Steel bending processing method

A technology of bending processing and section steel, which is applied in metal processing equipment, manufacturing tools, storage devices, etc., can solve the problems of uncontrollable deformation of section steel and uneven force, and achieve the effect of ensuring the quality of section steel, high pass rate and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

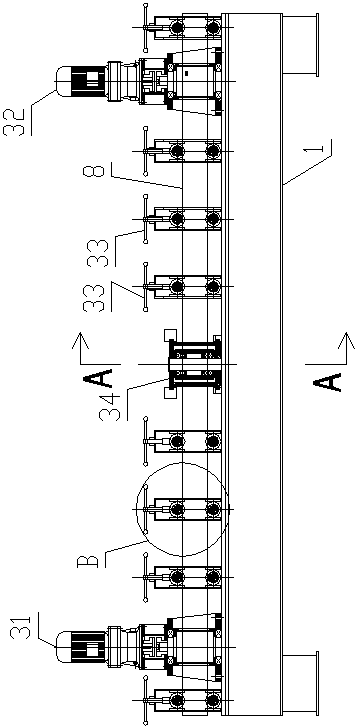

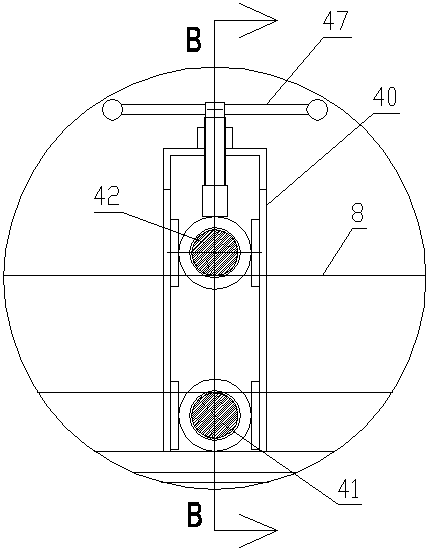

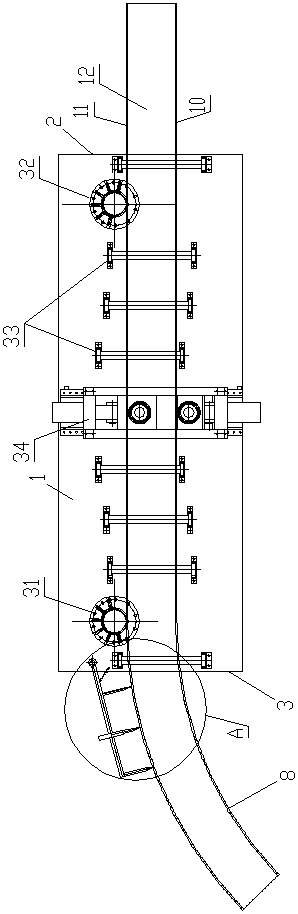

[0048] like Figure 1 to Figure 8 As shown, the present invention provides a method for bending a section steel, which is carried out by a top-pull section steel bending machine; the section steel 8 (I-beam or H-beam) includes a front end plate 10, a rear end plate 11 and a front end plate 11, which are oppositely arranged. 10 and the middle plate 12 between the rear end plate 11; the top-pull type steel bending machine of the present invention includes a section steel limit conveying mechanism, a section steel bidirectional synchronous bending device and a bending degree measuring device;

[0049] The section steel limit conveying mechanism includes a workbench 1, the right end of the workbench 1 is the loading end 2 of the section steel 8, and the left end of the workbench 1 is the unloading end 3 of the section steel 8;

[0050] The left end of the worktable 1 is provided with a left driving device 31 for driving the profiled steel 8, and the right end of the worktable 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com