Winch device

A winch and installation position technology, applied in the field of construction machinery, can solve problems such as complex structure, reduced reliability, and inability to meet diverse functional requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

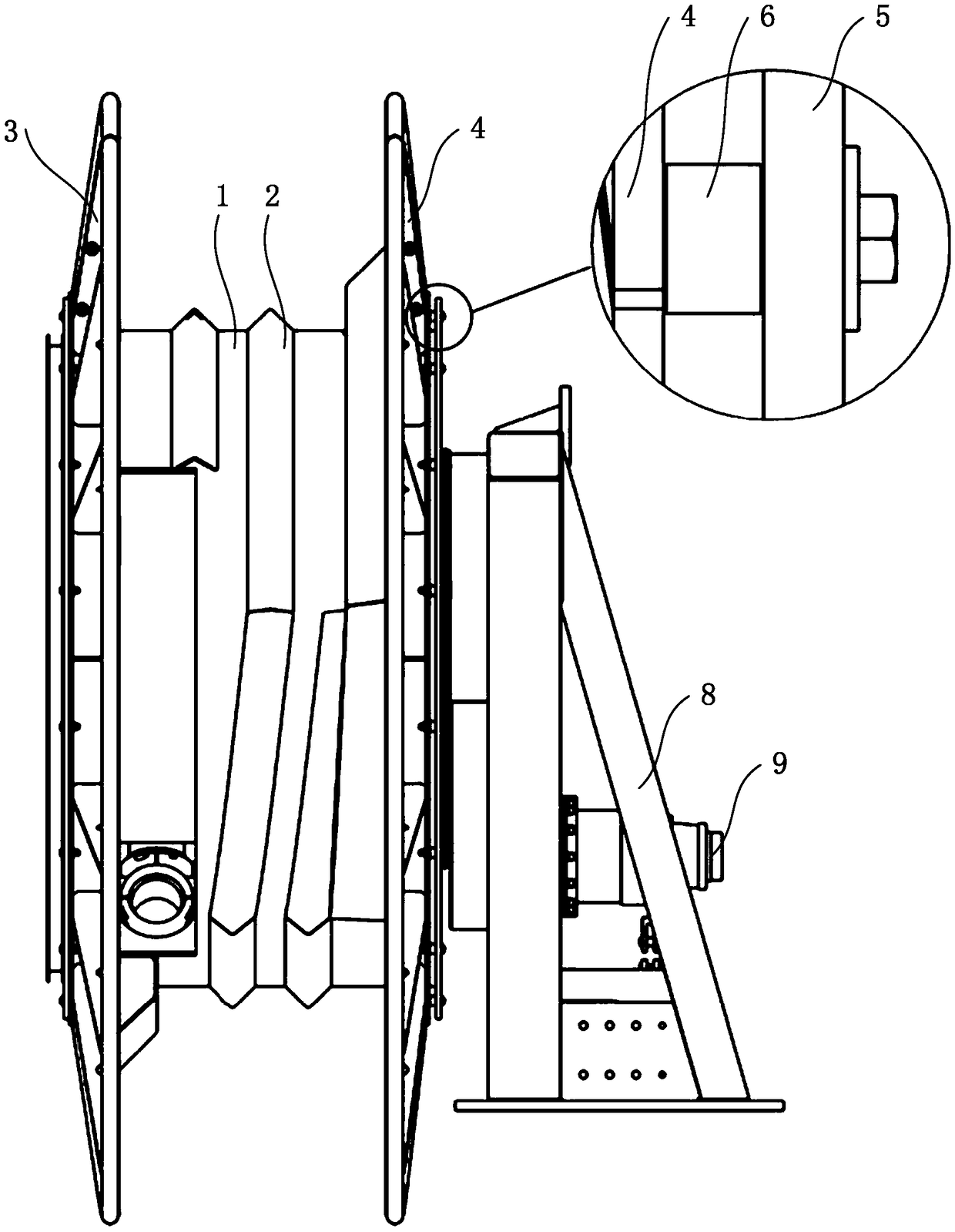

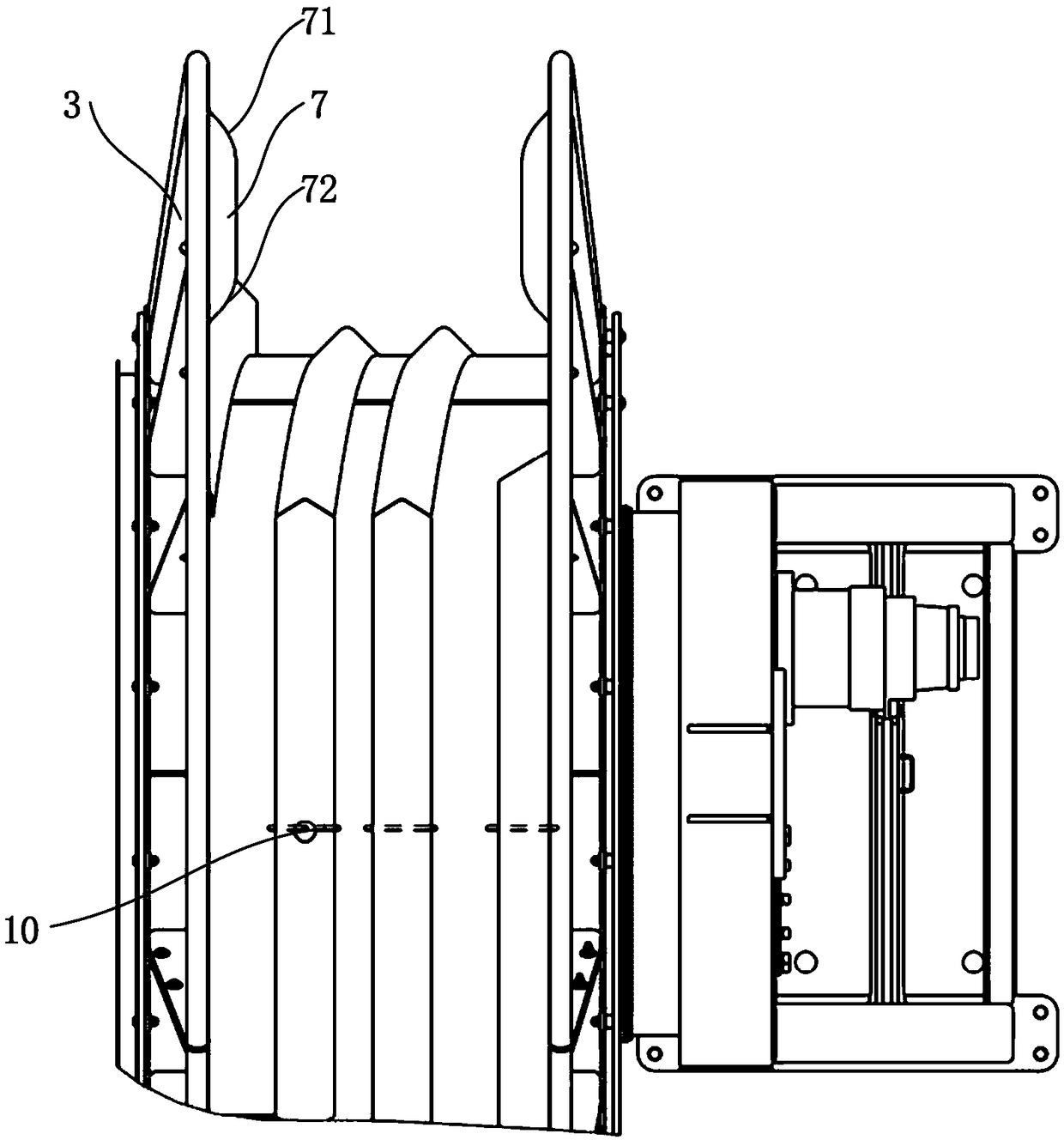

[0040] Combine below Figure 1 ~ Figure 2 The technical solution provided by the present invention is described in more detail.

[0041] see figure 1 with figure 2 , the embodiment of the present invention provides a winch device for winding and releasing the hose. The winch device includes a reel 1 and a guide assembly 2 . The guide assembly 2 is installed on the reel 1 , and the guide assembly 2 is configured to form a width-adjustable installation groove on the surface of the reel 1 .

[0042] For example, the width of the guide assembly 2 itself is adjustable, so that the width of the formed installation groove can be adjusted. Alternatively, the installation position of the guide assembly 2 can be adjusted, so that the width of the formed installation groove can be adjusted. The guide assembly 2 includes, for example, a bent guide section, which is, for example, in an inverted V shape as viewed from a cross-sectional view. The guide assembly 2 either adopts a strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com