Orthotropic steel bridge deck slab structure

A steel bridge deck, orthotropic technology, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of steel bridge deck pavement damage, steel bridge deck fatigue cracking, etc., to improve fatigue resistance and manufacturing requirements Low, easy to industrialize the effect of manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

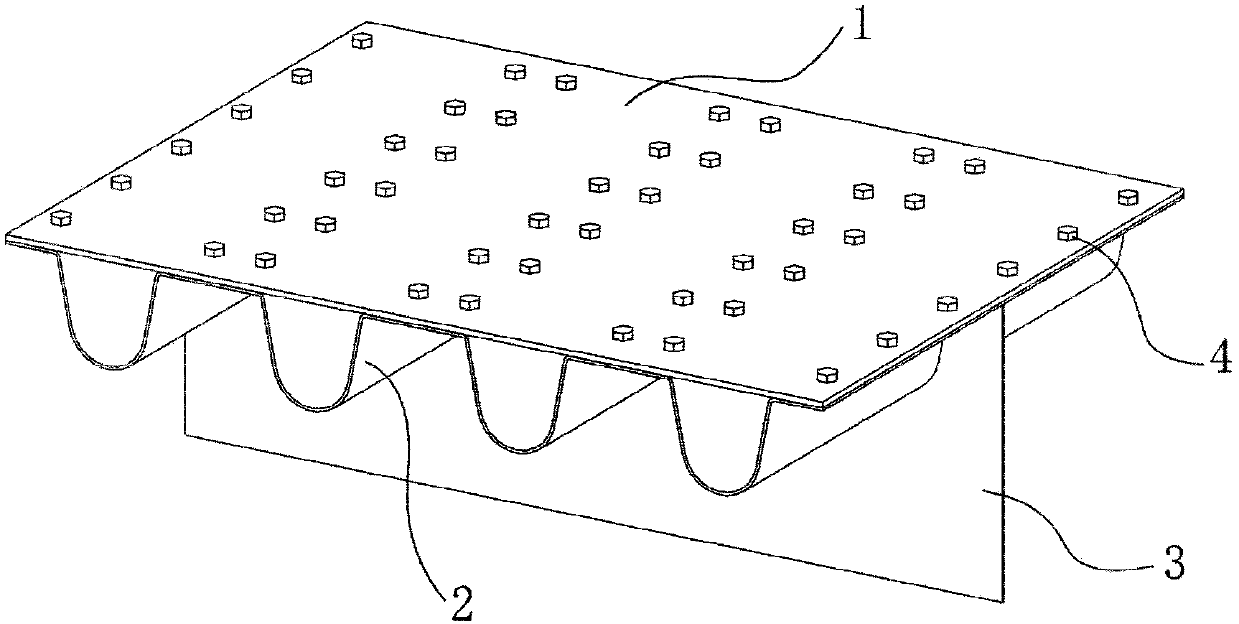

[0033] An orthotropic steel bridge deck structure includes a roof 1 , a continuous multi-U plate 2 and a transverse diaphragm 3 .

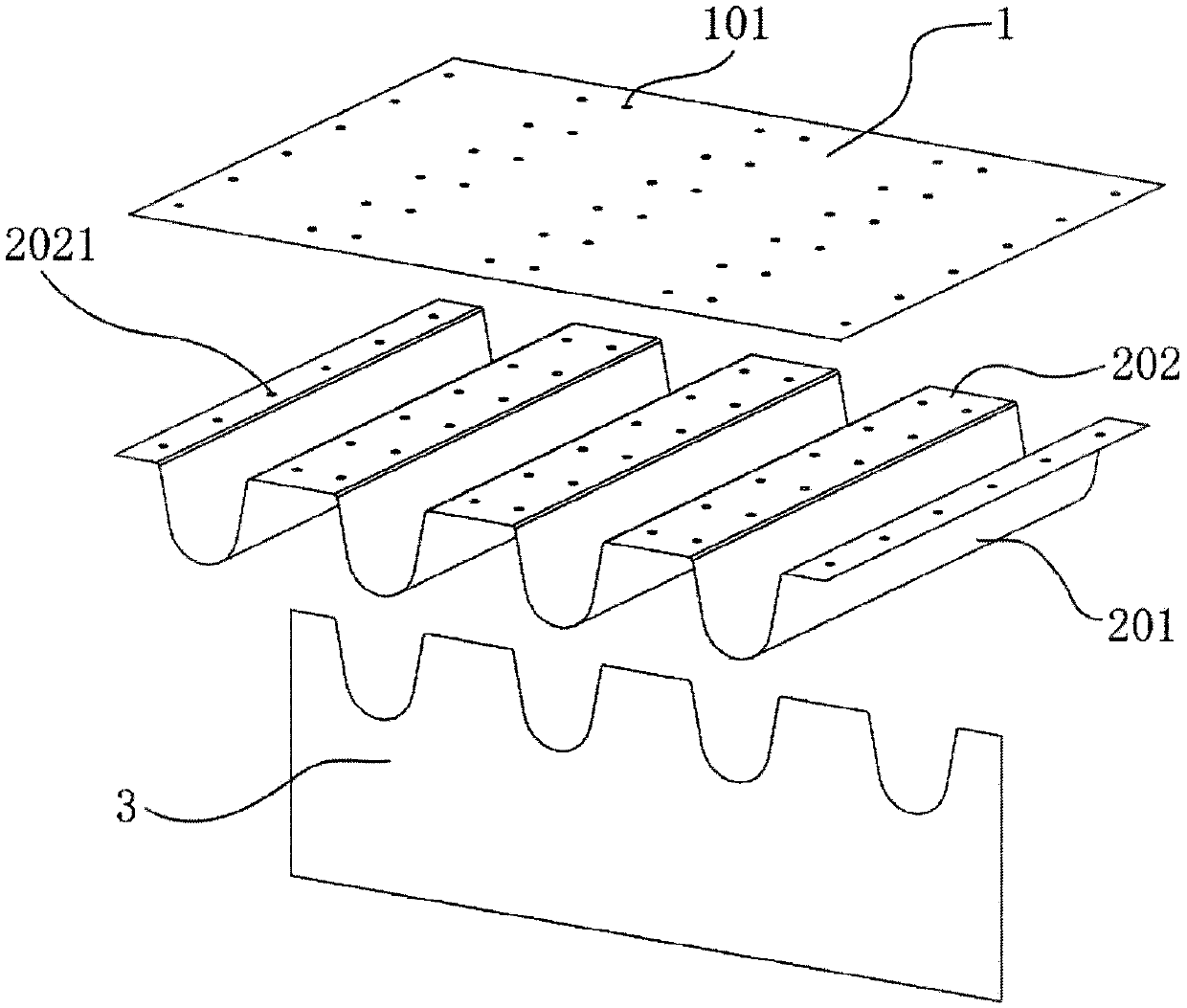

[0034] see image 3 , the top plate 1 and the diaphragm 3 are straight steel plates. The continuous multi-U plate 2 is a corrugated steel plate. The top plate 1, the continuous multi-U plate 2 and the transverse partition plate 3 have a uniform thickness.

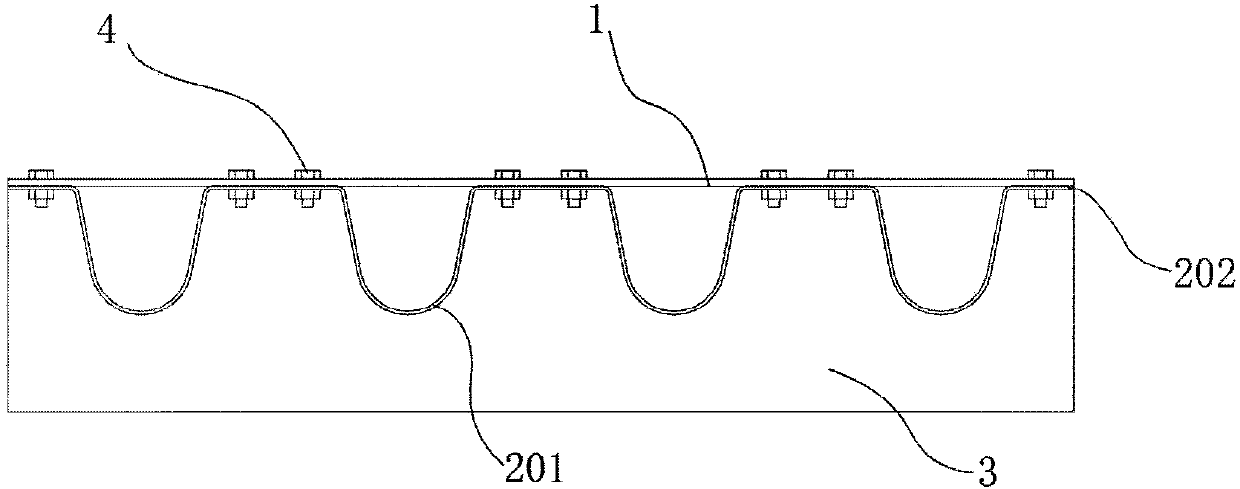

[0035] see figure 2 , the continuous multi-U plate 2 goes upward along the transverse bridge, and has U-shaped sections 201 and straight sections 202 appearing at intervals. The wave sections of the continuous multi-U plates 2 are U-shaped connected one by one.

[0036] see figure 1 , the continuous multi-U board 2 is arranged under the top board 1 . The straight section 202 of the continuous multi-U board 2 is in contact with the top board 1 . The continuous multi-U board 2 and the top board 1 are connected together by a plurality of high-strength bolts 4 . Each straight section 202 i...

Embodiment 2

[0040] An orthotropic steel bridge deck structure includes a top plate 1, a continuous multi-U plate 2 and three transverse diaphragms 3.

[0041] The top plate 1 and the transverse partition plate 3 are straight steel plates. The continuous multi-U plate 2 is a corrugated steel plate. The top plate 1, the continuous multi-U plate 2 and the transverse partition plate 3 have a uniform thickness.

[0042] The continuous multi-U plate 2 goes upward along the horizontal bridge, and has U-shaped sections 201 and straight sections 202 that appear at intervals. The wave sections of the continuous multi-U plates 2 are U-shaped connected one by one.

[0043] The continuous multi-U board 2 is arranged under the top board 1 . The straight section 202 of the continuous multi-U board 2 is in contact with the top board 1 . The continuous multi-U board 2 and the top board 1 are connected together by a plurality of high-strength bolts 4 . Each straight section 202 is provided with a bolt...

Embodiment 3

[0047] This embodiment discloses a construction method for any orthotropic steel deck structure described in Embodiment 1 or 2, comprising the following steps:

[0048] 1) The factory makes the top plate 1 and the continuous multi-U plate 2.

[0049] 2) Bolt hole I101 and bolt hole II2021 are prefabricated in the factory.

[0050] 3) The roof 1 and the continuous multi-U board 2 are bolted in the factory or on the construction site.

[0051] 4) Weld the top plate 1, the continuous multi-U plate 2 and the diaphragm 3 in the factory or on the construction site.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com