Steel ball pressing machine for luggage universal wheel

A universal wheel and press-in machine technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of steel ball track deviation, drop, inconvenience, etc., and achieve the effect of convenient clamping size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

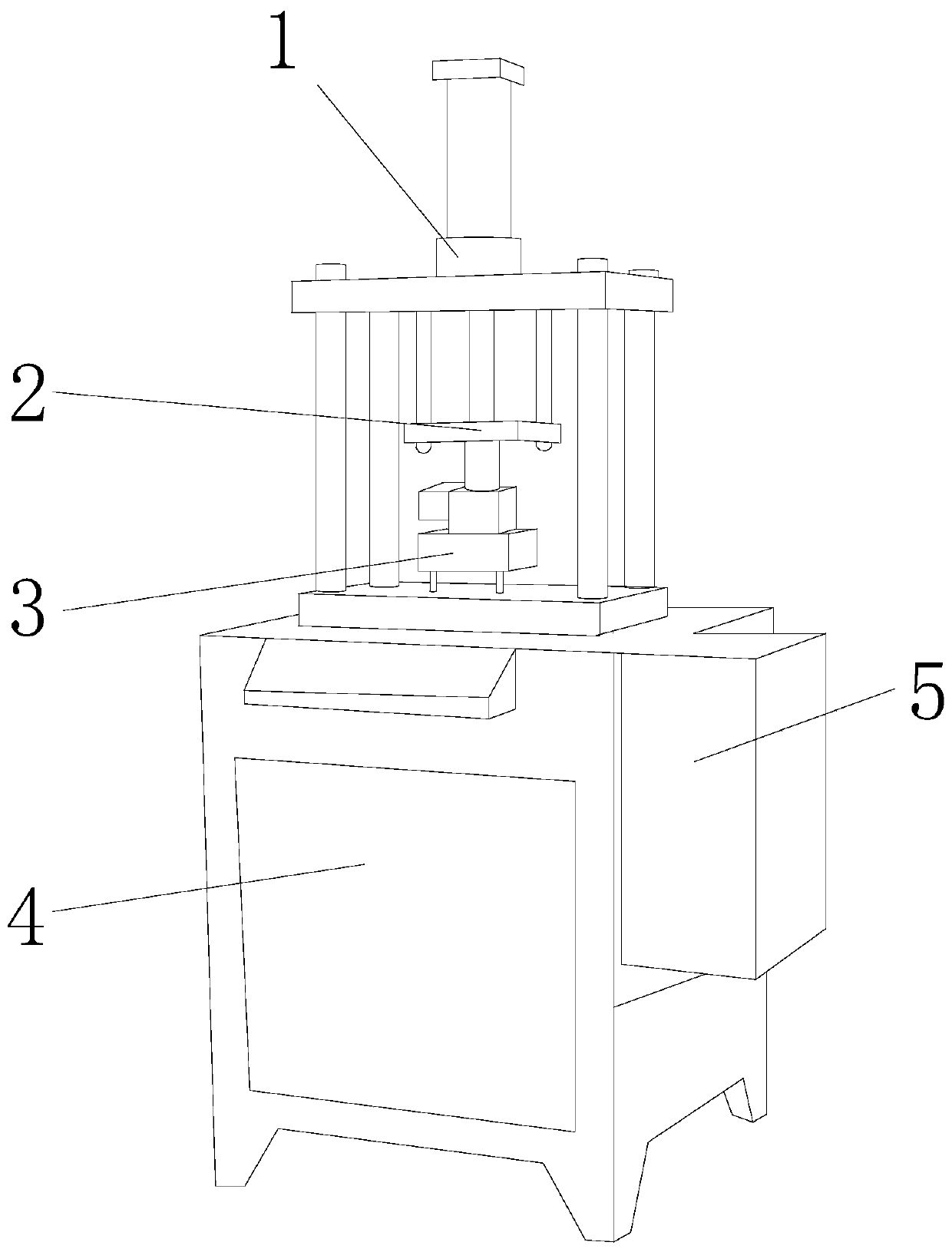

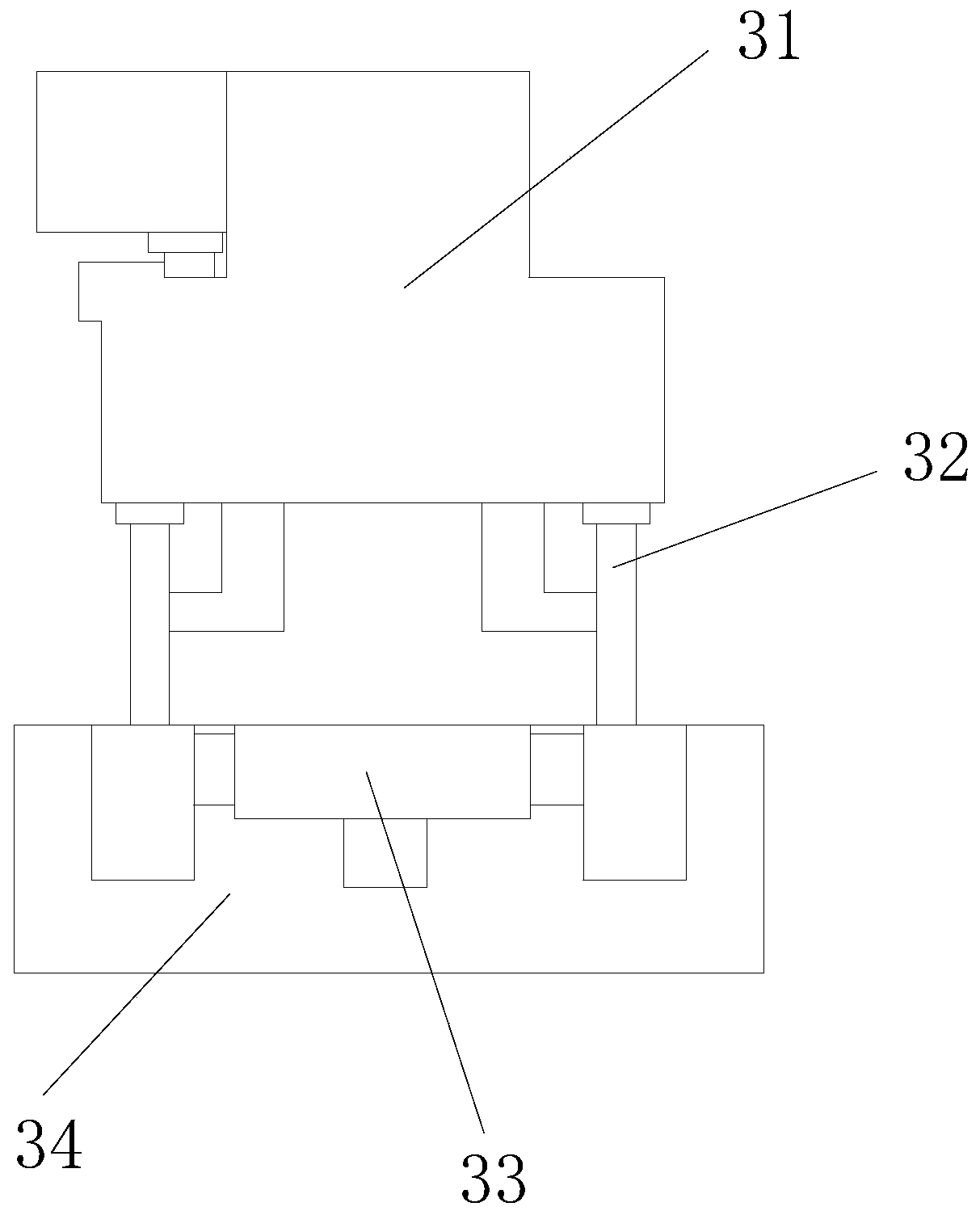

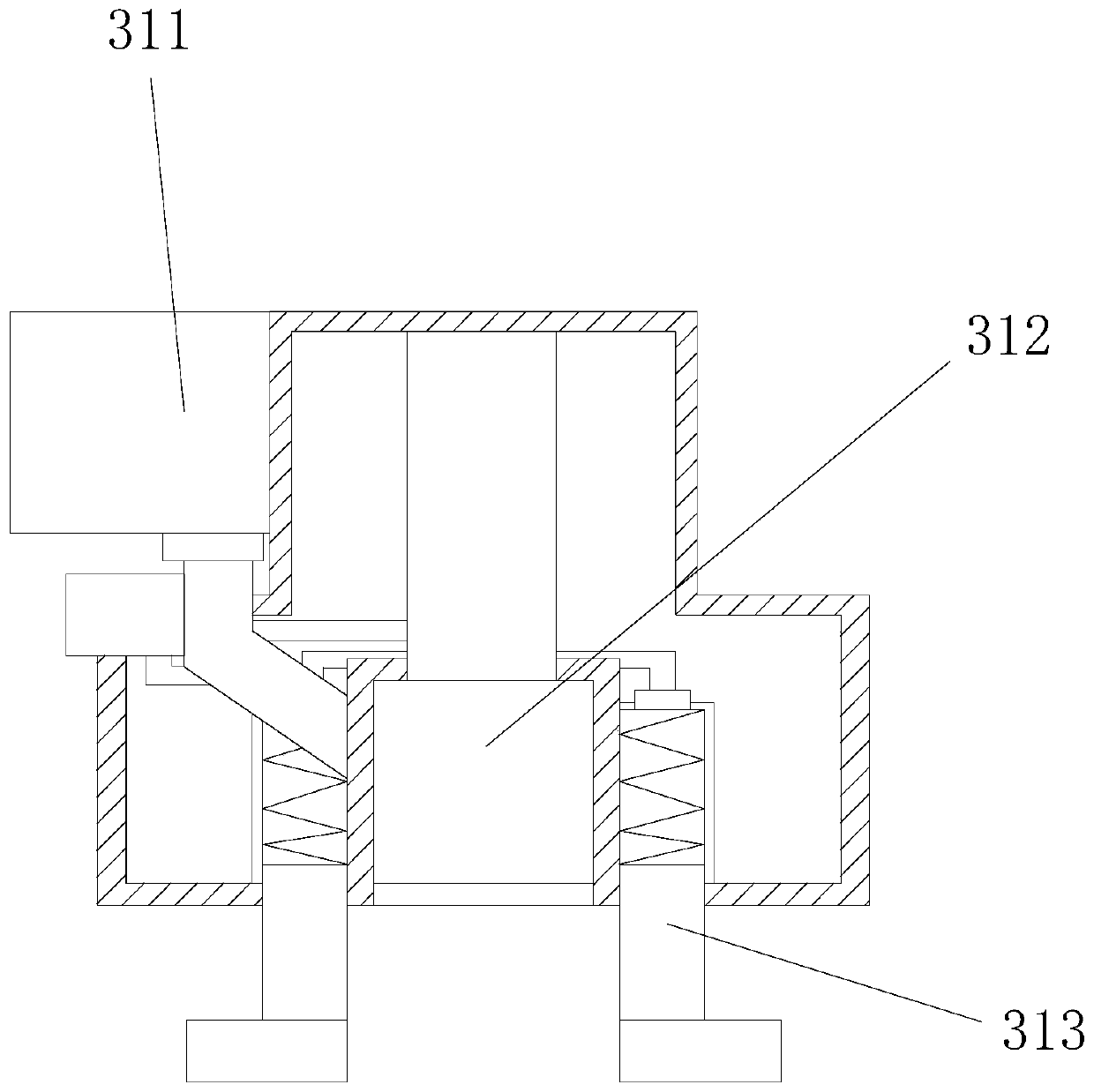

[0029] see Figure 1-Figure 9, the present invention provides a steel ball press-in machine for universal wheels of luggage. Its structure includes a hydraulic rod 1, a lower press block 2, a press-in module 3, a body 4, and a controller 5. above, and the two are movably coordinated, the lower pressing block 2 is located directly above the pressing module 3, the bottom end of the pressing module 3 is welded to the top of the body 4, the left end of the controller 5 is connected to the body 4 The right end of the said press-in module 3 comprises a steel ball filling mechanism 31, a pressing sliding mechanism 32, a clamping mechanism 33, a base 34, the bottom end of the steel ball filling mechanism 31 and the top of the pressing sliding mechanism 32 The bottom end of the press-down sliding mechanism 32 is vertically embedded in the top of the base 34, the press-down slide mechanism 32 is respectively located on both sides of the clamping mechanism 33, and the steel ball filling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com