Identical-intensity flexible piping joint clasp and its production

An equal-strength, flexible pipe technology, applied in the direction of pipes/pipe joints/fittings, hose connection devices, mechanical equipment, etc., can solve the problems of low mechanical strength of clamps, inability to achieve equal strength, and high production costs, and achieve energy change. Consumption, changing the process material consumption, changing the weakening effect of the strength of the clamp body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

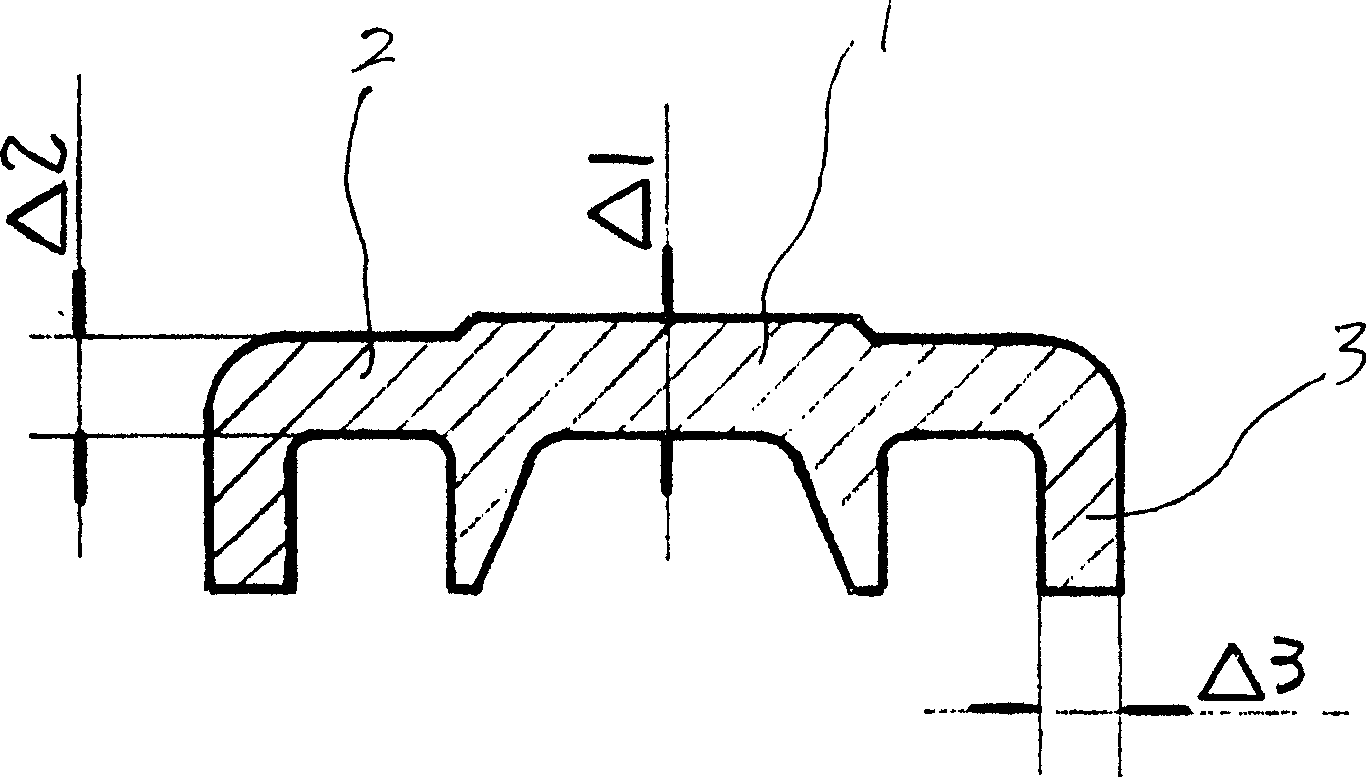

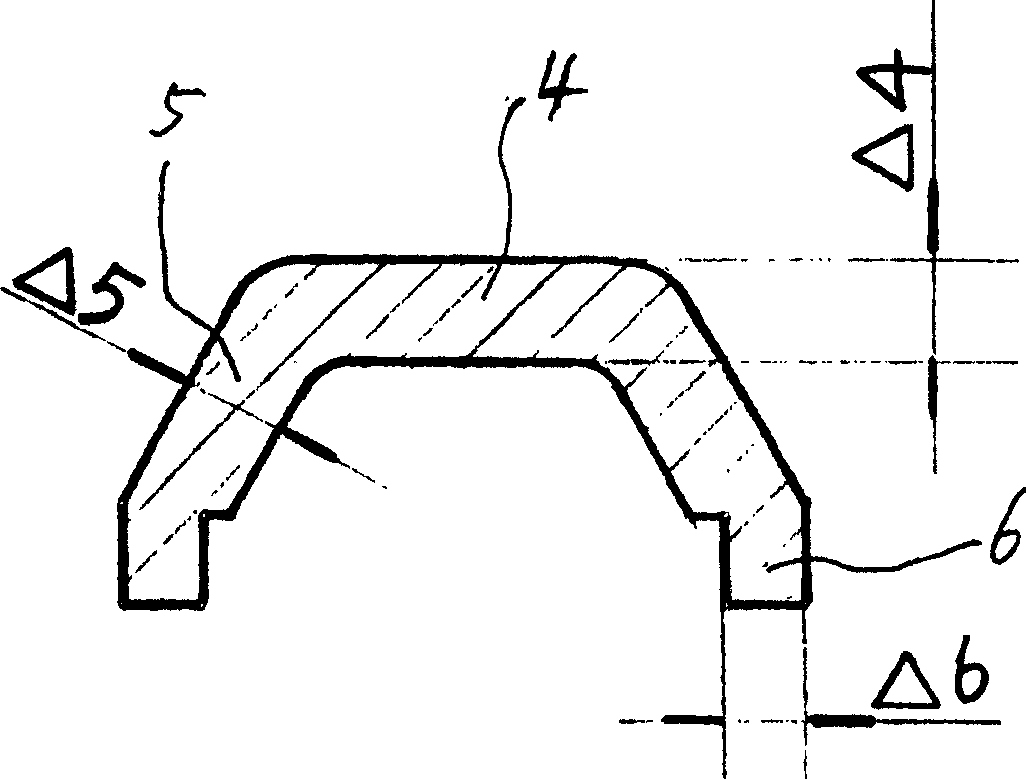

[0010] Specific embodiments 1. An equal-strength flexible pipe joint clamp, which includes a clamp body and ear seats at both ends of the clamp body. The wall thickness of the clamp body is set in proportion. Refer to figure 1 , the wall thickness Δ of the ring wall (1) in the ring clamp body 1 , The wall thickness Δ of the outer ring wall (2) 2 , The wall thickness Δ of the outer wall (3) 3 The ratio between is Δ 1 / Δ 2 =1.2, Δ 2 / Δ 3 = 1.1, the wall thickness Δ of the inner ring wall (4) of the shoulder clamp body 4 , Wall thickness Δ of the shoulder wall (5) 5 , The wall thickness Δ of the outer wall (6) 6 The ratio between is Δ 4 / Δ 5 =1.1, Δ 5 / Δ 6 = 1.1.

specific Embodiment approach 2

[0011] Embodiment 2, a manufacturing method of the above-mentioned equal-strength flexible pipe joint clamp, which includes the following steps: (1) rolling steel strip——rolling out the required steel strip blank on the rolling mill, the steel strip The cross-section of the blank is the same as the section geometry of the manufactured clamp body, see figure 1 , the wall thickness Δ of the inner ring wall (1) of the ring clamp body blank 1 , The wall thickness Δ of the outer ring wall (2) 2 , The wall thickness Δ of the outer wall (3) 3 The ratio between is Δ 1 / Δ 2 =1.2, Δ 2 / Δ 3 = 1.1, see figure 2 , the wall thickness Δ of the inner ring wall (4) of the blank of the shoulder clamp body 4 , Wall thickness Δ of the shoulder wall (5) 5 , The wall thickness Δ of the outer wall (6) 6 The ratio between is Δ 4 / Δ 5 =1.1, Δ 5 / Δ 6 = 1.1. (2) Blanking - according to the double length of the arc length of the clamp body, the corresponding length of the steel strip blank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com