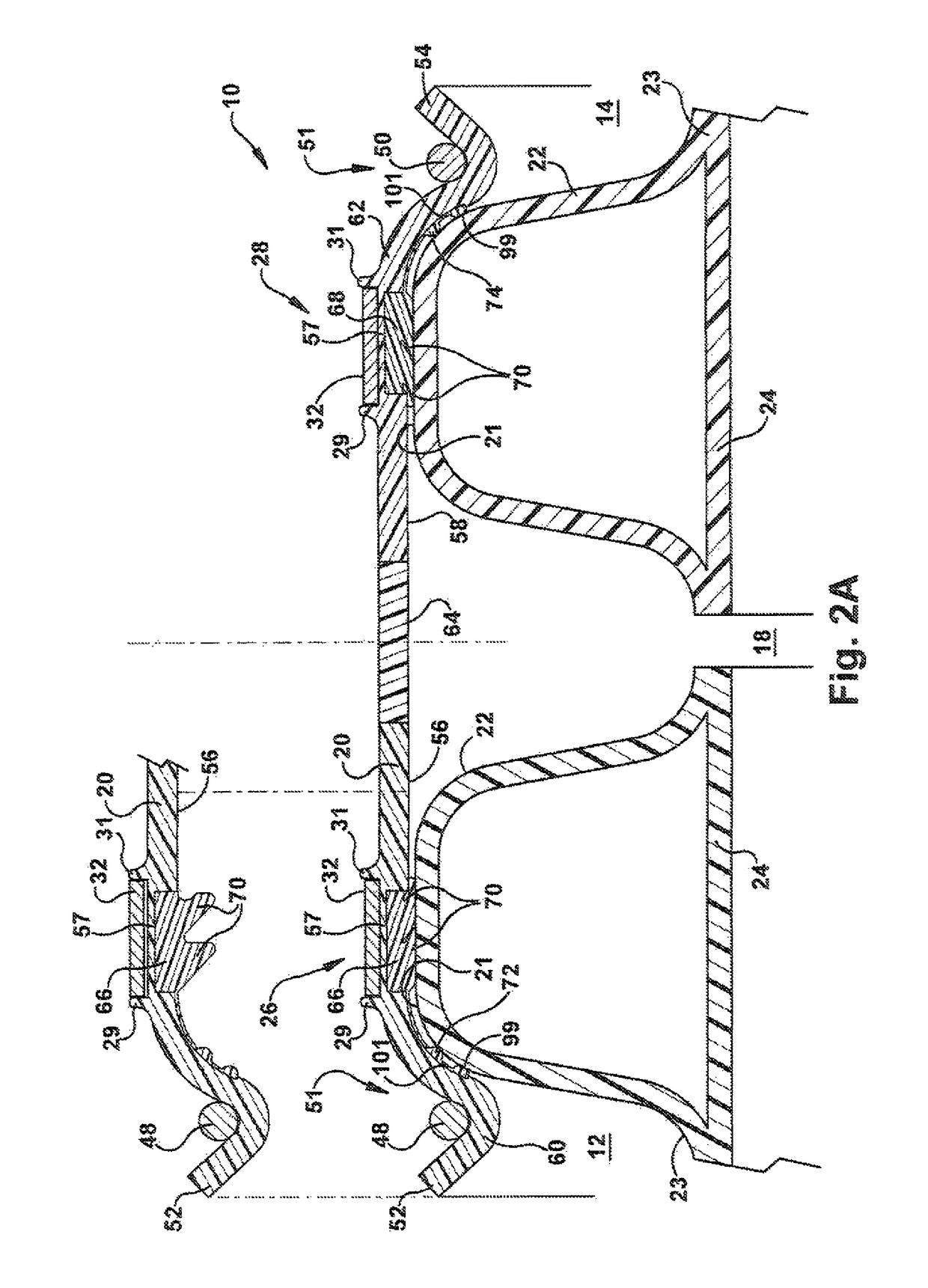

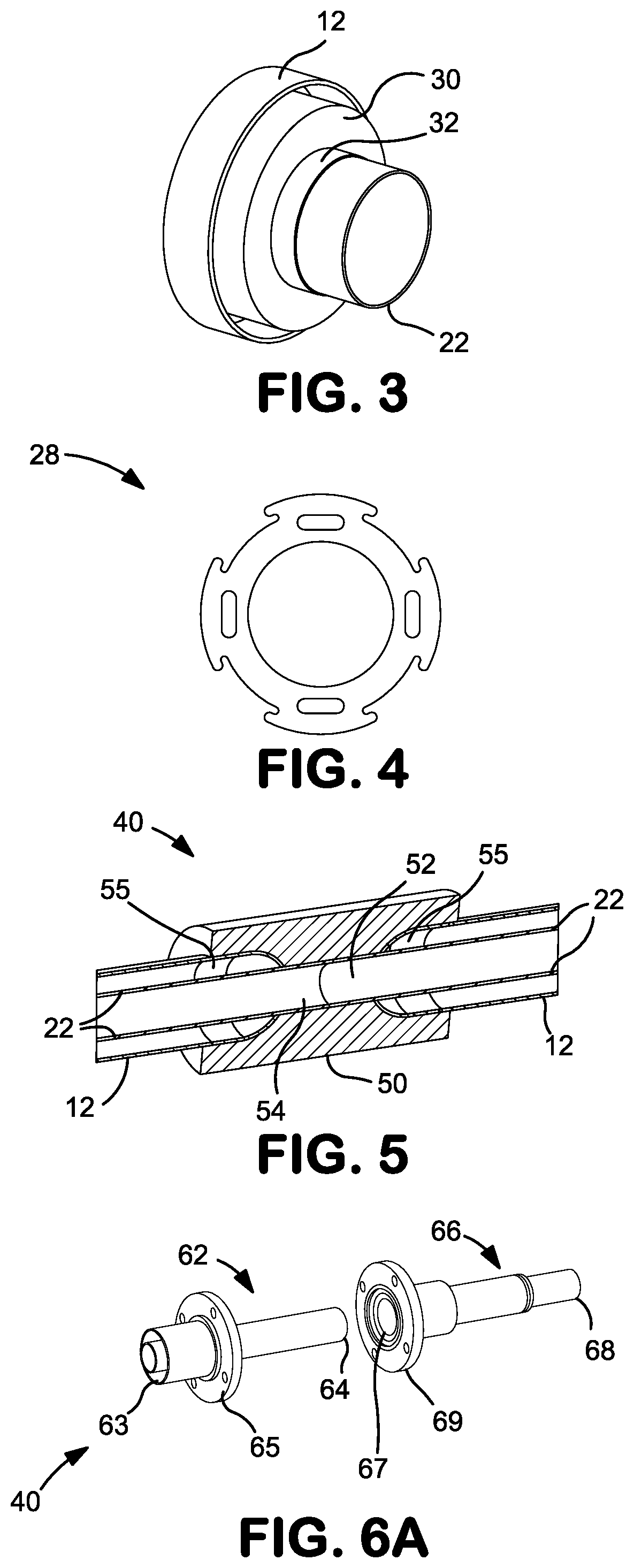

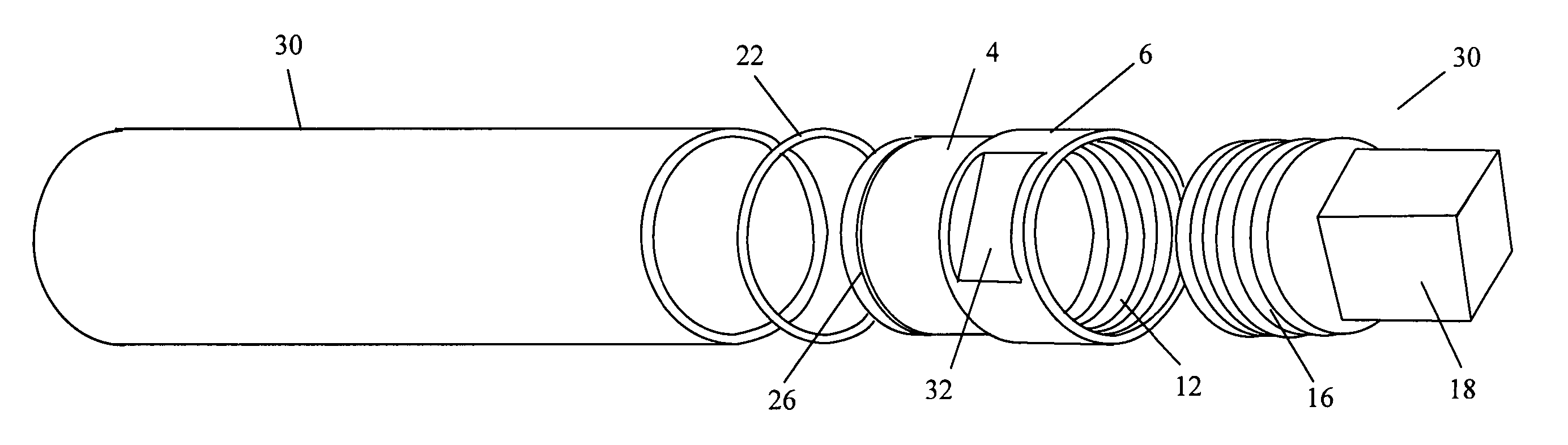

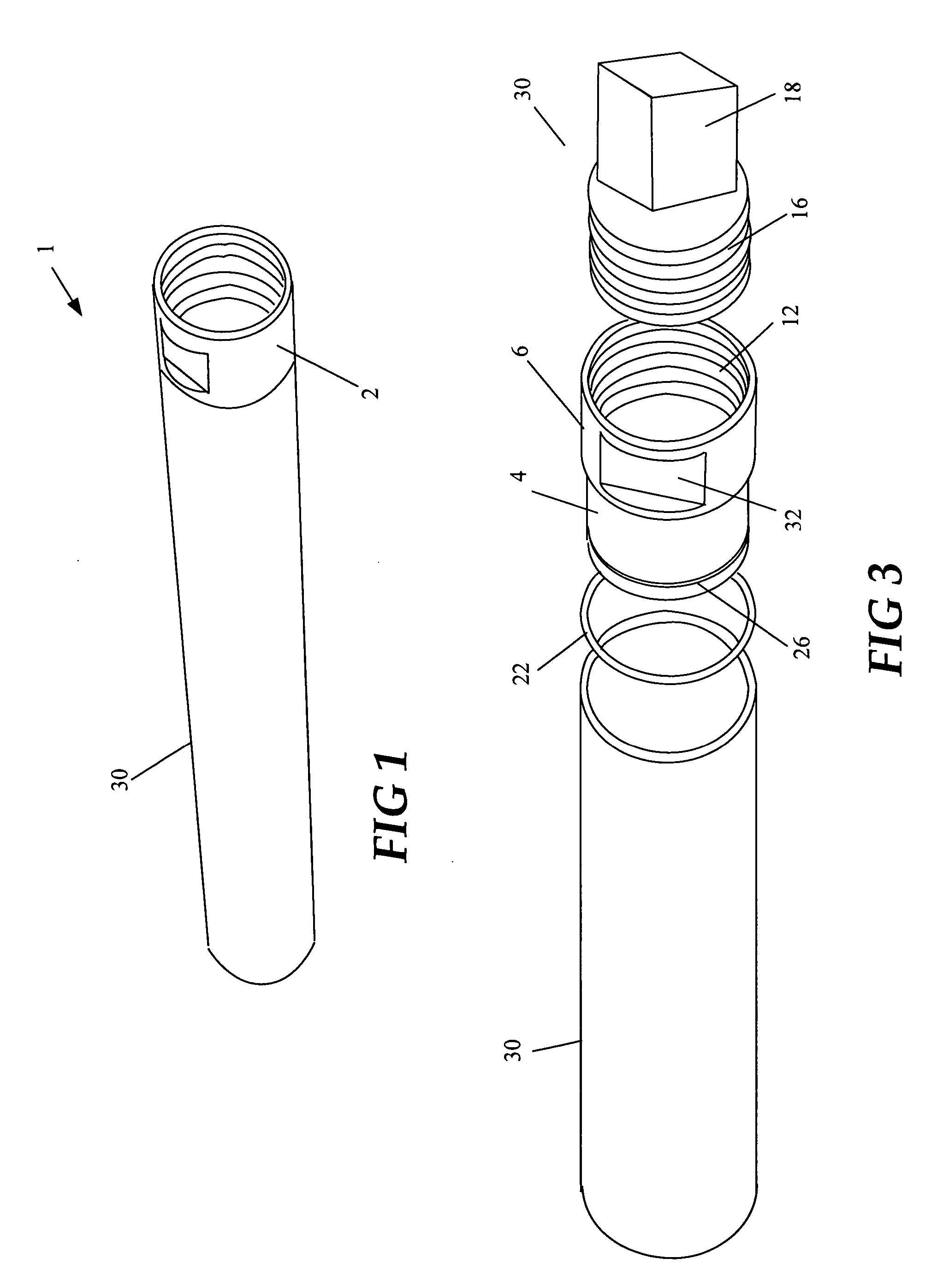

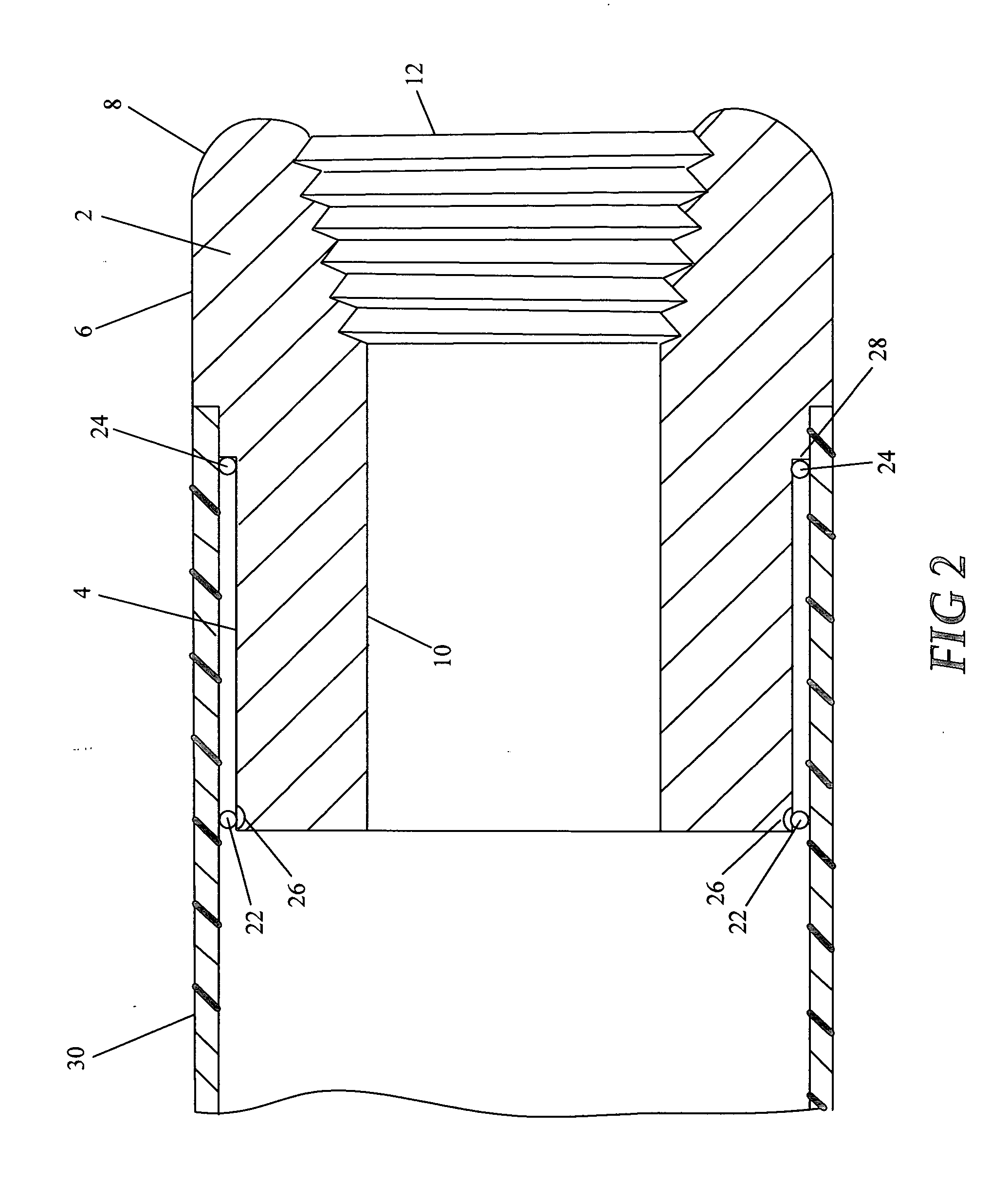

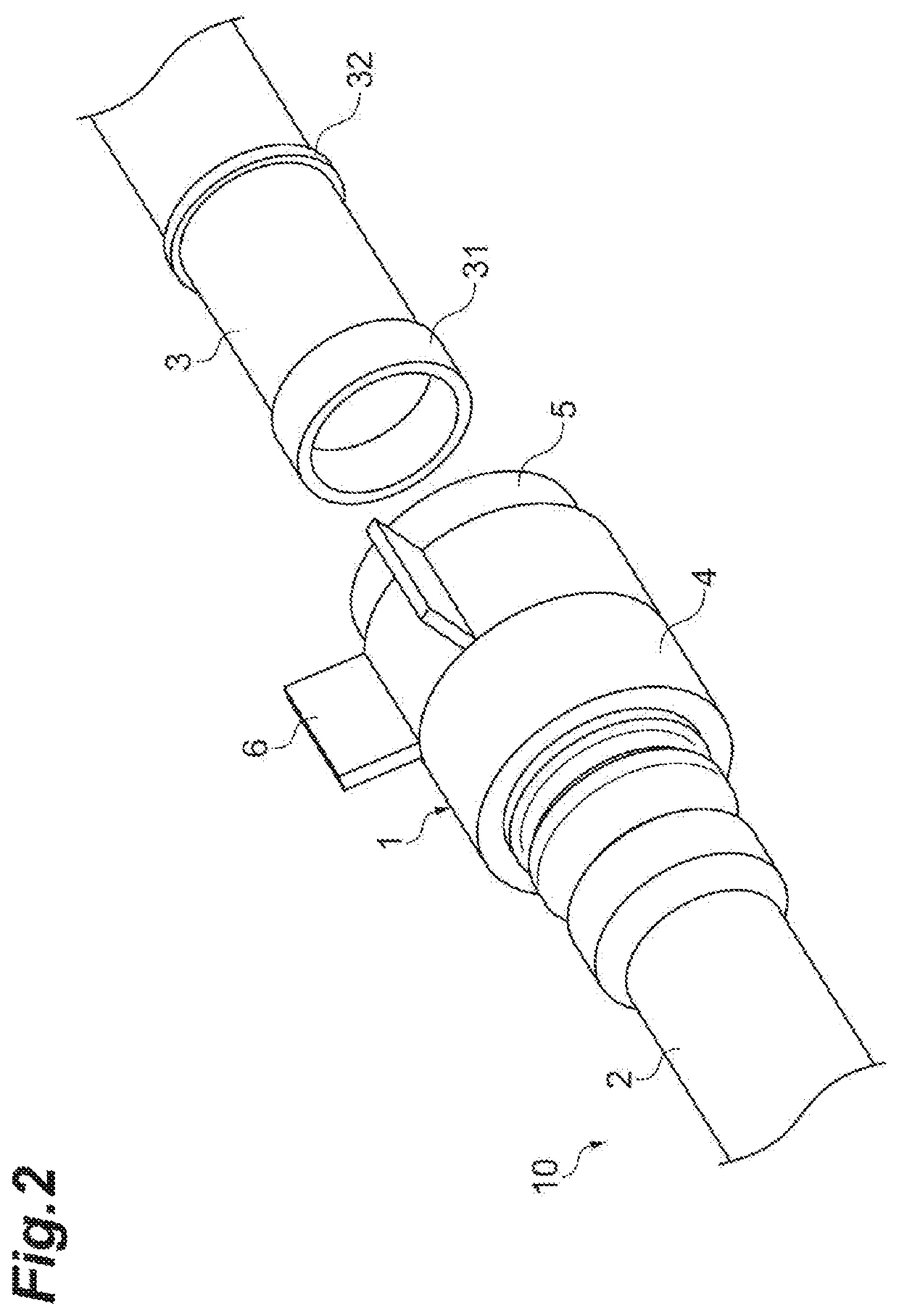

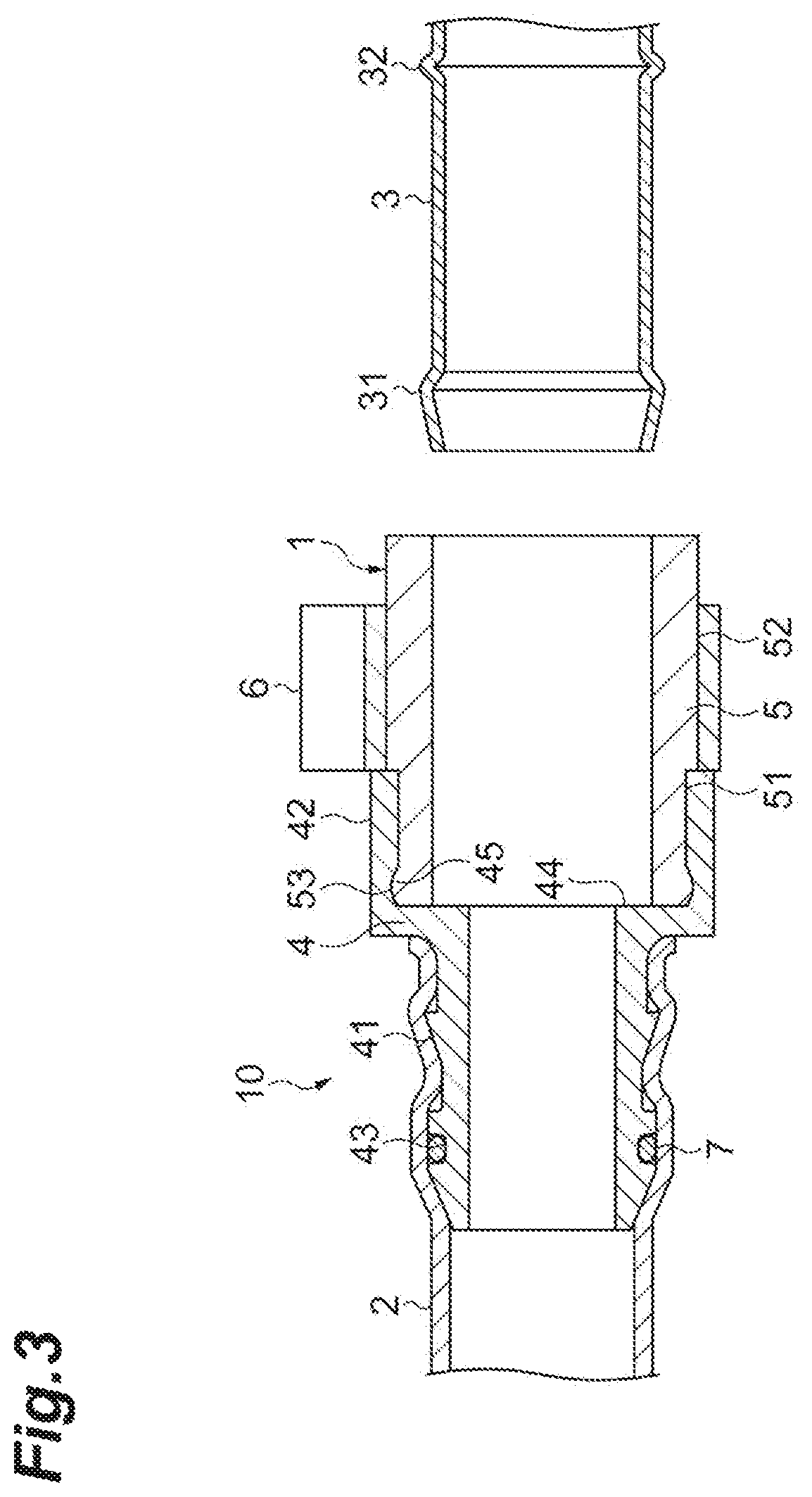

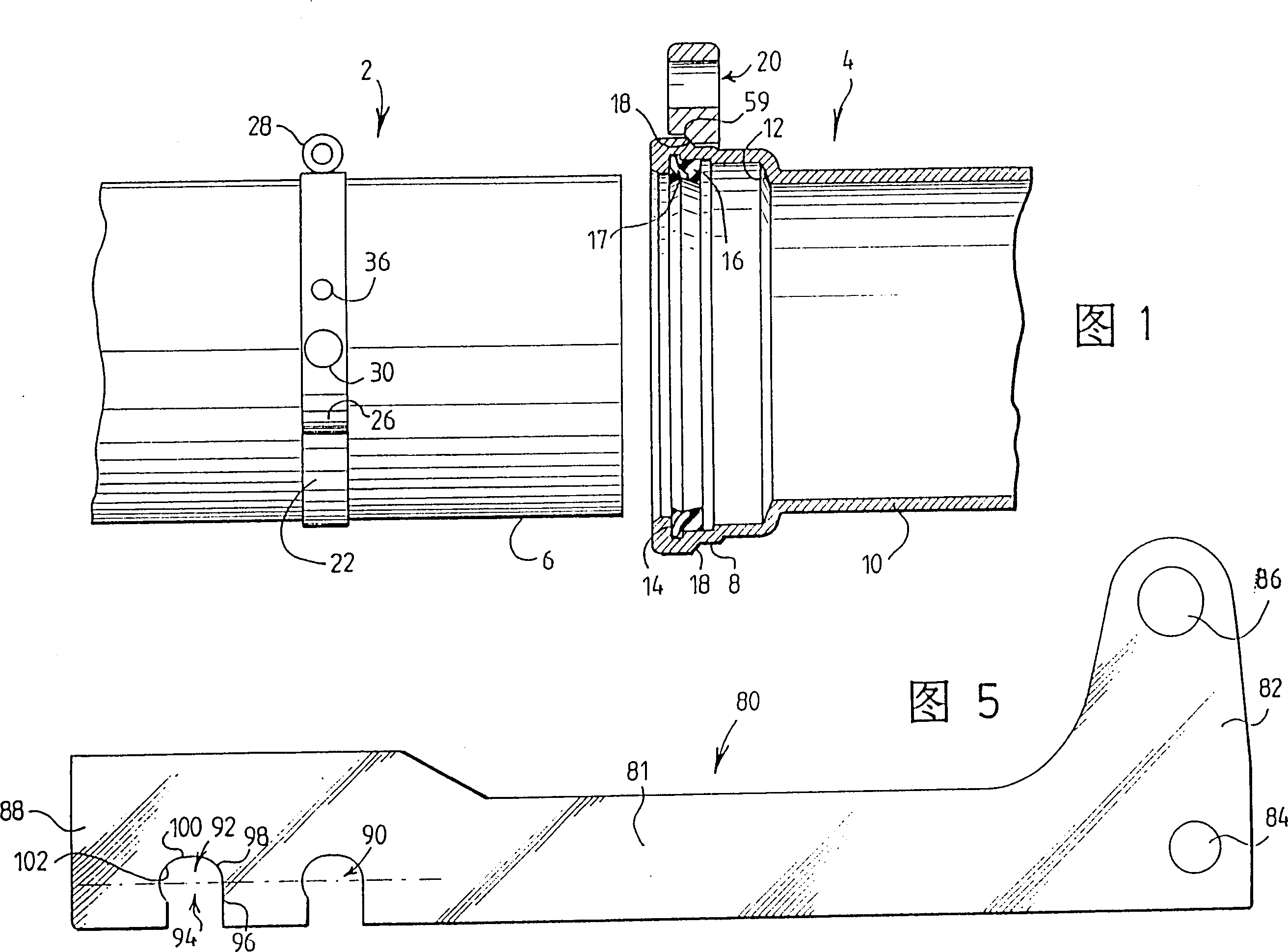

Pipe coupling assembly

A coupler assembly (10) and method of manufacture (10) for use with pipe comprising a unitary annular body (20) forming first and second cylindrical openings for surrounding a pipe or piping sections to facilitate forming a fluid-tight seal therein. The unitary annular body (20) comprises a medial portion (64) formed from a first material having a first durometer and first and second lateral portions (56, 58) integrally connected to opposite ends of the medial portion (64). The first and second lateral portions (56, 58) are made from a second material having a second durometer relatively higher than the first durometer of the first material. The coupler assembly (10) further comprises at least one clamping assembly (26) surrounding the unitary annular body member (20) adapted for compressing the coupler assembly (10) into a fluid-tight seal.

Owner:SPRINGSEAL

Identical-intensity flexible piping joint clasp and its production

InactiveCN1854589AReduce intensityChange consumptionHose connectionsEngineeringUltimate tensile strength

There is disclosed an equal strength hose connector clip and its manufacture method. The clip includes a clip body and ear-seats at both ends of the clip body. The manufacture method includes the following steps of setting the thickness of the clip in equal strength proportions; rolling the steel band blanks; cutting out the steel band blank of the corresponding length; milling the blank into the ring body using the roller mould under the condition of normal temperature and then being separated into half-round clip bodies to be made the inventive clip after welding the ear-seats.

Owner:LUDONG UNIVERSITY

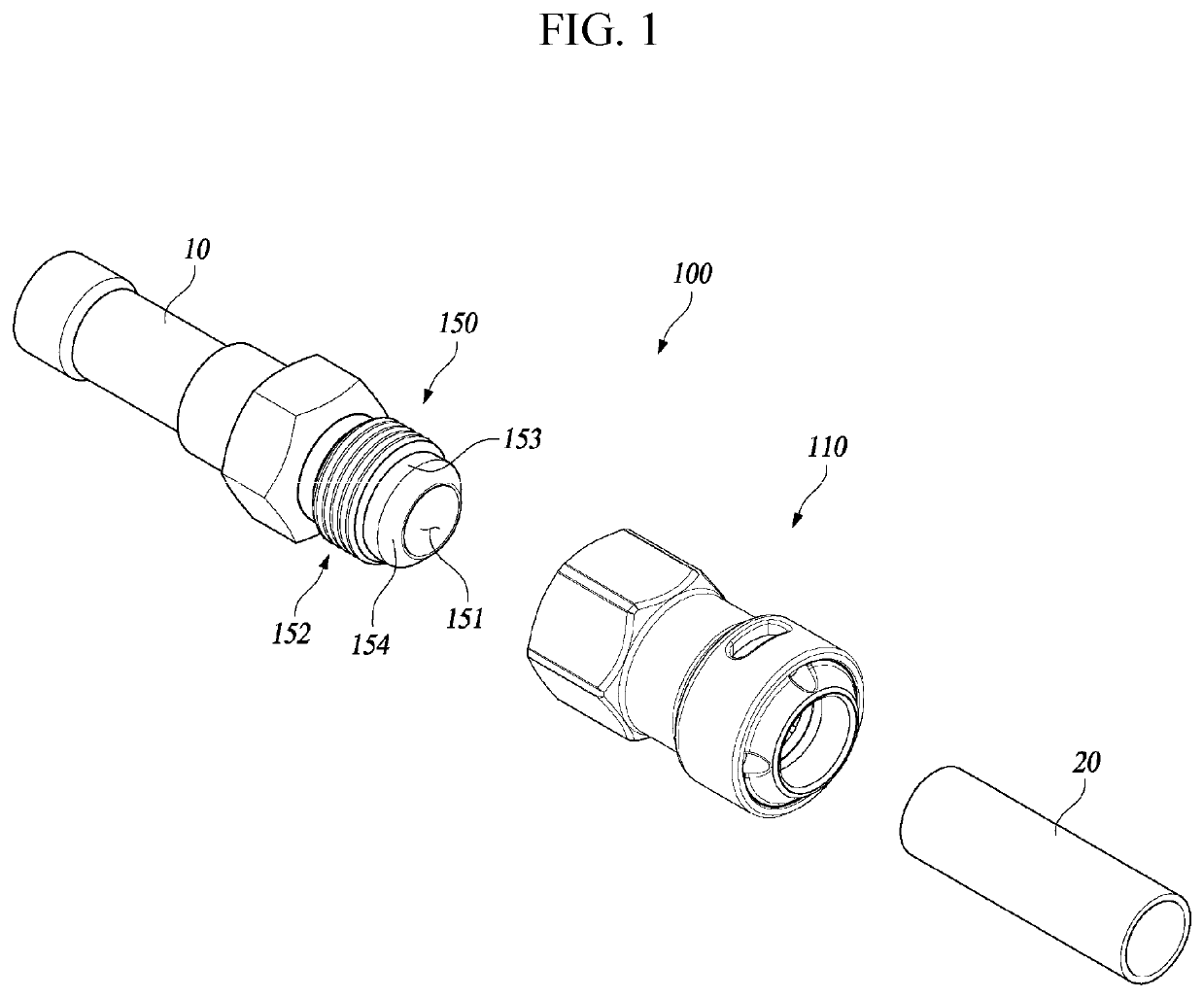

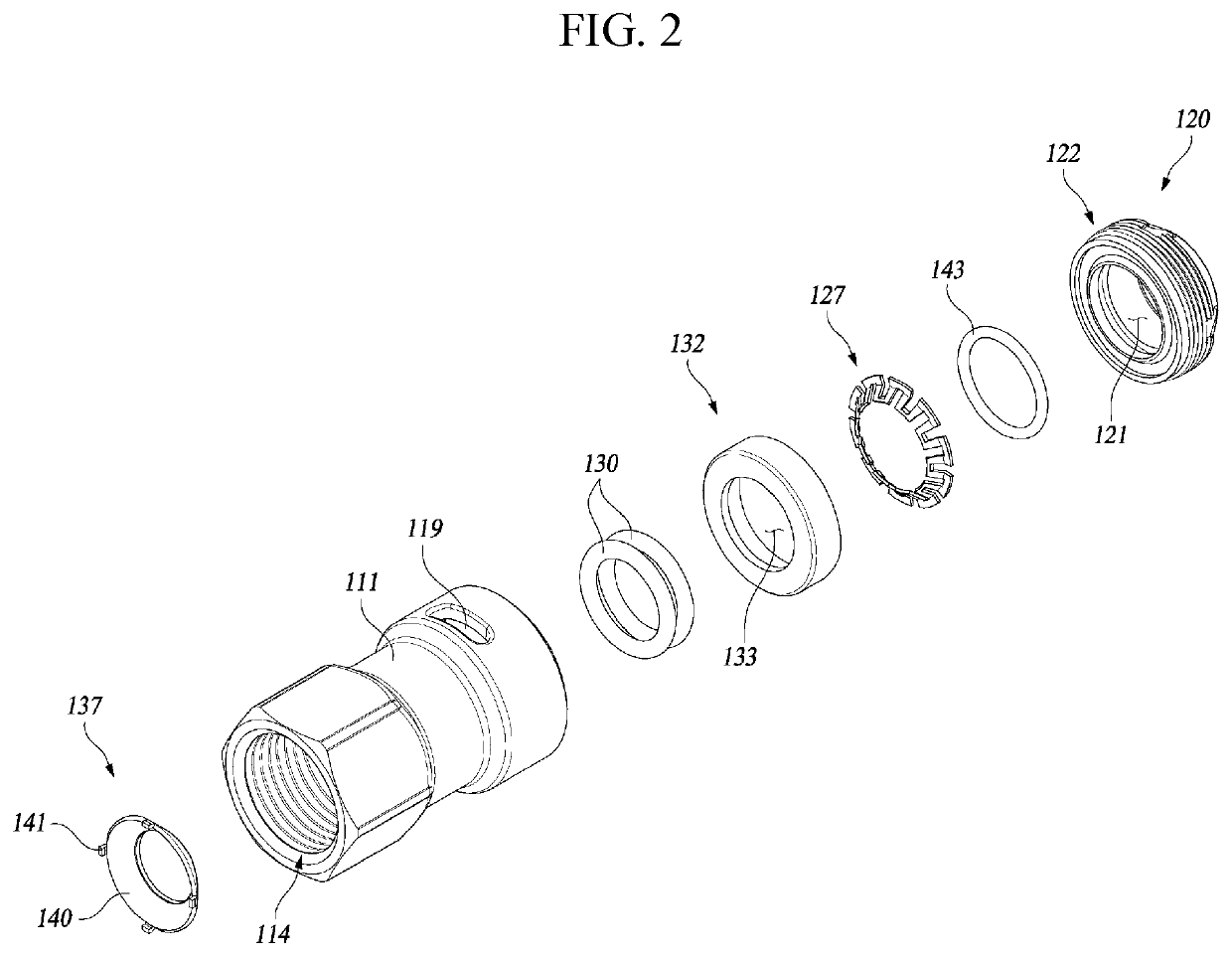

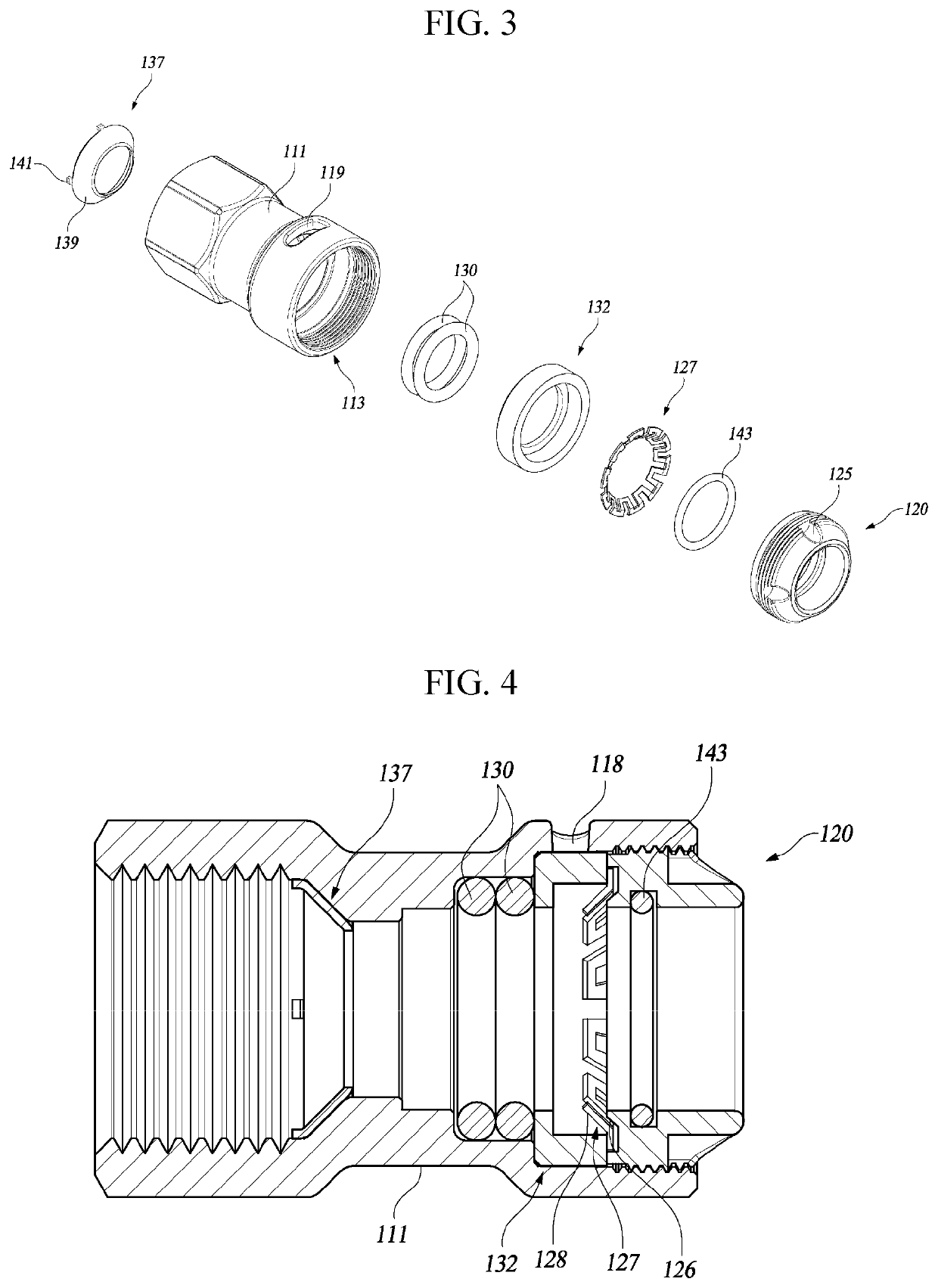

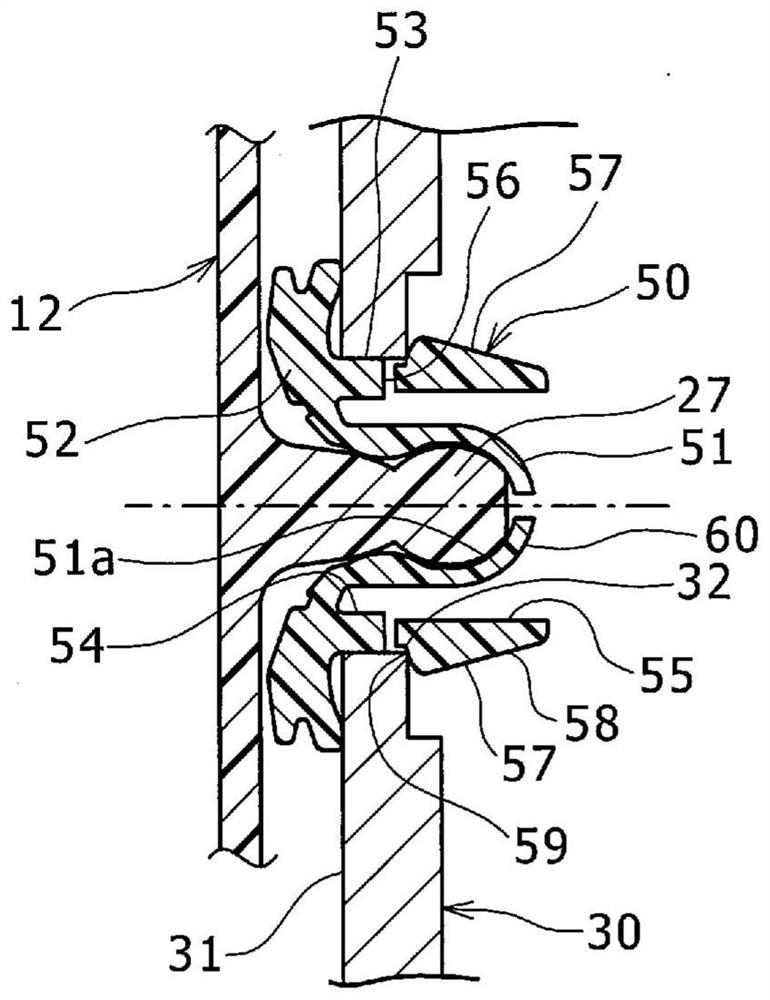

Connecting device for piping

ActiveUS11060648B2Reduce widthJoints with sealing surfacesCouplingsClassical mechanicsStructural engineering

Disclosed is a connecting device for piping for connecting a pipe to another pipe or to another part for piping. The connecting device includes an adapter and a pipe nipple configured to be threadedly engaged with the adapter. The pipe nipple is fixed to an end of a pipe, and an end of another pipe is inserted into the adapter. The adapter includes a hollow adapter body, a cap coupled to the adapter body, a grip ring configured to fix the pipe introduced into the adapter body, a body-sealing member configured to provide a seal between the adapter body and the pipe, a sleeve disposed between the grip ring and the body-sealing member, and a metal sealing member configured to provide a seal between the adapter body and the pipe nipple.

Owner:ESSEN TECH

Piping test device of seepage corrosion stress coupling

The invention relates to a piping test device of seepage corrosion stress coupling, wherein a leakage groove is arranged in the base, a pressure chamber is installed on the upper part of the base and a top cover is installed on the upper part of the pressure chamber; one end of the water outlet tube is connected with the bottom outlet of the base and the other end is extended into a measuring pot; a sample is installed in the pressure chamber on the base; a porous steel plate is installed between the sample and the base; a shrinkable tube is closely wrapped on the outside of the sample and a cover cap is arranged at the top part of the sample; a scree filter layer is filled in the cover cap; one end of the axial pressurizing rod is penetrated through the top cover to contact with the cover cap and the other end is connected with an axial pressurizer; a photoelectric sensor is installed on the body of the water outlet tube; a resistance strain gage is installed on the shrinkable tube. The invention researches a piping development process of the soil body under a complex stress state from the seepage corrosion stress coupling aspect, provides a new aspect for the comprehensive understanding of the soil body piping developmental mechanism and also provides an important theoretical basis and a technical support for the prediction and the effective treatment of the dam piping dangerous case.

Owner:HOHAI UNIV

Modular vacuum insulated piping

A modular, aerogel-based vacuum insulated pipe section comprising an outer conduit; an inner conduit concentrically disposed within the outer conduit with aerogel insulation and a condensable gas being disposed in the insulation space between the concentric conduits. As a stand-alone pipe section, the insulation space is at a pressure within the range of from about 100 microns Hg to about 1000 microns Hg. However, in operation, when a cryogenic fluid is traversing the inner conduit, the condensable gas condenses and the pressure within the insulation space is further reduced to range of from about 1 microns Hg to about 5 microns Hg. The vacuum insulated pipe section further includes a coupling arrangement disposed on a first end of the inner conduit and a second end of the inner conduit, the coupling arrangement configured to engage or mate with a corresponding end of another modular vacuum insulated pipe section.

Owner:PRAXAIR TECH INC

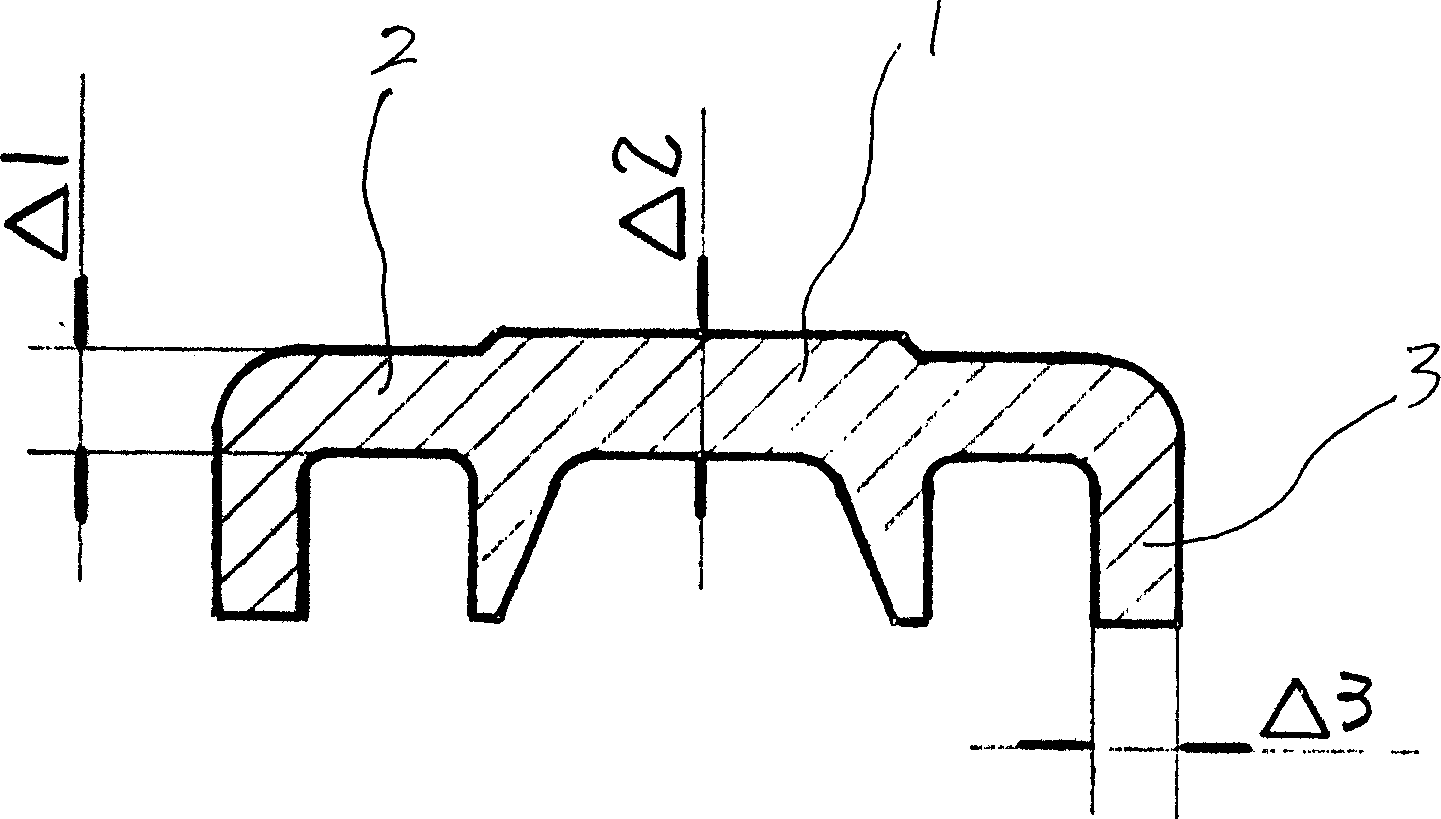

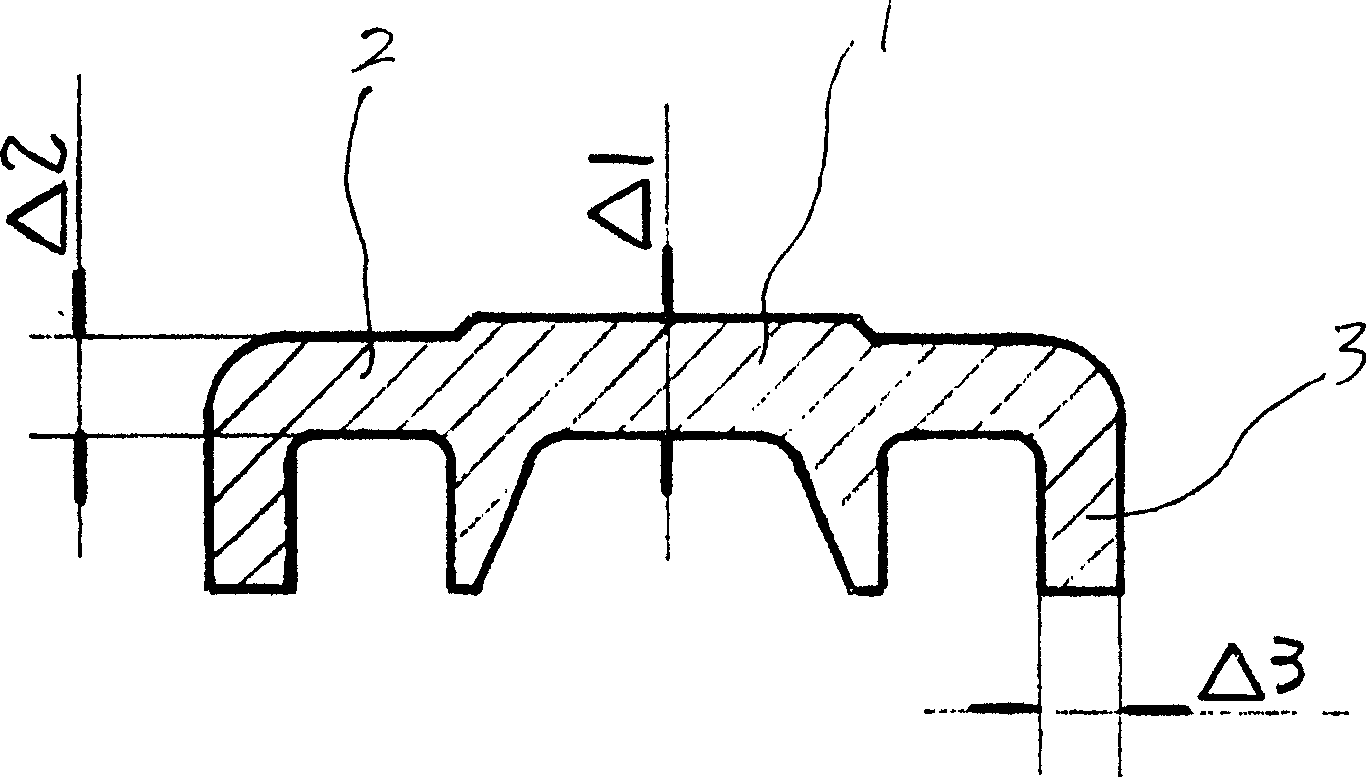

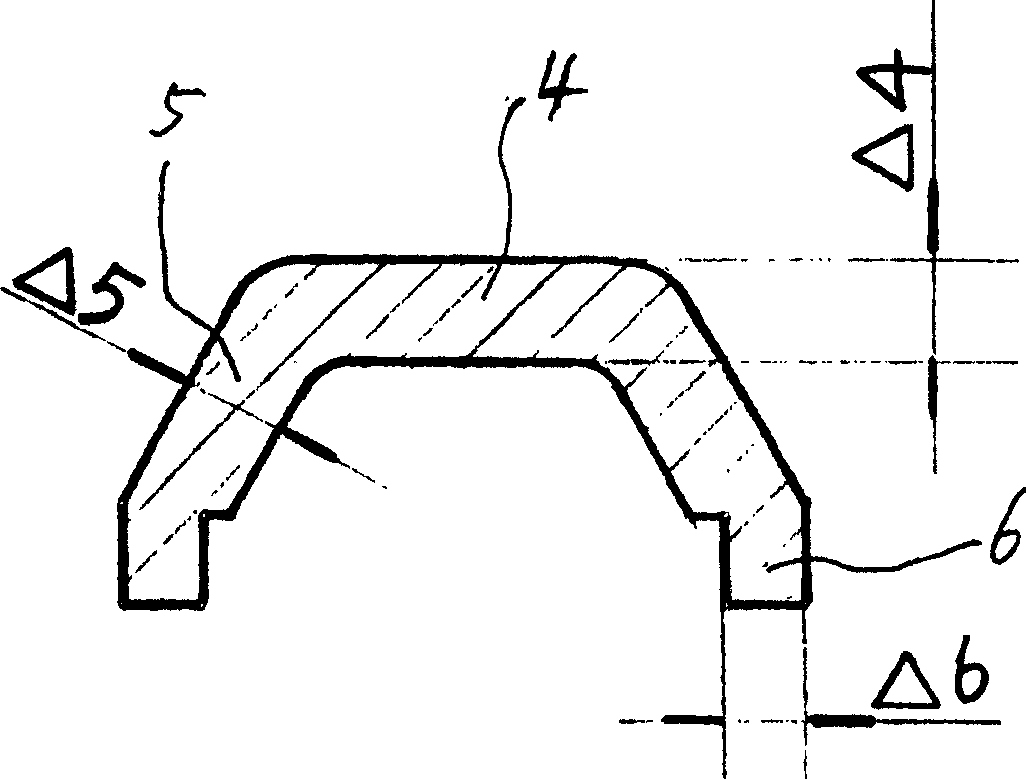

Identical-intensity flexible piping joint clasp and its production

InactiveCN100467929CReduce intensityChange consumptionHose connectionsStructural engineeringSteel belt

There is disclosed an equal strength hose connector clip and its manufacture method. The clip includes a clip body and ear-seats at both ends of the clip body. The manufacture method includes the following steps of setting the thickness of the clip in equal strength proportions; rolling the steel band blanks; cutting out the steel band blank of the corresponding length; milling the blank into the ring body using the roller mould under the condition of normal temperature and then being separated into half-round clip bodies to be made the inventive clip after welding the ear-seats.

Owner:LUDONG UNIVERSITY

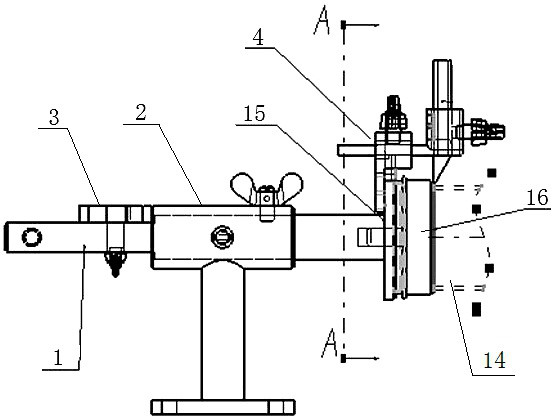

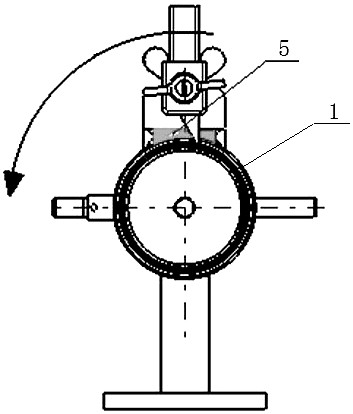

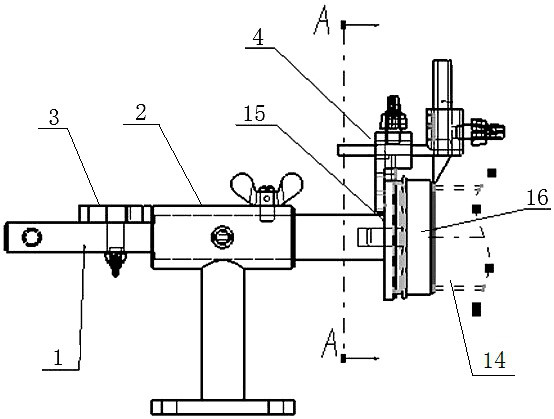

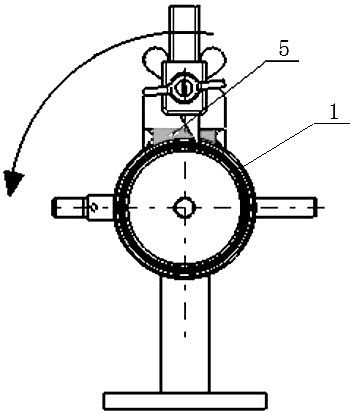

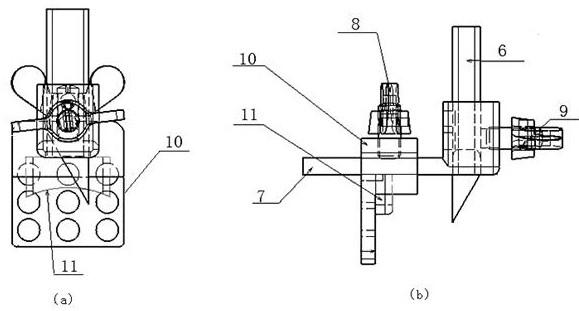

Guide pipe welding shrinkage control device

ActiveCN112122866AEnable connectivityRealize digital quantity controlWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWeld seam

The invention discloses a guide pipe welding shrinkage control device, and belongs to the technical field of aviation welding guide pipe precision manufacturing. The guide pipe welding shrinkage control device comprises a digital control device and a piping marking device; the digital control device comprises a casing positioner, a pipe support and a digital measurer; a connecting disc is providedat one end of the casing positioner; the casing positioner is coaxially connected with a pipe joint through the connecting disc; the pipe support is used for supporting the casing positioner; the digital measurer is rotatably connected to the casing positioner, and can be rotated to drive the casing positioner to slide in the pipe support; and the piping marking device is fixed on the connectingdisc and used for drawing a circle of weld line at the joint of a guide pipe and the pipe joint. The digital control device and the piping marking device are provided to be used in cooperation; the welding shrinkage variable is obtained by the digital control device and transmitted into the piping marking device; the weld line position before welding is obtained by the piping marking device; and technical guarantee is provided for the gapless welding requirement.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Bullthread

A connector for use in combination with piping to transform plumbing pipe stub outs to re-sealable leak-proof open or closed stub outs. The connector is an elongated hollow cylindrical brass fitting having first and second ends wherein the first end slides into an open end of a copper stub out pipe and securely attached thereto. The second end of the elongated hollow cylindrical brass fitting has a threaded interior surface that is configured as a female threaded receptor to engage a male threaded plug. The threaded plug removably engages the second end of the elongated hollow cylindrical brass fitting by screwing into or out of the elongated hollow cylindrical brass fitting. The insertion and removal of the threaded plug allows for the drain of debris, pressure testing and inspection of the copper piping throughout a newly constructed building without the traditional cutting and recapping now permanently closed stub outs which may have been bullet stub outs or stub outs that have been soldered closed.

Owner:GRAY FRLIN E

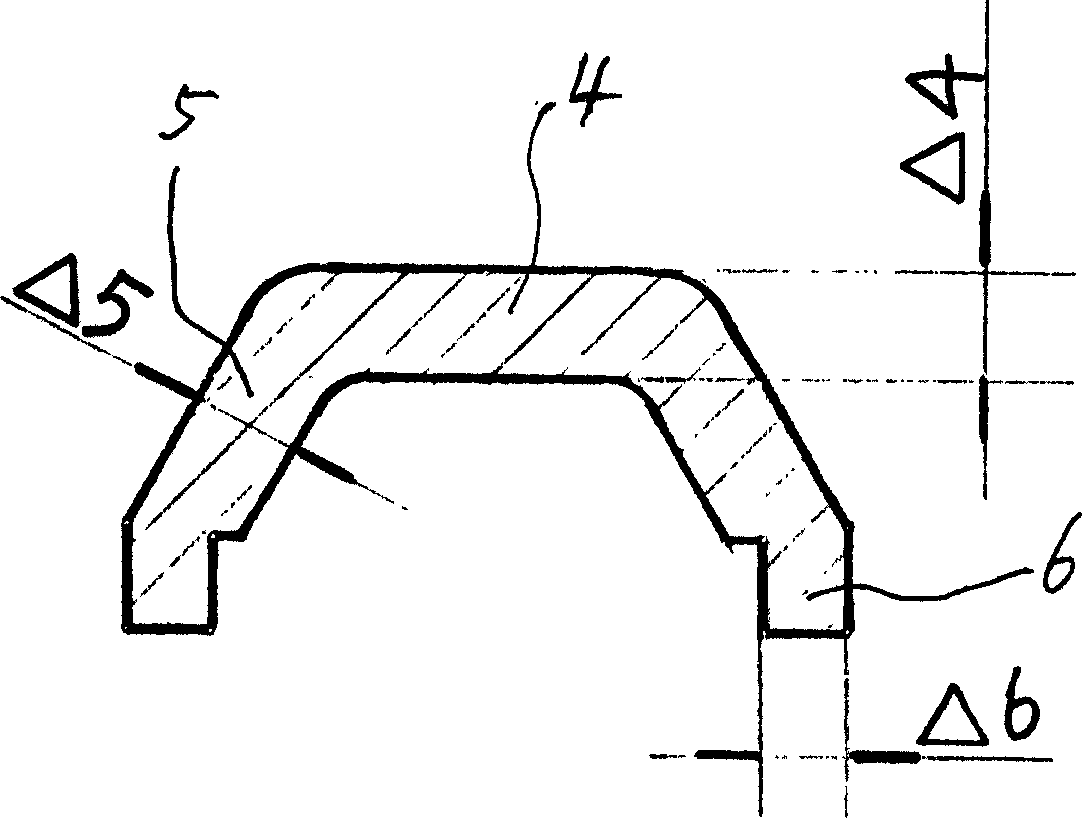

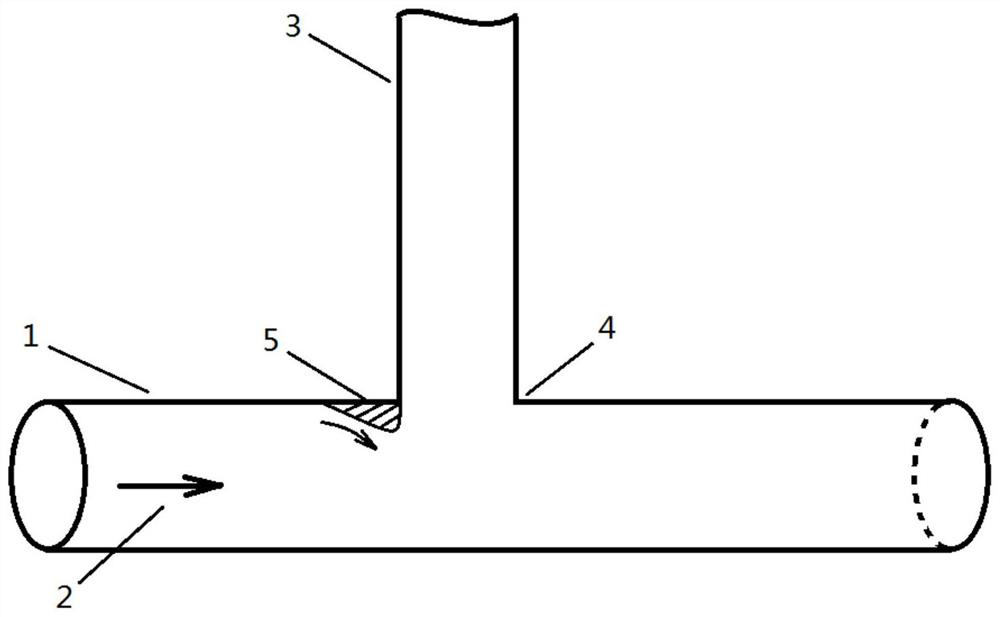

Device for weakening piping system vibration caused by vortex shedding

The invention discloses a device for weakening piping system vibration caused by vortex shedding. The device is a surfacing (5), and the surfacing (5) is welded to the position, close to the joint ofa main pipeline (1) and a branch pipeline (3), on a main pipeline tee joint (4) in the main pipeline (1). According to the design, surfacing is carried out on the upstream of the main pipeline tee joint, the flow direction of local fluid in the pipeline is changed through surfacing, so that vortexes formed by the fluid in the main pipeline tee joint are weakened, vortex fluctuation is restrained from being amplified in the branch pipeline due to audio frequency coupling, and vibration of a piping system is reduced. The design starts from weakening vortexes at the tee joint, suppresses the acoustic resonance phenomenon, reduces piping system vibration, eliminates overlarge stress or fatigue of the pipeline due to acoustic resonance, and improves the safety of the piping system.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

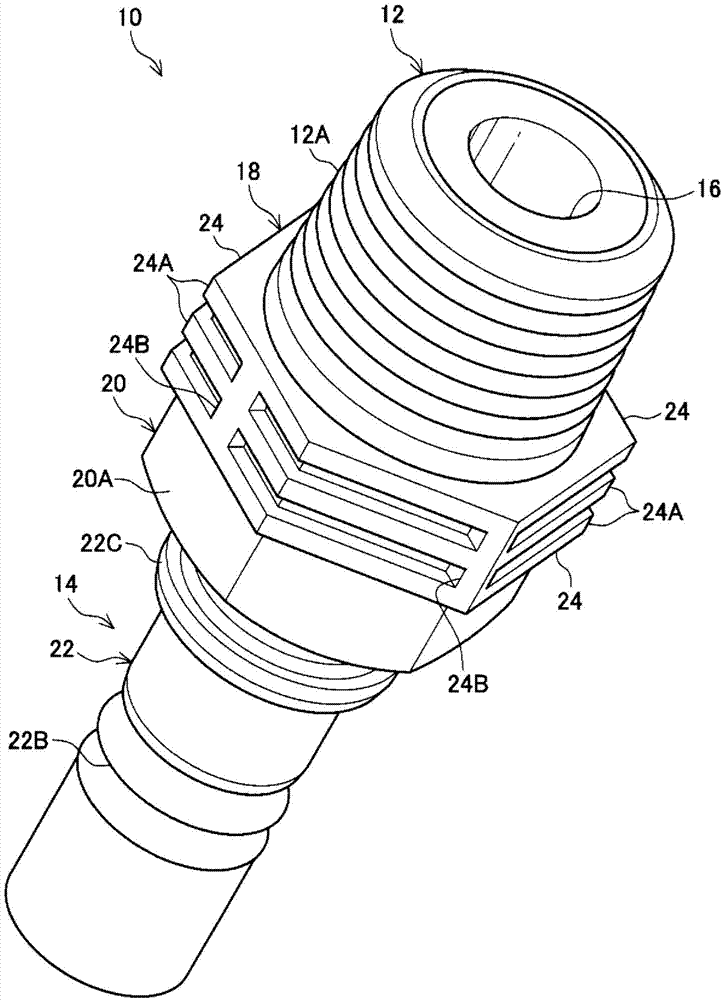

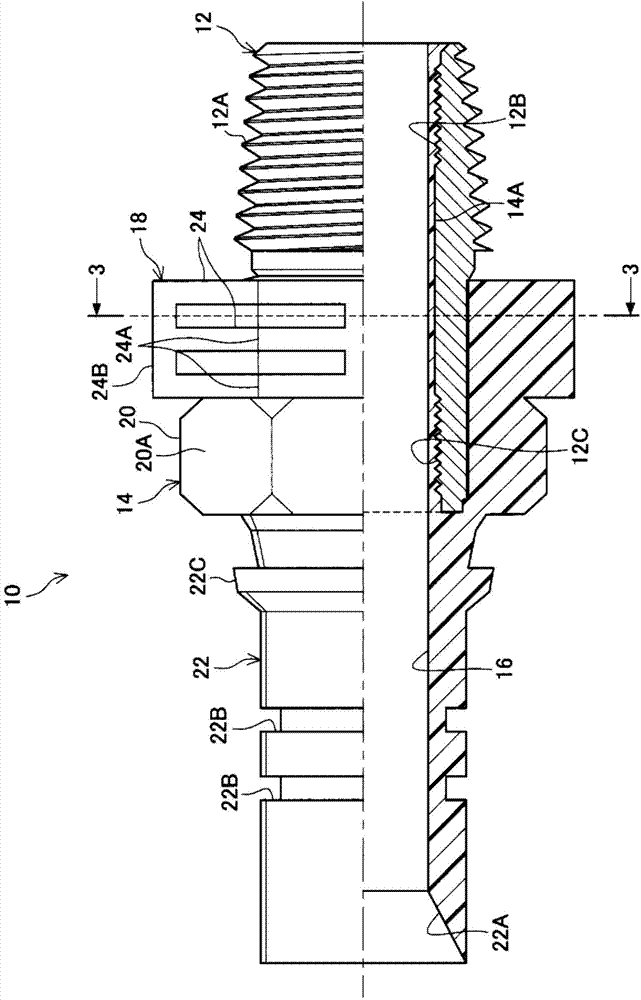

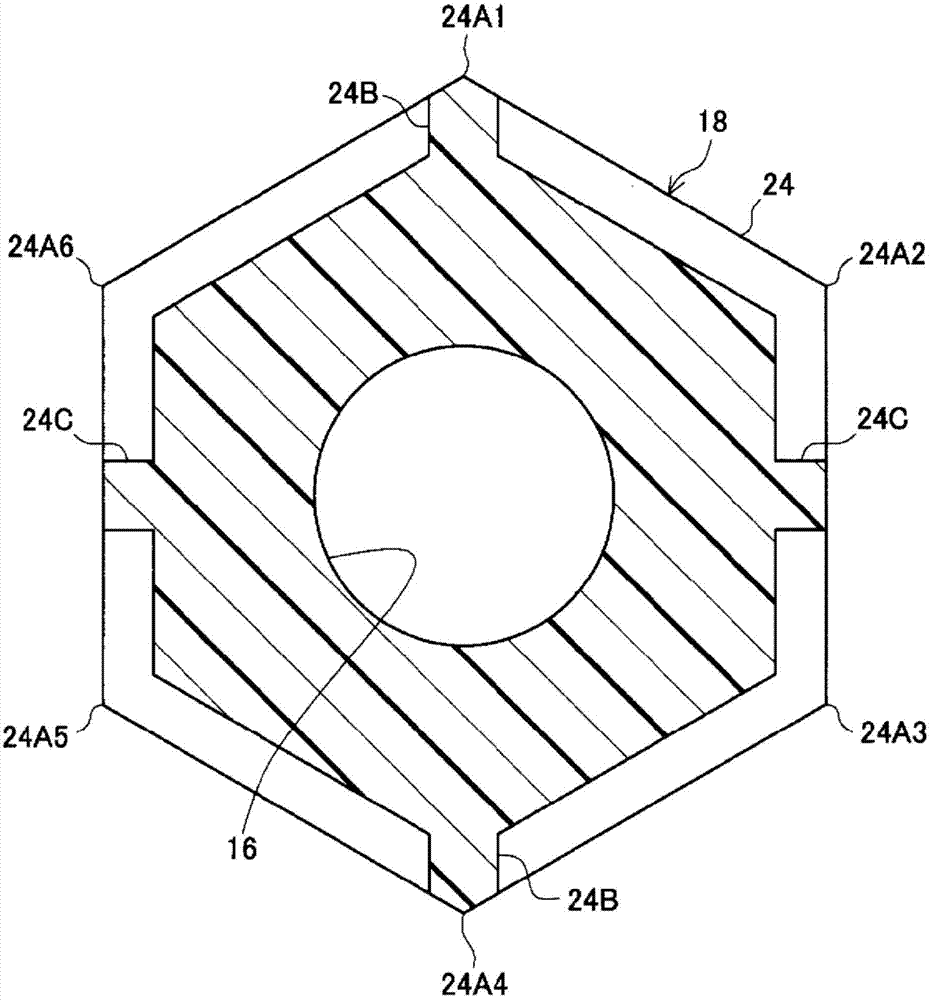

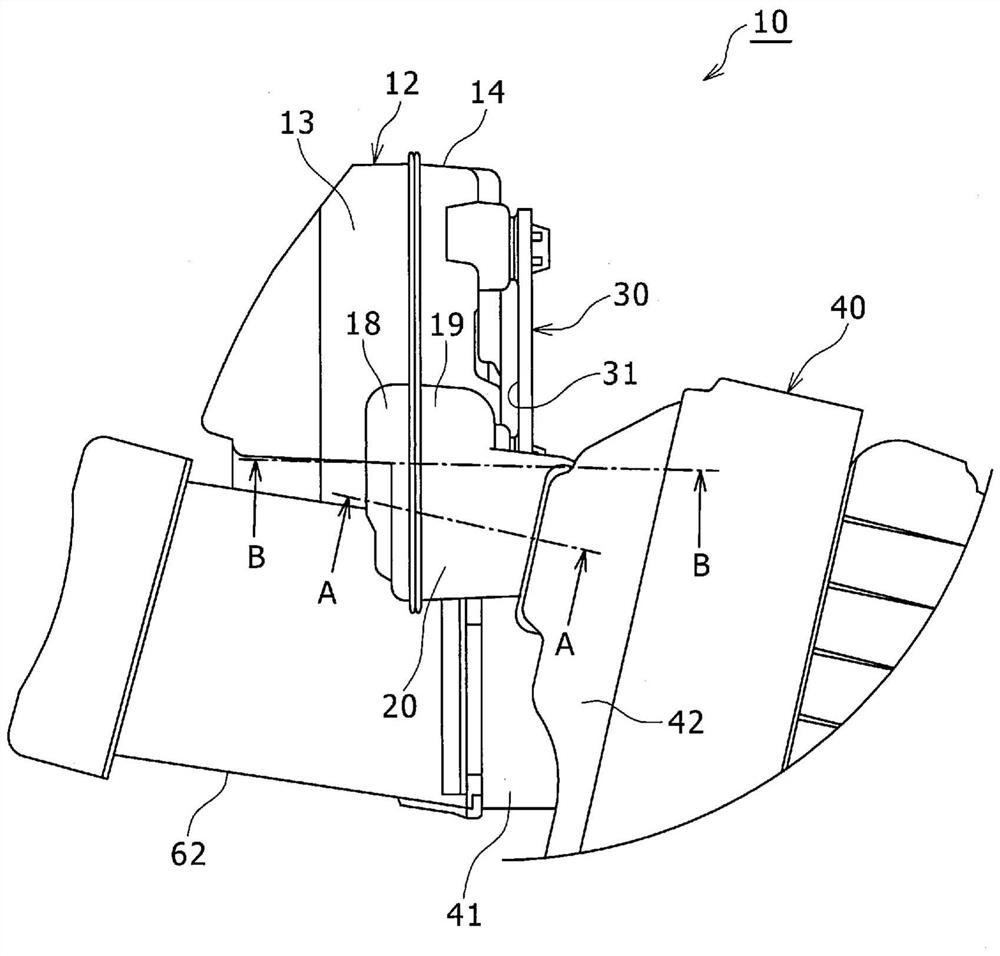

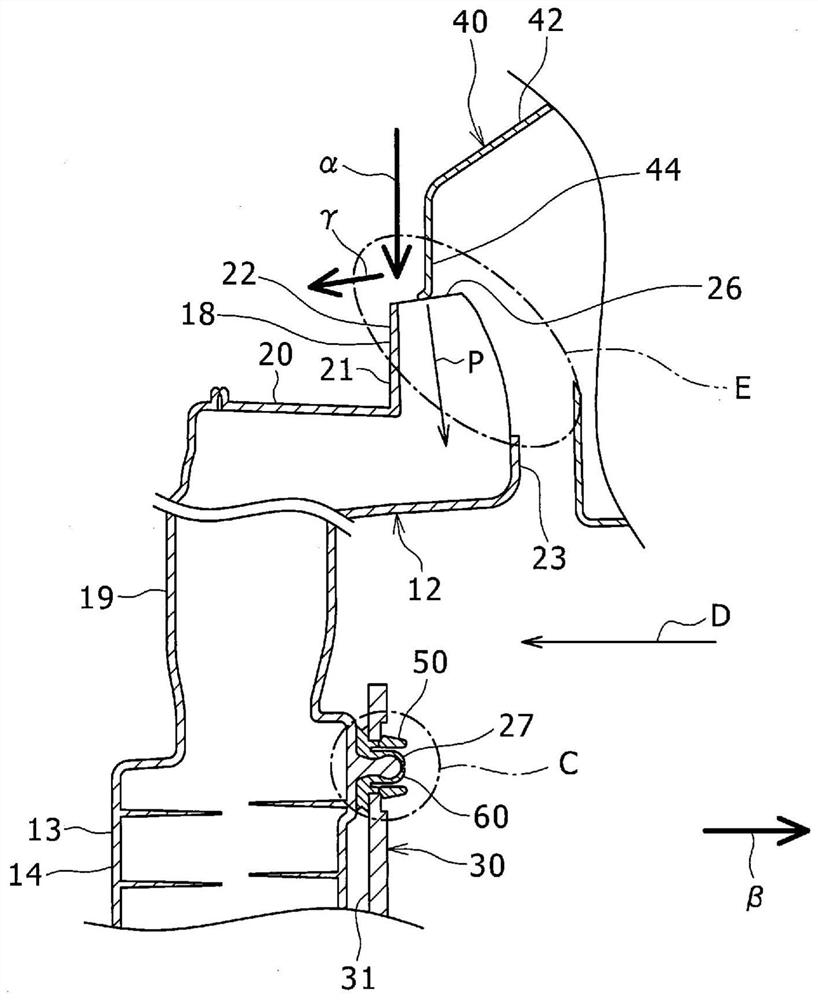

Piping joint

ActiveCN104769348AContainment leakAvoid separationJoints with sealing surfacesLoad modified fastenersEngineeringPiping

Provided is a piping joint (10) comprising: a metal pipe (12) that can be screwed into a pipe body; a resin pipe (14) having one end section that is configured to be connectable with another pipe body and another end section that is integrally formed with the metal pipe (12); and a first polygonal section (18) that is provided to the outer peripheral surface of the resin pipe (14) and that comprises a corner section (24A) that requires less torque to break than the amount of torque required to separate the metal pipe (12) and the resin pipe (14).

Owner:BRIDGESTONE CORP

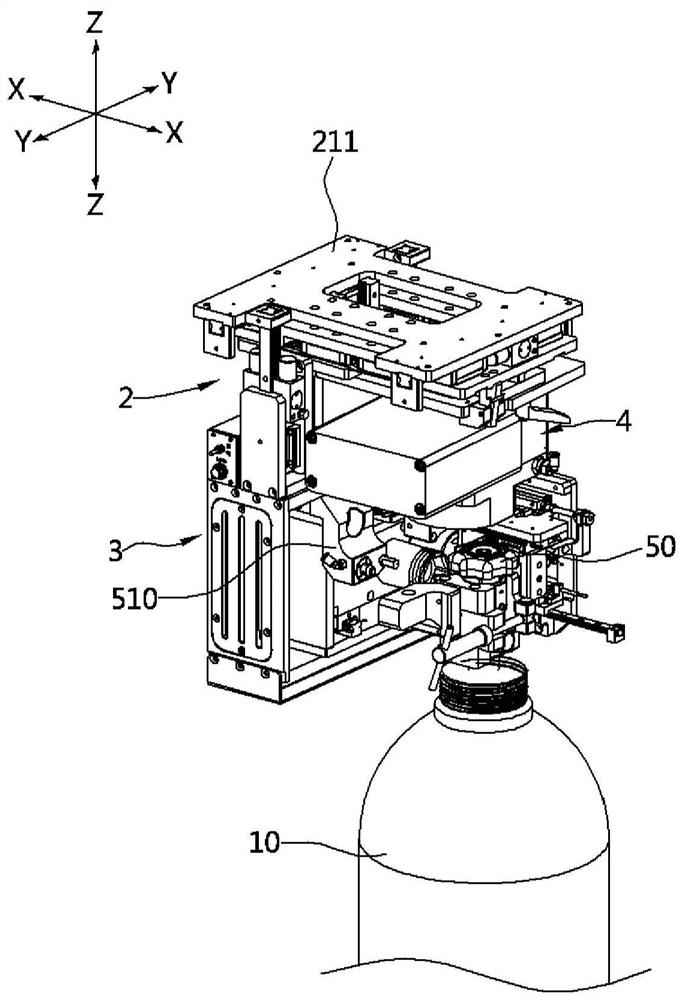

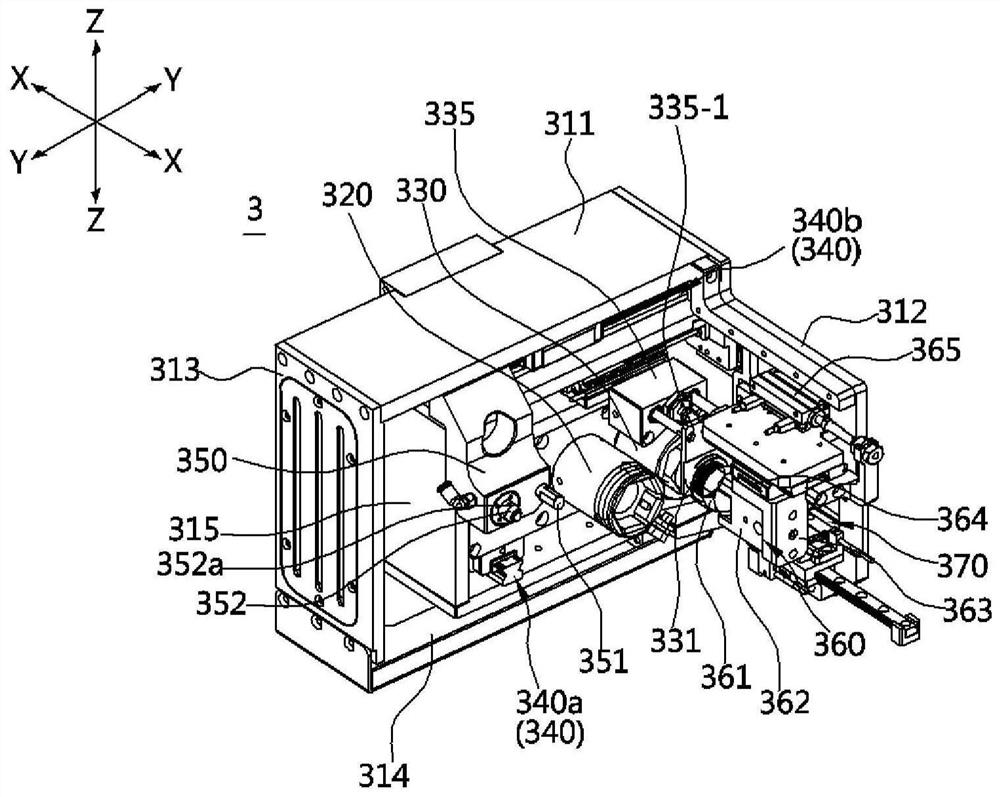

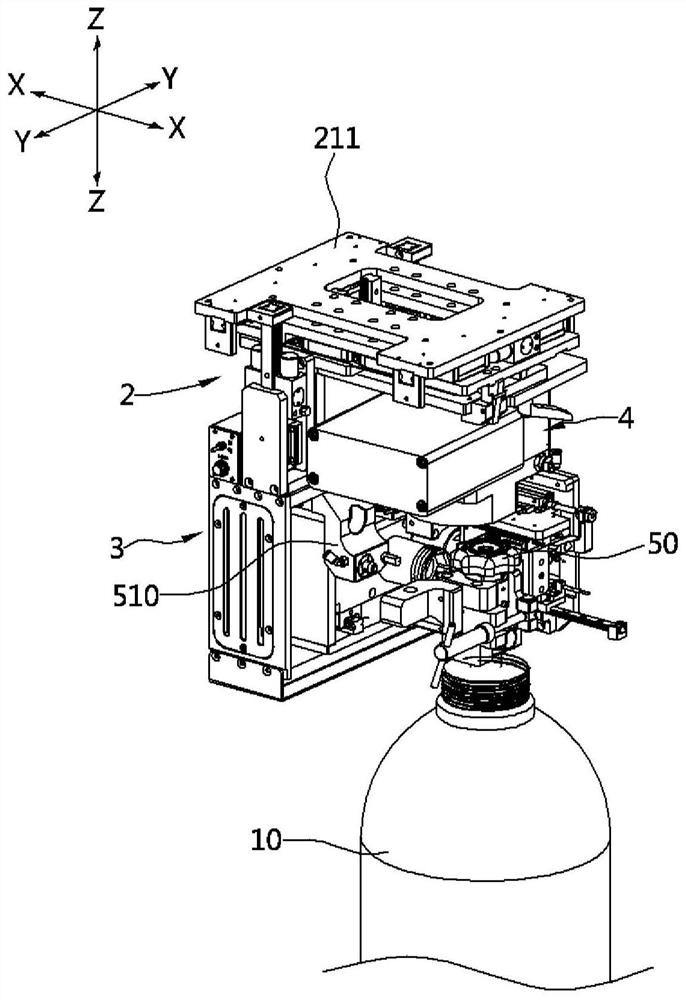

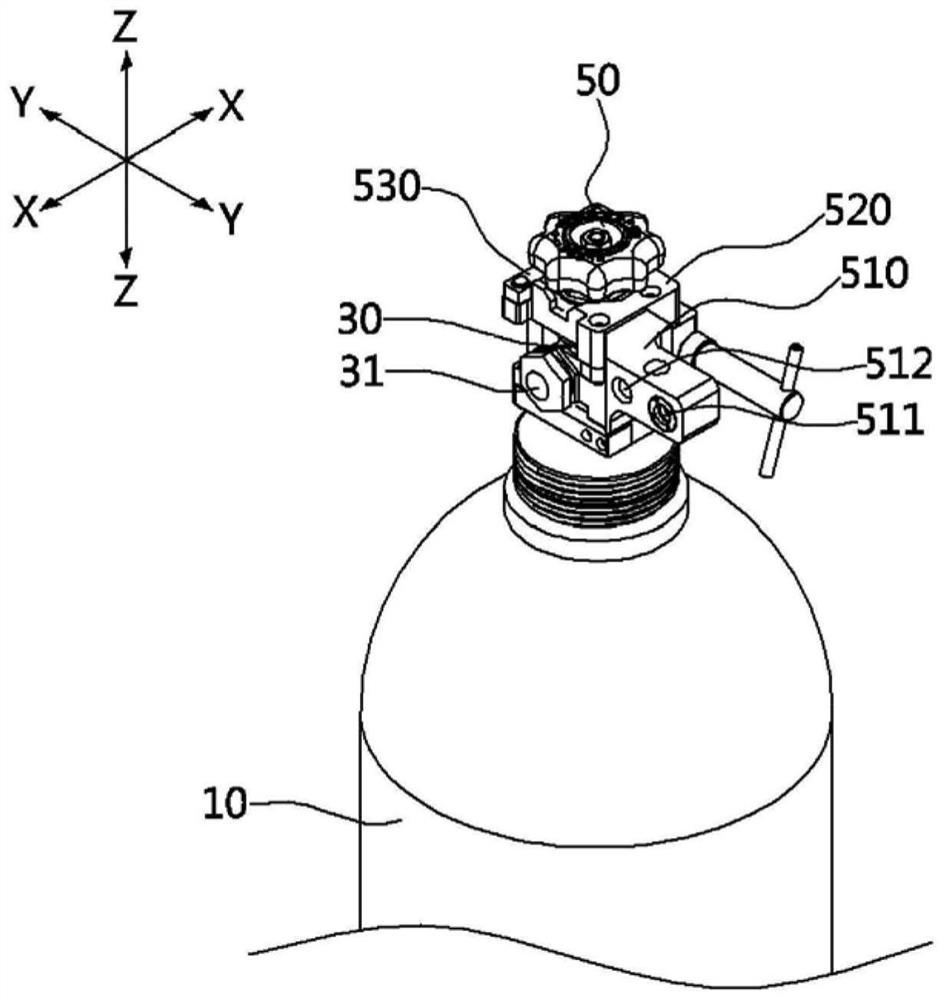

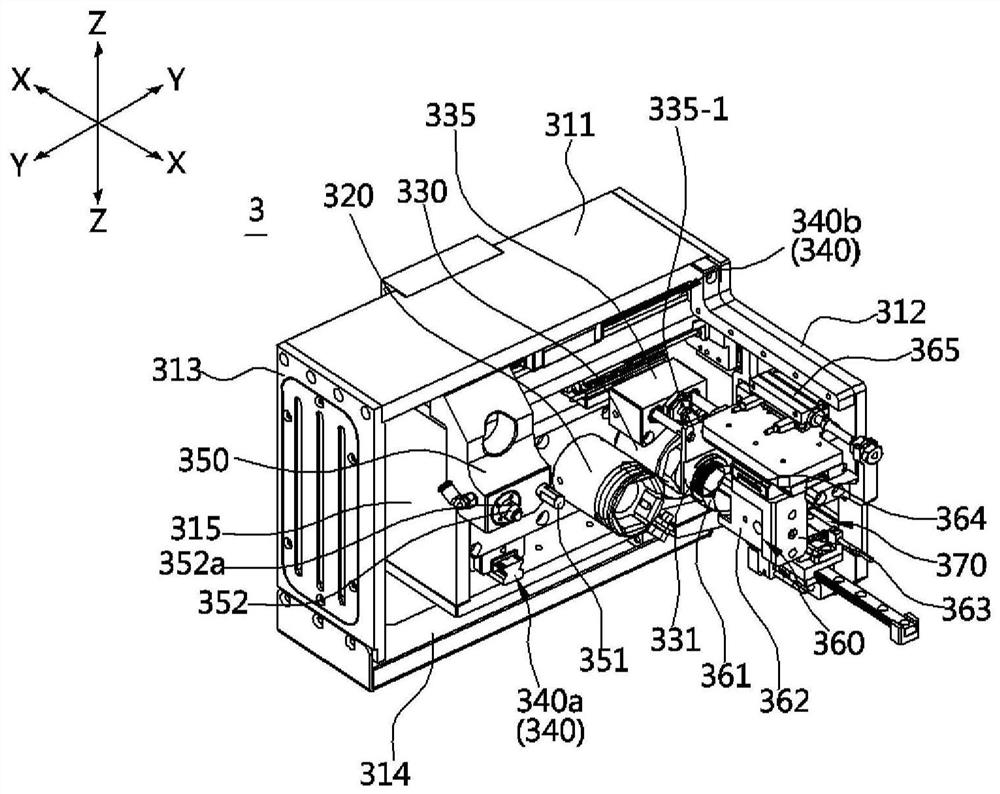

Gas supply device equipped with connector transfer unit and connector coupling method therefor

ActiveCN113685729AIncreased durabilityFriction minimizationVessel mounting detailsVessel geometry/arrangement/sizeTransfer mechanismScrew thread

The purpose of the present invention is to provide: a gas supply device provided with a connector transfer unit capable of improving durability of components by minimizing wear of a screw thread when a valve connector and a connecting piping connector are coupled; and a connector coupling method for the gas supply device. In order to implement the same, the gas supply device comprises: a connector fastening part including a connection piping connector, one side and the other side of which are respectively connected to a valve connector and a gas demand point provided in a container, wherein a connection piping connector housing surrounds an outer side of the connection piping connector and is configured to rotate together with the connection piping connector; a first transfer mechanism for transferring the entire connector fastening part in the direction of the valve connector; and a connector transfer unit for transferring the connection piping connector in the direction of the valve connector.

Owner:KC

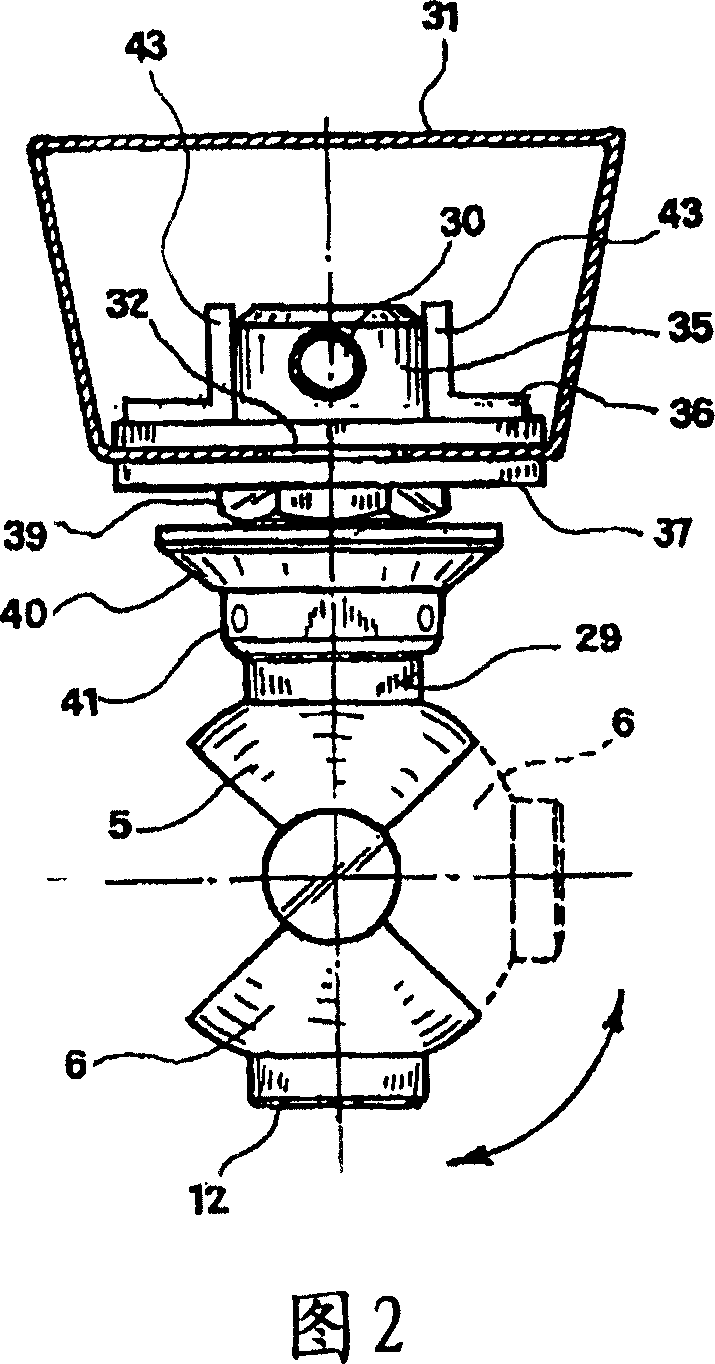

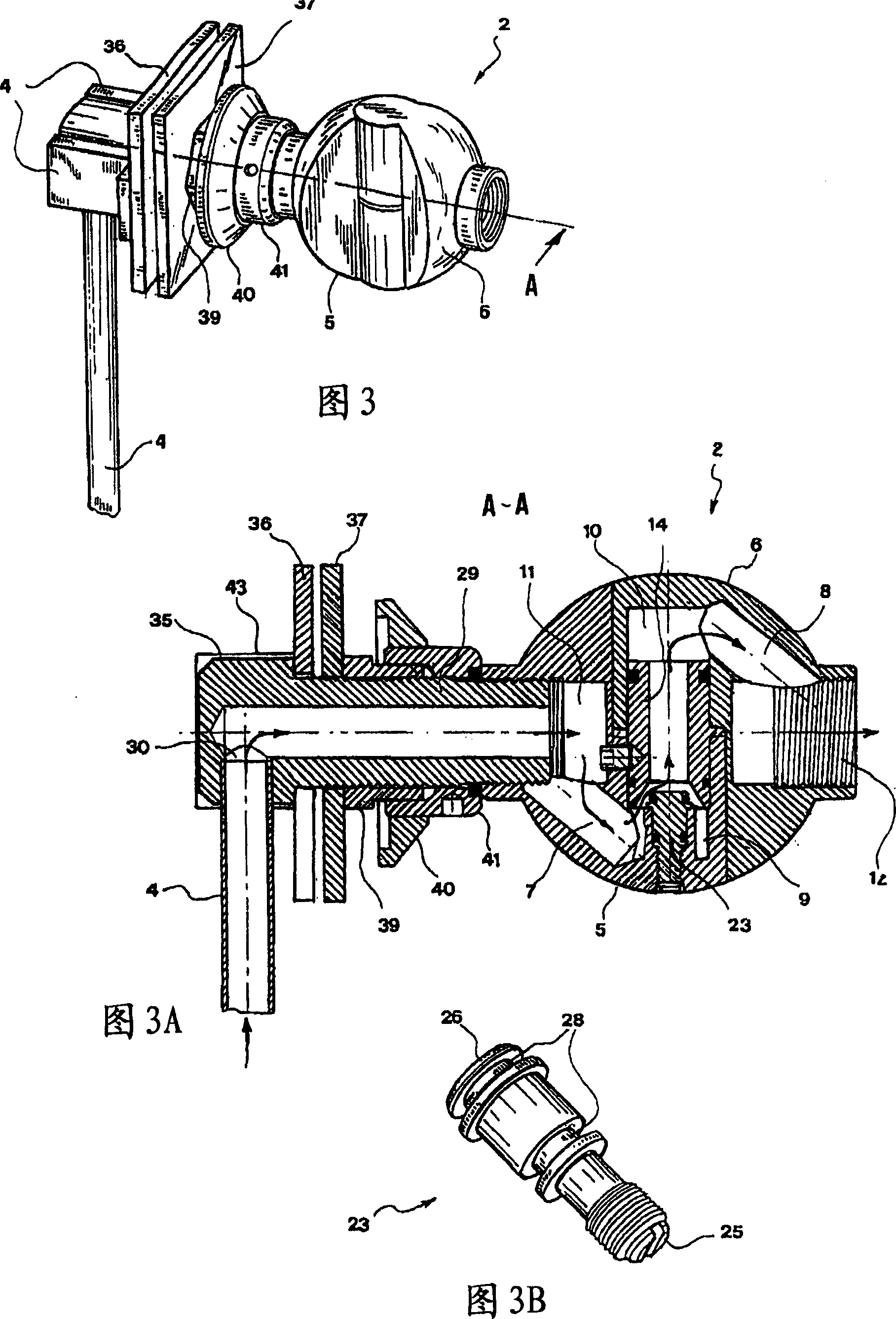

Hydraulic joint articulated device and use thereof with a heat radiator

A hydraulic joint articulated device (1) effectively supports a radiator allowing a remarkable freedom of motion and has a pair of articulated connectors (2), each comprising: hinge members (5, 6) apt to be assembled and comprising a respective hydraulic channel (7, 8), in which there is obtained a pin seat (9, 10) with a tubular pin (14) having a respective hydraulic channel (21) forming a hydraulic joint extending between the respective connector seats (11, 12); and a valve seat (22) at one end of said tubular pin (14), and a respective shutter member (23) located in an opening (24) obtained in one (5) of said hinge members (5, 6), further comprising, at each articulated connector (2), a tubular duct (29) extending from the respective connector seat (11) to a mouthpiece section (30) apt to receive a waterworks piping (4), extending inside a masonry.

Owner:阿莱亚德罗·博齐 +2

Apparatus and method for in-situ electrosleeving and in-situ electropolishing internal walls of metallic conduits

ActiveUS11280016B2Reduce deposition thicknessImprove stabilitySealing devicesCurrent conducting devicesStraight tubeMetallic materials

An apparatus and system for in-situ electropolishing and / or for in-situ electroforming a structural or functional reinforcement layer such as a sleeve of a selected metallic material on the internal surfaces of metallic tubular conduits are described. The apparatus and system can be employed on straight tubes, tube joints to different diameter tubes or face plates, tube elbows and other complex shapes encountered in piping systems. The apparatus includes components which can be independently manipulated and assembled on or near a degraded site and, after secured in place, form an electrolytic cell within the workpiece. The apparatus contains counter-electrodes which can be moved relative to the workpiece surface during the electroplating and / or electropolishing operation to provide flexibility in selecting and employing electropolishing process parameters and electroplating process parameters to design and optimize the surface roughness as well as the size, shape and properties of the electrodeposited reinforcing layer(s).

Owner:INTEGRAN TECH

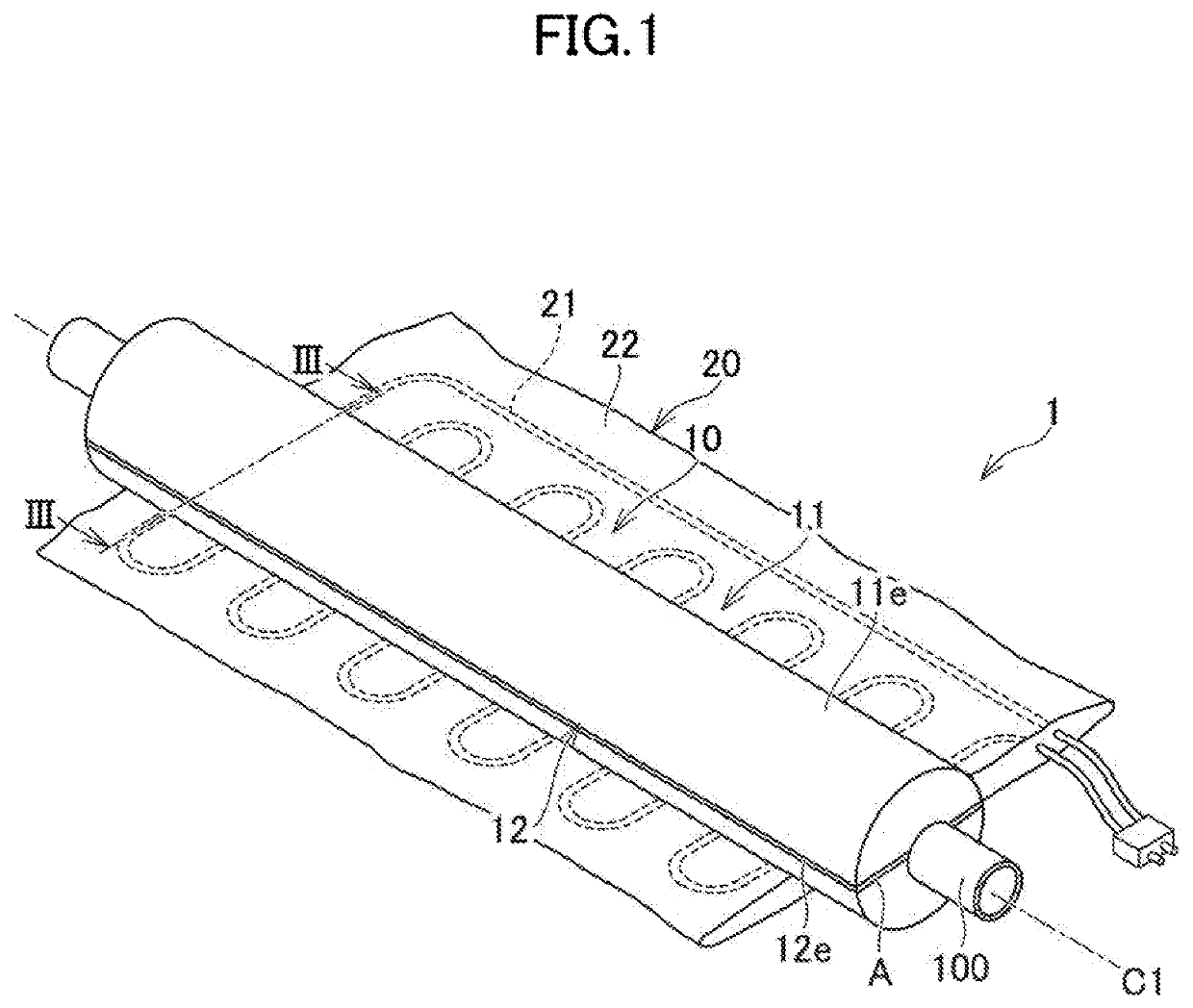

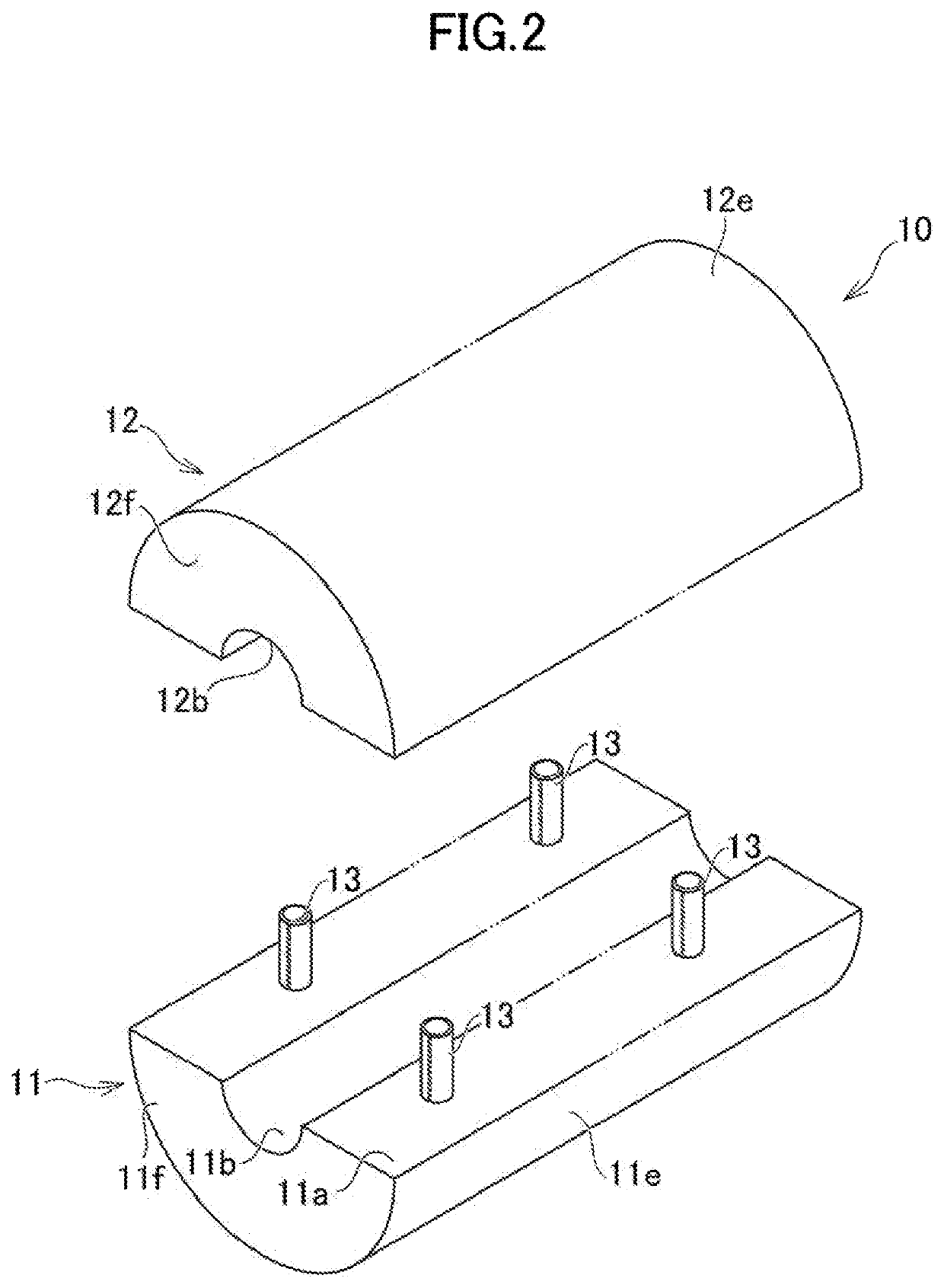

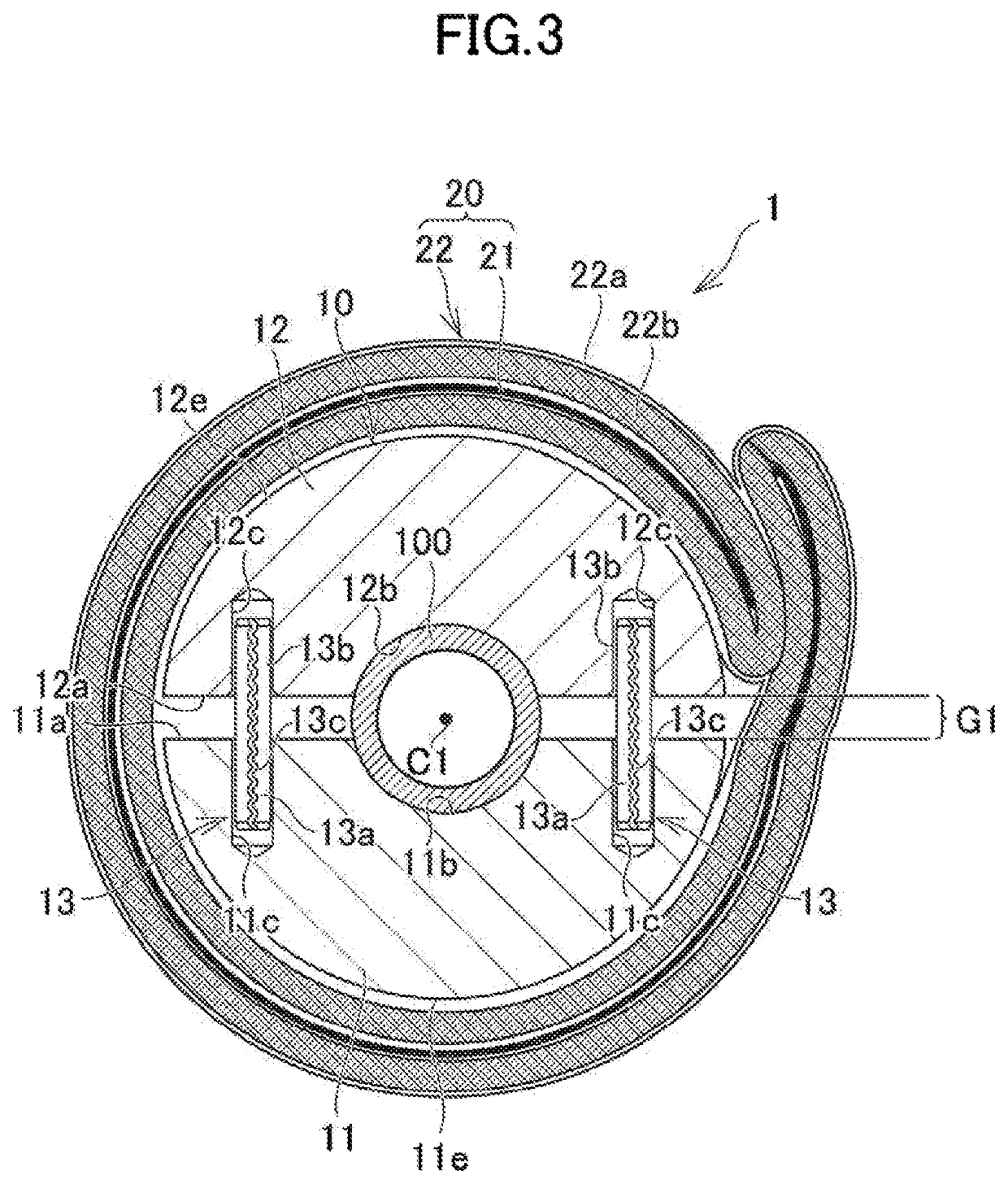

Thermally conductive cover for piping system, heating device for piping system, manufacturing method and attachment method for thermally conductive cover, and manufacturing method and attachment method for heating device

A thermally conductive cover improves workability of attachment and detachment. The thermally conductive cover includes a first thermal conductor on which a coupling hole is formed and a second thermal conductor on which a coupling hole is formed. The thermally conductive cover further includes a coupling member having a first inserted part to be inserted into the coupling hole and a second inserted part to be inserted into the coupling hole. At least one of the inserted parts is elastically deformable in a direction perpendicular to an inserting direction of the coupling member.

Owner:NICHIAS CORP

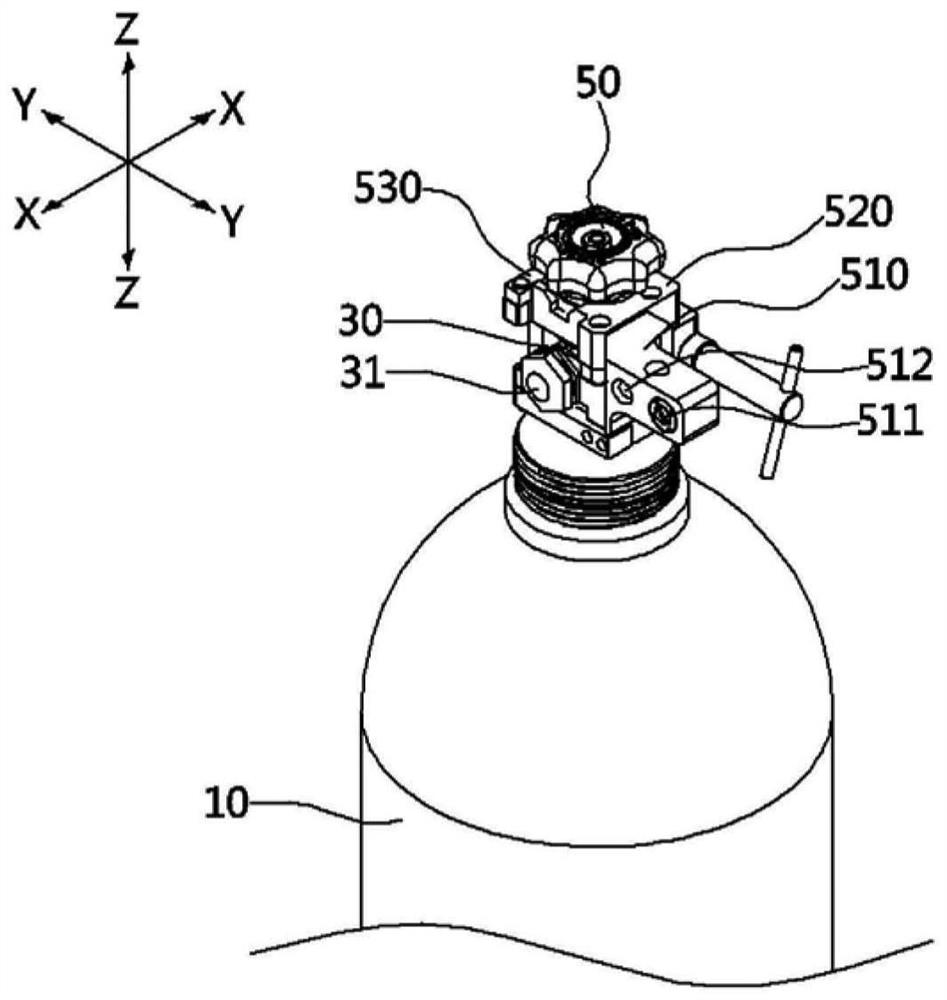

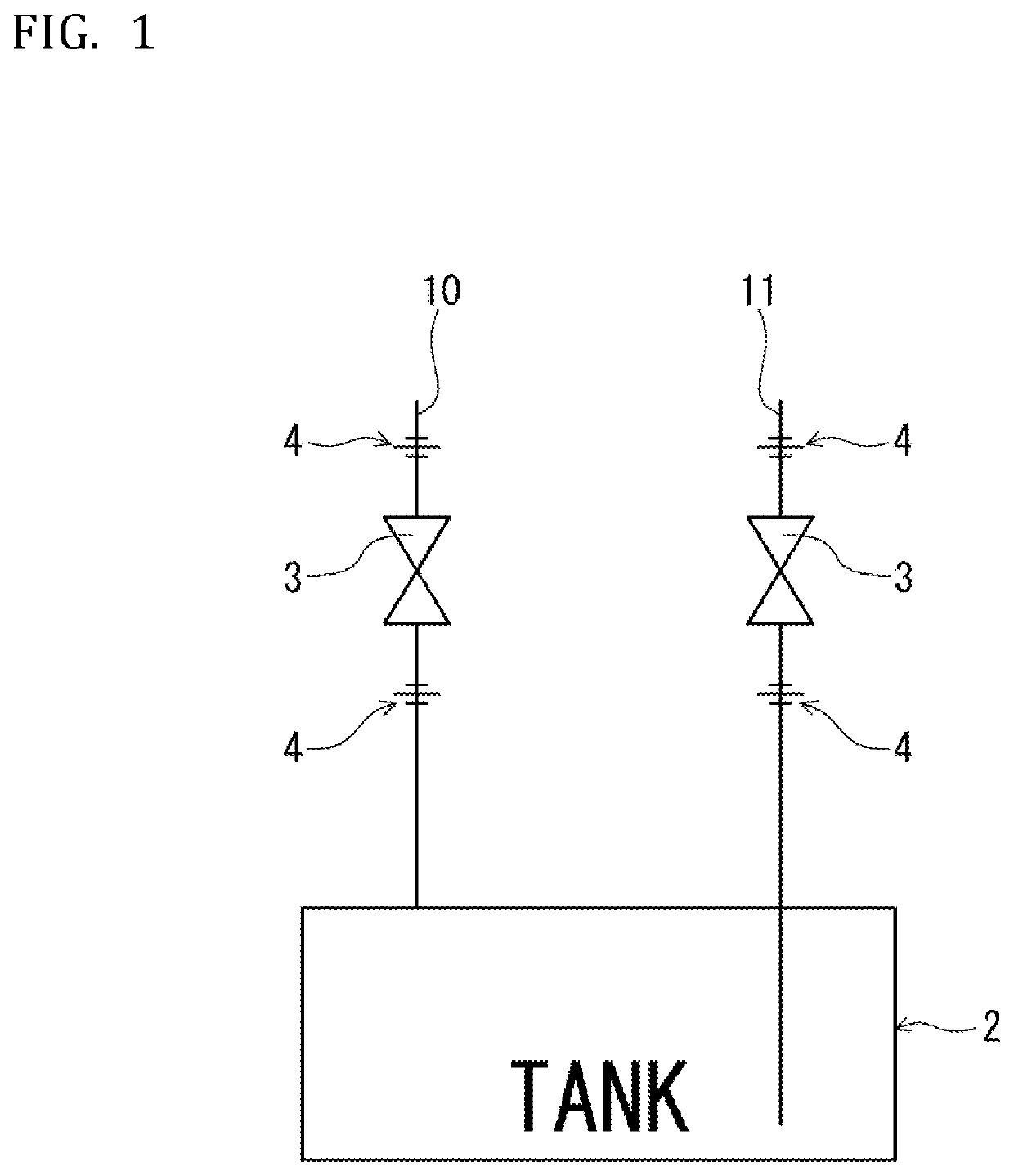

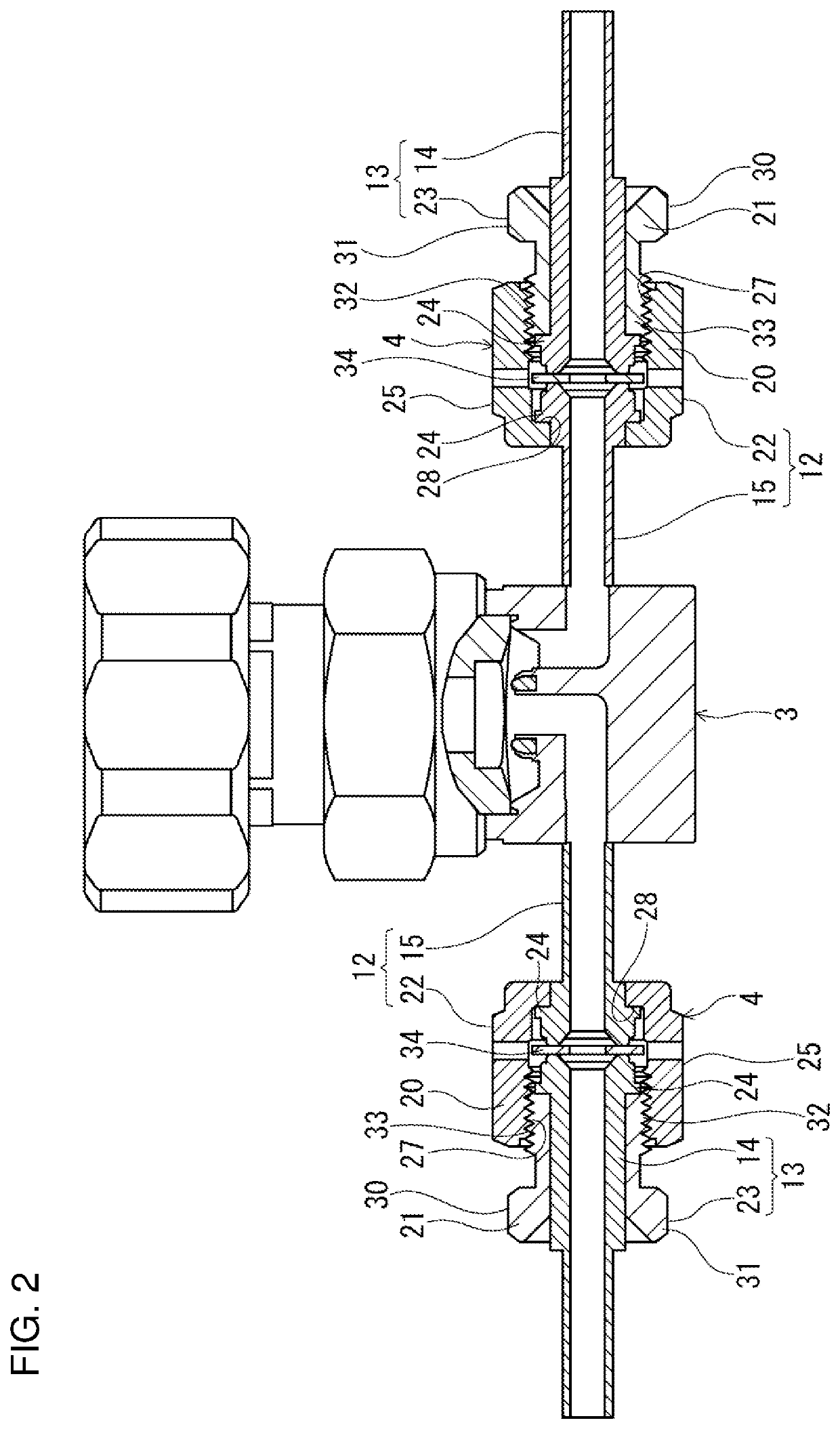

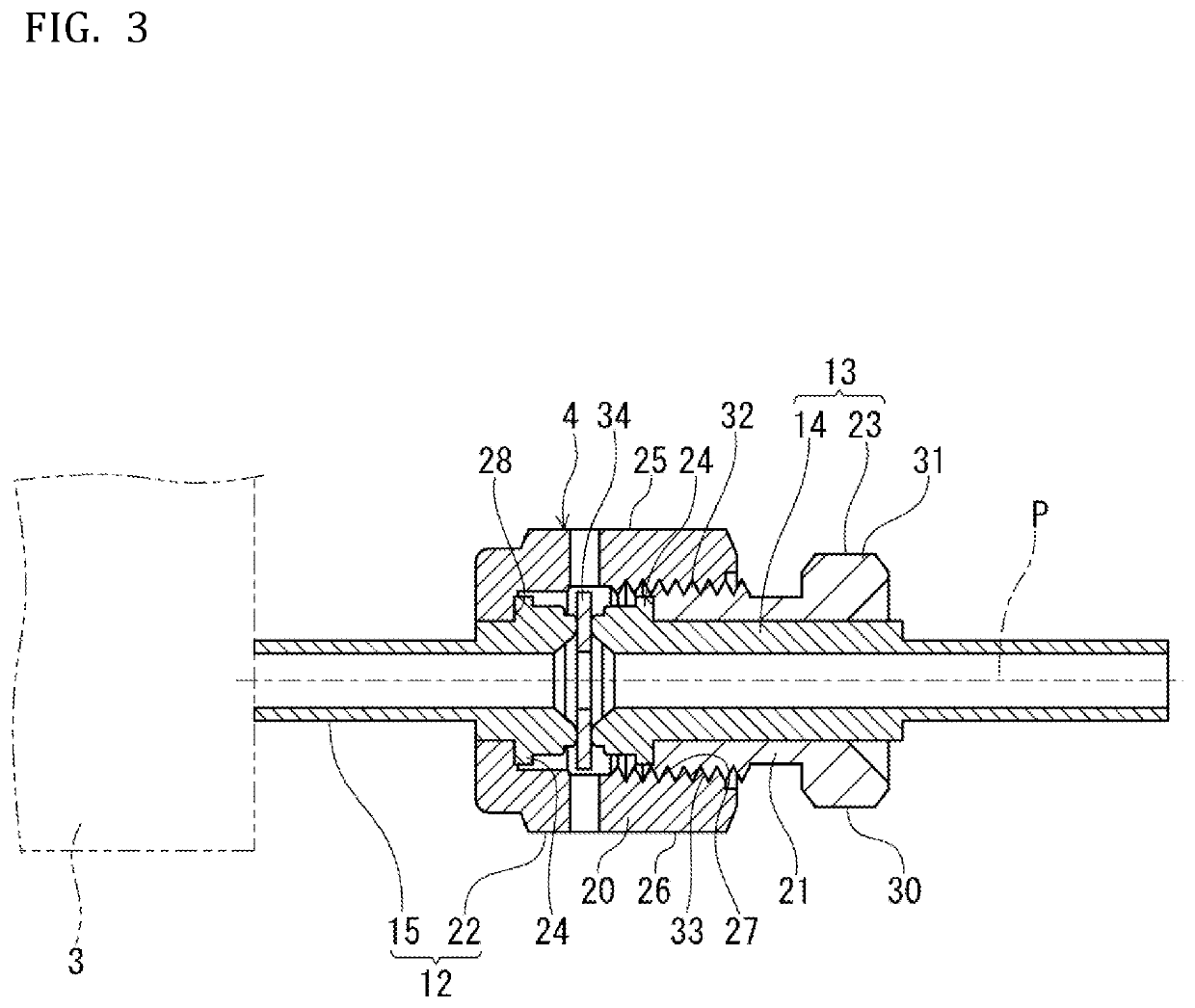

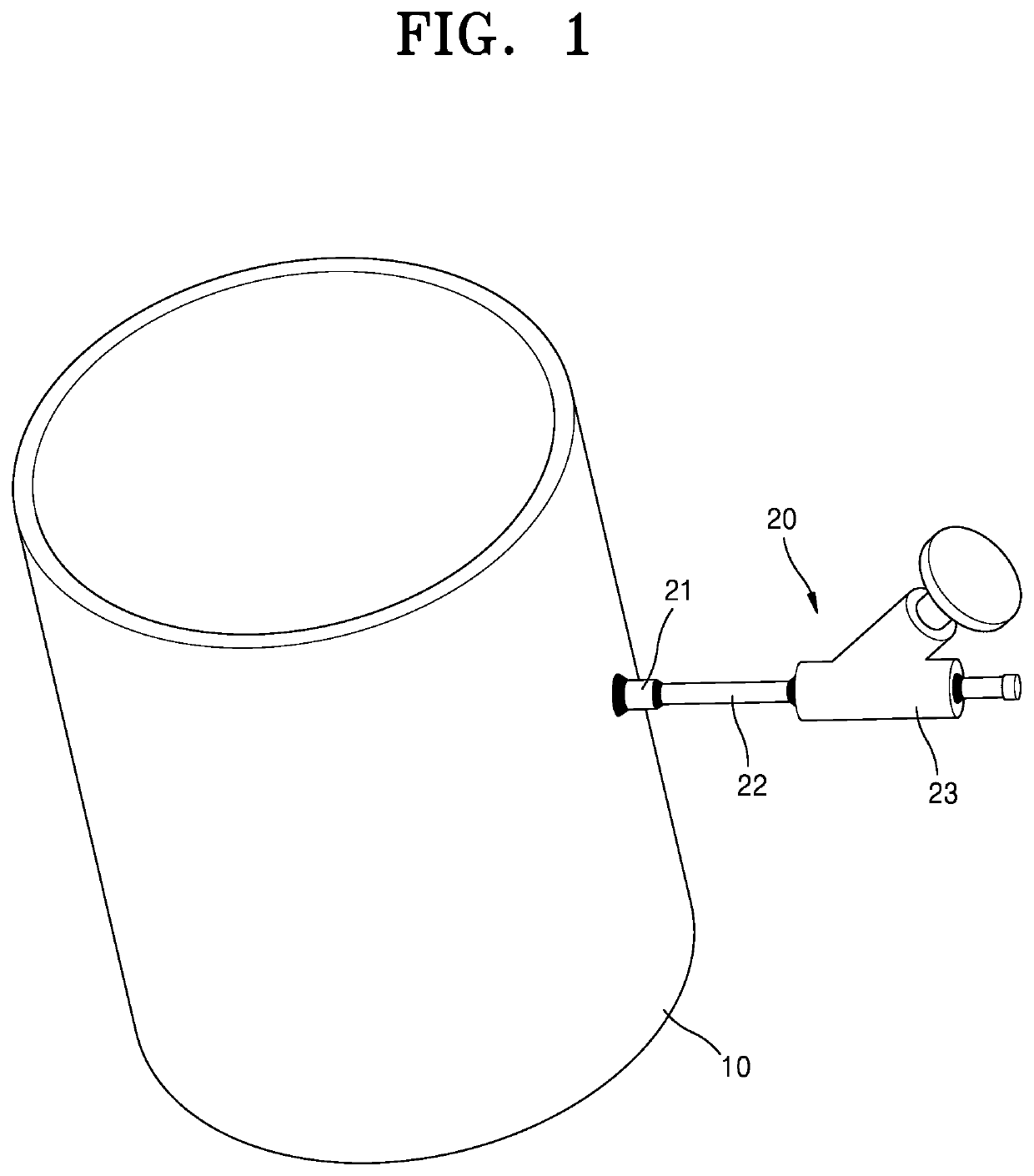

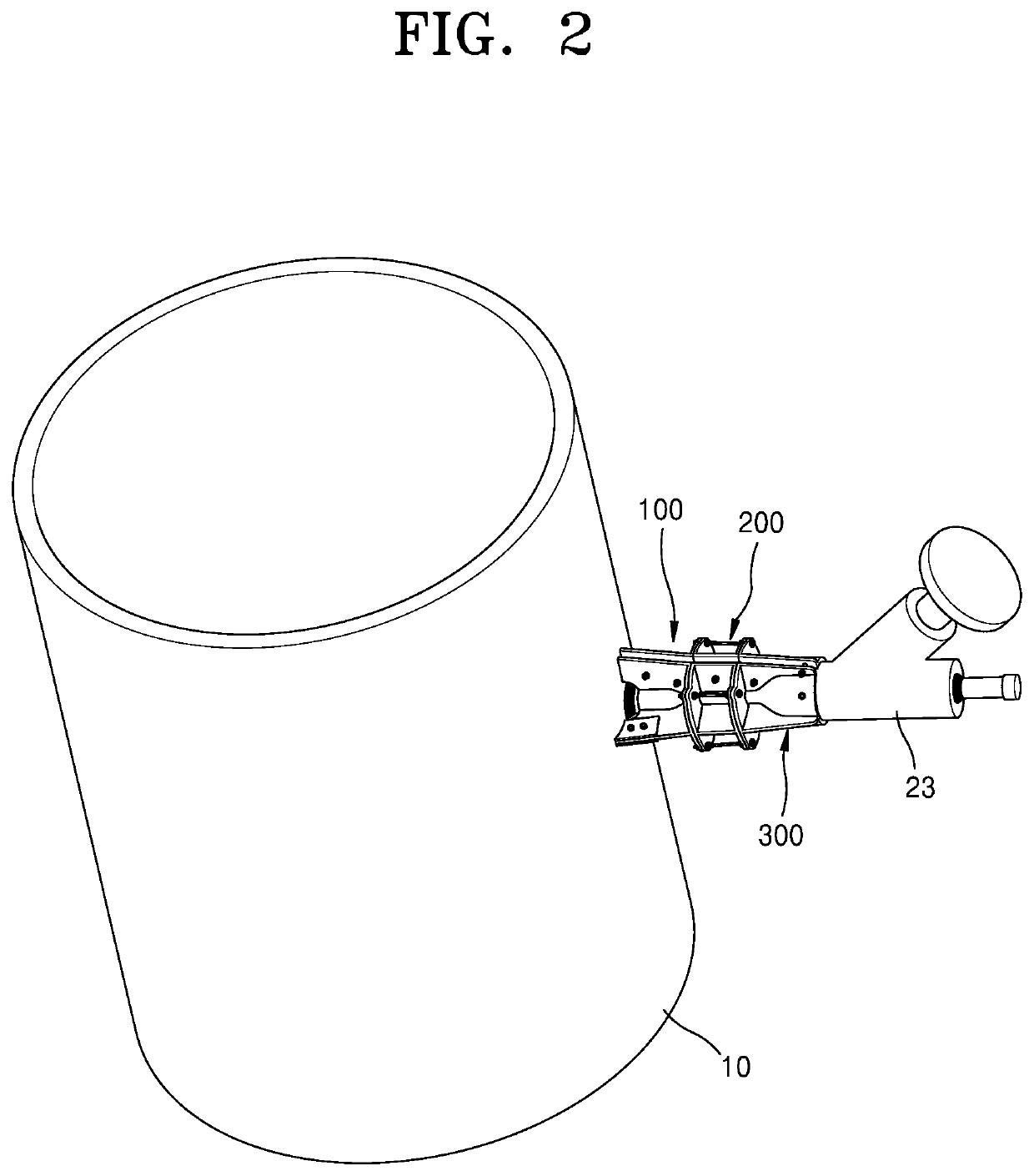

Lock device for pipe coupling and valve coupling part

ActiveUS20210071786A1Simple processPrevent mutual rotationValve arrangementsJoints with sealing surfacesClassical mechanicsScrew thread

A lock device for a coupling part of a piping or valve of a raw-material container or the like, capable of preventing looseness and erroneous operation of a coupling, and having favorable stability because the device is fixed as a force is applied to a direction of additionally fastening the coupling. The lock device is provided for achieving prevention of looseness of a coupling part (4) formed of a screwed member (20) and a screwing member (21) side, and includes a clamp member (42) for additional fastening attached to the screwed member side, a clamp member (41) for positioning and fixing attached to the screwing member side, and a screw member (43) for fastening the clamp members. The clamp members are fastened with the screw member (43), thereby being fixed to the coupling part while a force is applied to a direction of additionally fastening the screwing member side.

Owner:KITZ SCT

Piping joint and resin tube assembly

A piping joint connects a resin tube to a connection pipe having a protrusion formed on an outer peripheral surface of a distal end portion of the connection pipe. The piping joint includes a housing press-fitted into the resin tube and an elastically extendable and contractible seal member into which the connection pipe is inserted such that sealing is performed between the connection pipe and the seal member. The housing has a first housing portion positioned in one end portion and having an outer peripheral surface side press-fitted into the resin tube and a second housing portion positioned in the other end portion. The seal member has a first seal portion inserted on an inner peripheral surface side of the second housing portion.

Owner:SANOH IND CO LTD

Piping joint structure

There is provided a pipe part joint structure, including: a first member formed with a first hole; a second member including a pipe part coupled to the first member by being inserted into the first hole; and a third member coupled through the joint part on the second component. The second member has an inclined surface formed at a front end portion of the piping portion. When the inclined surface is pressed by the first member when the piping portion of the second member is inserted into the first hole of the first member in a state where the second member and the third member are coupled, the joint portion , a force is applied from the second member in a direction opposite to the direction in which the second member separates from the third member.

Owner:TOYOTA JIDOSHA KK +1

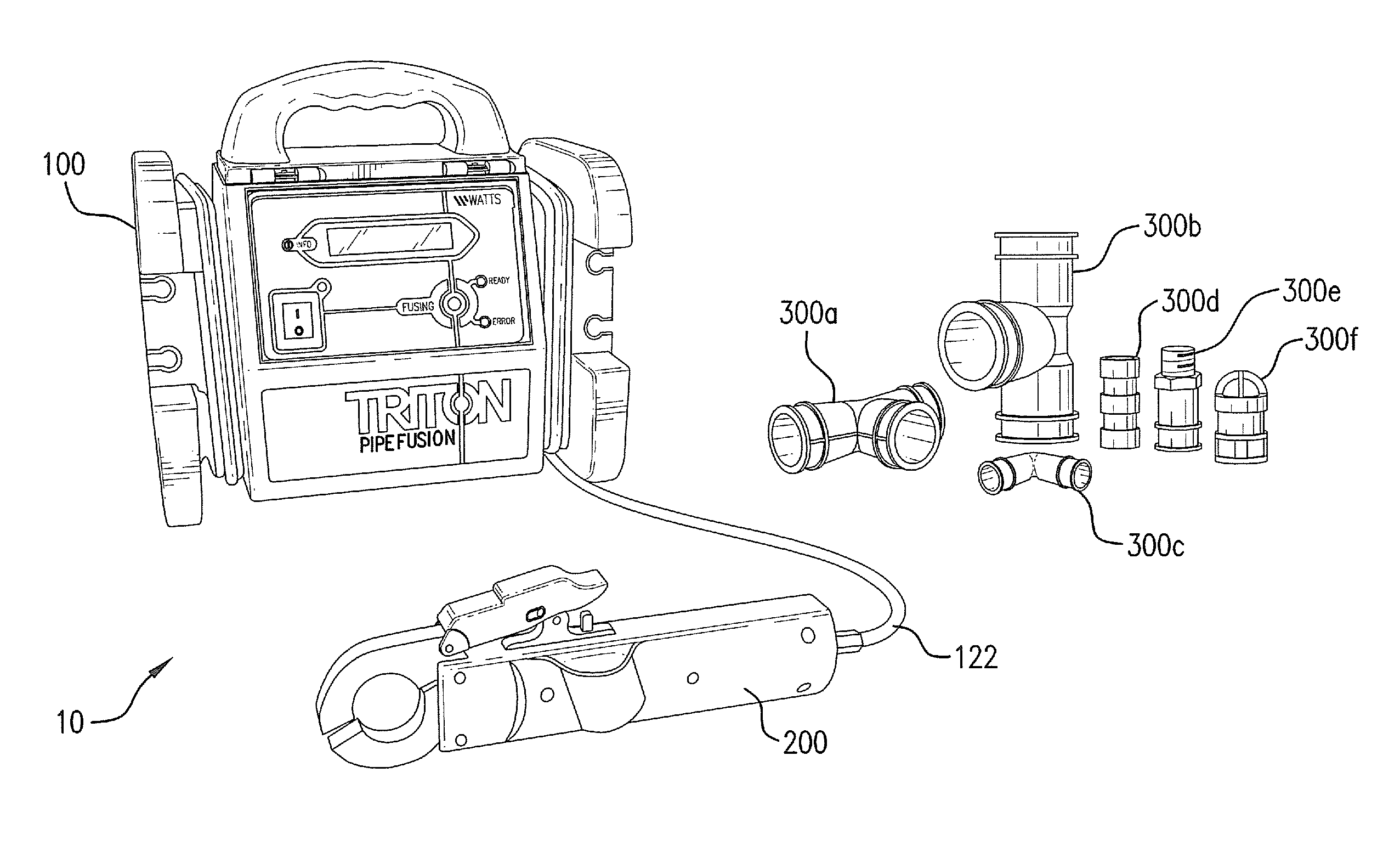

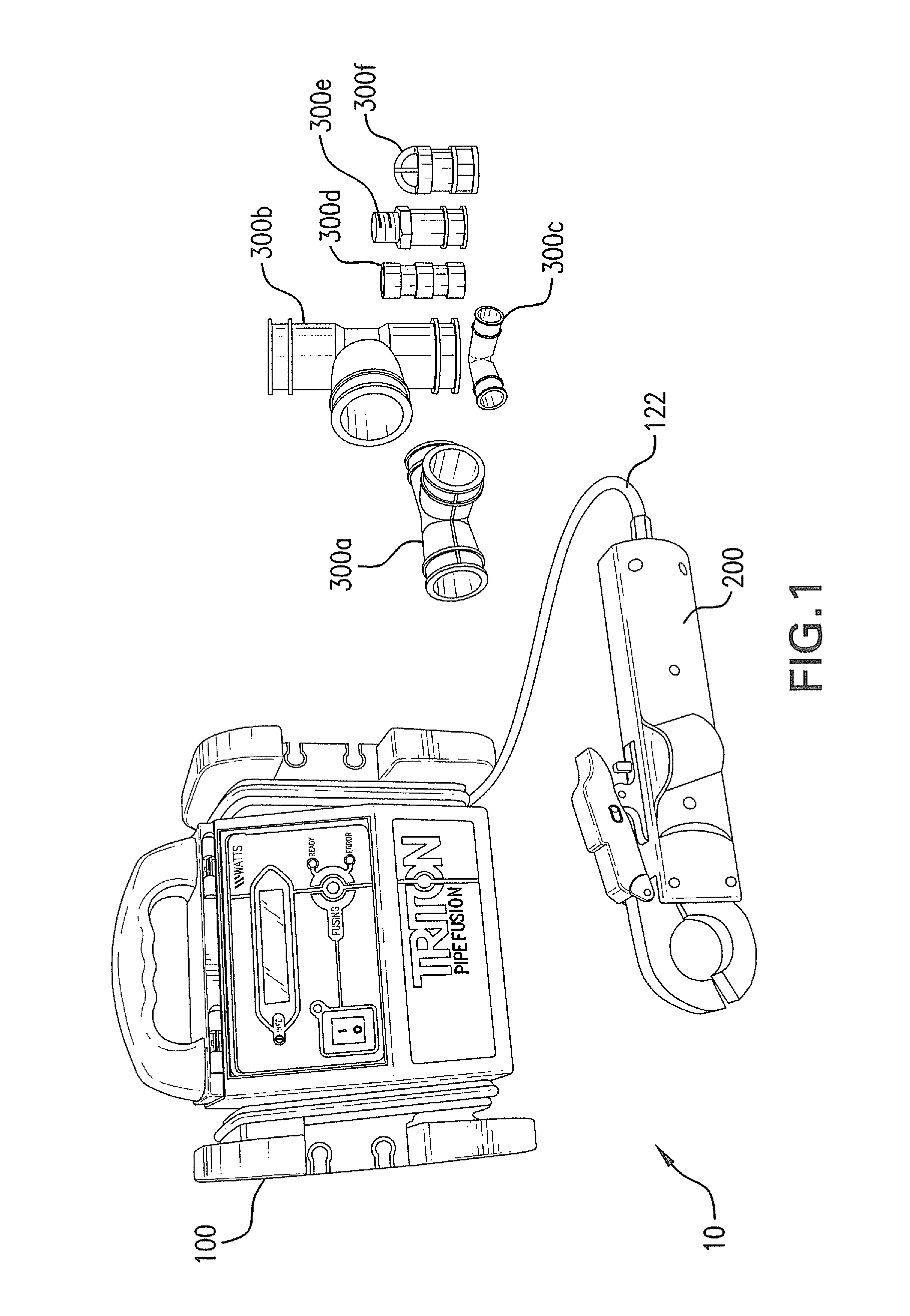

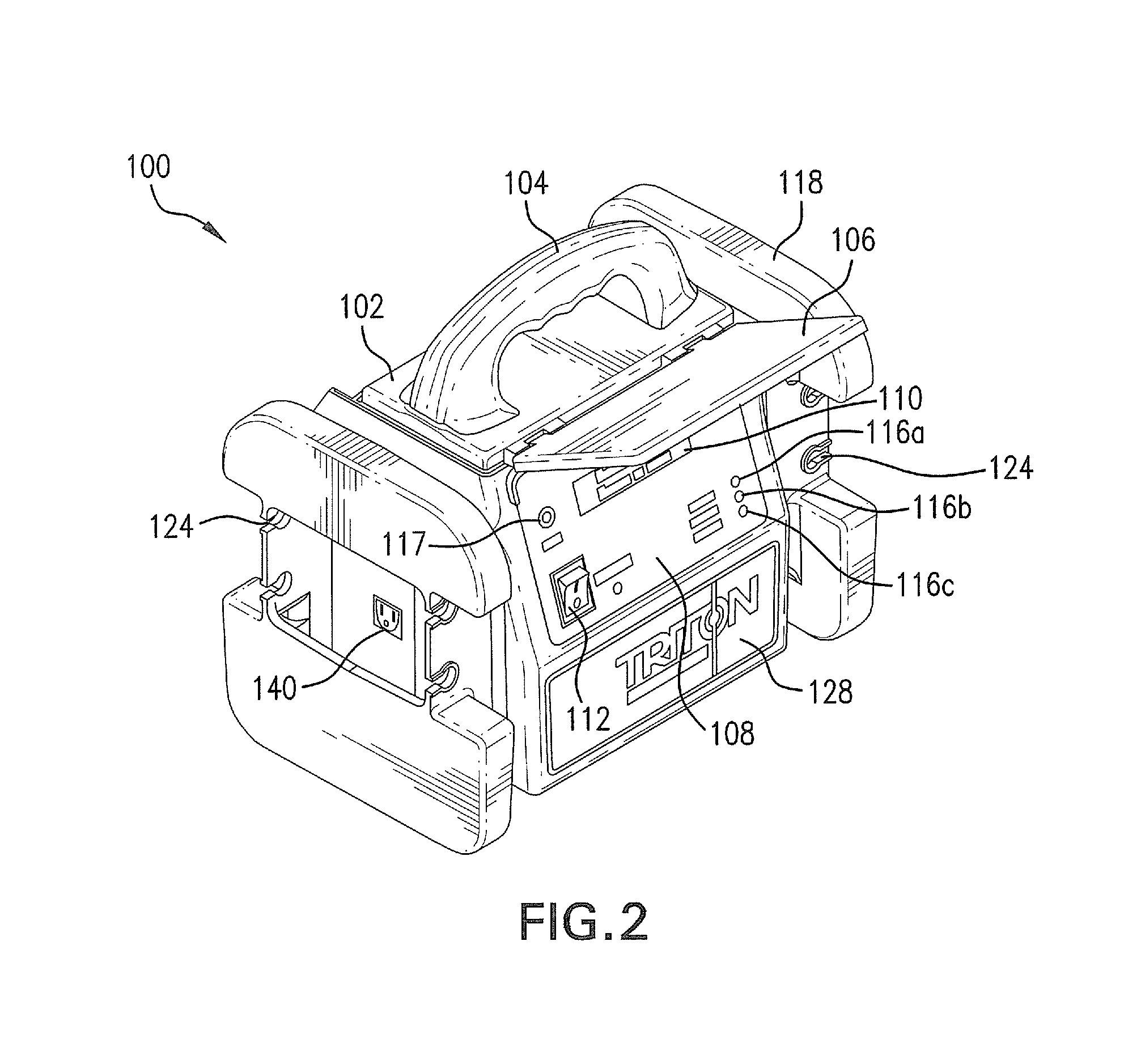

Portable system for bonding pipes

ActiveUS9296153B2Inhibition of activationPipe connection arrangementsTubular articlesSusceptorElectrical conductor

A kit for fusing piping includes a plurality of couplings, each coupling having a susceptor layer concentric with a weld zone. A control unit provides a current to a wand with a handle for gripping by a user. The handle has opposing jaws mounted on the distal end, each jaw including an arcuate conductor such that the arcuate conductors form a circular inner diameter when the jaws make contact. A lever system couples to the distal end for opening and closing the jaws. The lever system includes a spring for selectively biasing the lever system in a latched position with jaws closed and an open position with the jaws open. Each coupling is sized such that the jaws will only close about the weld zone. The arcuate conductors create a fuse zone about the susceptor layer and the spring is outside the fuse zone.

Owner:WATTS REGULATOR

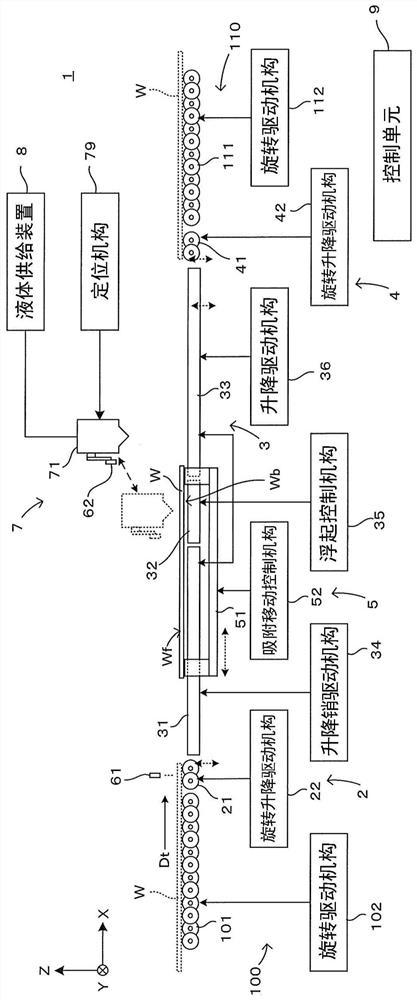

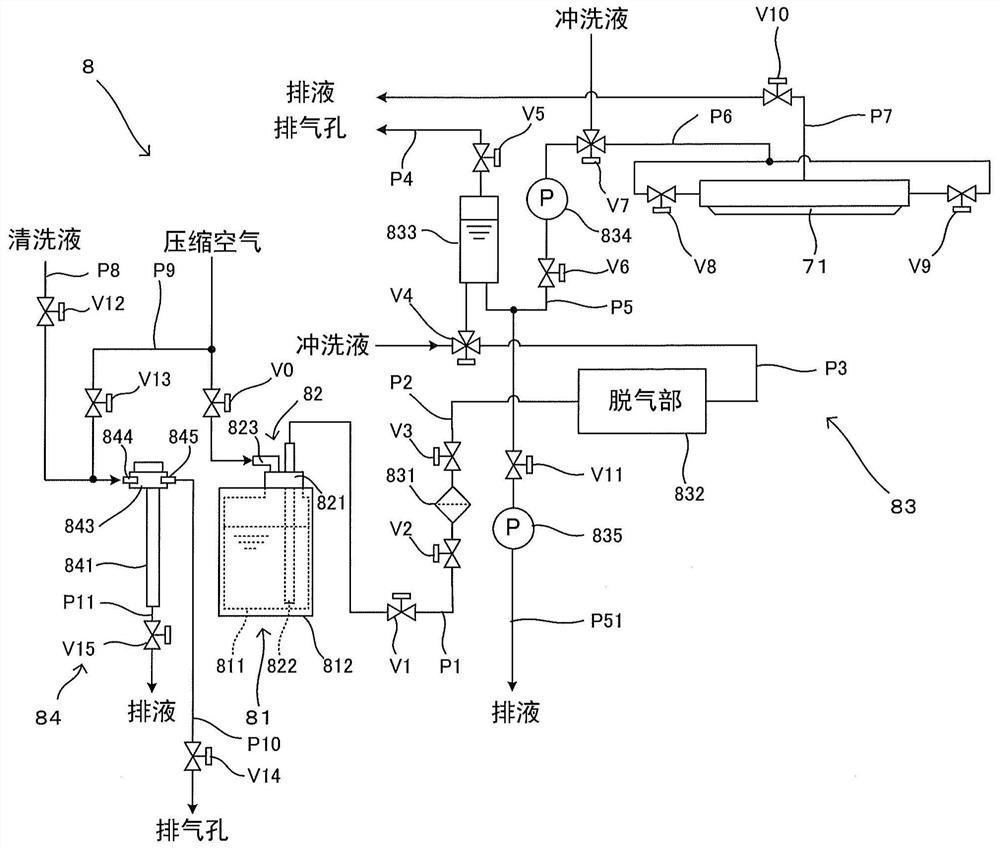

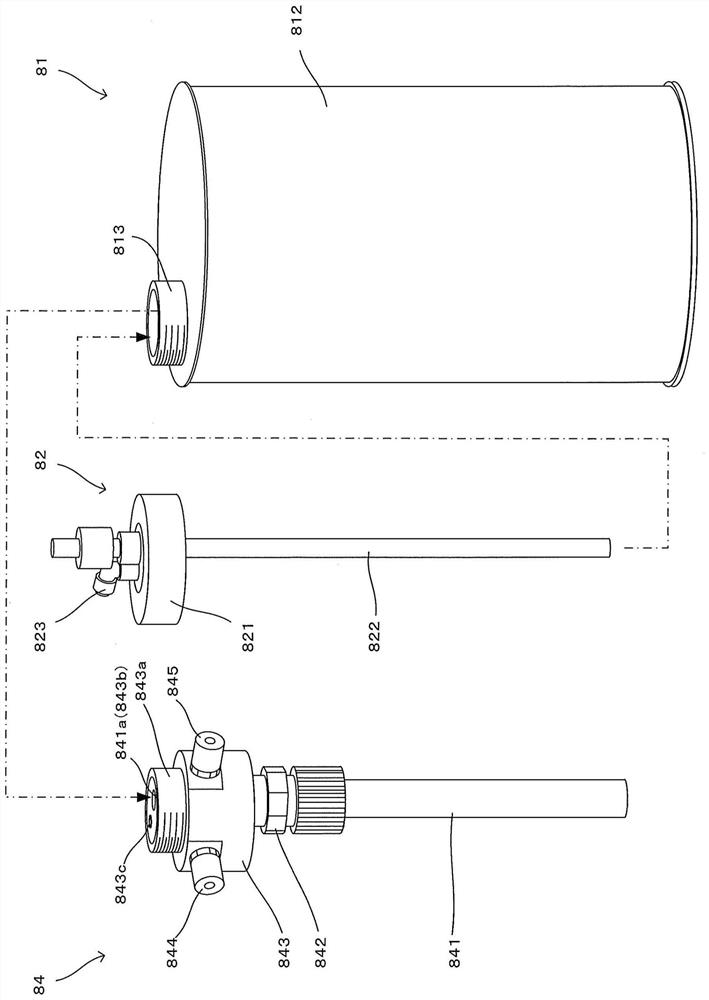

Cleaning appliance, cleaning method, and liquid supply device

ActiveCN109482582BEasy to cleanLiquid surface applicatorsHollow article cleaningInterior spaceCleaning methods

The present invention relates to a cleaning tool, a cleaning method, and a liquid supply device for better cleaning a coupling with a cleaning liquid in a short time. The piping of the cover part, by inserting the piping into the interior of the liquid storage body, the liquid stored in the interior can be taken out through the piping, and the cleaning tool has: a container with an opening into which the piping can be inserted; An internal space for accommodating the piping via the opening, and a holding portion installed near the opening of the container for holding the coupler detached from the liquid storage body; The space communicates with the interior of the piping to clean the piping, and the interstitial space is formed between the inner surface of the container and the outer surface of the piping in which the piping is housed in the internal space. Space.

Owner:DAINIPPON SCREEN MTG CO LTD

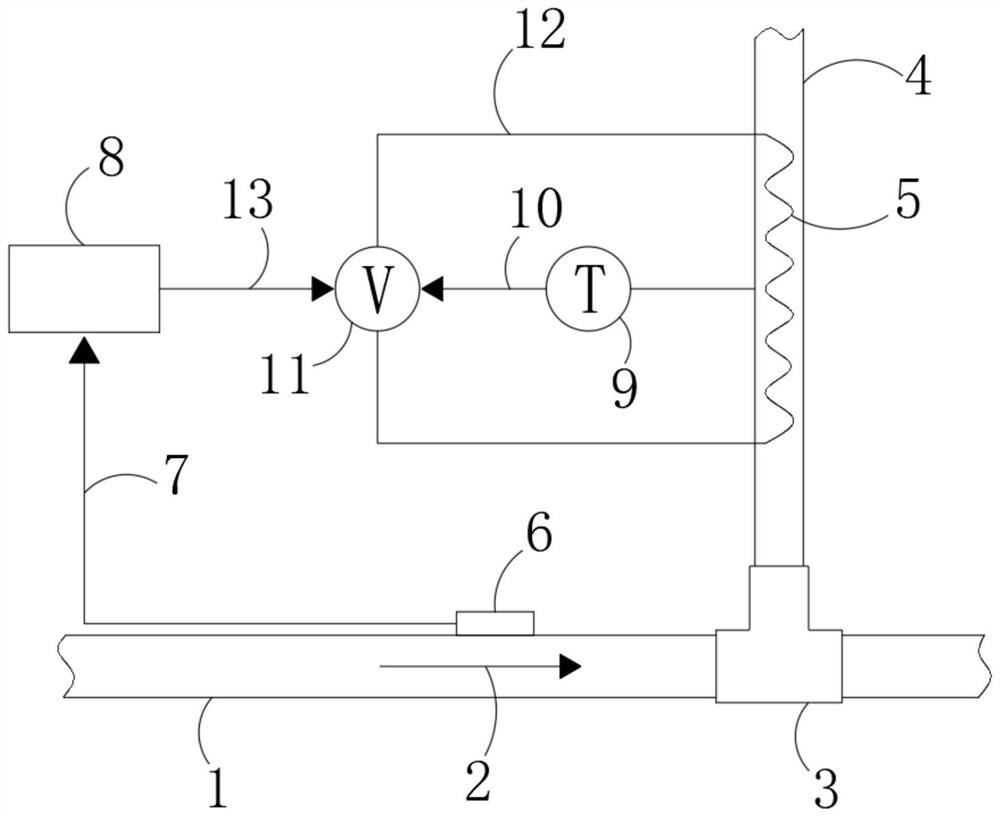

A Device for Avoiding Acoustic Resonance of Piping System

ActiveCN110925514BAvoid acoustic resonanceStress reliefPipe heating/coolingPipe elementsElectrical connectionEngineering

The invention discloses a device for avoiding acoustic resonance of a piping system, which includes a vibration sensor, acquisition and processing control equipment, and heating equipment. The vibration sensor is fixedly installed on the surface of the main pipeline, the heating equipment is installed on the branch pipeline, and the vibration sensor The sensor is electrically connected to the collection and processing control equipment, and the collection and processing control equipment is electrically connected to the heating equipment. In the present invention, by configuring the vibration sensor on the main pipeline, the vibration sensor monitors the vibration signal of the amplified vibration after the fluid passes through the tee of the main pipeline due to the coupling of the vortex shedding frequency and the acoustic frequency of the branch pipe, and controls the change of the fluid temperature of the branch pipe through the heat removal equipment Acoustic frequency, so as to avoid the occurrence of acoustic resonance; starting from the mechanism of acoustic resonance coupling, the device adopts changing temperature to decouple the frequency of vortex shedding in the main pipeline from the acoustic frequency of the branch pipe, eliminating the excessive stress or fatigue of the pipeline caused by acoustic resonance, and improving the safety of the piping system.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

Conduit welding shrinkage control device

ActiveCN112122866BEnable connectivityEasy to useWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWeld seam

The invention discloses a catheter welding shrinkage control device, which belongs to the technical field of precision manufacturing of aviation welding catheters. It includes a digital control device and a pipe marking device. The digital control device includes a casing positioner, a pipe support and a digital measuring device. A connection plate is provided at one end of the casing positioner. The joints are coaxially connected, and the pipe support is used to support the casing positioner; the digital measuring device is rotatably connected to the casing positioner, and rotating the digital measuring device can drive the casing positioner to slide in the pipe support; The scriber is fixed on the connection plate, and is used to draw a circle of welding seam line at the junction of the conduit and the pipe joint. In the present invention, the digital control device and the pipe marking device are used in conjunction with each other, the welding shrinkage variable is obtained by the digital control device, and transmitted to the pipe marking device, and the position of the weld seam before welding is obtained by the pipe marking device, so that there is no gap Welding requires technical support.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

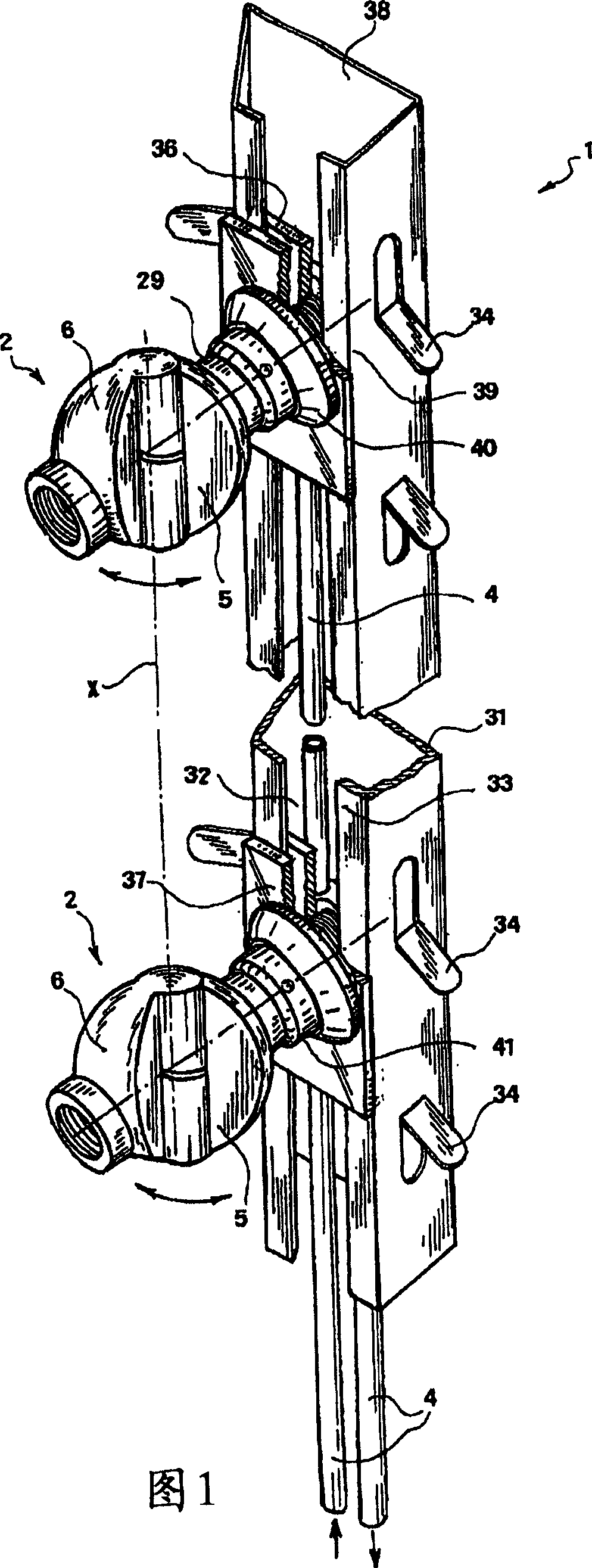

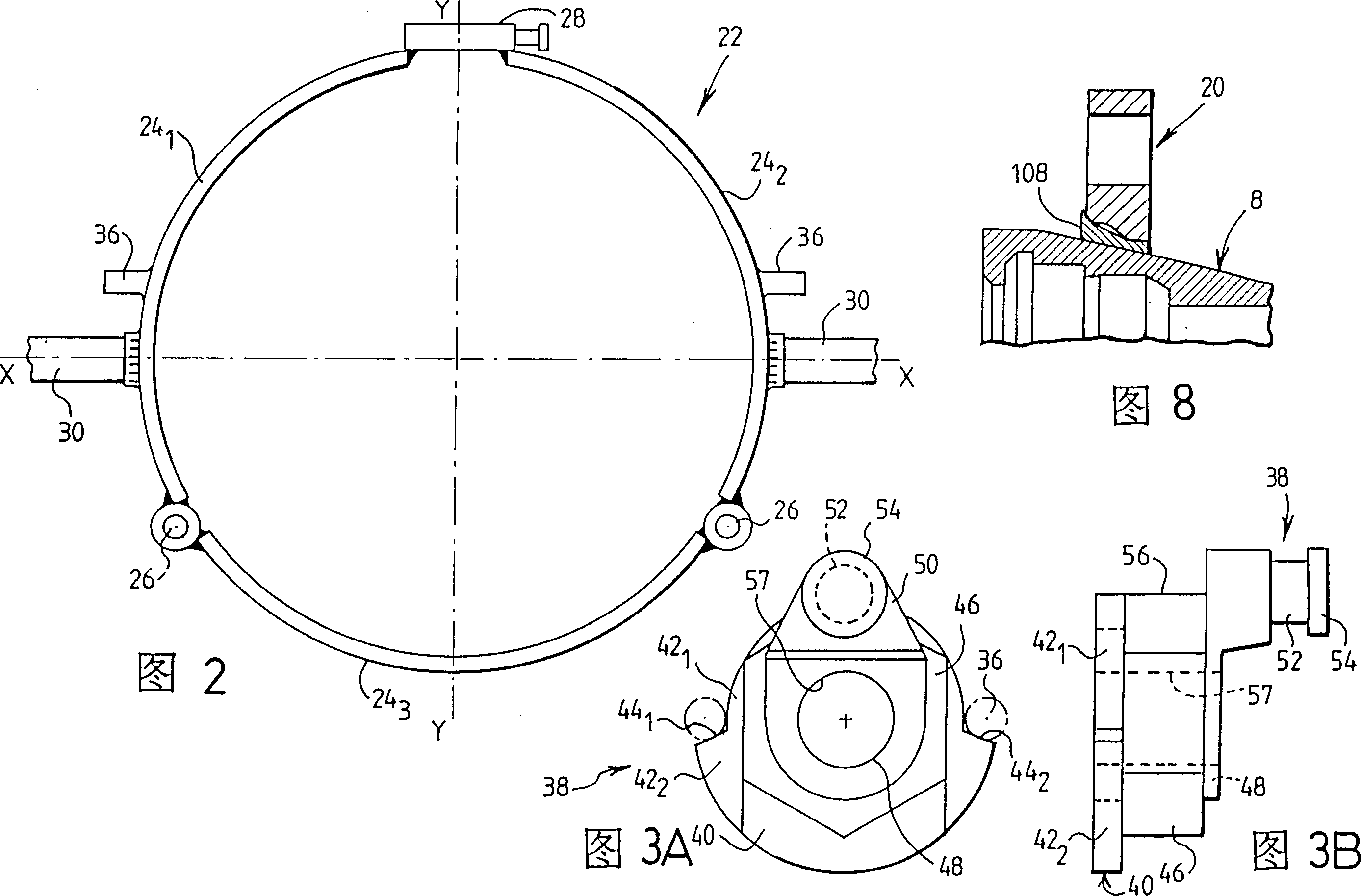

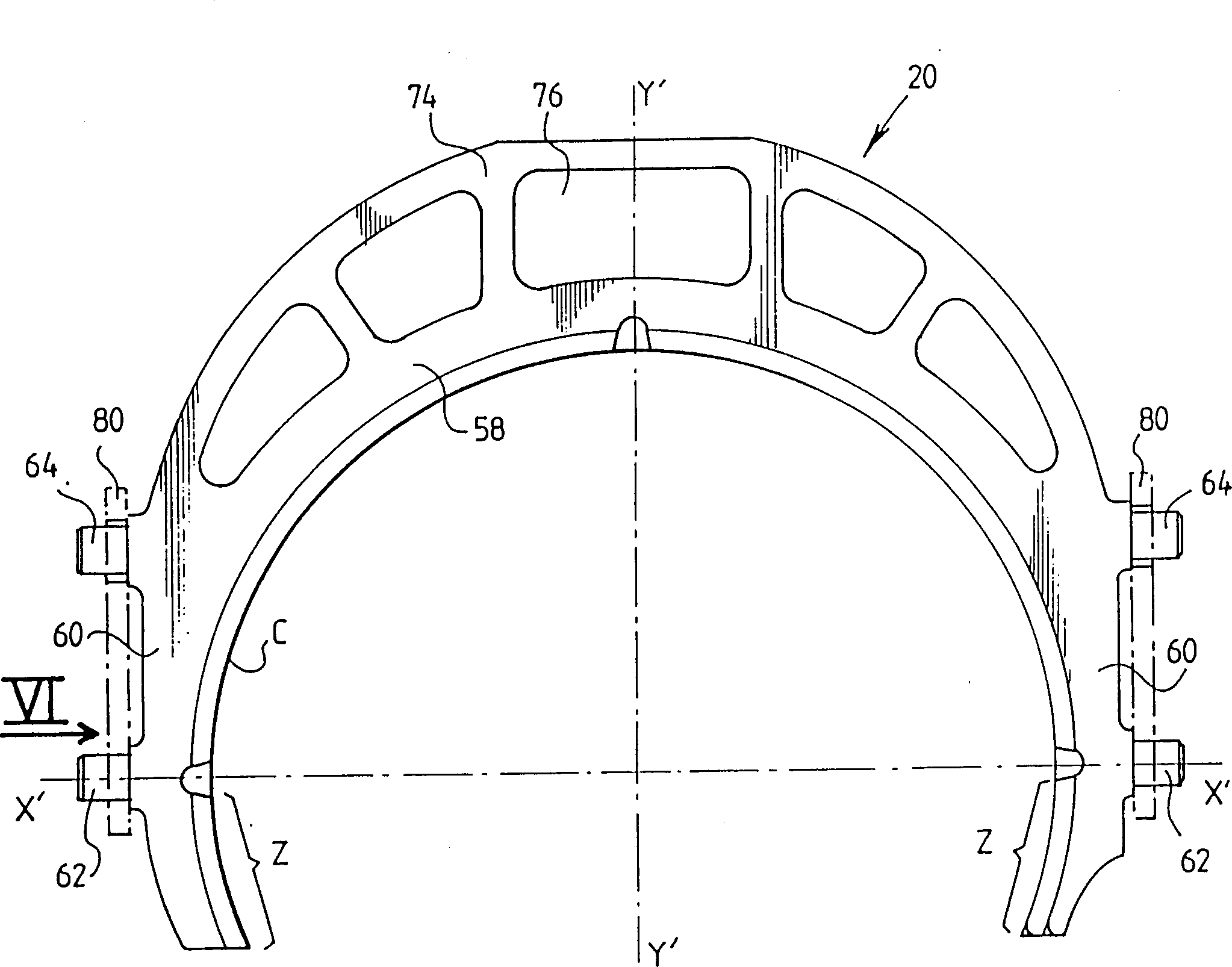

Pipe connecting device

The connection for piping components (4) respectively at the smooth end and at the fitting (8) containing a radial compression seal comprises the following parts. A first support (22) integral with the first piping component comprises a operating crank (38). A second support part (20) is fixed to the second piping component (4). A rod engages with one end of the crank and pivots on the second support, particularly by engaging a hole (84) in the rod with a pivot pin (62) in the external periphery of the second support. The rod and the second support comprise associated stops (64,104,106) which limit the rod pivoting relative to the support.

Owner:SAINT GOBAIN PAM SA

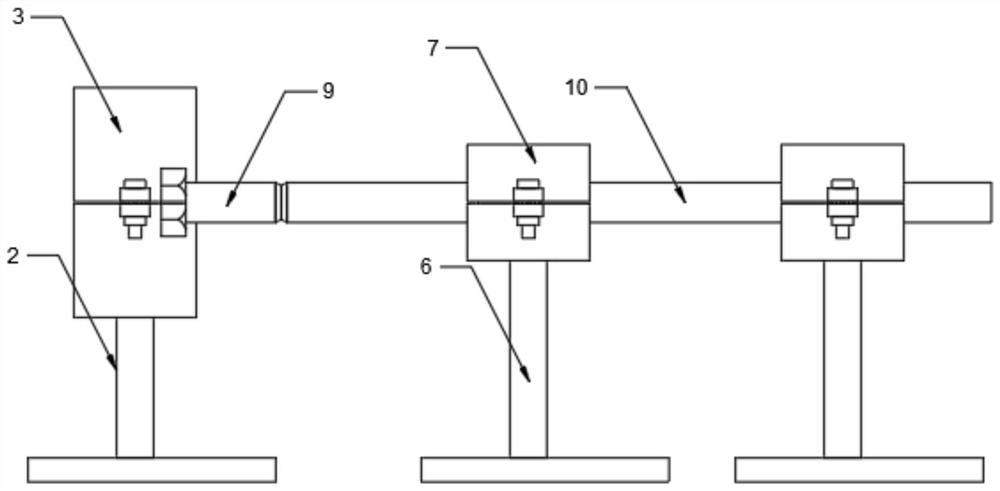

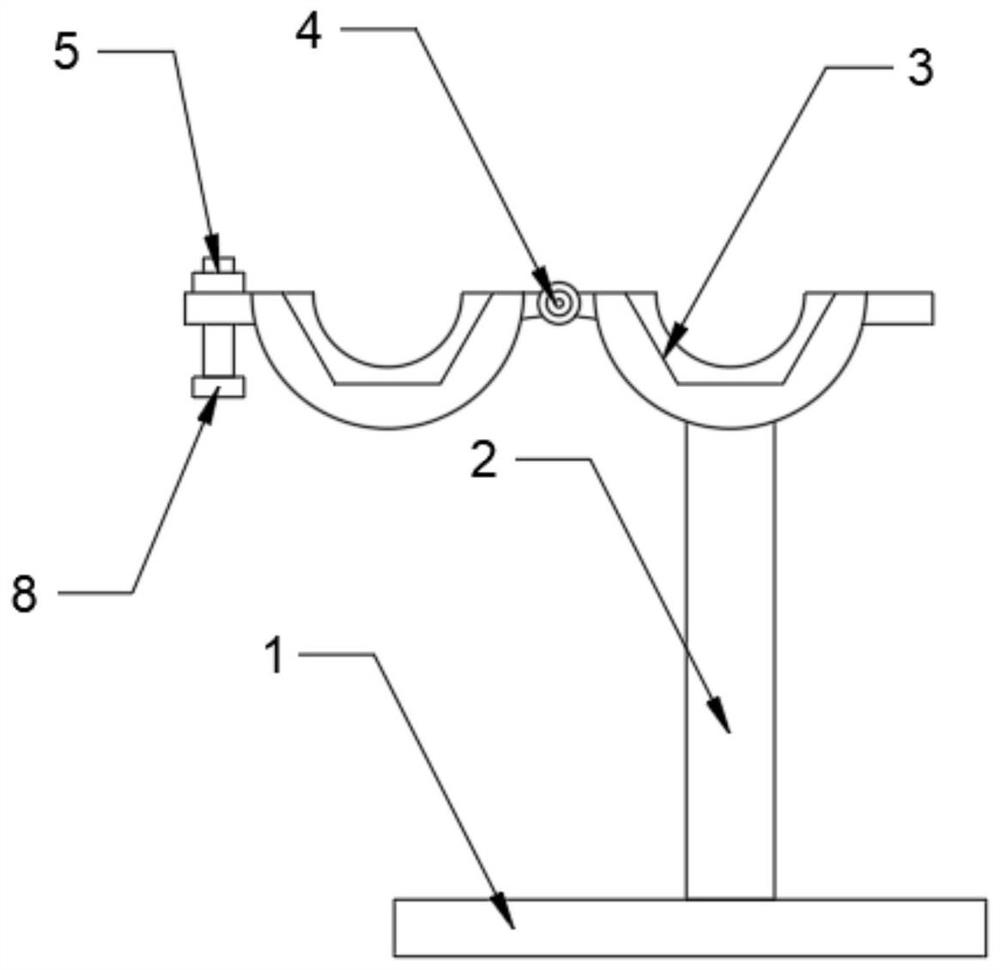

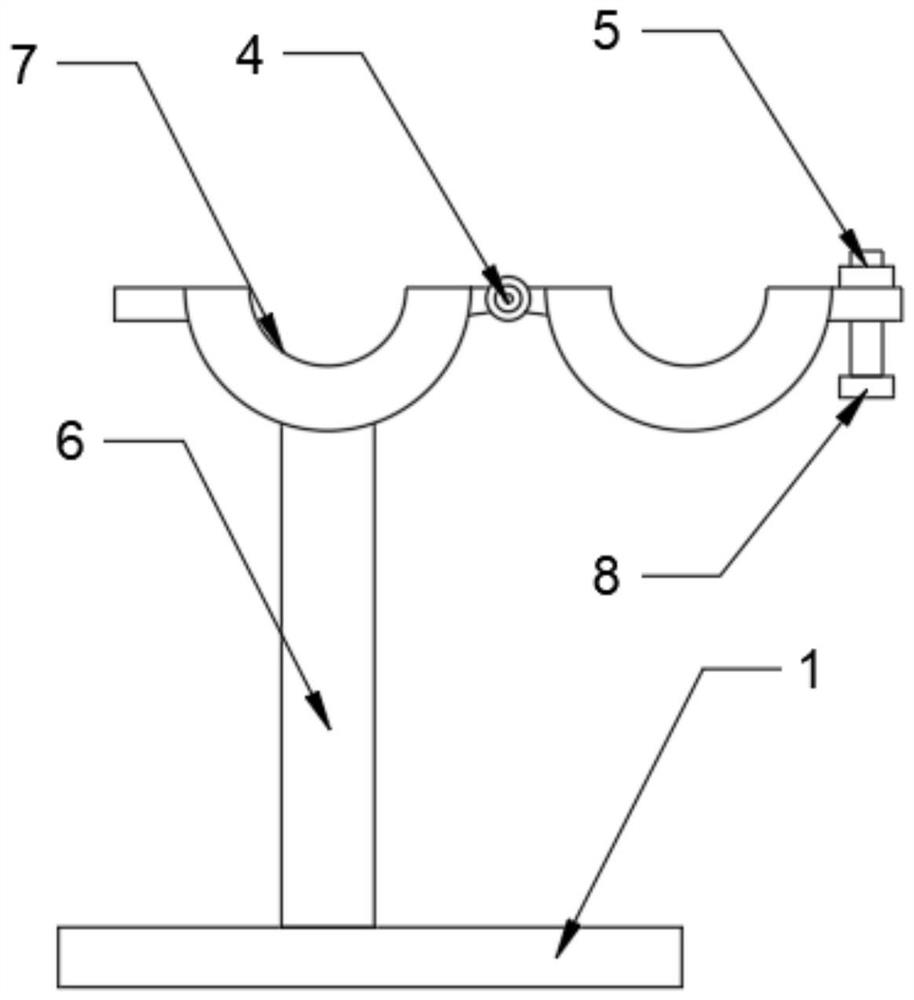

Device for butt welding of pipe joint and pipe and using method

PendingCN114289988AImprove stabilityHigh concentricityWelding/cutting auxillary devicesAuxillary welding devicesButt weldingStructural engineering

The invention discloses equipment for butt welding of a pipe joint and a pipe and a using method, relates to the field of ship building piping system welding, and provides the following scheme aiming at the problems that during butt welding, deviation is possibly generated during centering of the pipe joint and the pipe, welding is unstable and the like. A first supporting rod and a second supporting rod are welded to the top of the supporting base, and a fixing pipe joint hoop is welded to the end, away from the supporting base, of the first supporting rod. According to the butt welding equipment, the pipe joint fixing hoop, the pipe fixing hoop, the supporting rod and other structures are installed, the pipe joint fixing device and the pipe fixing device are arranged, the stability and concentricity of a pipe joint and a pipe during butt welding are improved, the butt spot welding operation can be completed by only one person through the equipment, the labor cost is reduced, and the production efficiency is improved. And the construction difficulty is reduced, and the centering precision and the welding quality during butt welding of the pipe joint and the pipe are improved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

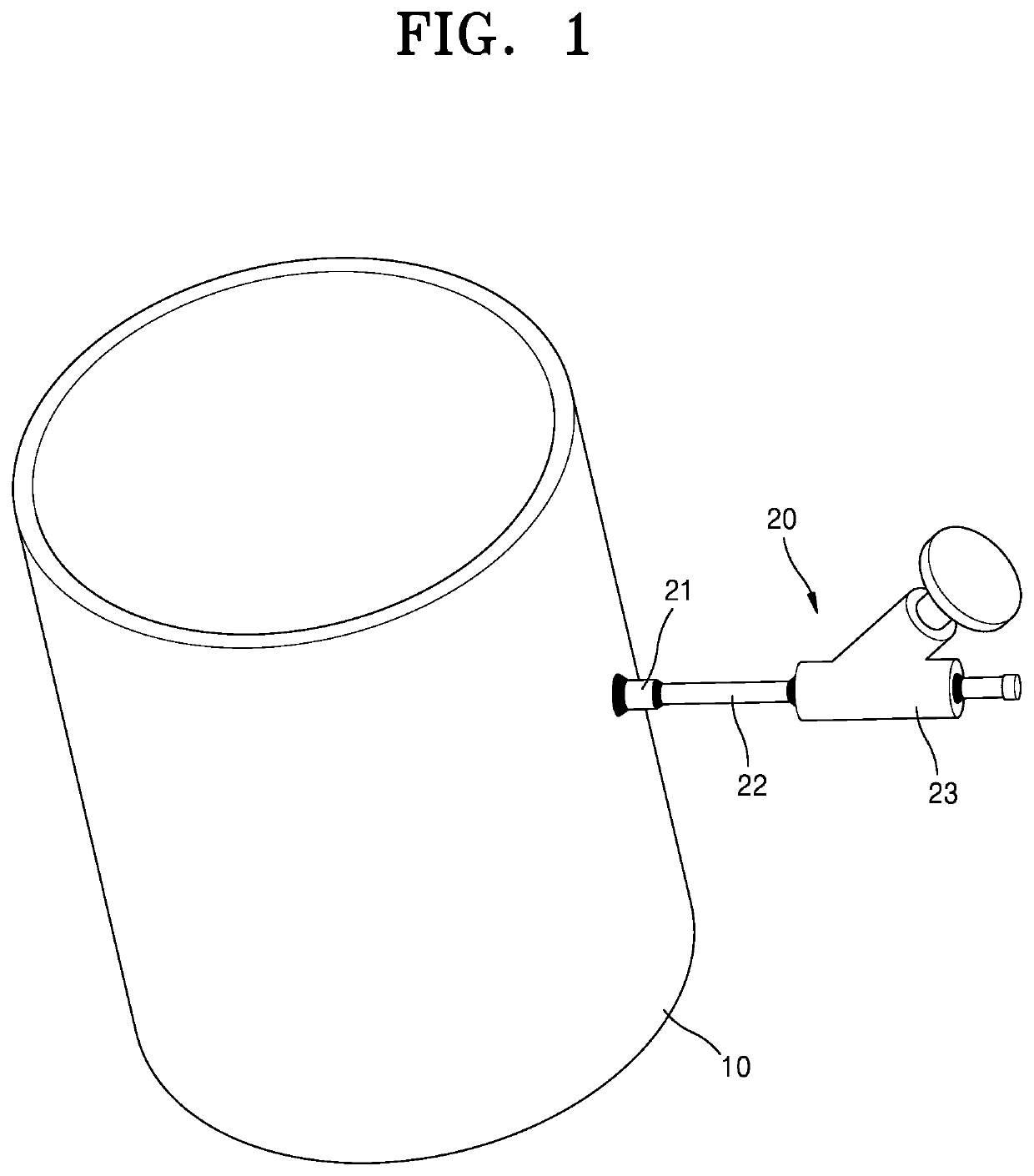

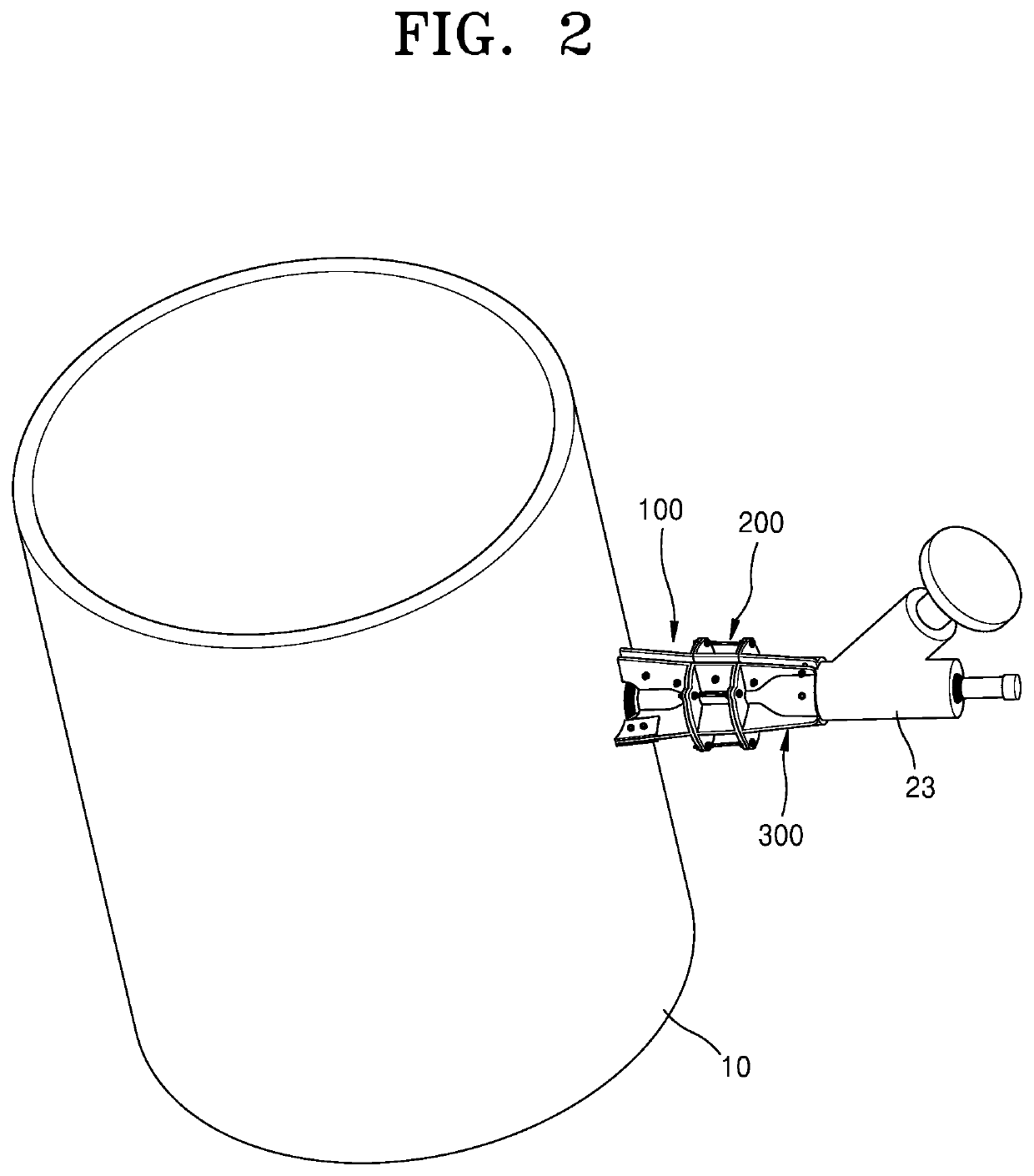

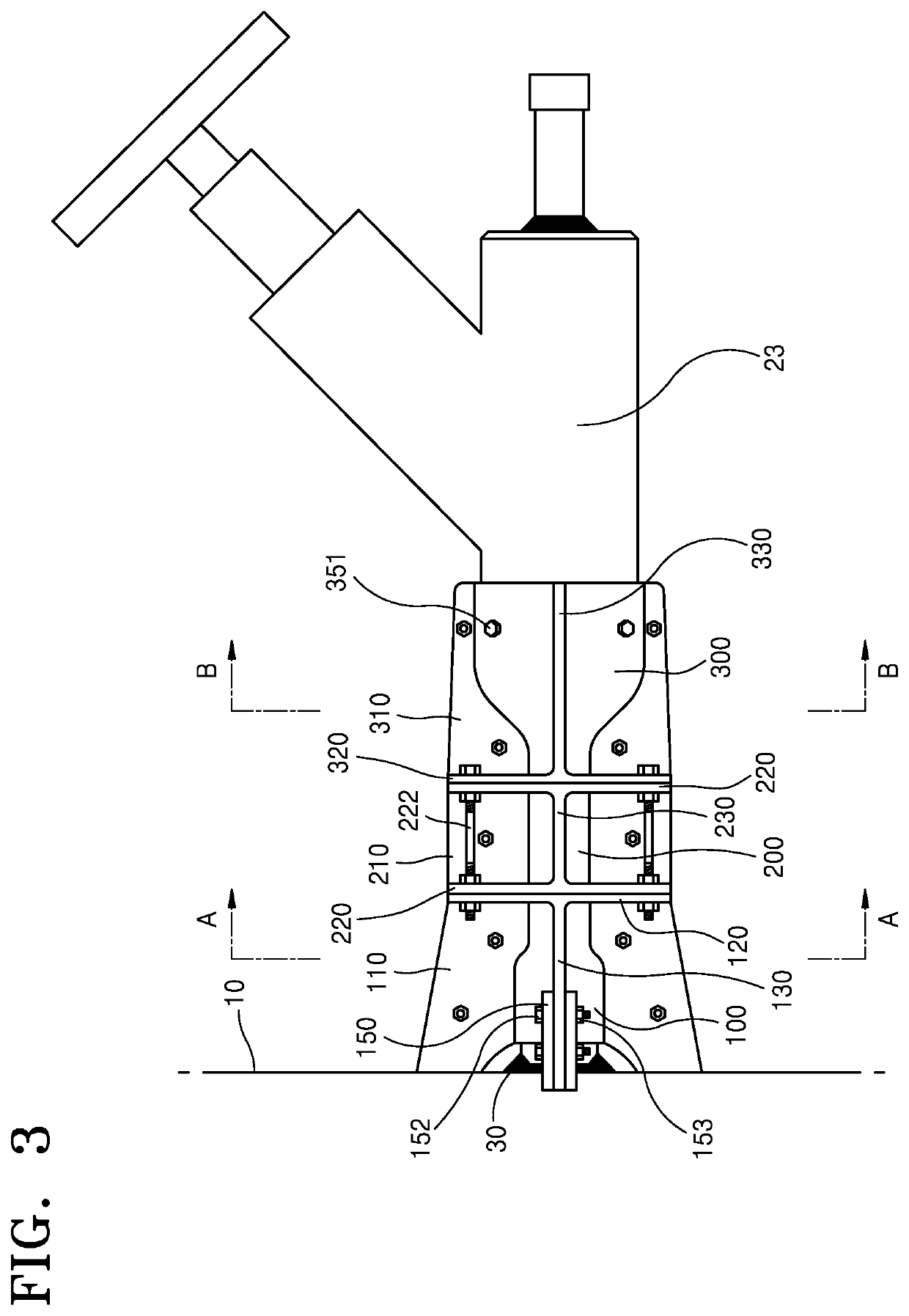

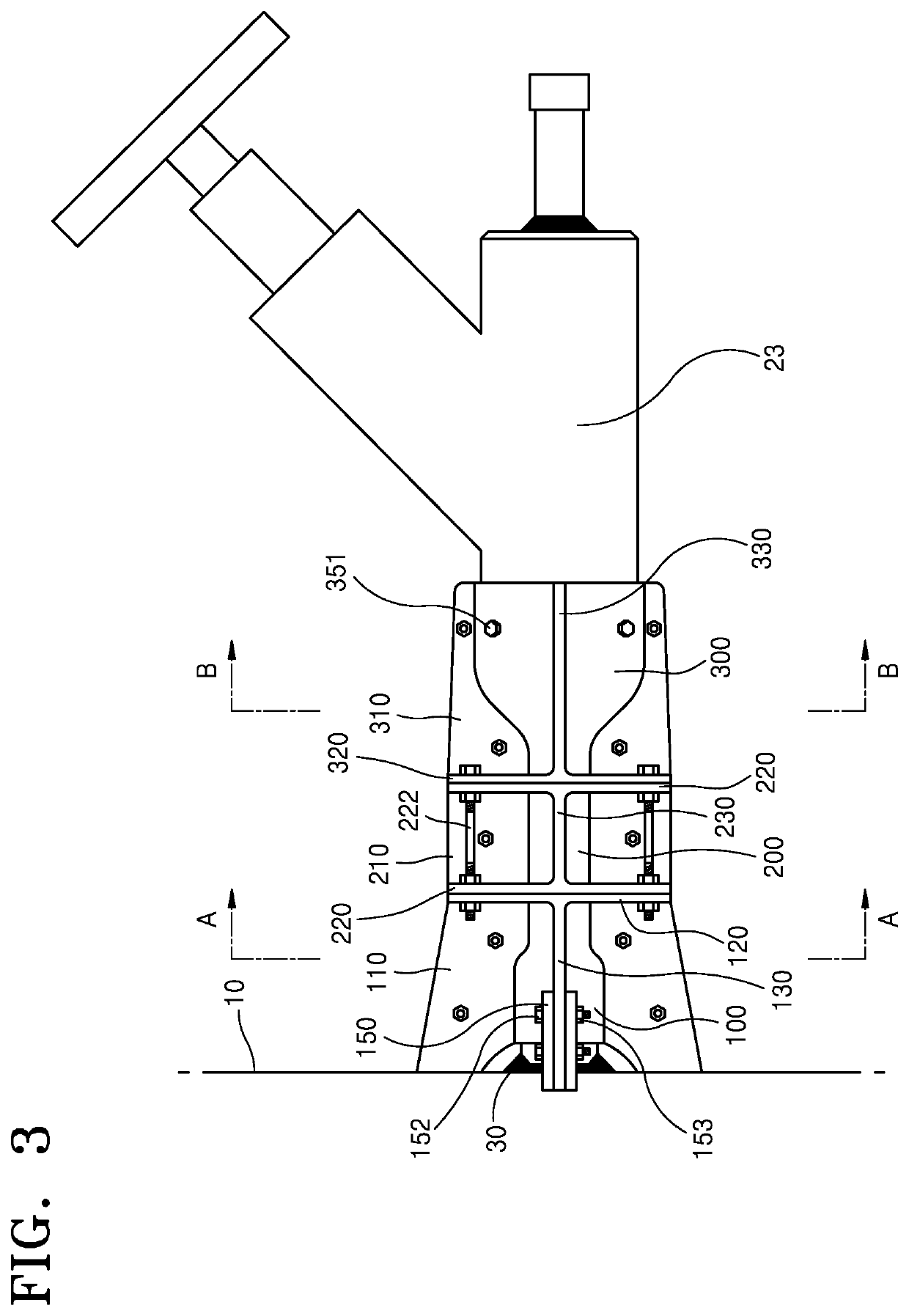

Non-welded type branch piping reinforcement apparatus

ActiveUS11199277B2High strengthAvoid damageSleeve/socket jointsPipe supportsStructural engineeringMechanics

A non-welded type branch piping reinforcement apparatus capable of preventing damage to a branch pipe system by increasing the strength of the branch pipe system by covering and protecting the branch pipe system connected to a header pipe, by a joint clamp, a connection pipe clamp, and a valve clamp includes: a joint clamp arranged to cover the branch pipe joint and the connection pipe and having an arc-shaped cross section; a connection pipe clamp arranged to cover the connection pipe and having an arc-shaped cross section; and a valve clamp arranged to cover the connection pipe and the valve and having an arc-shaped cross section, wherein one end of the connection pipe clamp is connected to the joint clamp and the other end of the connection pipe clamp is connected to the valve clamp.

Owner:KEPCO ENG & CONSTR CO INC

Gas supply device and sealing gasket replacement method of gas supply device

ActiveCN113669622ACases to prevent double insertionCircumstances to prevent disengagementVessel mounting detailsEngine sealsPinch gripEngineering

The purpose of the present invention is to provide a gas supply device and a sealing gasket replacement method capable of preventing double insertion of a gasket due to adhesion of the gasket to a valve connector of a container. The sealing gasket replacement method of a gas supply device according to the present invention comprises the steps of: a) placing a sealing gasket between a valve connector provided in a container and a connection piping connector connected to a gas demand site to couple the valve connector and the connection piping connector; b) releasing the coupling of the valve connector and the connecting piping connector; and c) transferring the sealing gasket after separating the sealing gasket from between the valve connector and the connecting piping connector, wherein the process of performing the steps a) to c) includes a process in which the sealing gasket is gripped by a sealing gasket gripper and the sealing gasket gripper gripping the sealing gasket and the connecting piping connector are simultaneously transferred.

Owner:KC

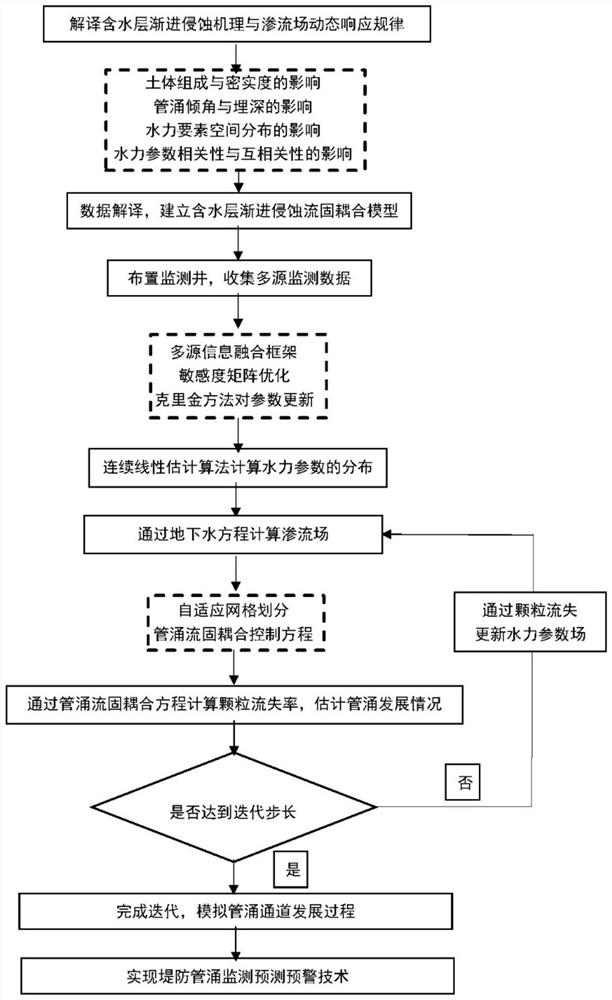

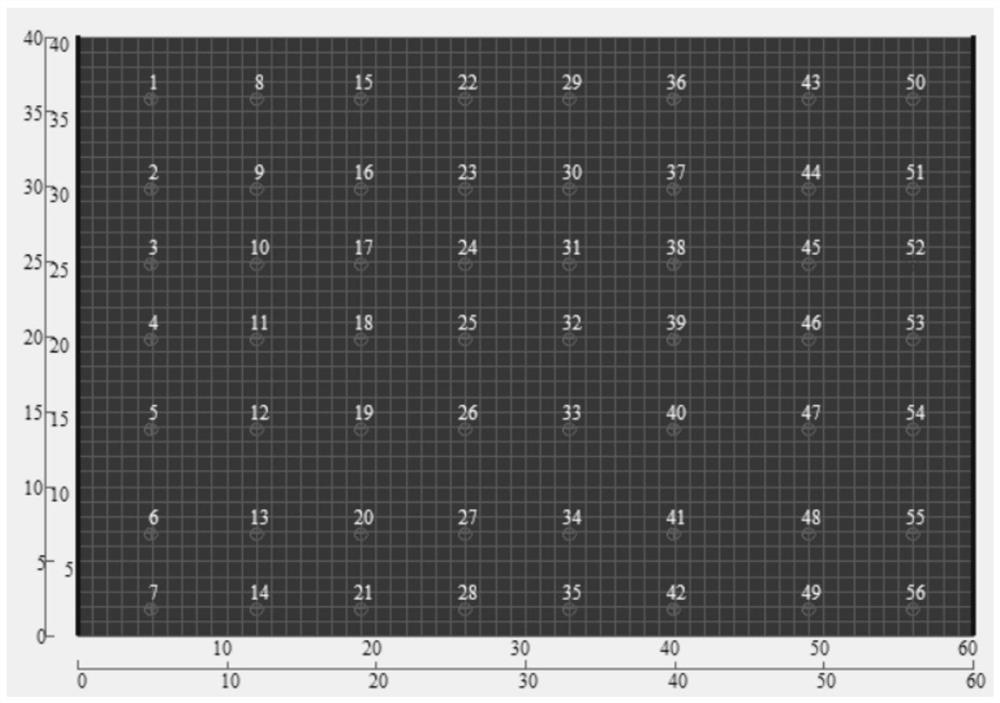

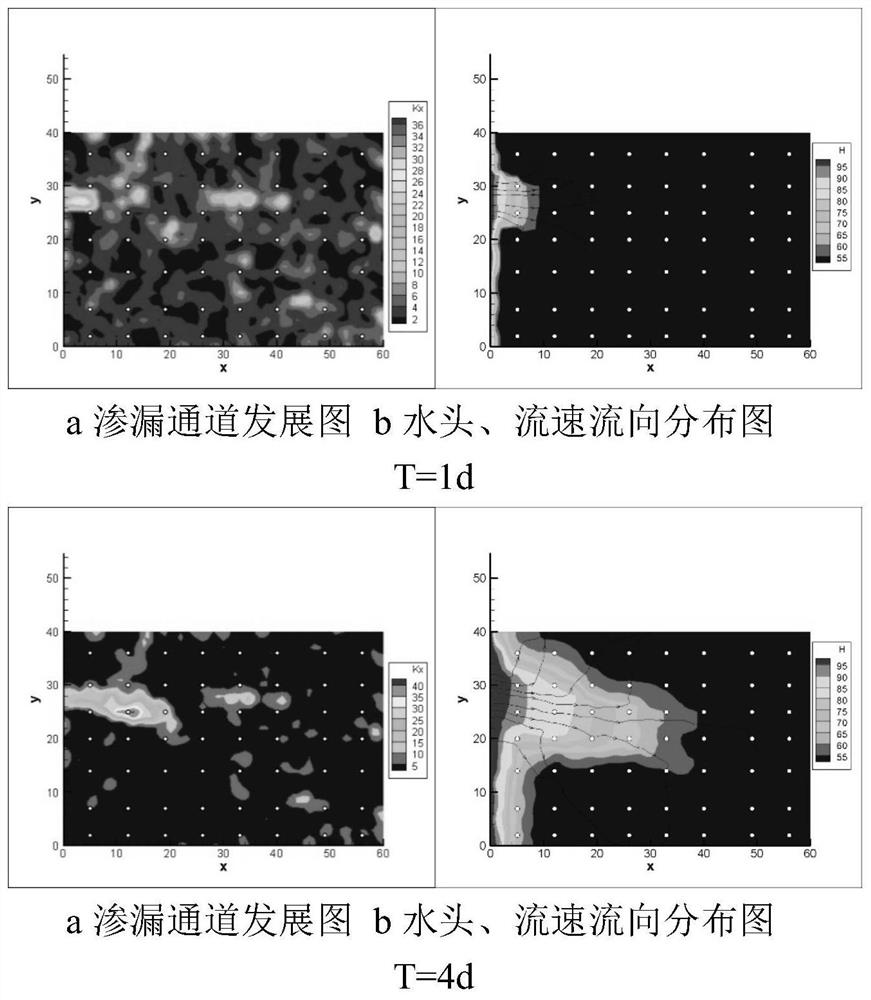

A prediction and early warning method of piping development based on dynamic tomographic scanning

ActiveCN111723477BFast dynamic responseCalculation speedMaterial analysis by electric/magnetic meansDesign optimisation/simulationHydraulic tomographyFluid solid coupling

The invention discloses a pipeline development prediction and early warning method based on dynamic tomographic scanning, comprising the following steps: interpreting the progressive erosion mechanism of aquifers and the dynamic response law of seepage field; establishing a fluid-solid coupling model of progressive erosion of aquifers; arranging monitoring wells to collect data Monitoring data; establishing a multi-source monitoring data interpretation model for progressive erosion of aquifers; calculating the current seepage field; calculating the erosion situation with the piping fluid-solid coupling model; updating the seepage field and iteratively calculated to the step size requirement. The method of the invention combines the characteristics of the piping fluid-solid coupling model and the advantages of the hydraulic tomography scanning to characterize the heterogeneous aquifer, and predicts the dynamic development of the piping channel. Real-time feedback and precise positioning have been greatly improved.

Owner:CHONGQING JIAOTONG UNIVERSITY

Non-welded type branch piping reinforcement apparatus

ActiveUS20200132226A1High strengthAvoid damageSleeve/socket jointsPipe supportsEngineeringStructural engineering

A non-welded type branch piping reinforcement apparatus capable of preventing damage to a branch pipe system by increasing the strength of the branch pipe system by covering and protecting the branch pipe system connected to a header pipe, by a joint clamp, a connection pipe clamp, and a valve clamp includes: a joint clamp arranged to cover the branch pipe joint and the connection pipe and having an arc-shaped cross section; a connection pipe clamp arranged to cover the connection pipe and having an arc-shaped cross section; and a valve clamp arranged to cover the connection pipe and the valve and having an arc-shaped cross section, wherein one end of the connection pipe clamp is connected to the joint clamp and the other end of the connection pipe clamp is connected to the valve clamp.

Owner:KEPCO ENGINEERING & CONSTRUCTION COMPANY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com