High-power lithium ion battery electrolyte

A lithium-ion battery, electrolyte technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the deterioration of lithium-ion battery rate performance, lithium-ion batteries can not be well used in the field of power batteries, cycle performance decline, etc. problems, to achieve excellent rate performance and cycle performance, prevent gas swelling, and improve the effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

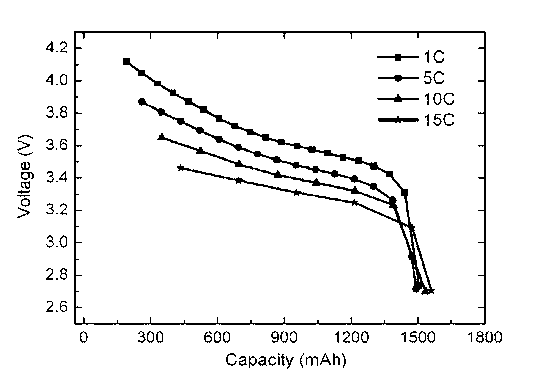

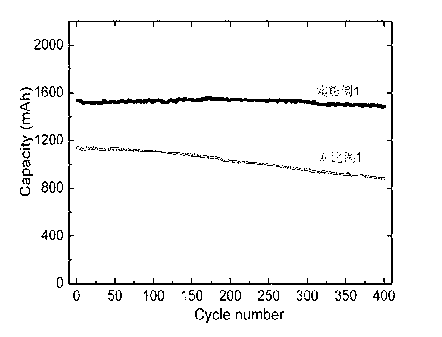

[0038] The composition of the electrolyte is as follows: based on the total mass of the organic solvent and additives as 100%, the mass fractions of non-aqueous organic solvents: ethylene carbonate, dimethyl carbonate, and propylene carbonate are: 25%, 18%, and 35% respectively , additives perfluorinated vinyl sulfite derivatives, ethylene carbonate, and cyclic carboxylate-butyrolactone mass fractions are: 11%, 3%, and 8%, respectively, and electrolyte salts are lithium hexafluorophosphate and difluorooxalate boric acid The mass fractions of lithium are 60% and 40%, respectively, and the molar concentration in the electrolyte is 1 mol / L. Add this electrolyte to make 18650 battery. Test the electrical properties of the battery at 1 C, 5 C, 10 C and 15 C rates. The cut-off capacities are 1456 mAh, 1404 mAh, 1447 mAh and 1473 mAh respectively. See figure 1 ; Among them, at 10 C rate, the capacity after 400 cycles is 1398 mAh, and the capacity retention rate is 96%, see figure 2...

Embodiment 2

[0040]The composition of the electrolyte is as follows: based on the total mass of the organic solvent and additives as 100%, the mass fractions of non-aqueous organic solvents: ethylene carbonate, dimethyl carbonate, and propylene carbonate are: 28%, 16%, and 34% respectively , the mass fractions of additives perfluorinated vinyl sulfite derivatives, ethylene carbonate, and cyclic carboxylate-butyrolactone are 9%, 6%, and 7%, respectively, and the electrolyte salts are lithium hexafluorophosphate and lithium diacetate borate , the mass fractions are 70% and 30% respectively, and the molar concentration in the electrolyte is 1 mol / L. Add the electrolyte to make a 18650 battery and test the battery at 1 C, 5 C, 10 C and 15 C. Electrical properties, the cut-off capacities are 1463 mAh, 1402 mAh, 1441 mAh and 1469 mAh respectively; under 10 C rate, the capacity of 400 cycles remains at 1396 mAh, and the capacity retention rate is 95%.

Embodiment 3

[0042] The composition of the electrolyte is as follows: based on the total mass of organic solvent and additives as 100%, the mass fractions of non-aqueous organic solvents: ethylene carbonate, dimethyl carbonate, and propylene carbonate are: 15%, 5%, and 30% respectively , the mass fractions of additives perfluorinated vinyl sulfite derivatives, ethylene carbonate, and cyclic carboxylate-butyrolactone are 20%, 7.5%, and 22.5%, respectively, and the electrolyte salts are lithium hexafluorophosphate and difluorooxalate boric acid The mixture of lithium and lithium diacetate borate, the mass fractions are 90%, 5%, and 5%, respectively, and the molar concentration in the electrolyte is 0.6mol / L. Add this electrolyte to make a 18650 battery. Test the battery at 1 C, The electrical properties at 5 C, 10 C and 15 C rates, the cut-off capacities are 1430 mAh, 1371 mAh, 1350 mAh and 1326 mAh respectively; at 10 C rate, the 400-cycle capacity remains at 1293 mAh, and the capacity reten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com