Automatic feeding device for plastic processing

An automatic feeding and plastic technology, applied in the field of plastic processing, can solve the problems of high price, high labor intensity, complex mechanism, etc., and achieve the effect of low cost, simple structure and convenient discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

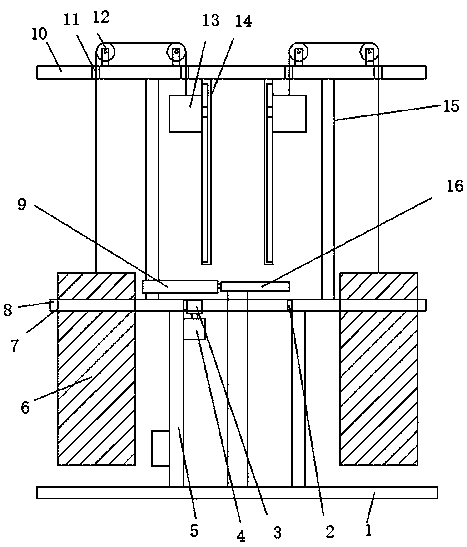

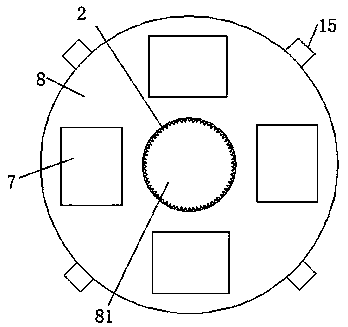

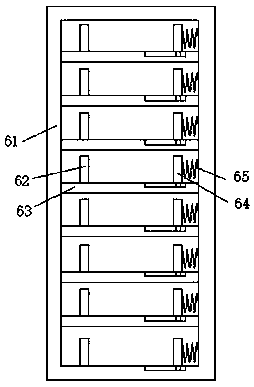

[0029] Embodiment: When in use, place the plastic sheet to be processed in the placing frame 61, clamp and fix it under the action of the spring 65 through the fixing plate 62 and the clamping plate 64, and place the frame 61 at the lowest end , the controller controls the telescopic column 16 on the pusher mechanism to drive the pusher plate 9 to push out a plastic sheet placed in the frame 61 for feeding. After one feeding is completed, the telescopic column 16 drives the pusher plate 9 to return to the original position , the weight of the placement mechanism is reduced. Driven by the counterweight box 13, the counterweight box 13 drives the position of the placement mechanism 6 through the connecting rope to lift a certain distance, so that the next storage chamber moves upwards to the relative position of the pushing mechanism, and the timer controls the control. The device regularly sends instructions, and the controller controls the telescopic column 16 on the pushing me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com