Linear motor

A linear motor and excitation technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problem of limiting the force density of linear motors, achieve the effect of compact structure, small size, and enhanced driving ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

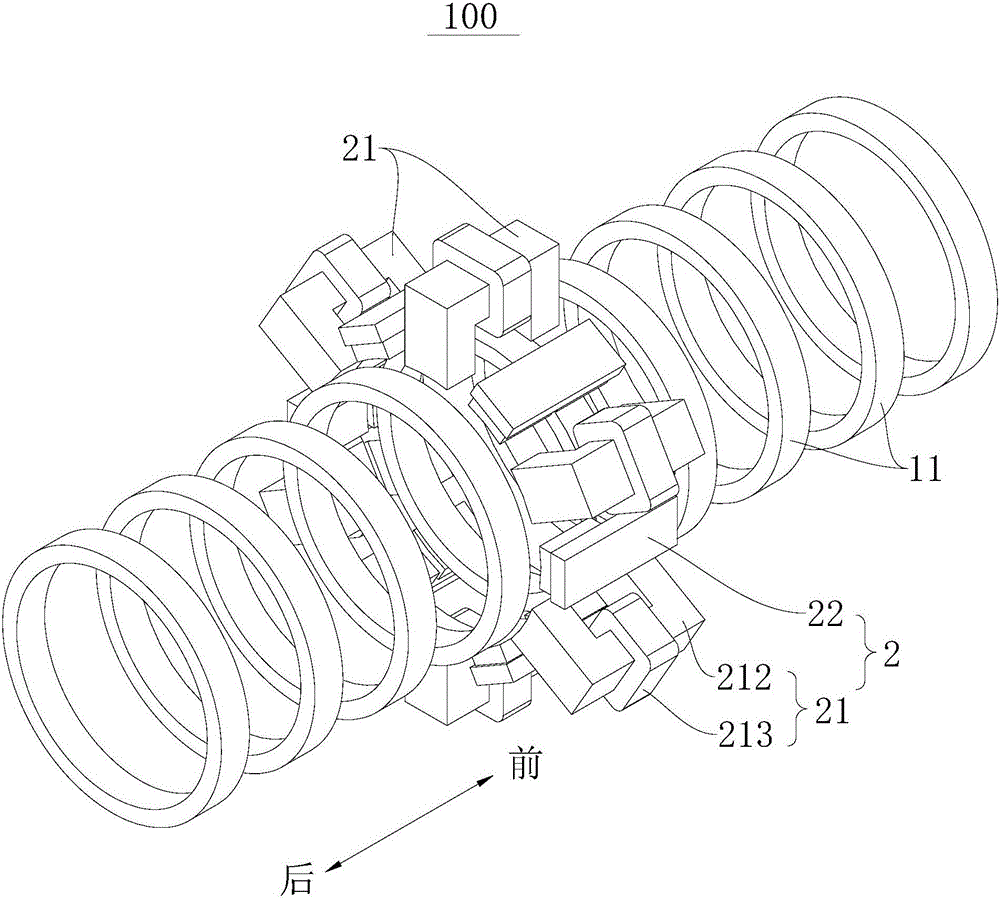

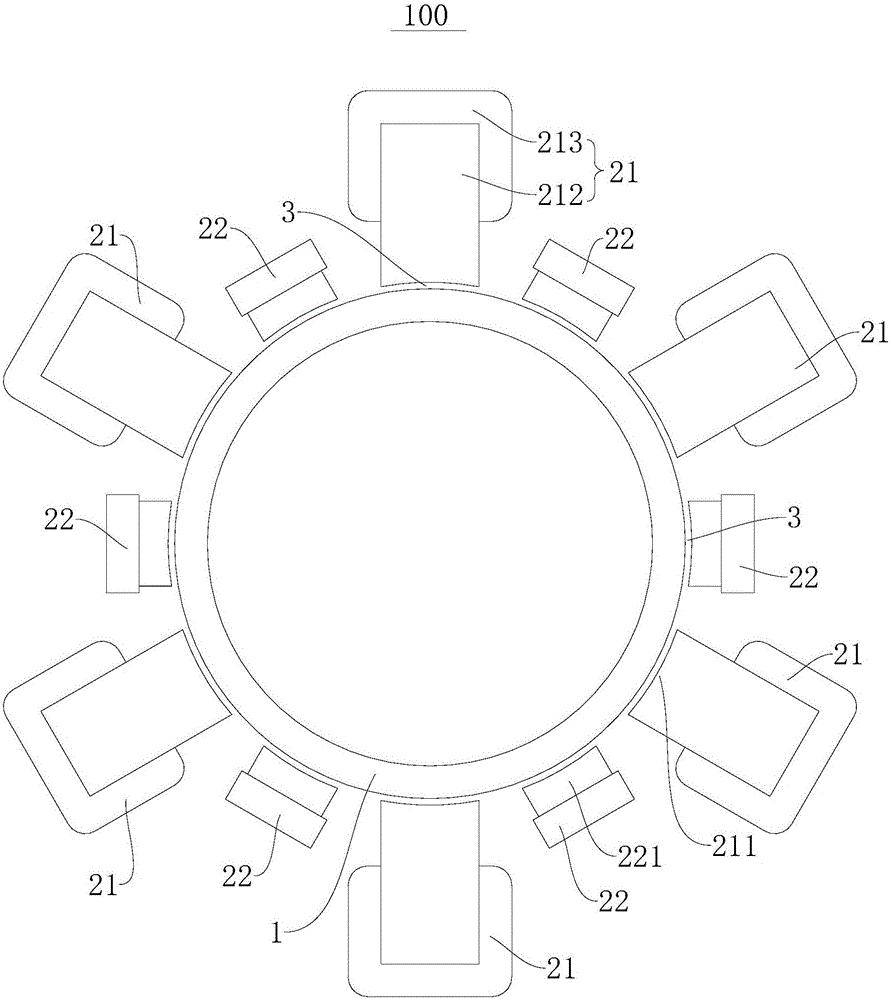

[0064] refer to figure 1 , the linear motor 100 includes a motor primary 2 and a motor secondary 1, wherein the motor primary 2 and the motor secondary 1 are spaced apart to form an air gap 3, and the motor primary 2 includes a plurality of winding excitation sides 21 and a plurality of permanent magnet excitation Side 22 , the motor secondary 1 comprises a reluctance side comprising a reluctance core 11 and a fixing plate.

[0065] Specifically, the reluctance side is composed of a reluctance iron core 11 made of a high magnetic permeability material and a fixing plate made of a non-magnetic material. arrangement, and the reluctance iron core is circular.

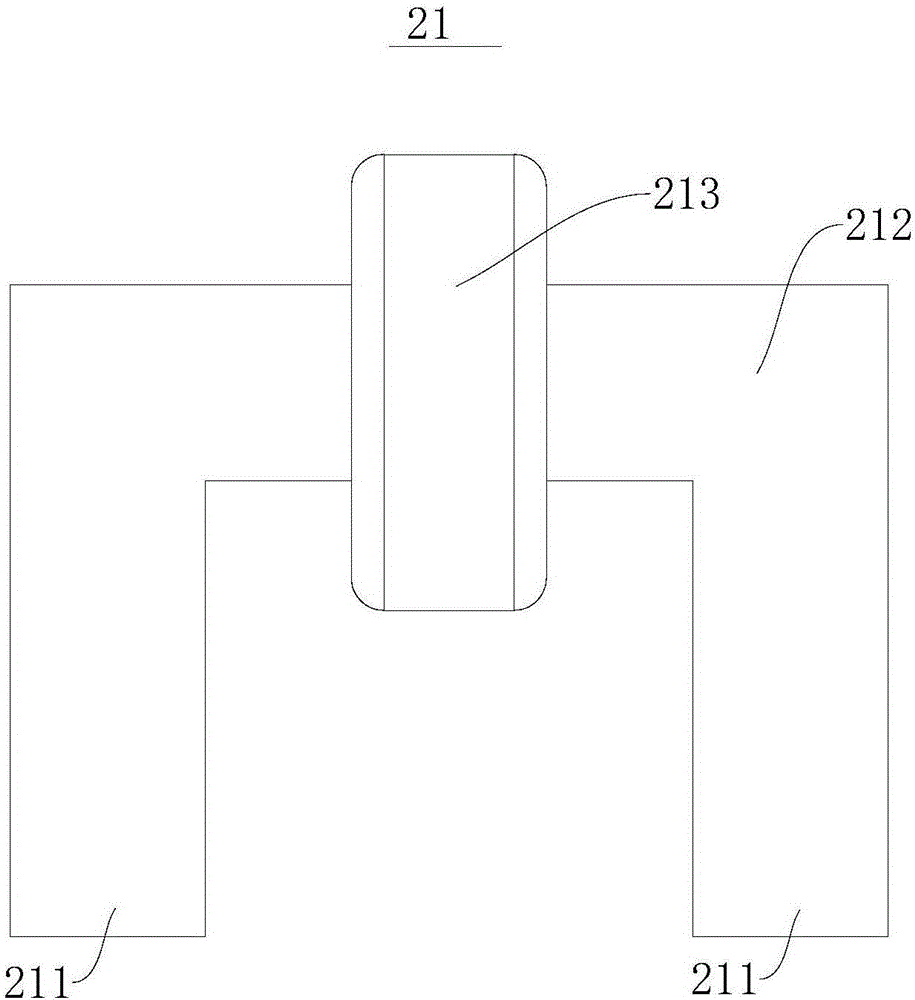

[0066] A plurality of winding excitation sides 21 and a plurality of permanent magnet excitation sides 22 are evenly spaced on the outer side of the reluctance core 11 in the radial direction along the circumferential direction of the reluctance core 11, and a plurality of winding excitation sides 21 and a plurality of pe...

Embodiment 2

[0070] Such as Figure 5 and Figure 6As shown, the structure of this embodiment is roughly the same as that of Embodiment 1, wherein the same components use the same reference numerals, the only difference is that the plurality of winding excitation sides 21 and the plurality of permanent magnet excitation described in Embodiment 1 side 22 is arranged on the outer side of the reluctance core 11 in the radial direction, while the multiple winding excitation sides 21 and the multiple permanent magnet excitation sides 22 in the second embodiment are arranged on the radially outer side of the reluctance core 11 to the inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com