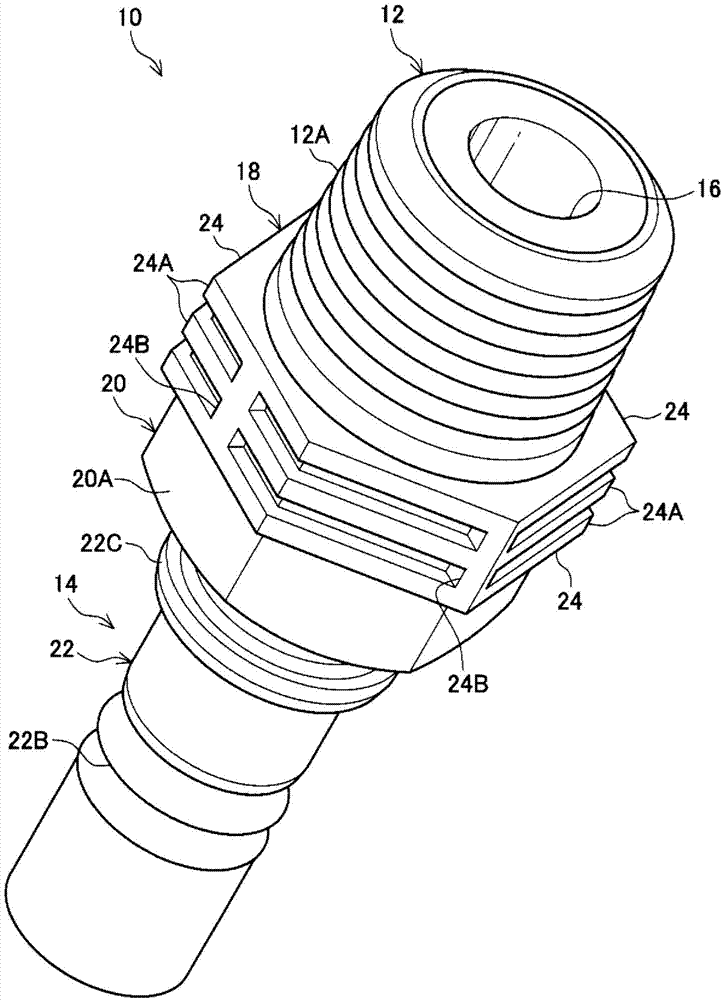

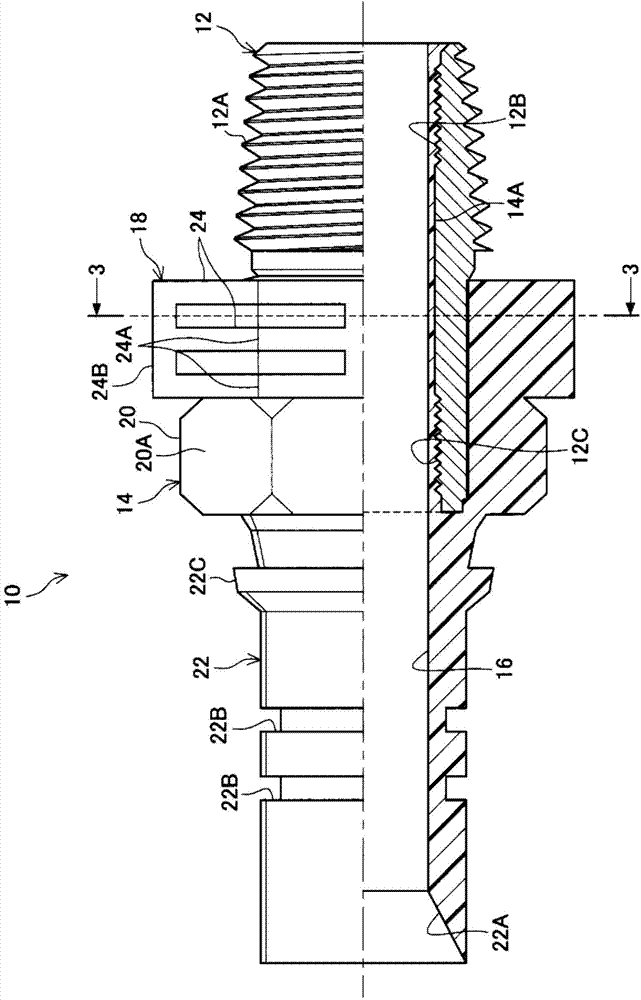

Piping joint

A piping and pipe body technology, applied in the direction of pipe/pipe joint/pipe fitting, pipe connection arrangement, threaded connection, etc., can solve problems such as the adverse effect of the watertight performance of the pipe joint, and achieve the effect of inhibiting leakage and inhibiting separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

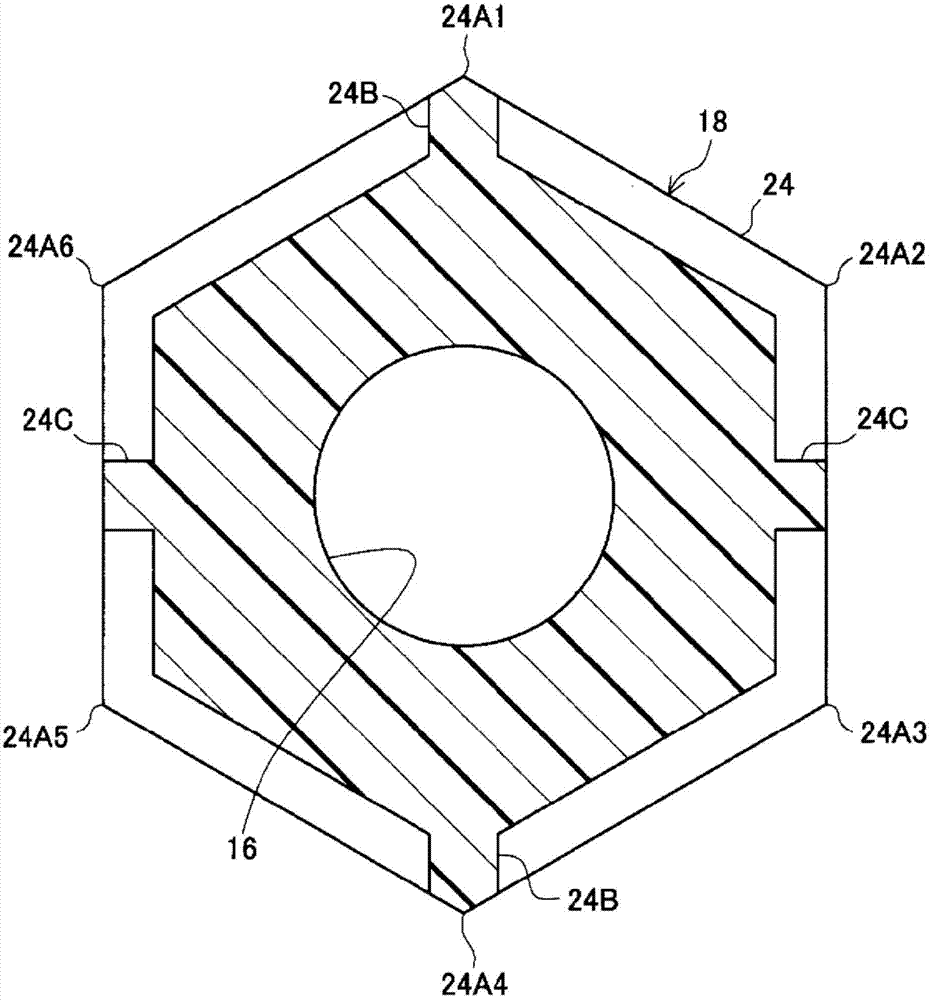

[0058] Next, a piping joint 30 according to a second exemplary embodiment will be described. The same configurations as those of the first exemplary embodiment are assigned the same reference numerals, and descriptions thereof are omitted. Such as Figure 9 As shown, in the pipe joint 30 according to the present exemplary embodiment, the rib 32B is formed at all six corners 32A1 to 32A6 of the annular protrusion 32 constituting the first hexagonal portion 31 . Other configurations are the same as those of the first exemplary embodiment.

[0059] In the pipe joint 30 according to the present exemplary embodiment, the rib 32B is formed on all six corners 32A1 to 32A6 of the annular protrusion 32 so that all the corners 32A1 to 32A6 obtain equal strength. Accordingly, when gripping the first hexagonal portion 31 with the wrench 200 , there is no need to consider the position of the rib 32B.

[0060]

[0061] Next, a pipe joint 50 according to a third exemplary embodiment wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com