Active radial magnetic bearing with a yoke coil

A magnetic bearing and radially protruding technology, applied in the field of radial magnetic bearings, can solve the problems of low force density and disadvantages, and achieve the effect of increased force density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

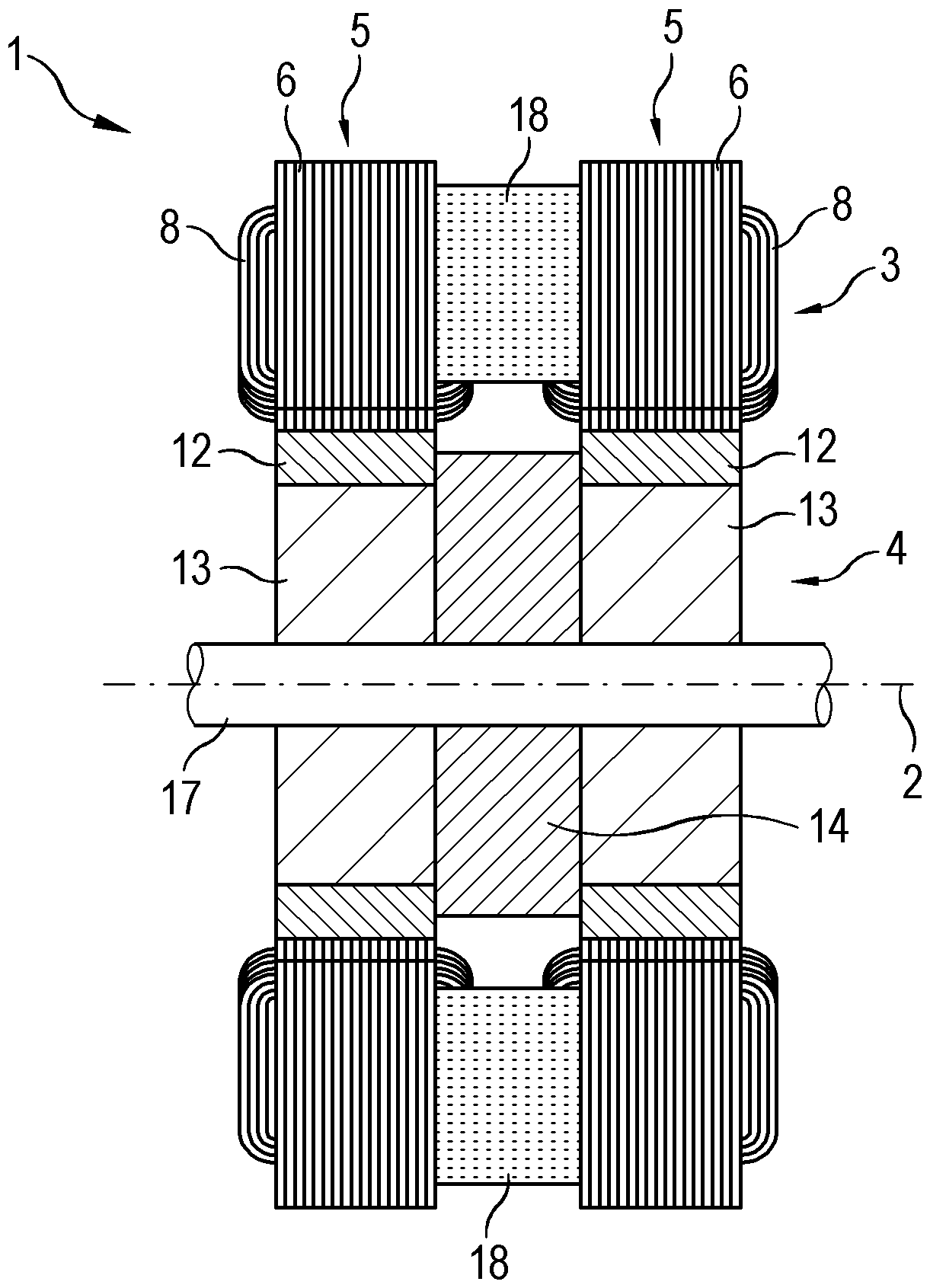

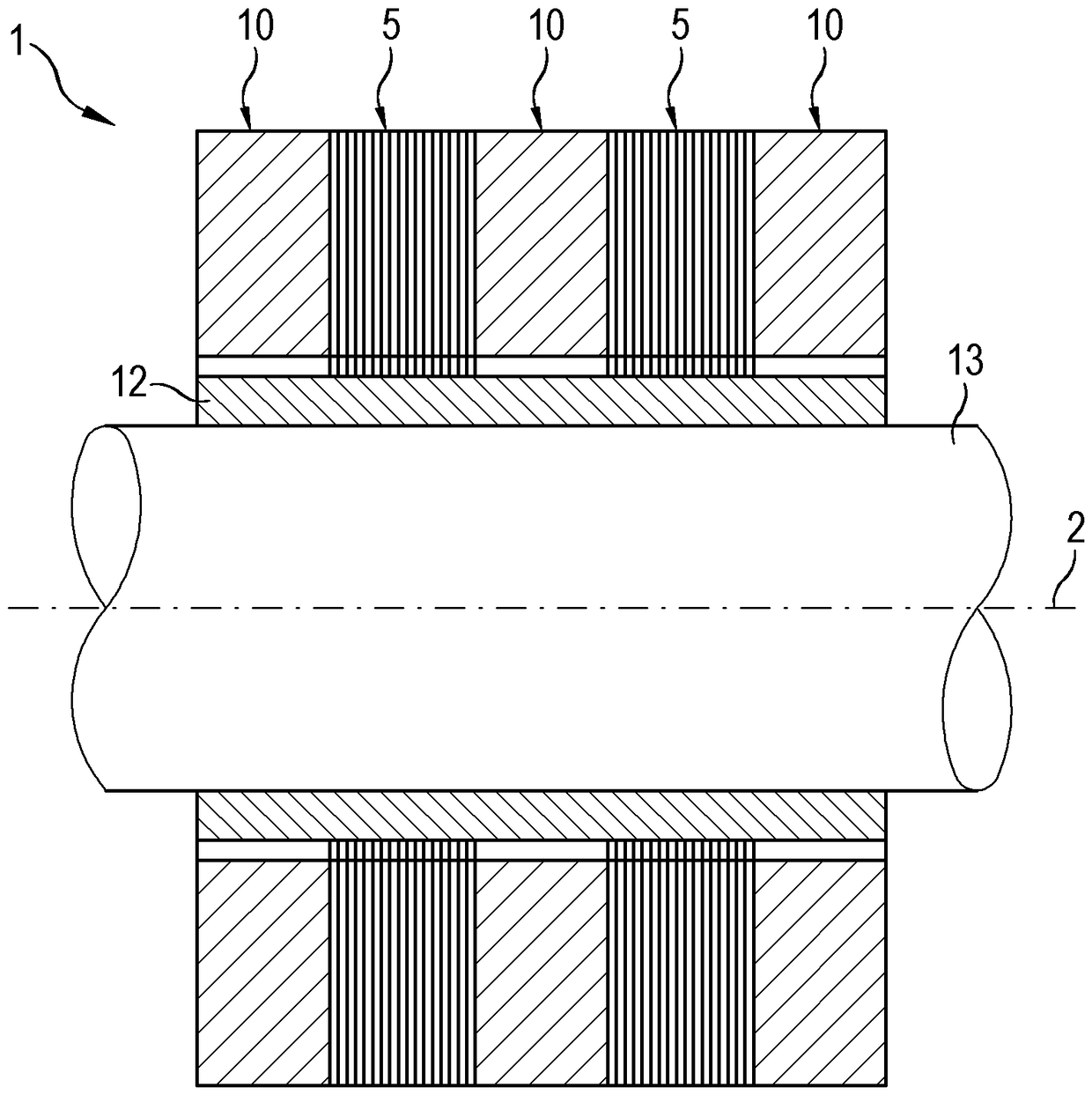

[0035] The same components are denoted by the same reference numerals for the following embodiments. If a figure contains a reference number which is not discussed in more detail in the relevant figure description, reference is made to the preceding or following figure description.

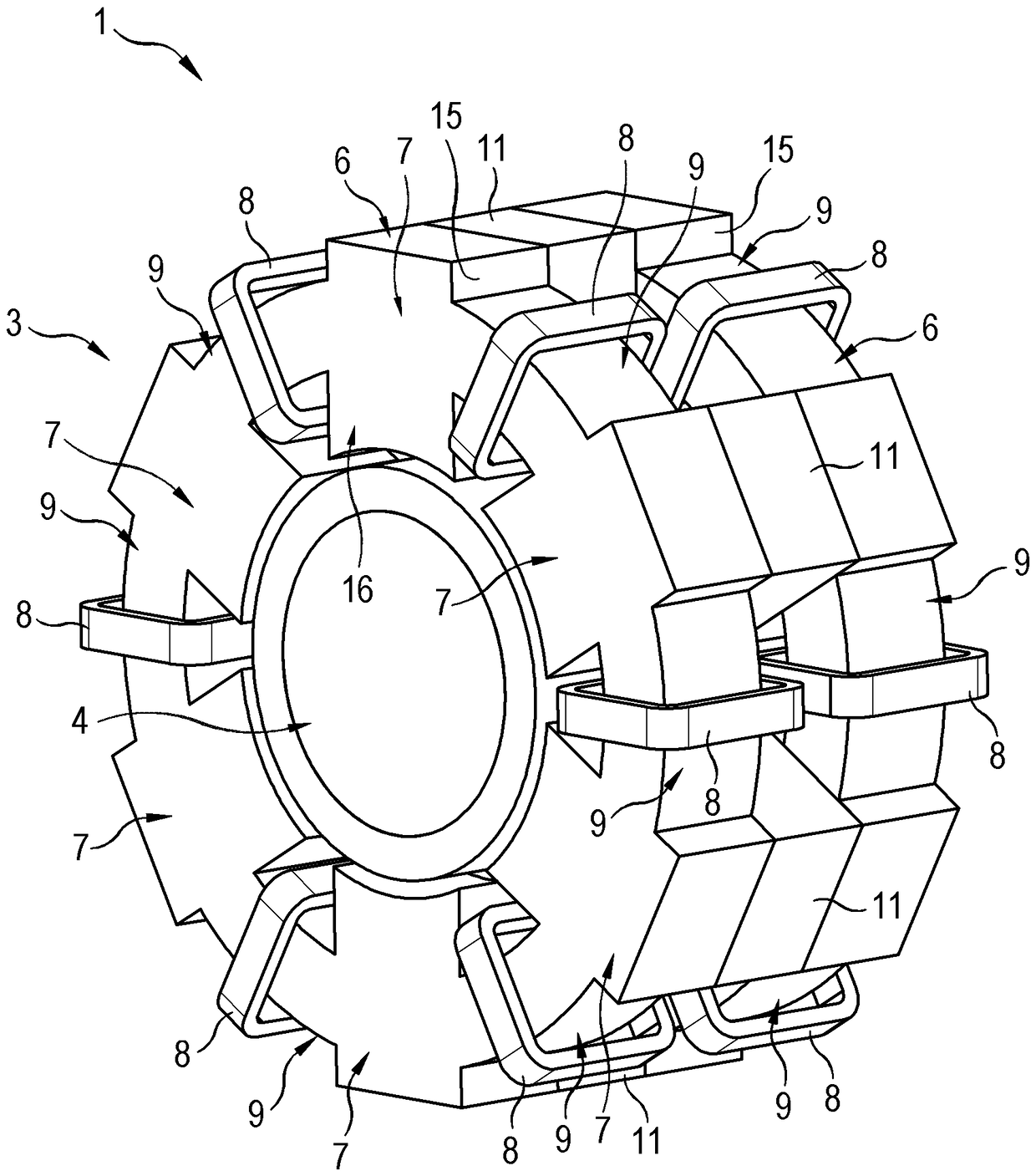

[0036] Figure 1 to Figure 3 A first embodiment of a radial magnetic bearing 1 according to the invention is shown. The magnetic bearing comprises an outer stator 3 and an inner rotor 4 . The stator 3 and the rotor 4 are arranged coaxially with each other. They are therefore both constructed substantially rotationally symmetrically about the common axis 2 of the magnetic bearings.

[0037]as in figure 2 As particularly shown in , the stator 3 includes two stator assemblies 5 spaced apart from each other in the axial direction. Each of the two stator assemblies 5 includes a soft magnetic core 6 . In the illustrated embodiment, the soft magnetic cores are each configured as a soft magnetic la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com