An insulator structure for protecting vacuum tubes

A technology of vacuum tubes and insulators, applied in high-voltage air circuit breakers, high-voltage/high-current switches, electrical components, etc., can solve the problems of high performance requirements, reliability failures, and application of thermal stress of vacuum tubes, and achieve processability and economy. The effect of highlighting, prolonging service life and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

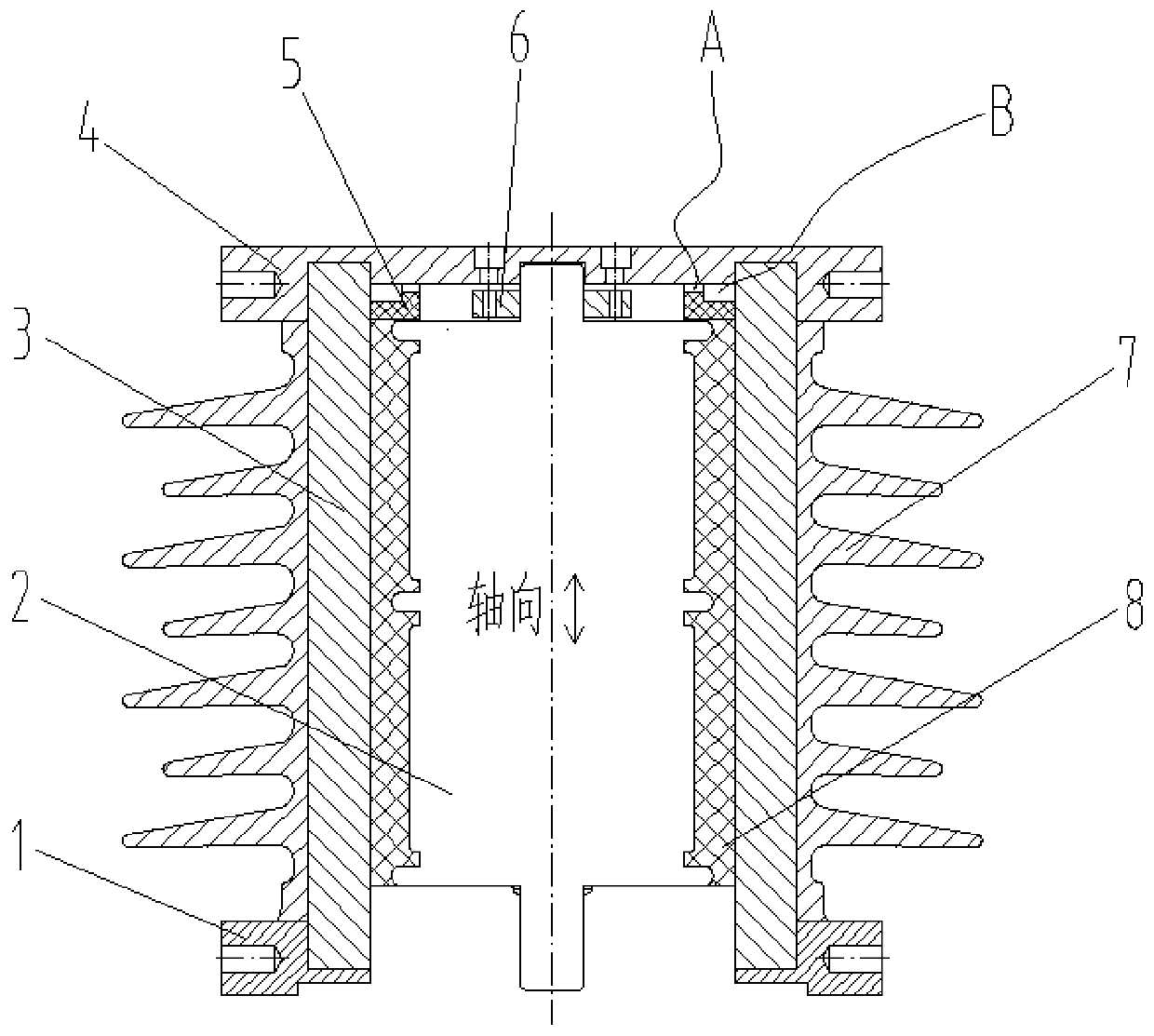

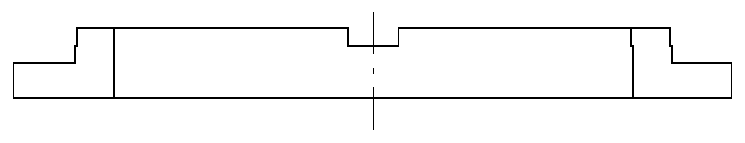

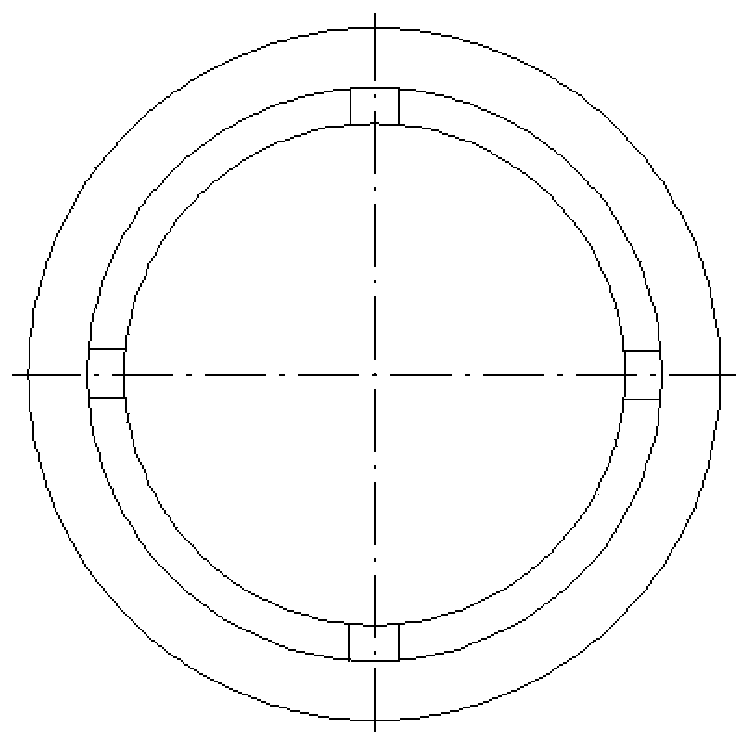

[0027] Such as Figure 1-3 As shown, the insulator structure for protecting the vacuum tube of the present invention includes a lower flange 1, a vacuum tube 2, an epoxy resin core tube 3, an upper flange 4, a sealing ring 5, a compression ring 6, an insulating shed 7 and a silicone rubber 8. Among them, the epoxy resin core tube 3 is covered with an insulating shed 7 on the outside, and the two ends are respectively glued to the upper flange 4 and the lower flange 1, and the vacuum tube 2 is installed in the middle of the inner cavity of the epoxy resin core tube 3. The ring 6 is fixed to the upper flange 4, and the sealing ring 5 matching the inner wall of the epoxy resin core tube 3 is pressed between the vacuum tube 2 and the upper flange 4, and the silicone rubber 8 is poured on the epoxy resin core tube 3, the vacuum tube In the annular cavity between 2 and sealing ring 5, the above-mentioned components together constitute an insulator structure. In this embodiment, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com