Sampling device and method

A sampling device and channel technology, applied in the field of sampling devices, can solve the problems of long cycle time, blockage removal, easy blockage of condenser pipelines, etc., and achieve the effect of reducing structural complexity and intelligent switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Sampling device, said sampling device includes a probe and an exhaust pipe;

[0036] a processing channel comprising a first channel and a second channel connected in parallel;

[0037] A temperature control unit, such as TEC, which adjusts the temperature in the first channel and the second channel;

[0038] A switching unit, such as a three-way valve, is used to selectively transmit the sample fluid to the exhaust pipe through the first channel or the second channel, and is arranged between the processing channel and the probe, or between the processing channel and the exhaust pipe. between air ducts;

[0039] A pressure detector, the pressure detector is used to detect the pressure difference of the processing channel: the pressure difference is the pressure difference between the inlet and outlet of the first channel, or the pressure change of the outlet of the first channel;

[0040] A comparison module, the comparison module is used to compare the pressure diffe...

Embodiment 2

[0061] An application example of the sampling device and method according to Embodiment 1 of the present invention in coke oven gas sampling.

[0062] In this application example, the sampling gas is coke oven gas, and the deposits are benzene, naphthalene and tar; the temperature control unit adopts TEC, and the hot end faces the first channel, and the cold end faces the second channel. The temperature in the second channel is increased while sampling the gas in the channel; the switching unit adopts a three-way valve, the two inlets are respectively connected to the first channel and the second channel, and the outlet is connected to the exhaust pipe; the high-pressure gas source is connected to the outlet, and Whether it is connected or not is controlled by a valve.

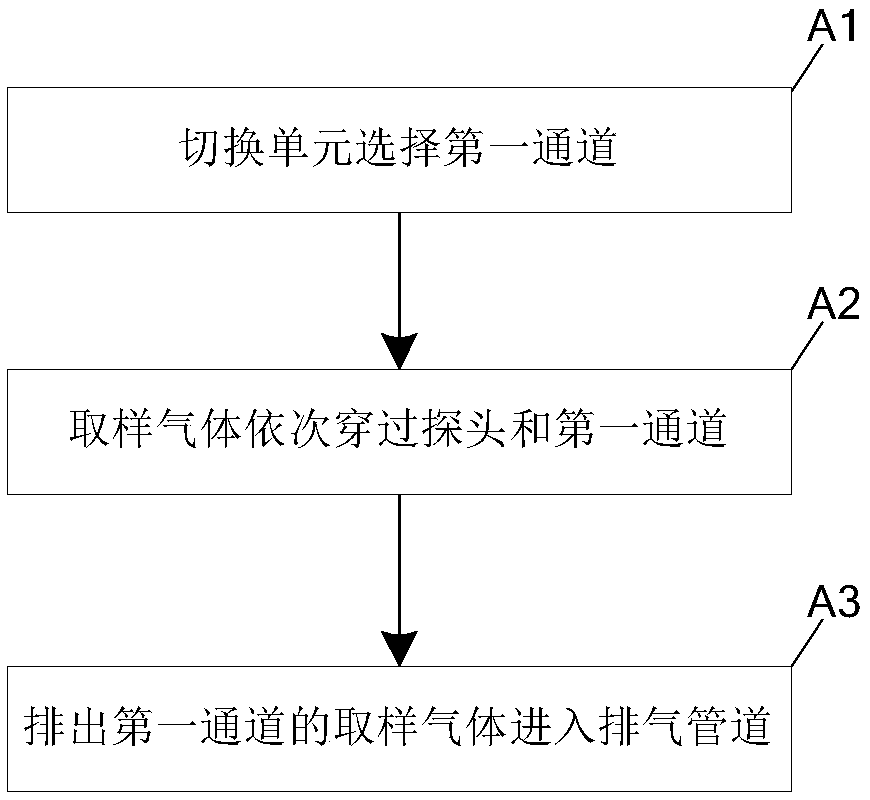

[0063] The sampling method consists of the following steps:

[0064] (A1) The three-way valve is switched so that the exhaust pipe communicates with the first channel;

[0065] (A2) The sampling gas passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com