Conduit welding shrinkage control device

A technology for controlling device and shrinkage, applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of difficult control of catheter accuracy, reduction of welding speed, disorder of lateral shrinkage, etc., to ensure welding accuracy and product quality, Easy and fast to use, operate the effect of editing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

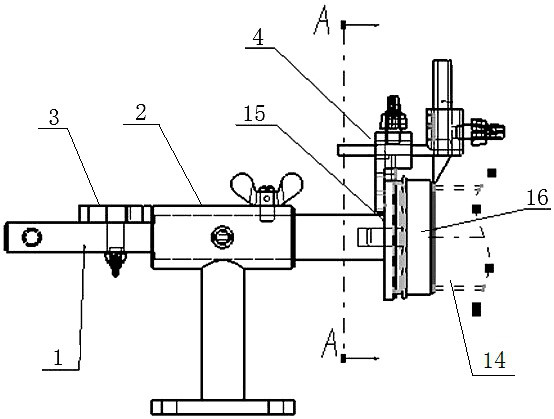

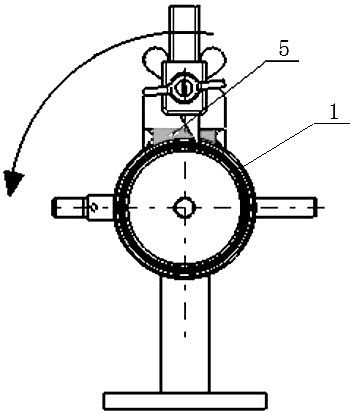

[0031] This example provides figure 1 A catheter welding shrinkage control device is shown, which is used to control the welding shrinkage in the welding process. Before welding, the shrinkage distance of the catheter 14 is reserved to prevent the overall connection accuracy of the catheter 14 caused by the displacement of multiple pipe joints 16. low problem. It includes a conduit 14 and a pipe joint 16 connected to the end of the conduit 14, and also includes a digital control device and a pipe marking device 4. The digital control device includes a casing positioner 1, a pipe support 2 and a digital measuring device 3. The casing positioning One end of the device 1 is provided with a connection plate 15, through which the casing positioner 1 is coaxially connected with the pipe joint 16, the pipe support 2 is used to support the casing positioner 1, and the middle section of the casing positioner 1 is inserted into the In the pipe support 2, a stop screw 12 and a latch 13 ...

Embodiment 2

[0036] This embodiment is based on the whole content of embodiment 1, the difference is:

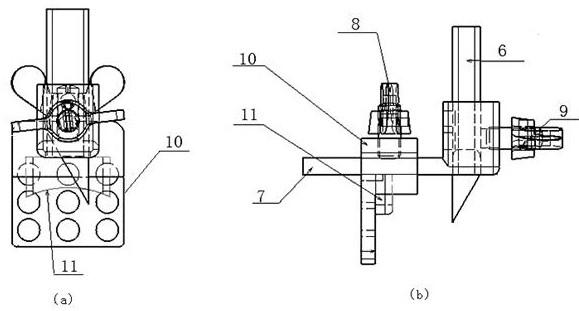

[0037] Further, the pipe marking device 4 is used in conjunction with a digital control device, the numerical control device obtains the welding shrinkage variable, and transmits it to the pipe marking device 4, and the pipe marking device 4 obtains the position of the weld seam before welding , so as to determine the processing benchmark. The function of the pipe marking device 4 is to map the weld line on the conduit. Since the weld line includes the welding shrinkage value, in order to ensure that the pipe marking device can automatically adapt to the welding shrinkage value, the main installation surface of the piping marking device is selected Only on the sleeve can it be ensured that it can adapt to the follow-up when adjusting the welding shrinkage value, and ensure the effectiveness of the reading accuracy of the digital controller; Different diameters and different casings, dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com