Split high-temperature preheating powder explosive sintering device

A sintering device and a split-type technology are applied in the field of split-type high-temperature preheating powder explosive sintering devices, which can solve the problems of complex shock wave propagation, precise control of unfavorable process parameters, and high requirements for safety and heat insulation of explosives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and examples.

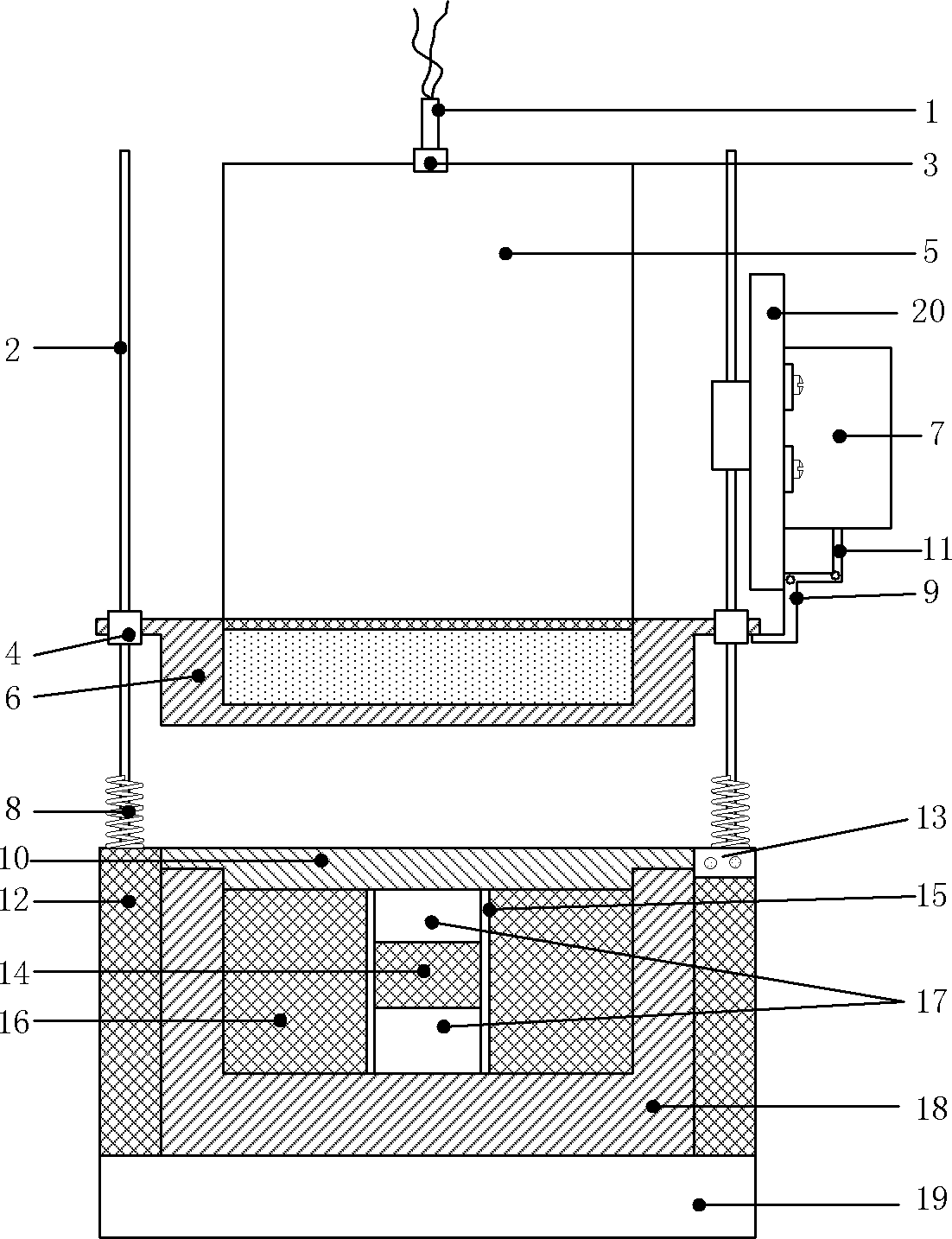

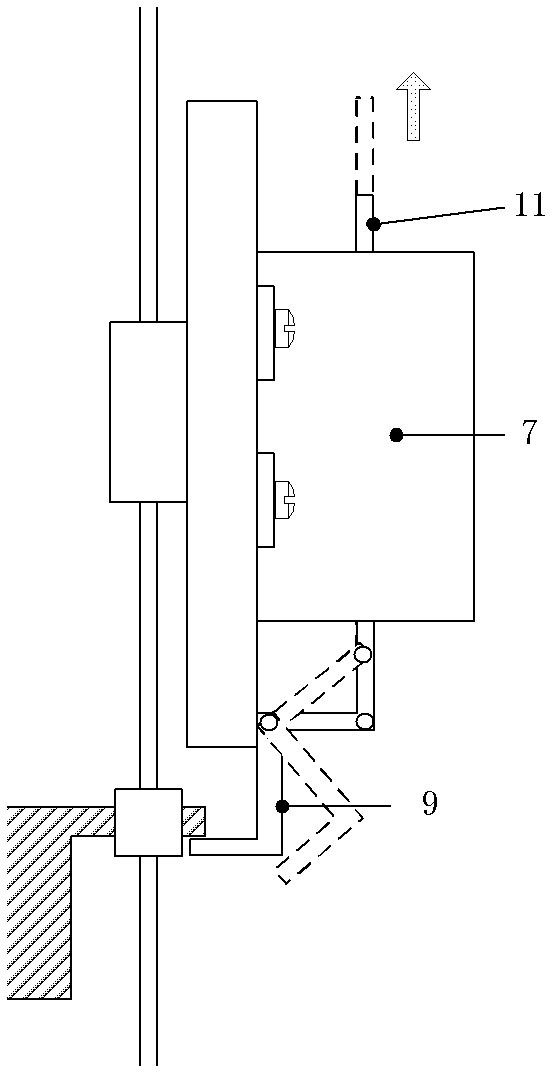

[0019] The invention provides a split-type high-temperature preheating powder explosive sintering device, which includes a shock wave loading component, a controllable split component and a sample high-temperature recovery component, figure 1 It is the physical picture of the device of the present invention, the upper shock wave loading component is used to generate the explosion shock wave, the lower sample high temperature recovery component is used to carry and preheat the powder to be sintered, and the controllable split component on the side locks the shock wave loading component Above the sample high-temperature recovery component, the shock wave loading component and the sample high-temperature recovery component are separated by air. When the controllable split component is triggered, the shock wave loading component can be released, so that the sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com