A kind of red luminous ceramic and its preparation method and application

A technology of red luminescence and ceramics, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., and can solve the problems of poor stability and low light efficiency of phosphors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the red luminescent ceramics of the present application comprises the following steps: putting the reaction raw materials in a vacuum sintering device (such as a vacuum sintering furnace), -3 Under the condition of Pa, the temperature is raised to 180-220°C for the first time, and the first time is kept for 1-5h, and then the temperature is raised to 500-700°C for the second time, and the second time is kept for 4-12h.

[0024] In some embodiments, the degree of vacuum can be specifically set to 1.5×10 -3 Pa or 2×10 -3 Pa et al.

[0025] In some embodiments, the temperature for the first heating can be 180°C, 190°C, 200°C, 210°C or 220°C, etc., or 185°C, 195°C, 205°C, or 215°C, etc., or 180°C. Any temperature value within the range of -220°C. The time for the first heat preservation can be 1h, 2h, 3h, 4h, or 5h, etc., or 1.5h, 2.5h, 3.5h, or 4.5h, etc., or any time value within the range of 1-5h. It is worth noting that, in this application...

Embodiment 1

[0039] Weigh K 2 Ti 0.94 f 6 :0.06Mn 4+ 30g of the powder is used as the reaction raw material, and the raw material is ball milled and mixed for 48 hours. After mixing evenly, the raw material is dried in a blast drying oven at 60°C for 48 hours, and then passed through a 200-mesh sieve; the sieved raw material is put into a graphite mold , dry pressing with a pressure of 20MPa first, and then put it into a vacuum sintering furnace at a vacuum degree of 2×10 -3 Under the condition of Pa, raise the temperature to 200°C, keep it warm for 2 hours, then raise the temperature to 700°C, and pass in argon until the pressure reaches 9.8MPa, keep it warm for 8 hours, and get a sintered body after cooling to room temperature; grind and polish the sintered body After that, get Mn 4+ Activated red luminous ceramic.

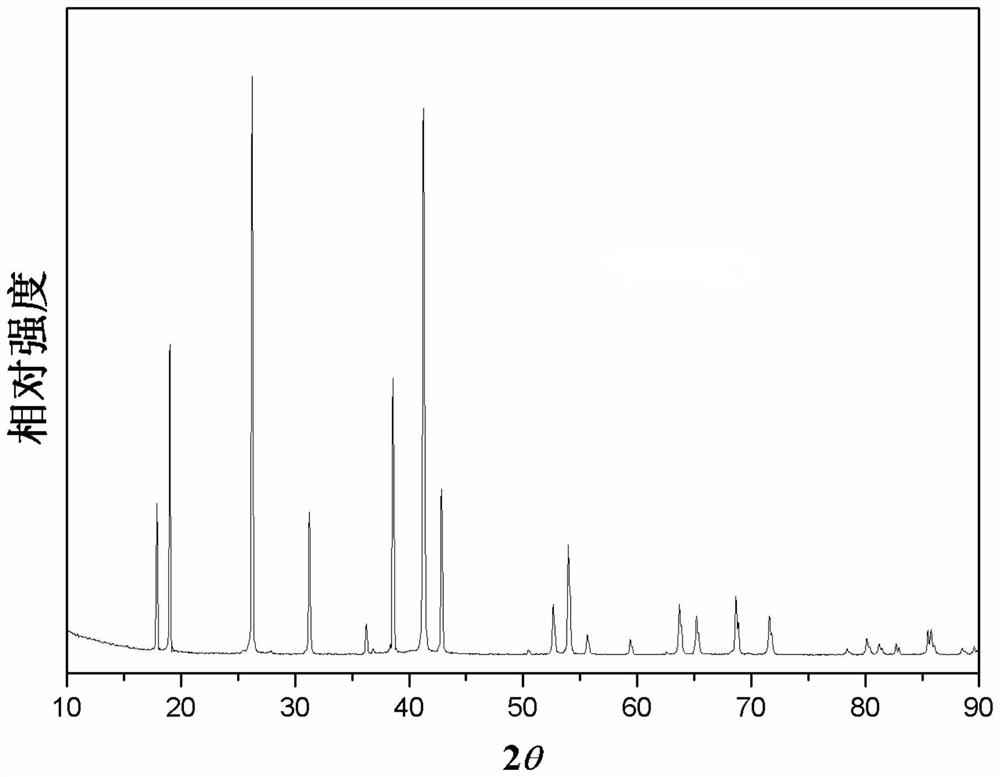

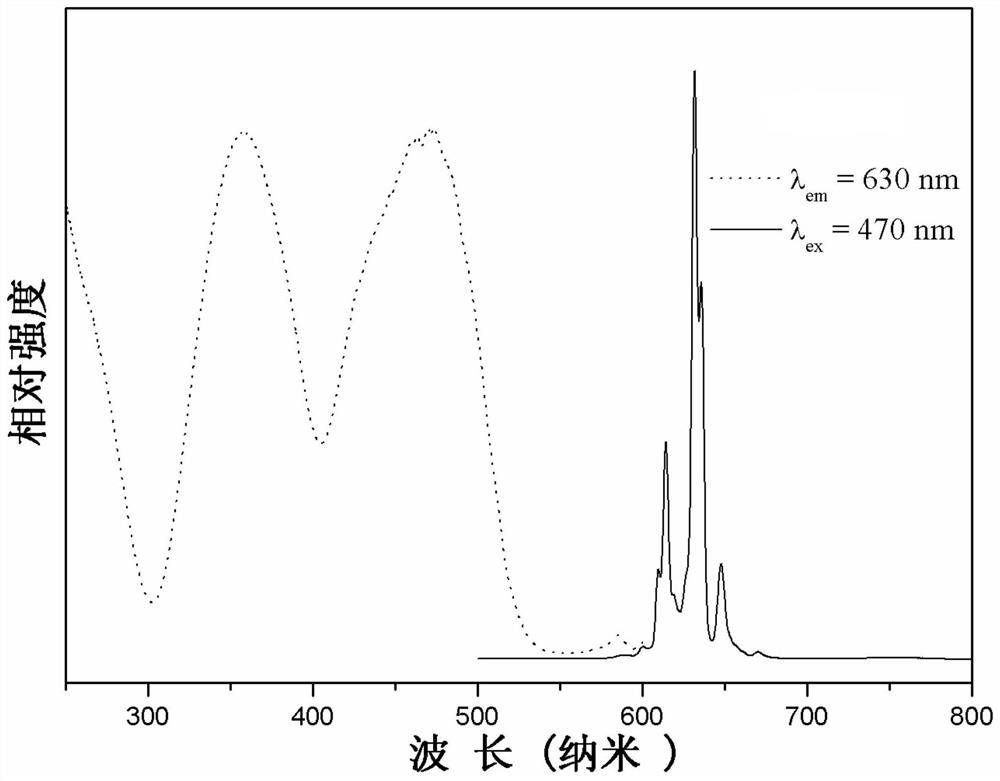

[0040] The XRD pattern of the red luminescent ceramic is as follows figure 1 Its excitation and emission spectra at room temperature (25°C) are shown in figure 2 As ...

Embodiment 2

[0042] Weigh Na 2 Ti 0.95 f 6 :0.05Mn 4+ 30g of the powder is used as the reaction raw material, and the raw material is ball milled and mixed for 30 hours. After mixing evenly, the raw material is dried in a blast drying oven at 60°C for 24 hours, and then passed through a 200-mesh sieve; the sieved raw material is put into a graphite mold , first dry pressed with a pressure of 10MPa, and then put into a vacuum sintering furnace at a vacuum degree of 2×10 -3 Under the condition of Pa, raise the temperature to 200°C, keep it warm for 3 hours, then raise the temperature to 600°C, and pass in argon until the pressure reaches 9.8MPa, keep it warm for 10 hours, and cool to room temperature to get a sintered body; grind and polish the sintered body After that, get Mn 4+ Activated red luminous ceramic.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap