Excavating construction method for special stratum cave

A construction method and chamber technology, which are used in underground chambers, earthwork drilling, wellbore lining, etc., can solve problems such as large engineering volume, weak excavation support, and easy collapse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

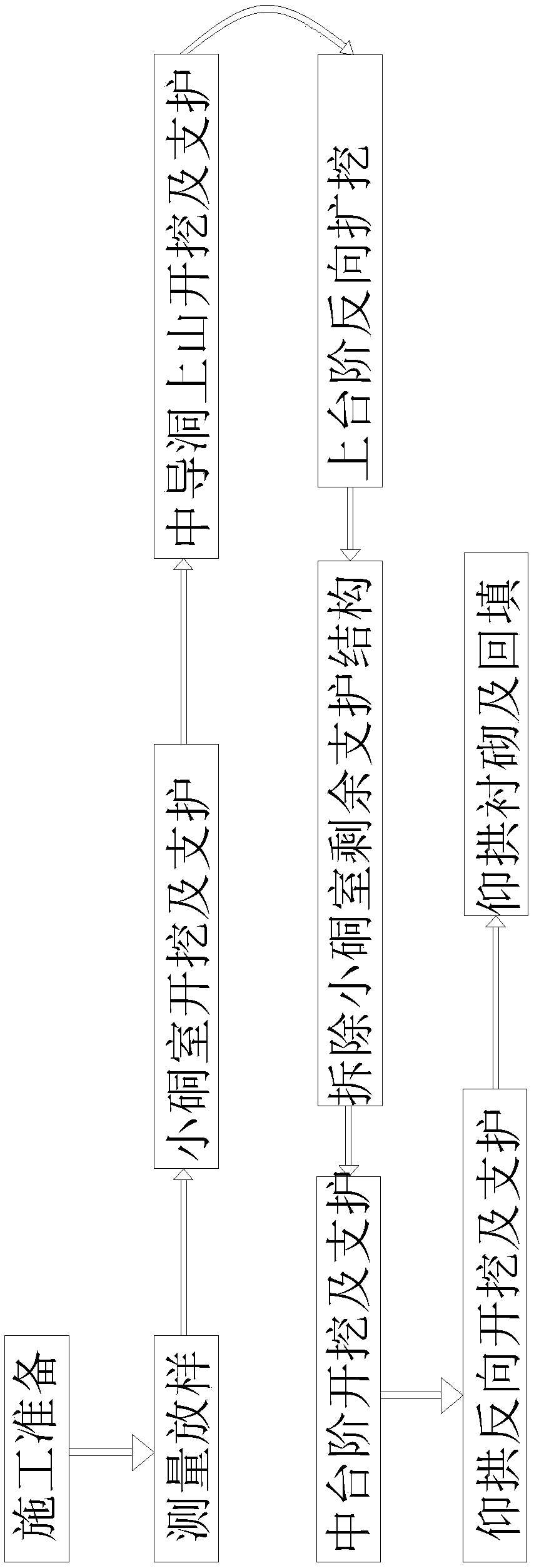

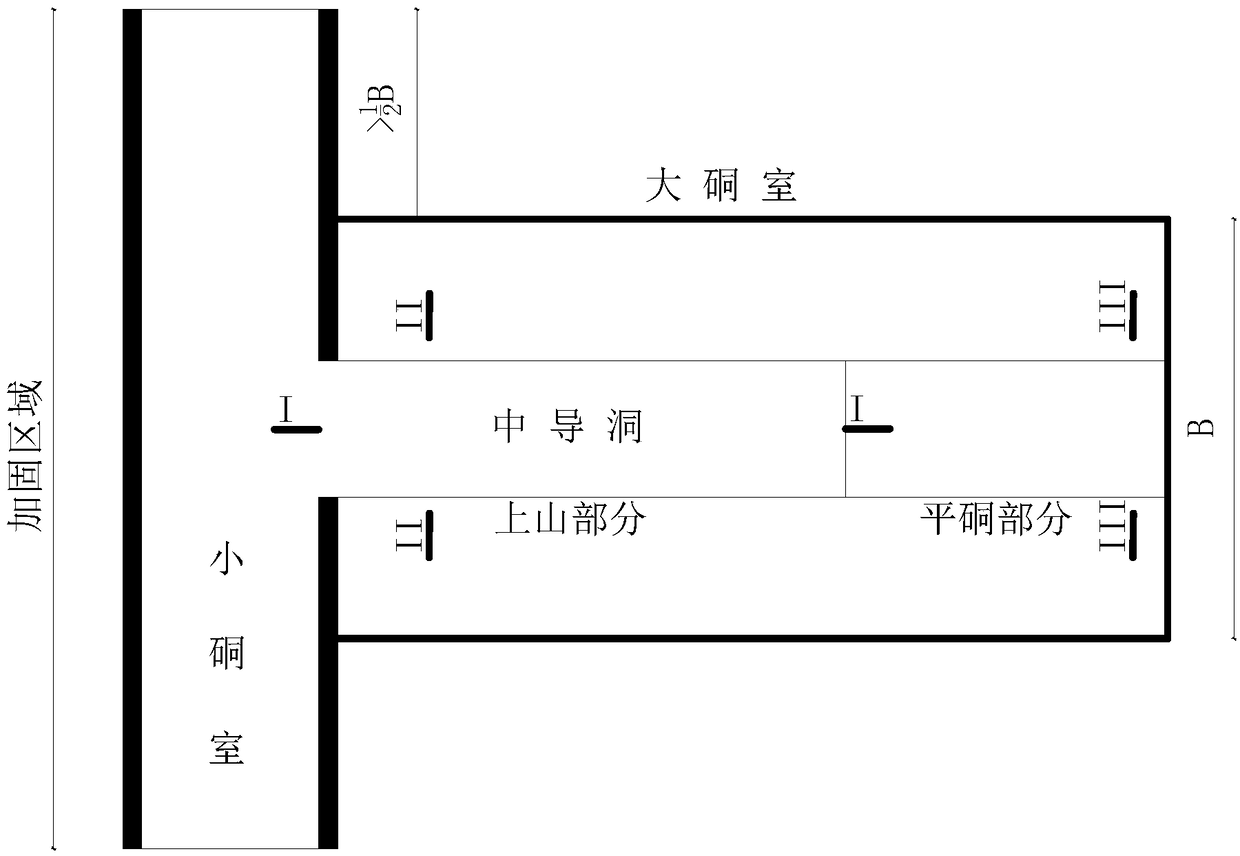

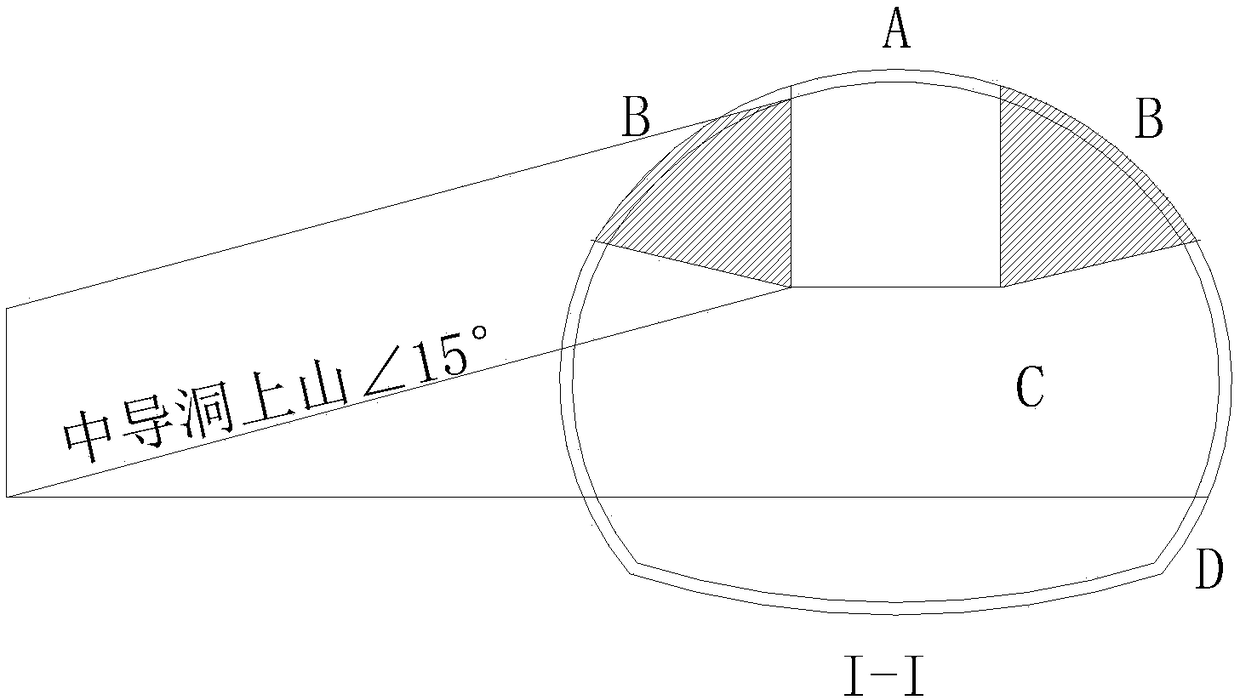

Method used

Image

Examples

Embodiment 2

[0067] The difference between this embodiment and Embodiment 1 is that this embodiment also provides an overall construction plan for the support of a large chamber hall.

[0068] The overall construction plan of the hall support

[0069] Such as Figure 4 As shown, (1) Design an integral steel mold trolley on the 6-meter span of the main body. The trolley consists of two parts, each of which is 3 meters long and can be docked.

[0070] (2) The hall adopts full-frame scaffolding as the intermediate support. The wall 20# industrial steel column and the arch part 12# industrial steel arch diagram form the main body of the supporting system, and the joint force is achieved through screw jacks. The arch of the formwork adopts a shaped steel formwork and a large steel-wood combined formwork for the side walls.

[0071] (3) I-steel assembled formwork for other sections and support holes, shaped steel formwork for arches, and large shaped steel formwork for side walls.

[0072] (4) Commercia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com