Piping joint structure

A technology combining structure and piping, applied in the direction of pipes, vehicle parts, pipes/pipe joints/pipe fittings, etc., can solve the problem of separation of the resonator and the third member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present disclosure will be described below using the drawings. The shapes, materials, and numbers described below are examples for explanation, and can be appropriately changed depending on the model of the vehicle including the pipe connection structure, and the like. Hereinafter, in all the drawings, the same reference numerals are given to the same elements for description. In addition, in the description herein, the reference numerals described before are used as necessary.

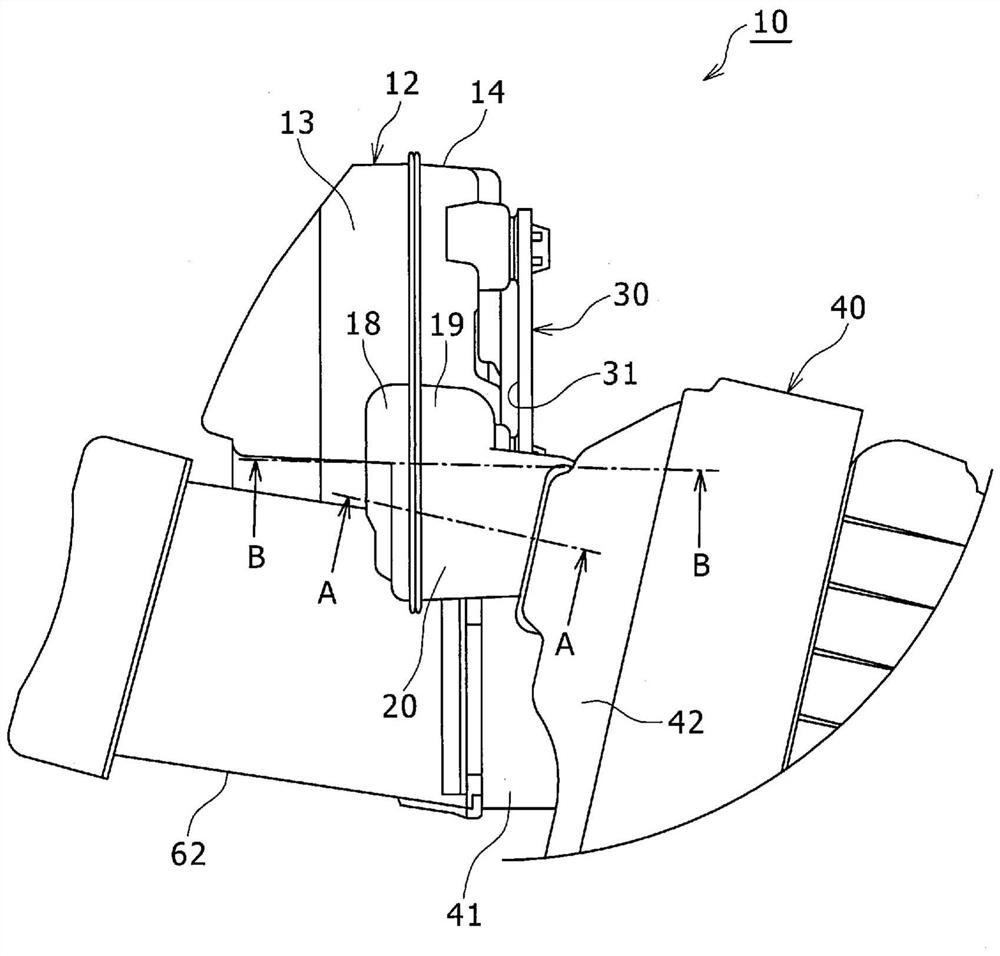

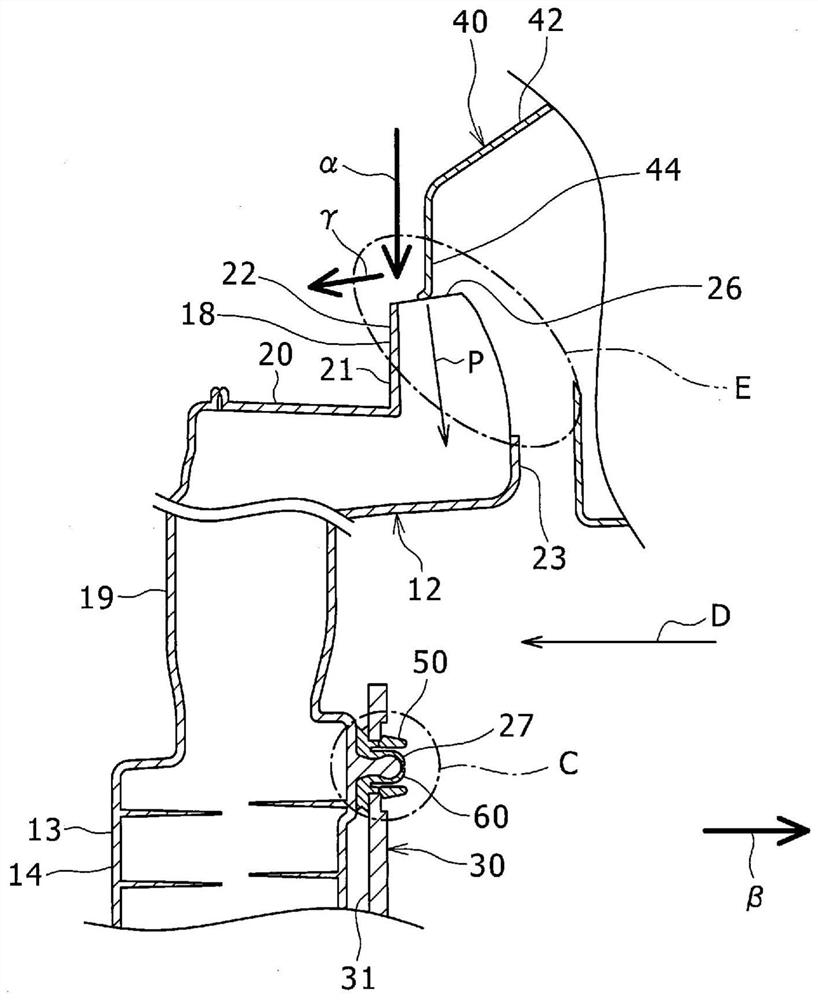

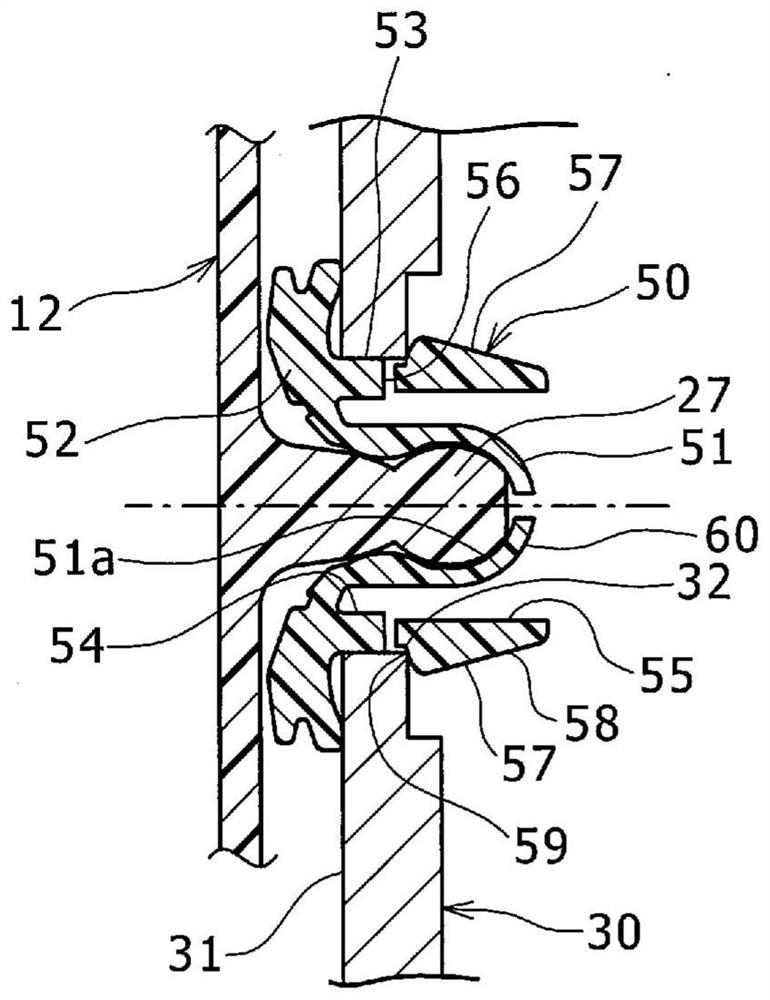

[0020] figure 1 It is a figure which looked at the pipe connection structure 10 of embodiment from the upper side of a vehicle. Figure 2A It shows the piping part where the resonator 12 is inserted into the first hole 44 of the air cleaner 40 as the first member in a state where the resonator 12 as the second member and the fixing member 30 as the third member are combined. 18 is a diagram showing a state where the end portion of the air cleaner 40 is pressed against the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com