A motor start control method, device and air conditioner

A technology of motor speed and start command, applied in mechanical equipment, high-efficiency regulation technology, climate sustainability, etc., can solve the problems of high fan speed, high noise, overshoot of duty cycle PG motor speed, etc., to achieve the duty cycle The effect of stable change, stable operation of the fan, and stable change without sudden change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

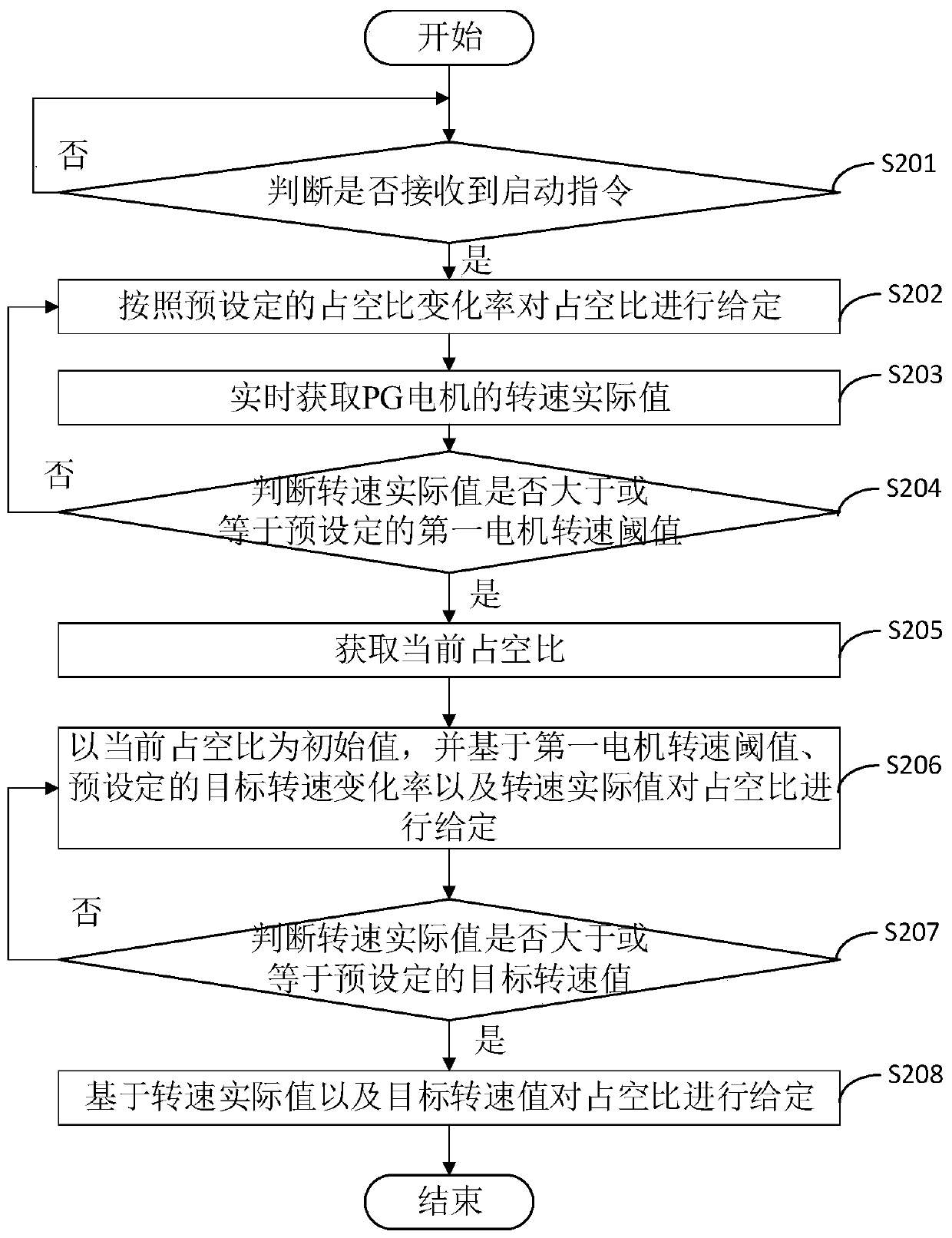

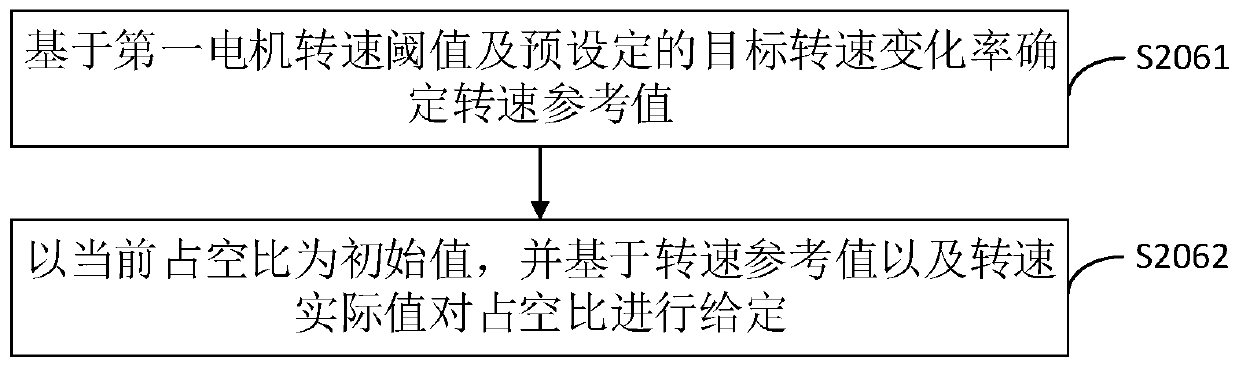

[0060] The embodiment of the present invention provides a motor start control method, which is used to ensure that the PG motor 5 can start smoothly. see figure 2 , is a flow chart of a method for controlling motor starting provided by an embodiment of the present invention. The motor starting control method includes:

[0061] Step S201, judging whether a startup instruction is received, if yes, execute step S202; if not, execute step S201 again.

[0062] It can be understood that when the user requires the fan 6 to run, the PG motor 5 will be run by inputting a start command to drive the fan 6 to run.

[0063] Step S202, setting the duty cycle according to the preset change rate of the duty cycle.

[0064] Specifically, the duty cycle is given based on the following formula:

[0065] θ = k 1 *t

[0066] Among them, θ is the duty cycle, k 1 is the preset duty ratio change rate, and t is the time.

[0067] Understandably, after receiving the start command, the PG motor...

no. 2 example

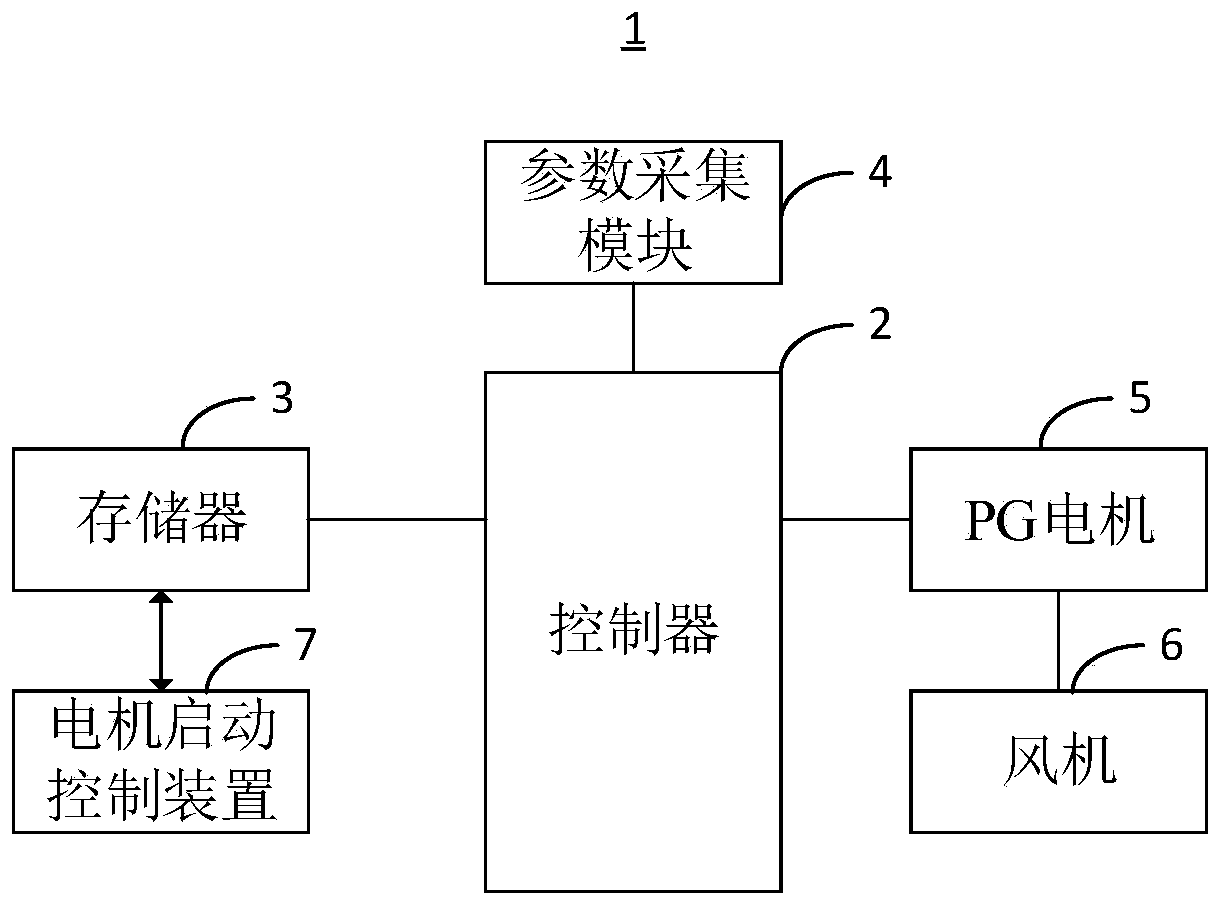

[0092] see Figure 5 , Figure 5A functional block diagram of a motor starting control device 7 provided by a preferred embodiment of the present invention. It should be noted that the basic principles and technical effects of the motor starting control device 7 provided in this embodiment are the same as those of the above-mentioned embodiment. corresponding content in the example. The motor start control device 7 includes a judging unit 8 , a duty ratio setting unit 9 and a parameter acquiring unit 10 .

[0093] Wherein, the judging unit 8 is used for judging whether a startup instruction is received.

[0094] It can be understood that, in an optional embodiment, the judging unit 8 may be configured to execute step S201.

[0095] The duty ratio setting unit 9 is used to set the duty ratio according to a preset duty ratio change rate when the PG motor 5 receives a starting instruction.

[0096] It can be understood that, in an optional embodiment, the duty ratio setting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com