Chemical fiber wig forming device

A molding device and chemical fiber technology, applied in wigs, clothing, applications, etc., can solve problems such as increased production costs, low resource utilization, environmental pollution, etc., and achieve the effects of ensuring molding quality, high recycling rate, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

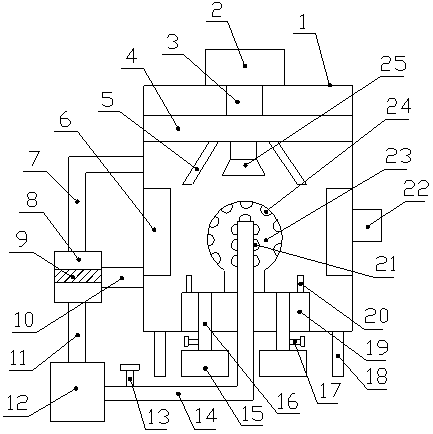

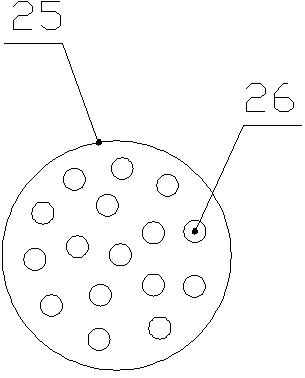

[0016] Such as Figure 1-2 As shown, a chemical fiber wig forming device includes a box body 1 and a hot air blower 12, the lower end of the box body 1 is provided with a leg 18, and the middle part of the upper end of the box body 1 is provided with a medicine storage tank 2. The medicine storage tank 2 is connected with the liquid distributor 4 through the medicine outlet pipe 3, the middle part of the lower end of the liquid distributor 4 is equipped with a nozzle 25, and the lower end of the nozzle 25 is provided with a liquid outlet 26, and the nozzle 25 is two Both sides are provided with a baffle A5, the baffle A5 is installed at the lower end of the liquid distributor 4, the middle part of the lower inner wall of the box body 1 is fixedly connected with a base 19, and the middle part of the upper end of the base 19 is provided with a wig head mold 23. The wig headform 23 is a hollow structure, and the wig headform 23 is provided with an air inlet 24, and one end of the...

Embodiment 2

[0019] Such as Figure 1-2As shown, a chemical fiber wig forming device includes a box body 1 and a hot air blower 12, the lower end of the box body 1 is provided with a leg 18, and the middle part of the upper end of the box body 1 is provided with a medicine storage tank 2. The medicine storage tank 2 is connected with the liquid distributor 4 through the medicine outlet pipe 3, the middle part of the lower end of the liquid distributor 4 is equipped with a nozzle 25, and the lower end of the nozzle 25 is provided with a liquid outlet 26, and the nozzle 25 is two Both sides are provided with a baffle A5, the baffle A5 is installed at the lower end of the liquid distributor 4, the middle part of the lower inner wall of the box body 1 is fixedly connected with a base 19, and the middle part of the upper end of the base 19 is provided with a wig head mold 23. The wig headform 23 is a hollow structure, and the wig headform 23 is provided with an air inlet 24, and one end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com