A filter milk bottle

A feeding bottle and filter foam technology, which is applied in the field of filter foam feeding bottles, can solve problems such as spitting up milk, flatulence, difficulty in removing the upper layer of foam, etc., and achieve the effect of avoiding flatulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

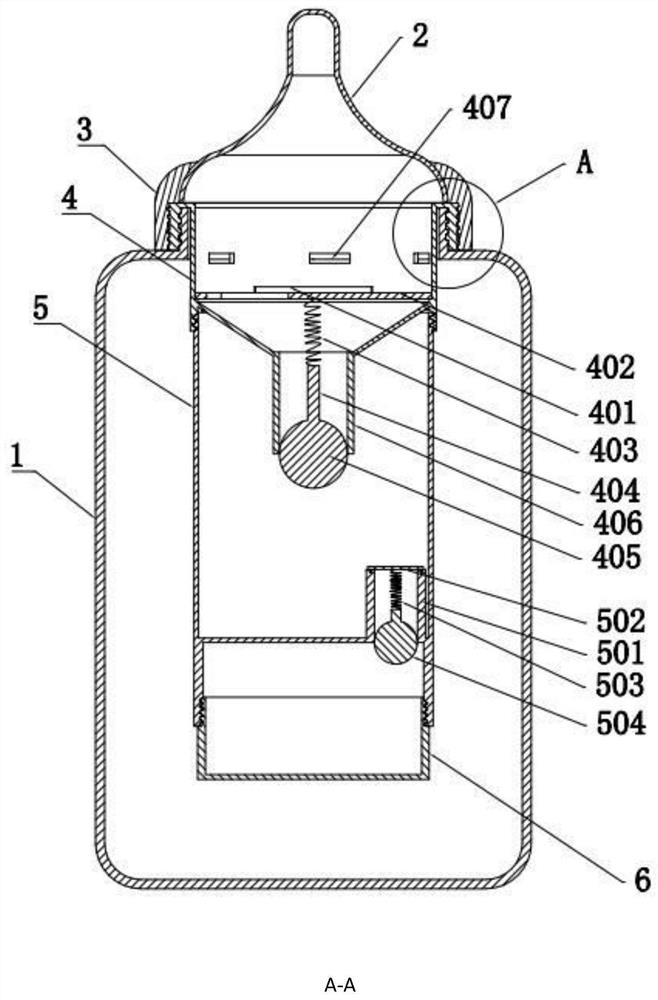

[0024] A filter foam feeding bottle, reference Figure 1-Figure 6 As shown, it includes a transparent bottle body 1, a pacifier 2, and a cover 3 that is socketed with the pacifier 2 and is sealed and fixed with the mouth of the bottle body 1. A filter mechanism is provided in the bottle body 1, and the filter mechanism includes from top to bottom. The liquid injection mechanism 4, the milk powder storage mechanism 5 and the filter mechanism 6 are detachably connected in sequence. The above-mentioned bottle body 1 is made of glass or plastic or silica gel, the nipple 2 is made of silica gel, and the filter foam mechanism is made of glass or plastic production.

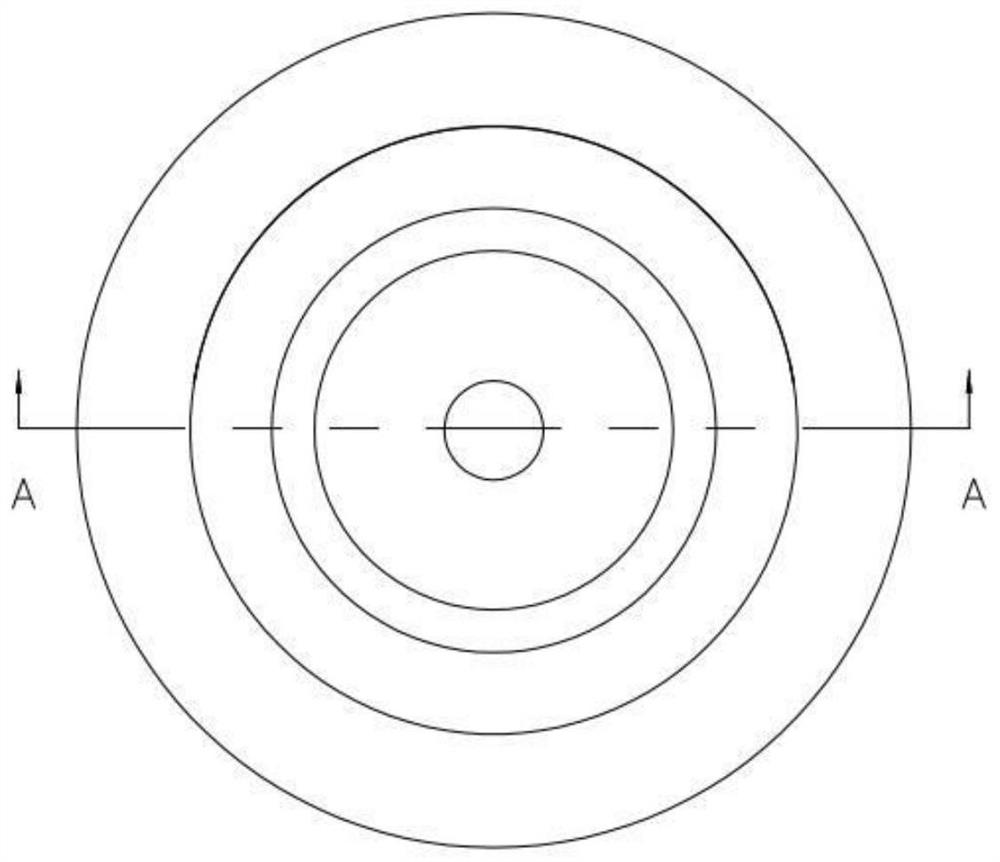

[0025] Wherein, the top of the liquid injection mechanism 4 is vertically folded outwards to have an inverted L-shaped hem 408, refer to Figure 3-Figure 4 As shown, the outer wall of the bottle mouth is rotationally threaded with the inner wall of the inverted L-shaped flange 408, and the inner wall of the sleeve cap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com