Friction overtorque protecting structure

A technology for protecting structures and friction plates, which is applied in the direction of automatic clutches, clutches, mechanical equipment, etc., can solve problems such as increased installation costs and unit damage, and achieve high adjustment accuracy and repeatability, stable performance, and high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

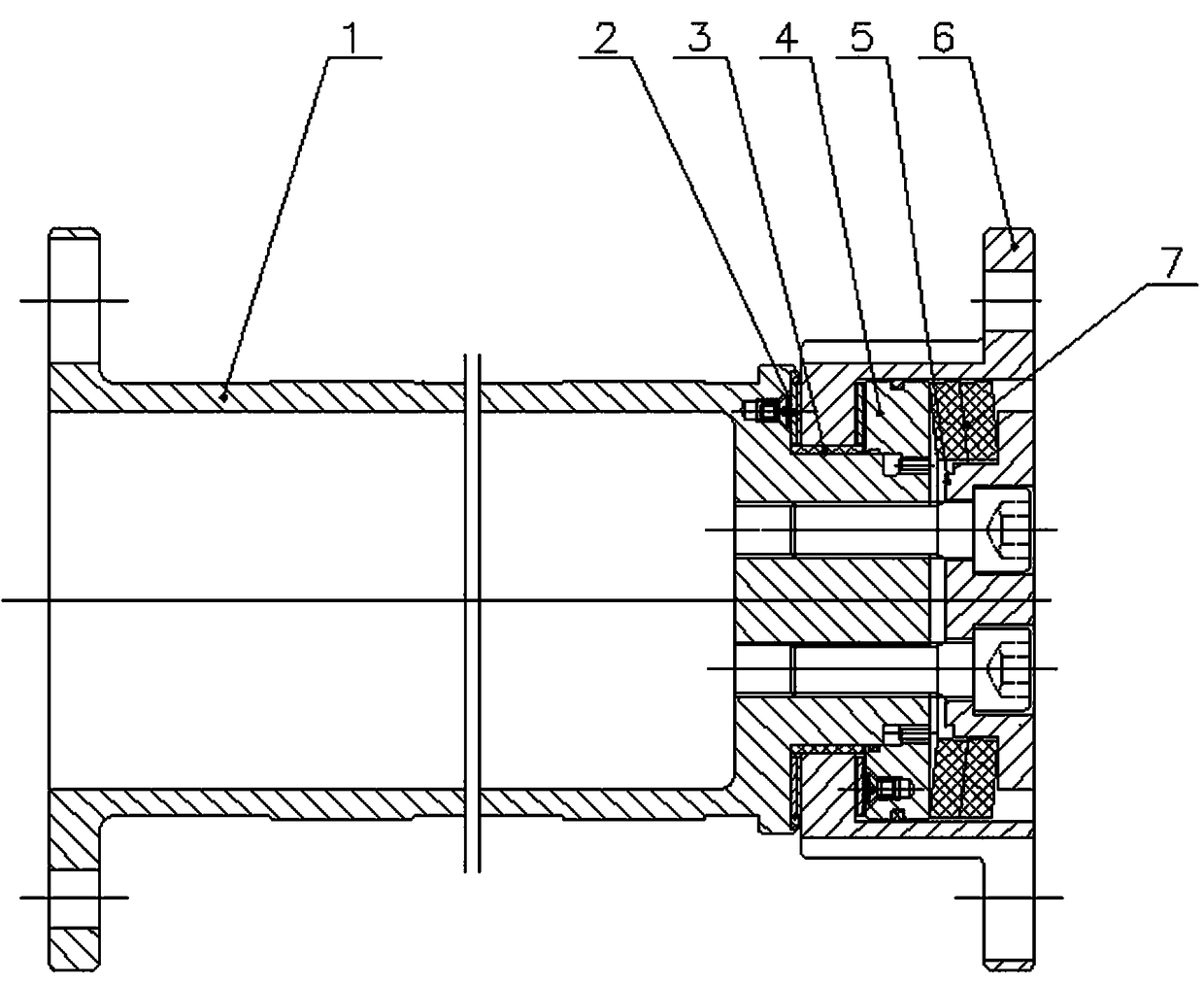

[0007] refer to figure 1 , a friction overtorsion protection structure, including a driving end flange 1, a friction plate 2, a copper sleeve 3, a pressure plate 4, a pressure plate 4, a driven end flange 6 and a disc spring 7, and one end of the driving flange 1 is covered with The pressing plate 4 is provided with a driven flange 6 between the pressing plate 4 and the driving flange 1, and the upper and lower end surfaces of the driven flange 6 are provided with friction plates 2, and the friction plates 2 are in contact with the driving flange 1, The inner side of the driven flange 6 is in contact with the active flange 1. A copper sleeve 3 is provided. The opposite end of the pressure plate 4 to the active flange 1 is connected to one end of the disc spring 7, and the other end of the disc spring 7 is connected to the pressure plate 5. .

[0008] The upper and lower surfaces of the driven end flange 6 are each equipped with a friction plate 2 to match with it. The driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com