A laser preparation method of porous magnesium alloy for living organisms

A technology of porous magnesium and organisms, which is applied in the field of laser preparation of porous magnesium alloys for organisms, can solve the problems of uneven stress, no public reports on the preparation of porous Mg-Cu alloys, etc., and achieves the effects of increased flexibility and freedom of design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

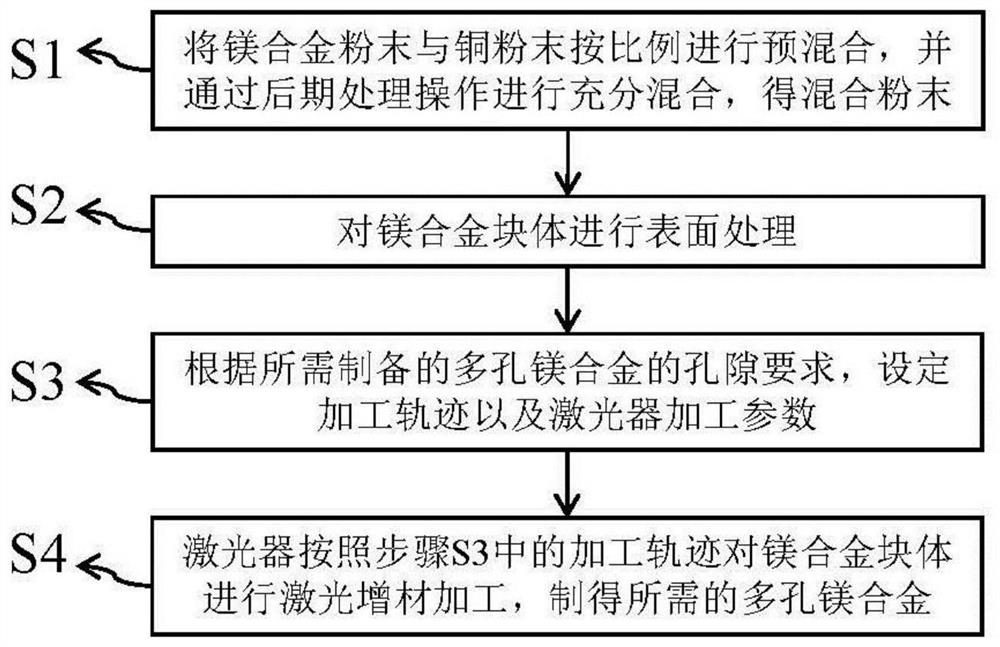

[0026] see figure 1 Shown, a kind of laser preparation method of porous magnesium alloy for living body, comprises steps as follows:

[0027] S1. Pre-mix magnesium alloy powder and copper powder in proportion, and place the pre-mixed powder in a ball mill, and feed argon or acetone. The speed of the ball mill is selected so that the surface temperature of the ball mill tank during work does not exceed 60°C. Preferably, the ball milling time is 1 to 3 hours to ensure that the magnesium alloy powder and copper powder are fully and uniformly mixed to obtain a mixed powder.

[0028] Among them, magnesium alloy powder and copper powder are all made of high-purity powder, and the purity is greater than or equal to 99.9%. Magnesium alloy powder is one of Mg-Al alloy powder, Mg-Zn alloy powder, and Mg-Mn alloy powder. The copper powder is analytically pure copper powder. The mass ratio of copper powder to magnesium alloy powder in the mixed powder is greater than 0% and less than or...

Embodiment 1

[0034] A laser preparation method for a porous magnesium alloy for living organisms, comprising the following steps:

[0035] S1. Pre-mix Mg-Al-Zn alloy powder with a purity greater than 99.9% and copper powder at a mass ratio of 0.5%, and place the pre-mixed powder in a ball mill, feed argon or acetone, and the speed of the ball mill is 50r / min, and the ball milling time is 1h to ensure that the Mg-Al-Zn alloy powder and copper powder are fully and uniformly mixed to obtain a mixed powder.

[0036] S2, performing surface treatment on the magnesium alloy block. The magnesium alloy block is made of biomedical magnesium alloy block, and the surface of the biomedical magnesium alloy block is cleaned by using sodium hydroxide solution as a cleaning agent, then washed with clean water, and dried with cold air.

[0037] S3. According to the pore requirements of the porous magnesium alloy to be prepared, the pore diameter is greater than or equal to 150 μm, and the processing traje...

Embodiment 2

[0042] A laser preparation method for a porous magnesium alloy for living organisms, comprising the following steps:

[0043] S1. Pre-mix Mg-Zn-Zr alloy powder with a purity greater than 99.9% and copper powder at a mass ratio of 1.5%, and place the pre-mixed powder in a ball mill, feed argon or acetone, and the speed of the ball mill is 100r / min, and the ball milling time is 2h to ensure that the Mg-Zn-Zr alloy powder and copper powder are fully and uniformly mixed to obtain a mixed powder.

[0044] S2, performing surface treatment on the magnesium alloy block. The magnesium alloy block is made of biomedical magnesium alloy block, and the surface of the biomedical magnesium alloy block is cleaned by using sodium hydroxide solution as a cleaning agent, then washed with clean water, and dried with cold air.

[0045] S3. According to the pore requirements of the porous magnesium alloy to be prepared, the pore diameter is greater than or equal to 150 μm, and the processing trajec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com