Self-diagnosis pre-cutting hole dynamic tension shear rock breaking method and device

A rock-breaking device and self-diagnosis technology, which is applied in the fields of earth drilling, cutting machinery, process efficiency improvement, etc., can solve the inconvenience of efficient mining of deep resources, difficult drilling of deep high-stress rock mass, and large wear of cutting tools, etc. problems, to achieve the effect of reducing the excavation workload, reducing equipment energy consumption and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] like Figure 6-10 As shown, the present invention includes a self-diagnosing pre-cut hole dynamic pulling and shearing rock breaking method, which specifically includes the following steps:

[0056] a. On the face to be mined, grooves are formed along the periphery of the face to form a prefabricated seam, and on the face of the face, the area enclosed by the prefabricated seam forms an area to be broken;

[0057] b. Open a plurality of vertical holes along the direction perpendicular to the face of the rock within the area to be broken, and form an annular groove with a diameter larger than the diameter of the vertical hole at the root of the vertical hole along the direction of the vertical hole. The root of the vertical hole is opened with a plurality of transverse holes along the radial direction of the vertical hole, the depth of the annular groove makes the adjacent vertical holes communicate, so that the prefabricated slit communicates with the vertical holes, an...

Embodiment 2

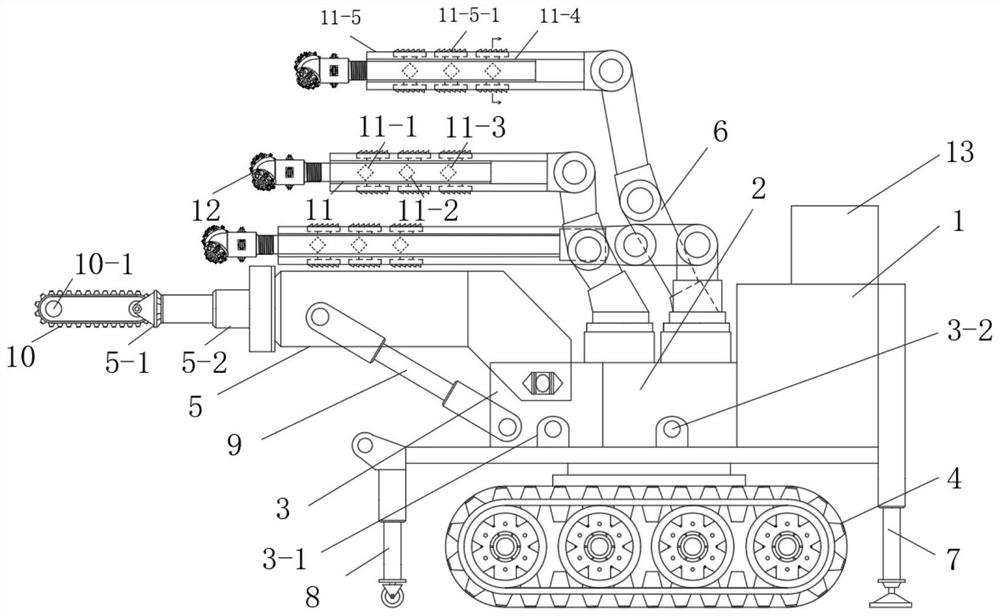

[0062] like Figures 1 to 12 As shown, the present invention also includes a self-diagnosing pre-cut hole dynamic pulling and shearing rock breaking device, including a control unit 1, an engine unit 2, a gas-liquid unit 3, a mobile unit 4, a cutting robotic arm 5, a drilling robotic arm 6, Fixed hydraulic support 7, movable hydraulic support 8 and stress and rock quality self-diagnosis system 13;

[0063] Described engine unit 2, gas-liquid unit 3 are provided with air pipe interface 3-1, water pipe interface 3-2, cutting robot arm 5, drilling robot arm 6;

[0064] The mobile unit 4 is powered by the engine unit 2 and controls the front, rear, left and right movement and steering movement;

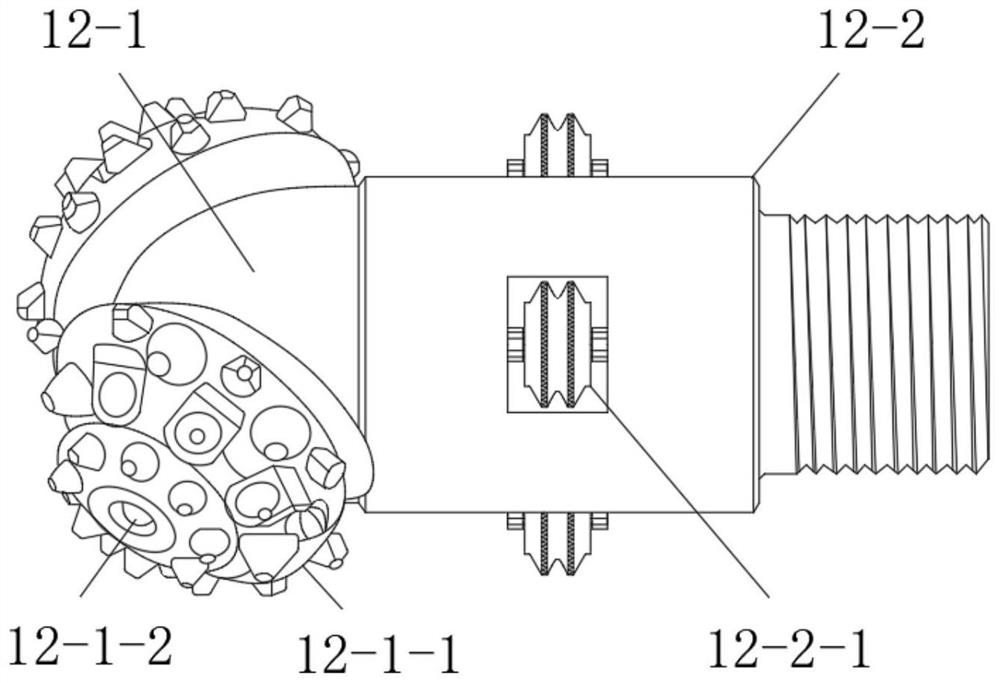

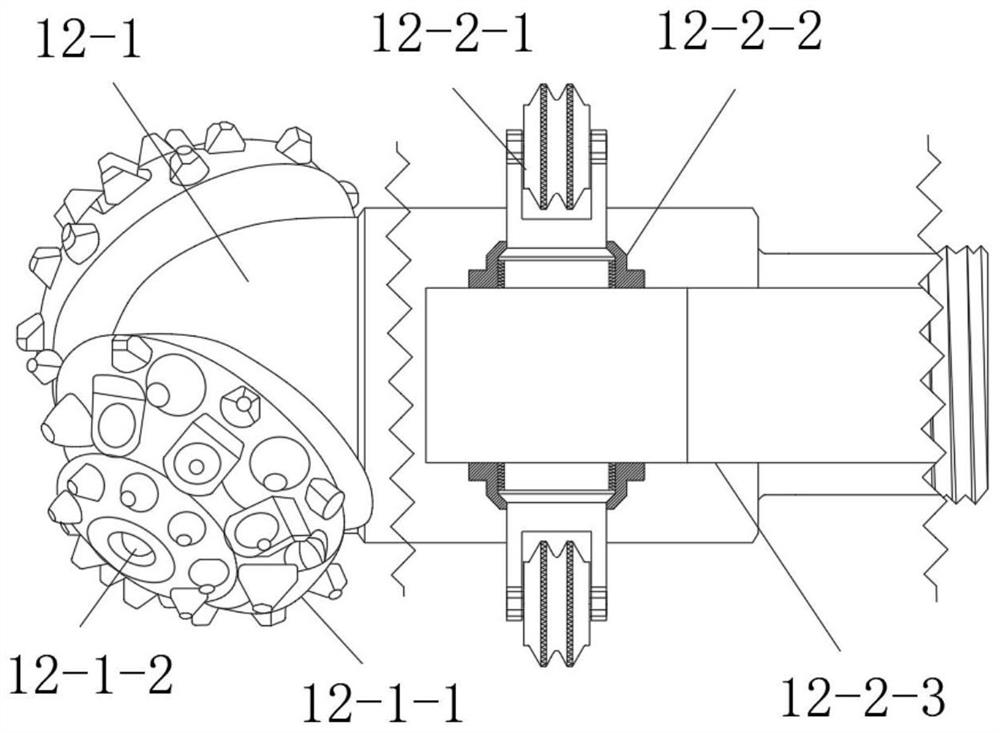

[0065] like Figure 5 As shown, one end of the cutting robotic arm 5 is hinged on the moving unit 4, and the other end supports the moving unit 4 through a hydraulic support rod 9, and the hydraulic support rod 9 provides hydraulic oil through the gas-liquid unit 3; the cutting robotic ...

Embodiment 3

[0091] like figure 1 , 11 , 12, the difference between this embodiment and Embodiment 2 is that the drill rod 11 is provided with an inner sleeve 11-4 and an outer sleeve 11-5, and the inner sleeve 11-4 is fixed on the drill rod 11 On the outside, the outer sleeve 11-5 is evenly divided into four outer sleeve plates along the circumferential direction with the central axis of the drill pipe 11 as the center, and the outer sleeve plates are fixed to the inner sleeve by the hydraulic telescopic support rod 11-4-1 On the outside of 11-4, the outer side of the outer casing plate is provided with a tooth plate 11-5-1, the teeth on the tooth plate 11-5-1 are inclined along the retraction direction of the drill pipe, and when drilling, the outer casing plate shrinks and closes to the inner side. The sleeve, when the drill pipe is pulled out, controls a plurality of hydraulic telescopic support rods 11-4-1 to extend outward, thereby driving the outer sleeve plate to drive the tooth p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com