Device for butt welding of pipe joint and pipe and using method

A technology of butt welding and pipe joints, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. Reduce labor costs, increase stability and concentricity, improve alignment accuracy and weld quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

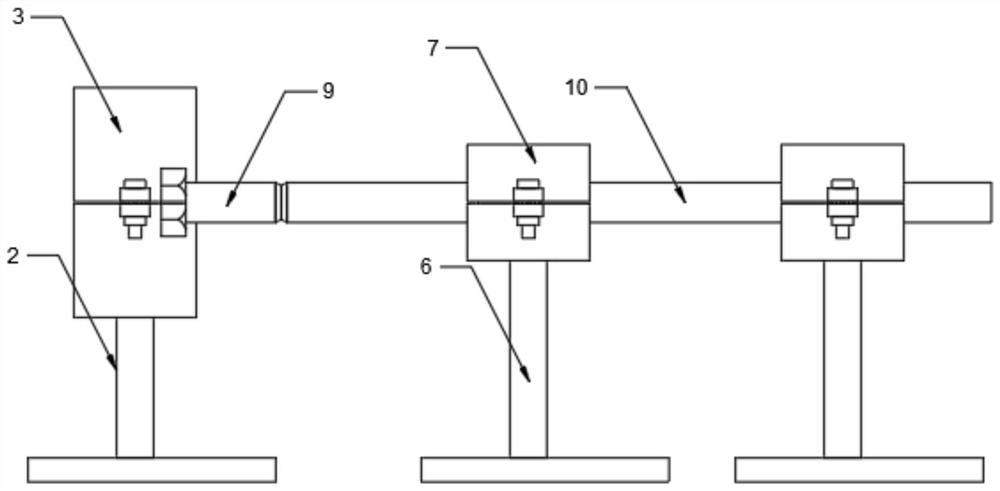

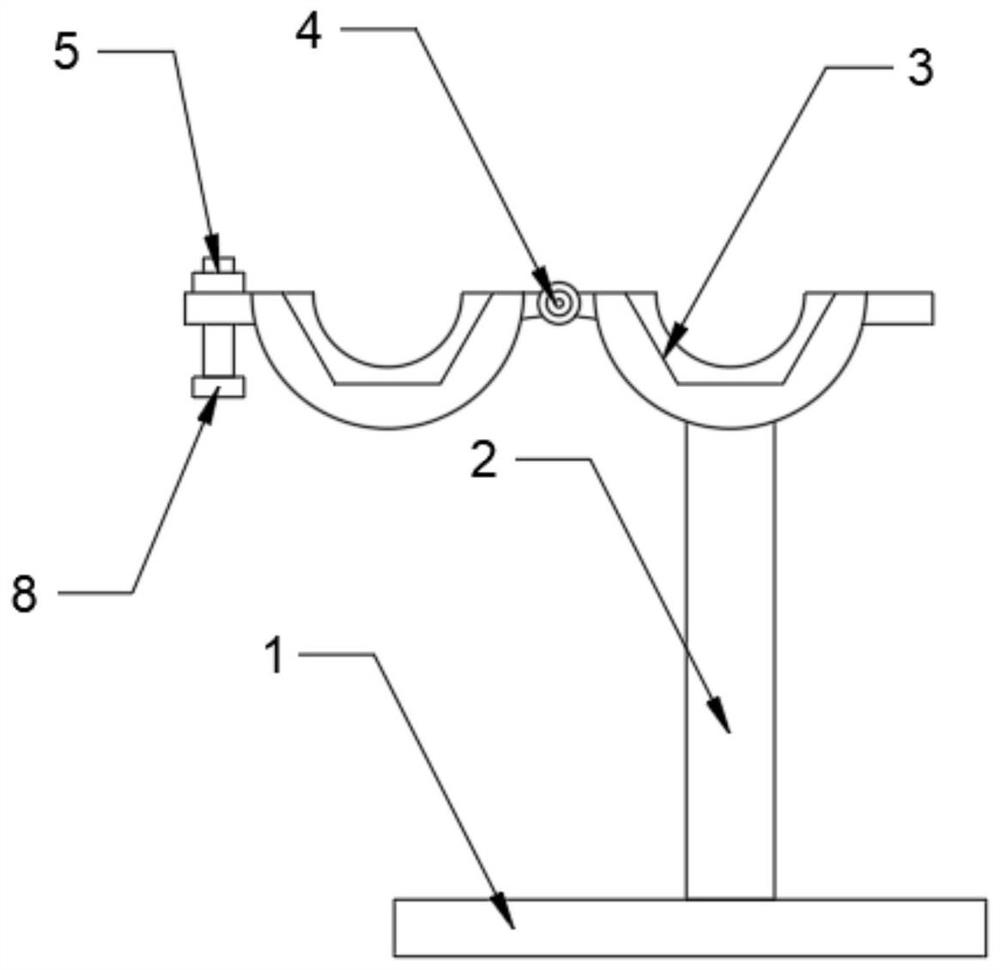

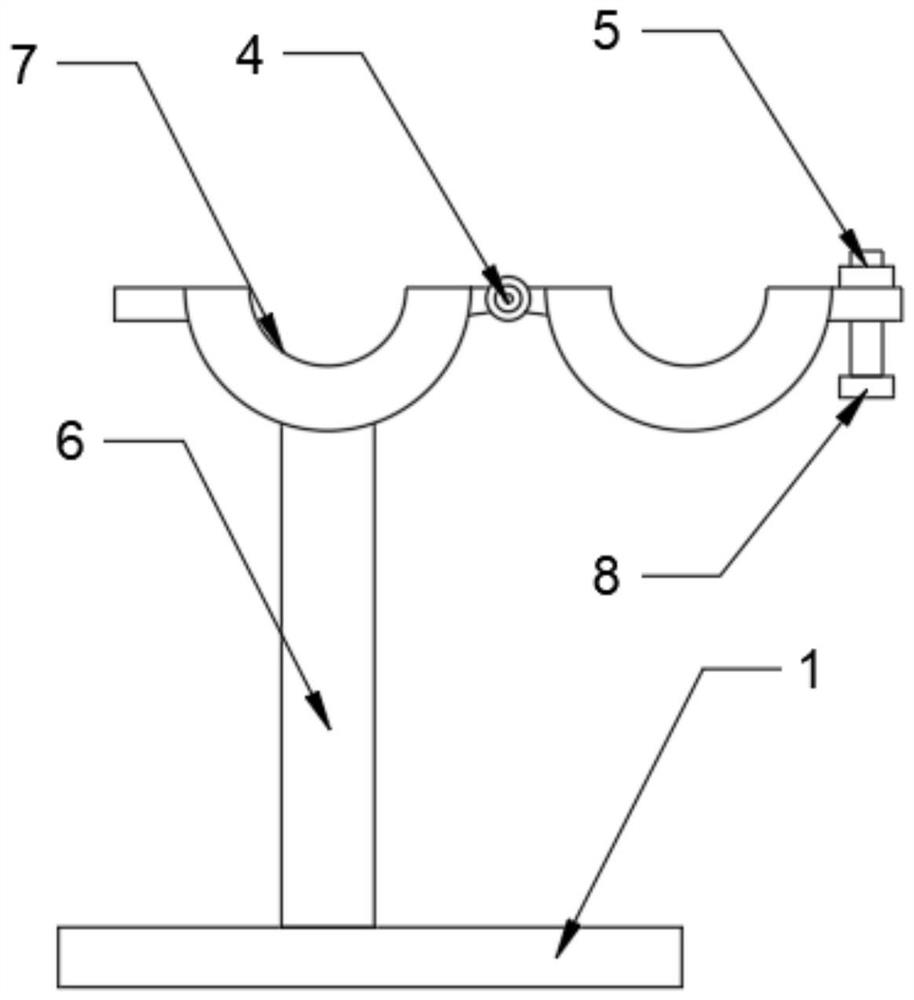

[0027] Embodiment one: refer to Figure 1-6 , the present invention relates to a pipe joint and pipe butt welding equipment, the equipment includes two support bases 1, the top of the support base 1 is respectively welded with a first support rod 2 and a second support rod 6, the first support rod 2 The end far away from the support base 1 is welded with a fixed pipe joint hoop 3, and the end of the second support rod 6 away from the support base 1 is welded with a fixed pipe hoop 7 to keep the centerline of the fixed pipe joint hoop 3 and the fixed pipe hoop 7 The installation directions of the center lines of the two are consistent, and the two center lines are on the same line to ensure concentricity. There are at least two fixed pipe hoops 7, which can be increased in moderation according to conditions such as pipe 10 lengths. The fixed pipe joint hoop 3 and the fixed pipe hoop 7 are equally divided into upper and lower parts, and a hinge 4 is arranged between the upper an...

Embodiment 2

[0029] Embodiment two: refer to Figure 1-6 , on the basis of Embodiment 1, a method for using equipment for butt welding of pipe joints and pipes, the method includes the following steps:

[0030] S1: Place the flat shoulder joint inside the hoop of the fixed pipe joint, and keep the relative height of the fixed pipe hoop that clamps the pipe consistent with the hoop of the fixed pipe joint;

[0031] S2: Fix the flat shoulder joint and the port where the pipe is close to each other by spot welding;

[0032] S3: After loosening the locking bolts, remove the spot-welded pipes and perform complete welding.

[0033]In the specific operation process, the method includes the following use process: placing the flat shoulder joint 9 inside the fixed pipe joint hoop 3, inserting the locking bolt 5 into the nut 8, and then placing the flat shoulder joint 9 in the fixed pipe joint hoop In the card groove inside the hoop 3, the flat shoulder joint 9 can protrude out of the fixed pipe j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com