Cylindrical linear motor

A technology of linear motors and cylinders, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of not being placed on the side of the motor at the same time, permanent magnets and permanent magnets demagnetization, etc., to achieve high reliability and prevent permanent magnets Effect of loss of magnetization and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

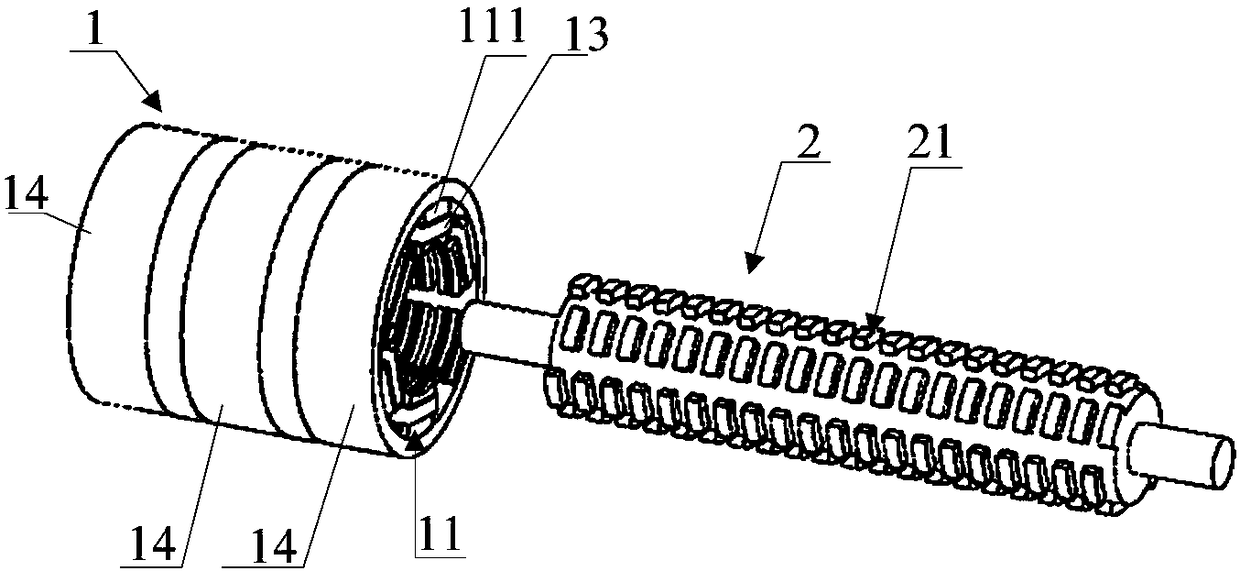

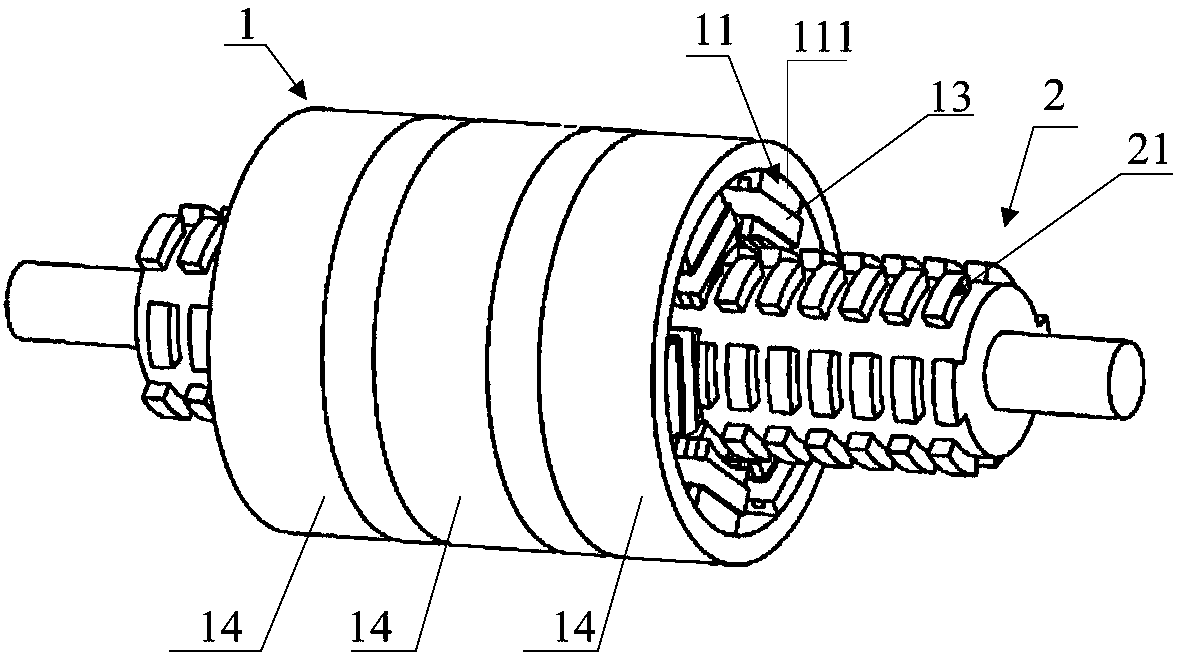

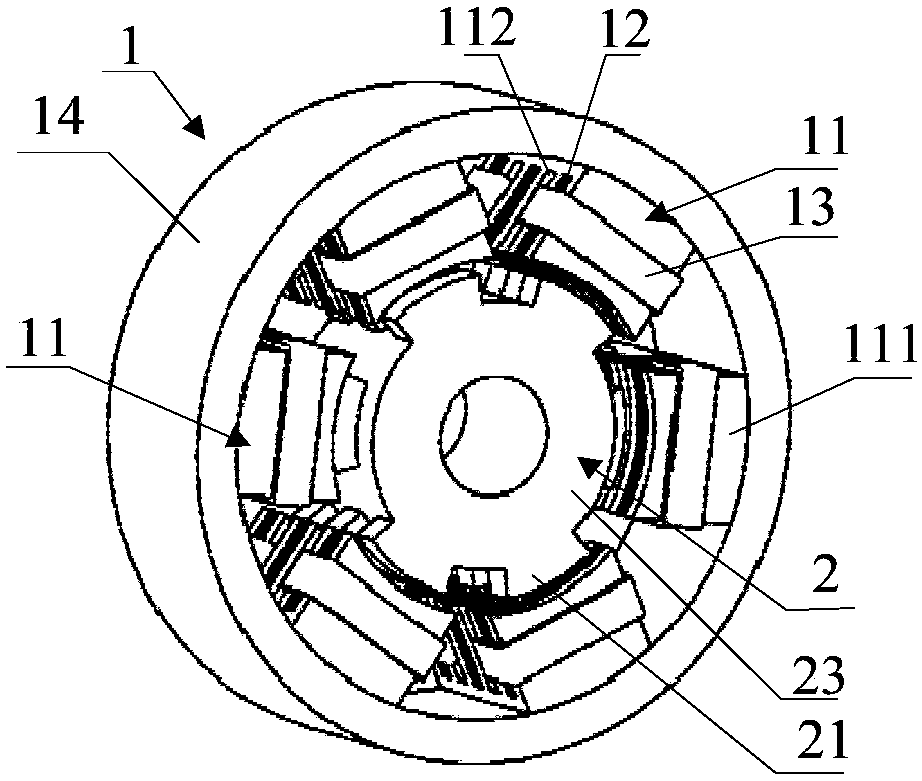

[0060] Such as Figure 1 to Figure 17 as shown, figure 1 One of the schematic structural block diagrams of the linear motor provided by the embodiment of the present invention; figure 2 The second schematic structural block diagram of the linear motor provided by the embodiment of the present invention; image 3 The third schematic structural block diagram of the linear motor provided by the embodiment of the present invention; Figure 4 The fourth schematic structural block diagram of the linear motor provided by the embodiment of the present invention; Figure 5 The fifth schematic structural block diagram of the linear motor provided by the embodiment of the present invention; Figure 6 The sixth schematic structural block diagram of the linear motor provided by the embodiment of the present invention; Figure 7 The seventh schematic structural block diagram of the linear motor provided by the embodiment of the present invention; Figure 25 It is the eighth schematic ...

Embodiment 2

[0097] Such as Figure 18 to Figure 30 as shown, Figure 18 It is one of the schematic structural block diagrams of the linear motor according to the second embodiment of the present invention. Figure 19 It is the second schematic structural block diagram of the linear motor according to the second embodiment of the present invention. Figure 20 It is the third schematic structural block diagram of the linear motor according to the second embodiment of the present invention. Figure 21 It is the fourth schematic structural block diagram of the linear motor according to the second embodiment of the present invention. Figure 22 It is the fifth schematic structural block diagram of the linear motor according to the second embodiment of the present invention. Figure 23 It is the sixth schematic structural block diagram of the linear motor according to the second embodiment of the present invention. Figure 24 It is the seventh schematic structural block diagram of the linea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com