Pipe connecting device

A technology for connecting devices and pipe fittings, applied in the direction of sleeve/socket connection, pipe/pipe joint/pipe fitting, through components, etc., can solve problems such as equipment damage, seal rupture, uneven seal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

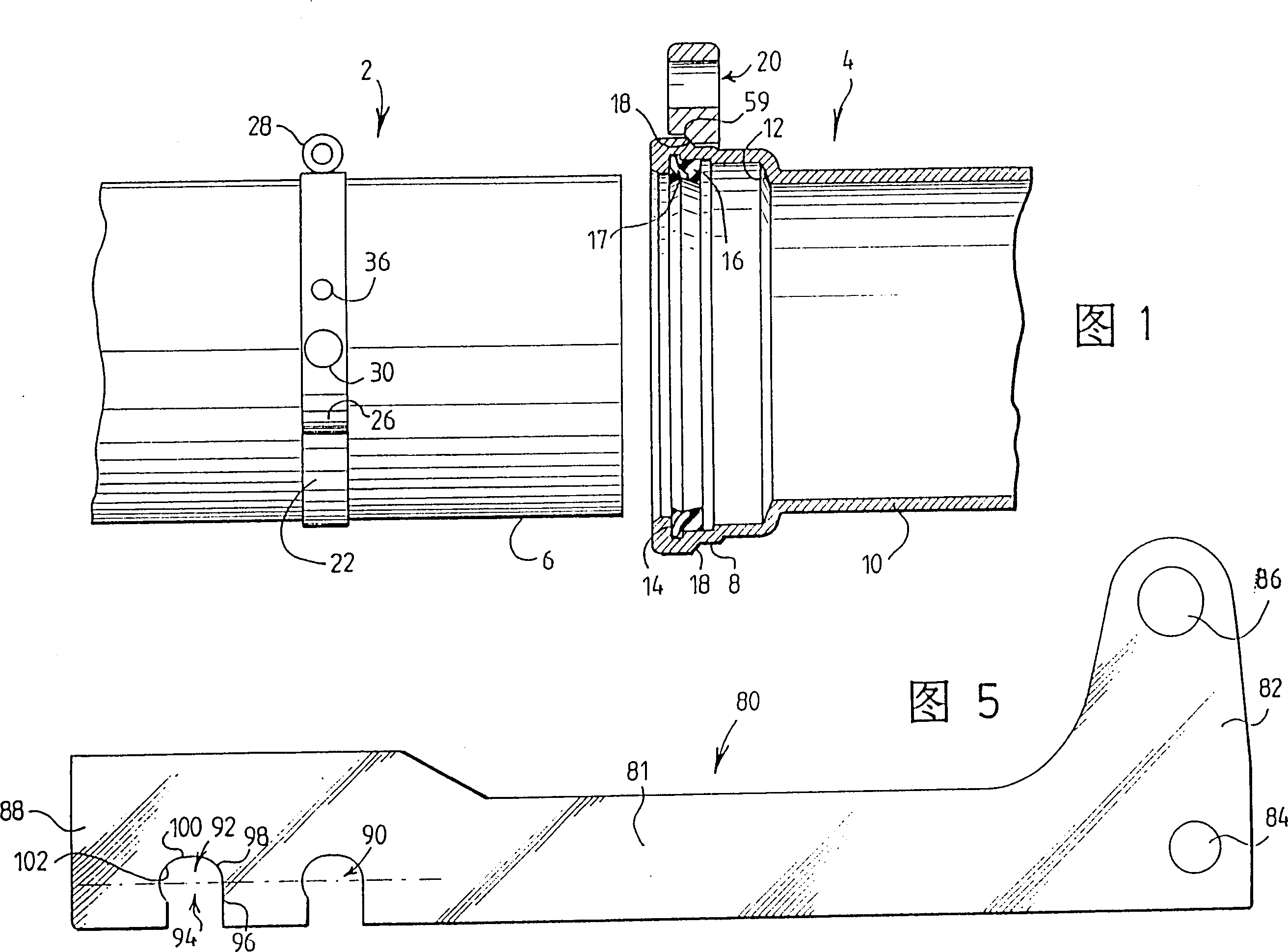

[0041] As shown in FIG. 1 , the invention consists in connecting a first pipe 2 into a second pipe 4 .

[0042] The connection of the two pipes is ensured by introducing the smooth cylindrical end (also called smooth cannula) 6 of the pipe 2 into the corresponding socket 8 of the pipe 4 .

[0043] The socket 8 has a diameter greater than the diameter of the body 10 of the pipe 4 and also has an axial boss 12 at the bottom against which the smooth cannula 6 abuts after the connection operation has been completed.

[0044] The socket also has an inner groove 14 for receiving an annular seal 16 . This seal, for example the seal described in FR-A-2679622 and the seal of specification Vi sold by the company PONT-A-MOUSSON, have a metal locking insert 17 that locks when the two pipes are connected. Hold the two fittings assembled.

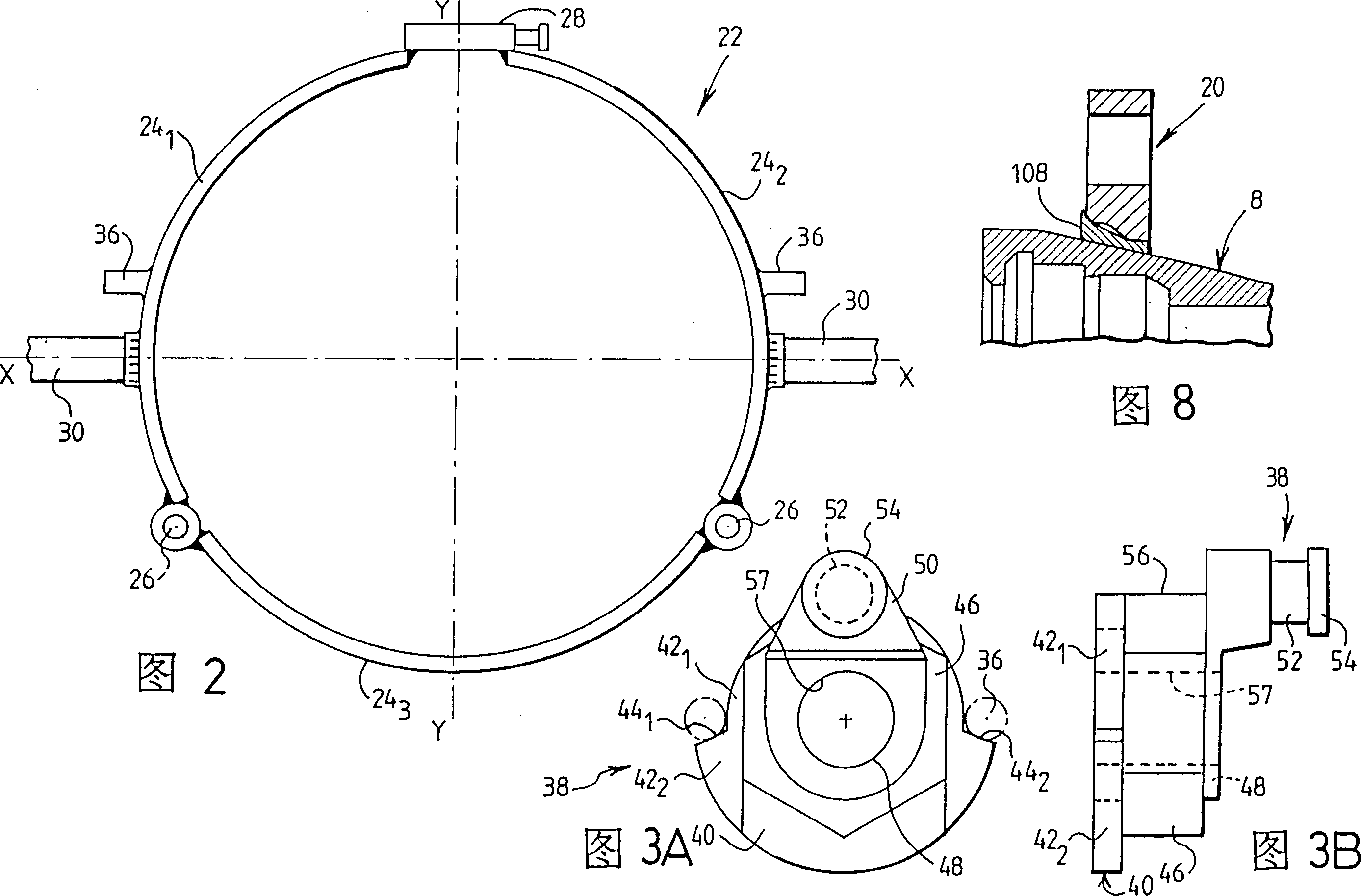

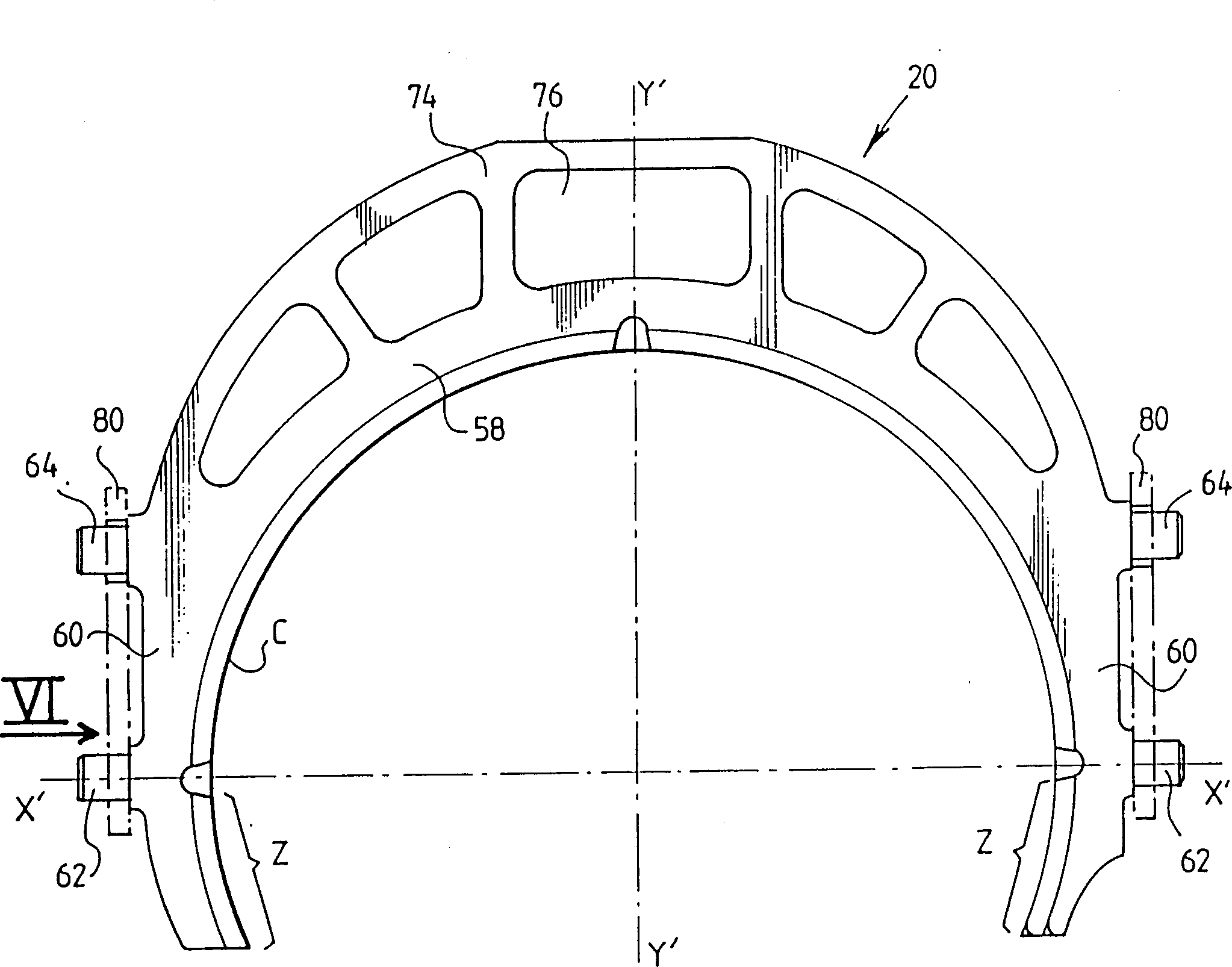

[0045] There is also an annular shoulder 18 on the outside of the socket tube 8, and the supporting member 20 shown in the figure is next to the shoul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com