A control performance monitoring method for boiler dynamic information of million-kilowatt ultra-supercritical units

An ultra-supercritical unit and dynamic information technology, applied in general control systems, control/regulation systems, test/monitoring control systems, etc., can solve problems such as inability to obtain monitoring effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

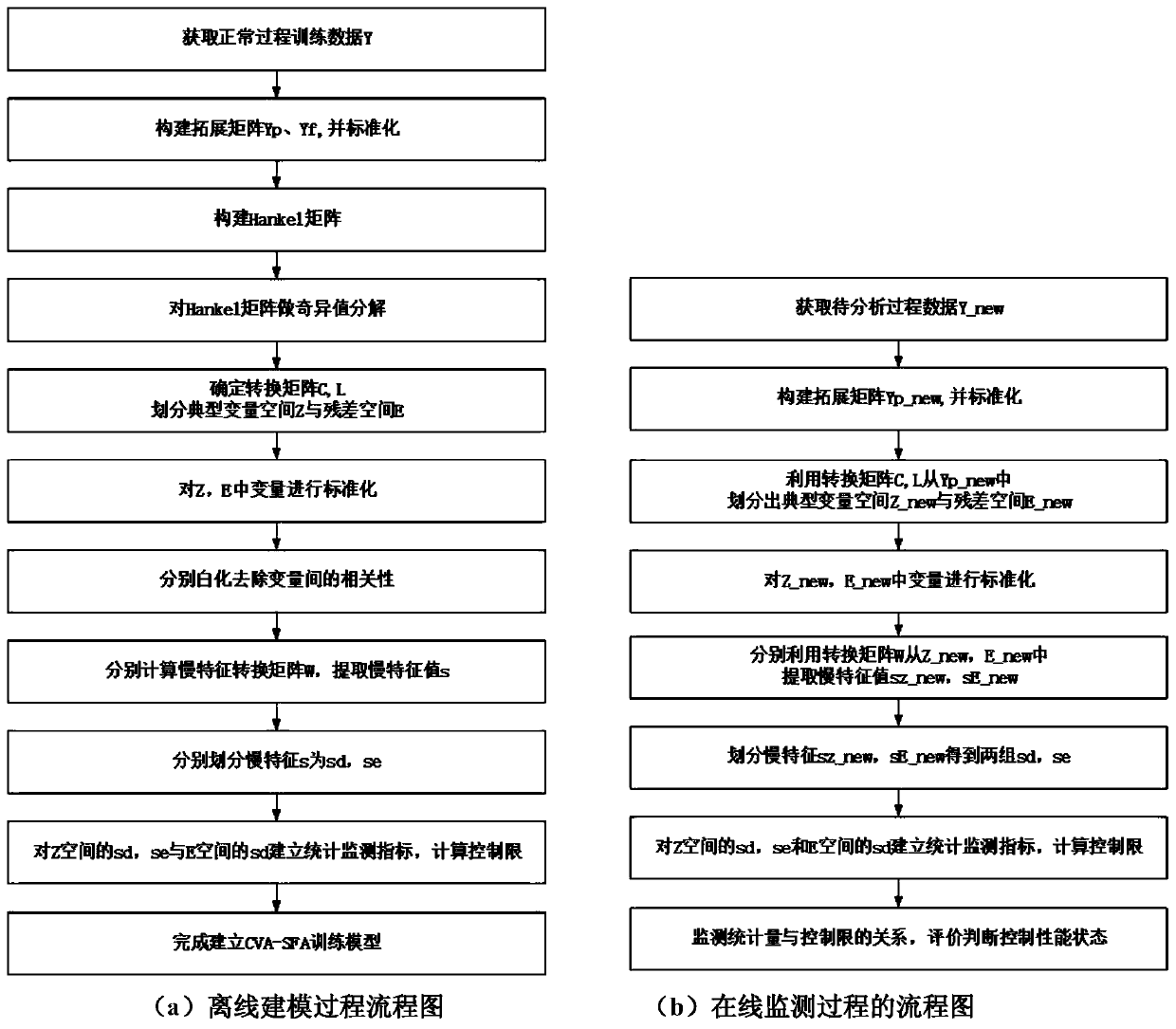

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples.

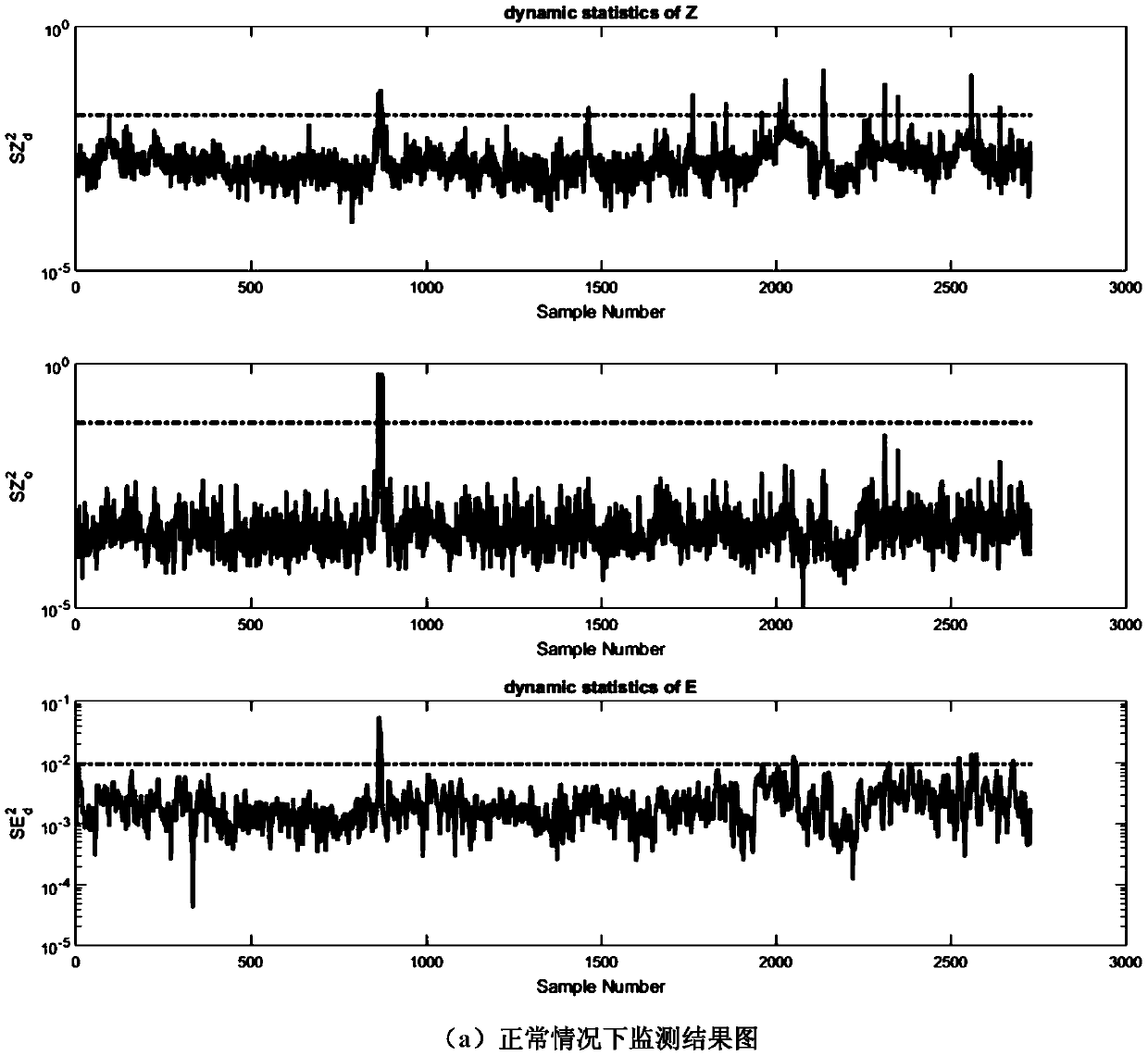

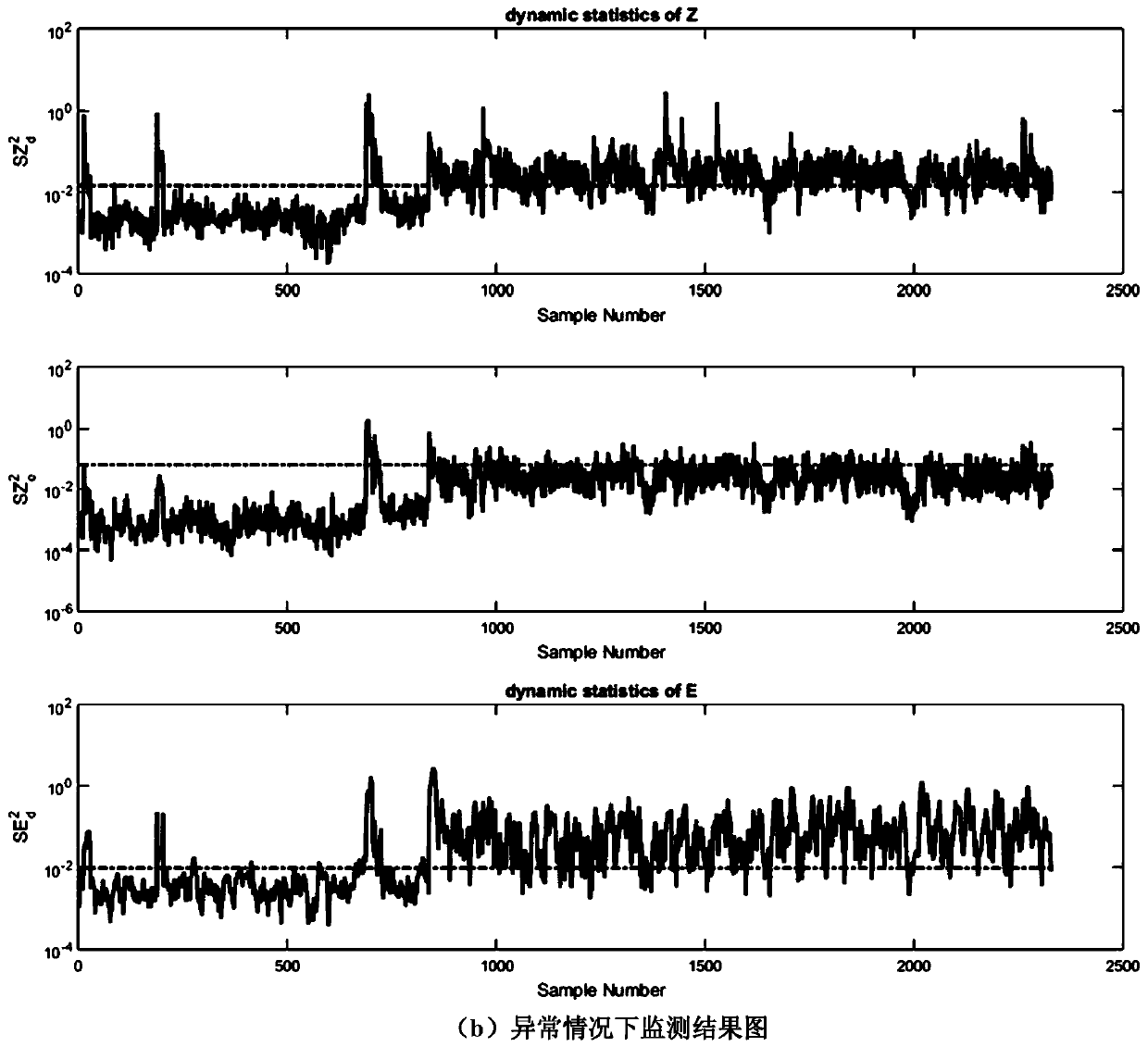

[0077]The present invention takes the No. 7 unit boiler of Jiahua Power Plant under Zheneng Group as an example. The unit has a power of 1 million kilowatts and belongs to a million-kilowatt ultra-supercritical unit. It includes 75 process variables, which are: main steam flow, main Steam outlet pressure, main steam outlet temperature, feed water pressure, feed water temperature, reheat steam flow, reheat steam outlet pressure, reheat steam outlet temperature, reheat steam inlet pressure, reheat steam inlet temperature, and some valve openings.

[0078] It should be understood that the present invention is not limited to the thermal power generation process of the above examples, and those skilled in the art can also make equivalent modifications or replacements without violating the present invention, and these equivalent modifications o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com