Sheep grouping device and control system thereof

A technology of guardrail and clamping mechanism, which is applied in the field of animal husbandry and can solve the problems of high labor intensity, high stress reaction of sheep, and unfavorable epidemic prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

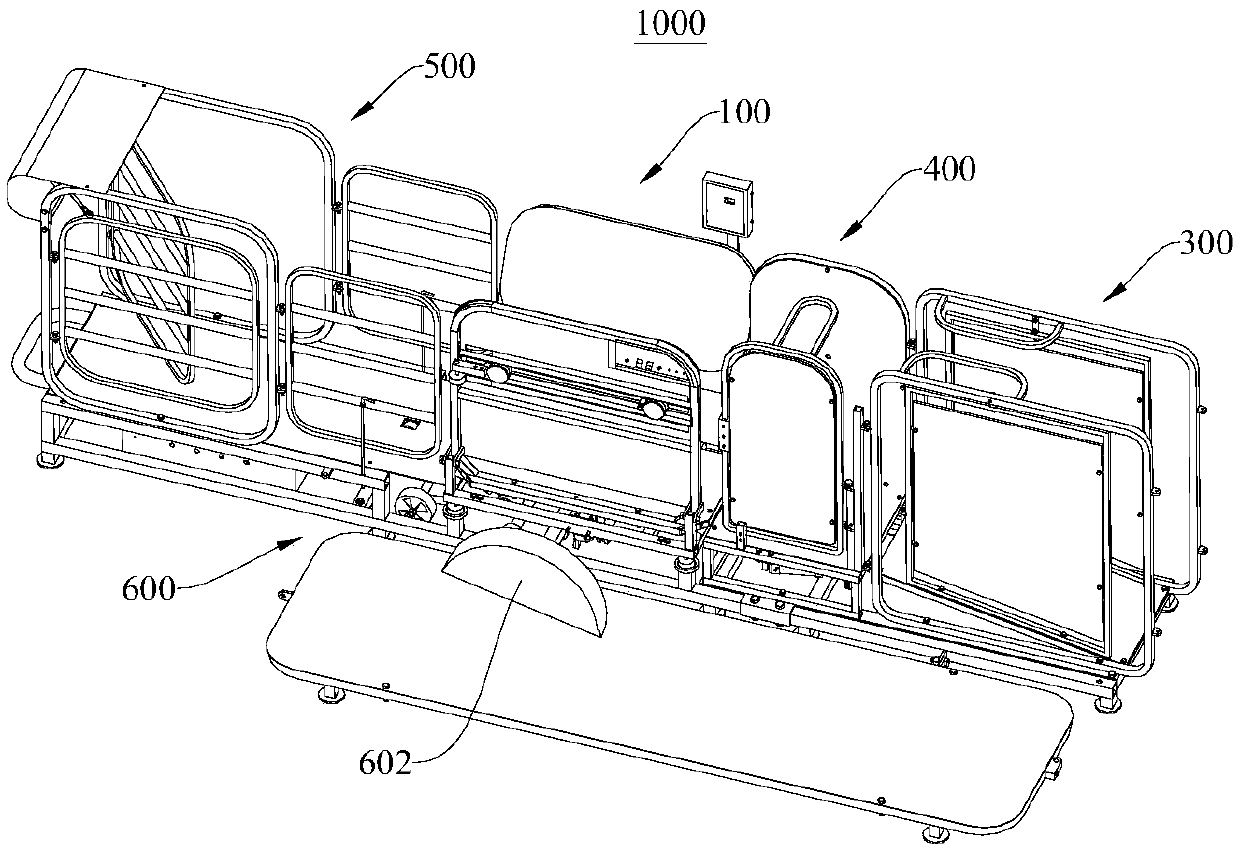

[0044] Please refer to figure 1 , figure 1 Shown is a schematic structural diagram of a sheep grouping device 1000 . This embodiment provides a sorting device 1000 for sheep, which is mainly used to assist management personnel in related management of sheep. Of course, in other embodiments, it can also be used to manage other livestock.

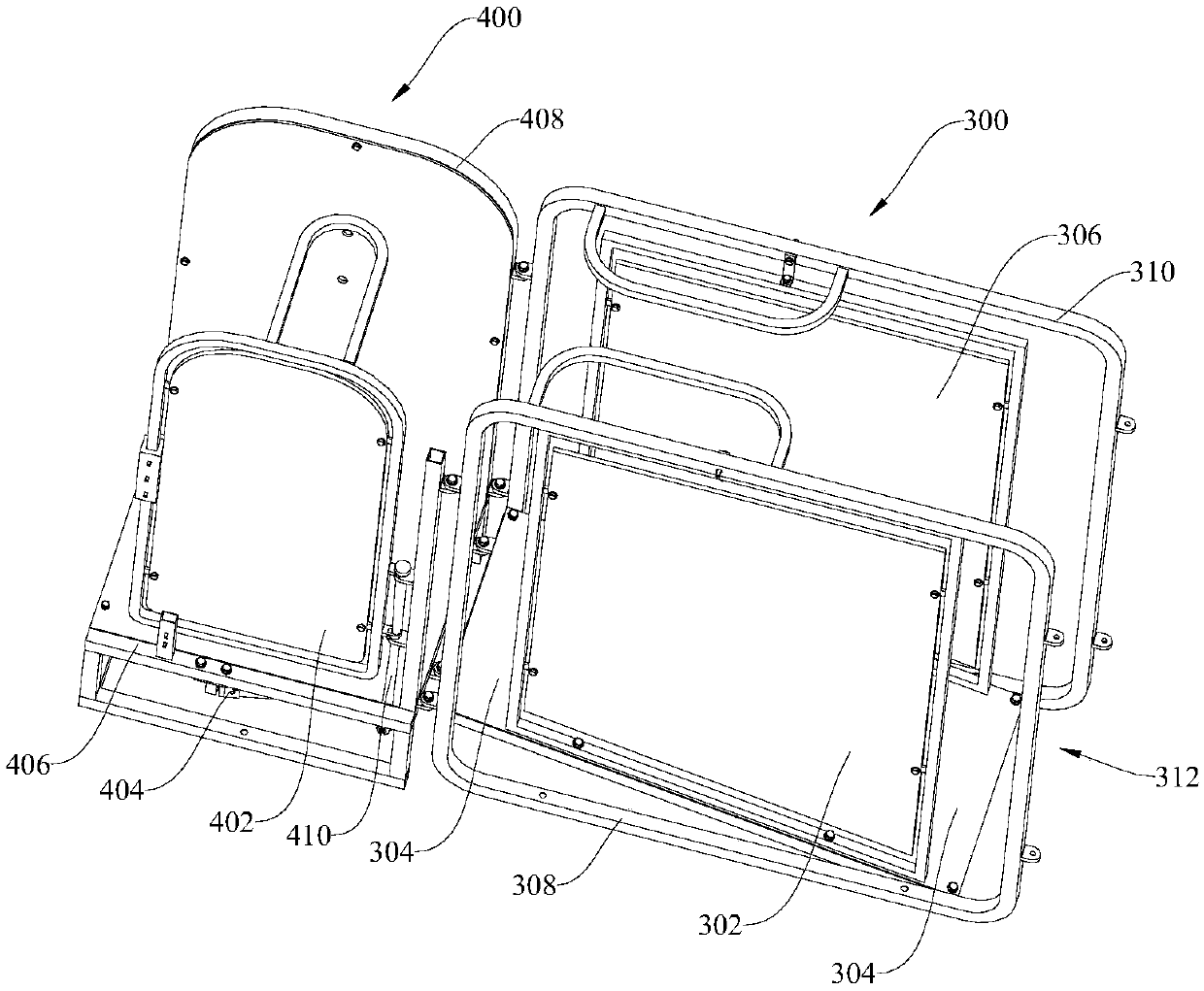

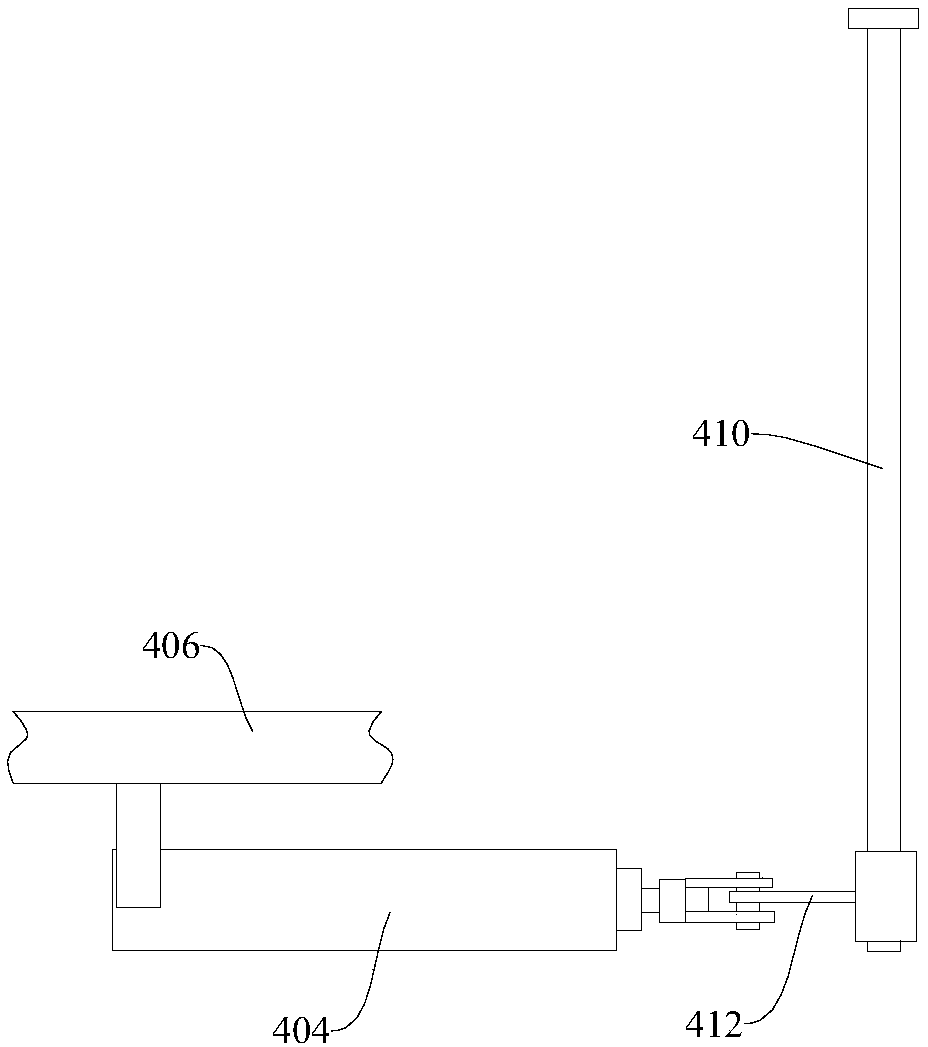

[0045] The sheep grouping device 1000 mainly includes a sheep clamping mechanism 100 , a detection mechanism 300 , a blocking mechanism 400 , a grouping mechanism 500 and a frame 600 . The detection mechanism 300 , the blocking mechanism 400 , the clamping mechanism 100 for sheep and the grouping mechanism 500 are all installed on the frame 600 . The detection mechanism 300, the barrier mechanism 400, the sheep clamping mechanism 100 and the grouping mechanism 500 are connected in sequence, and the sheep enter the detection mechanism 300, the barrier mechanism 400, the sheep clamping mechanism 100, and the grouping mechanism 500 in turn, a...

Embodiment 2

[0083] Please refer to Figure 10 , Figure 10 Shown is a control schematic diagram of the control system 2000 . This embodiment provides a control system 2000 for the above-mentioned sheep grouping device 1000 .

[0084] The control system 2000 mainly includes a PLC controller, a plurality of sensors, a man-machine interface (ie Figure 10 In the industrial control screen) and wireless transmission module. Sensors can be selected from ear tag readers, photoelectric switches, weight sensors, and object detectors according to specific needs. The number is not specifically limited. Multiple sensors can be installed at the same position for backup or to improve detection accuracy. Some sensors have been installed in corresponding positions in Embodiment 1, and object detectors for detecting the positions of sheep can also be installed in both the blocking mechanism 400 and the grouping mechanism 500 . The industrial control screen can move freely and record the physical chara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com