Heat insulation shell for high-temperature pump

A technology for high-temperature pumps and shells, applied in the field of heat-insulated shells for high-temperature pumps, can solve problems affecting the service life of the motor and the entire pump, and achieve the effects of ensuring the mechanical properties of the shell, saving energy, and reducing ultra-high thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

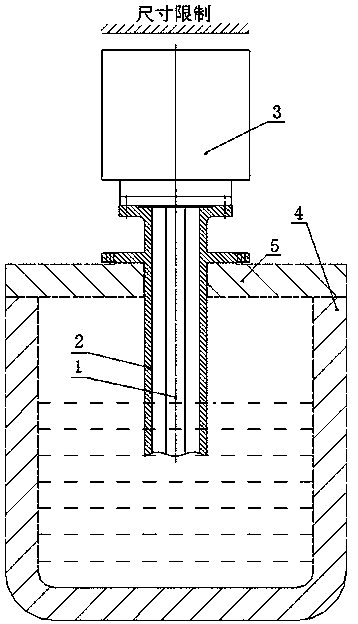

Image

Examples

Embodiment Construction

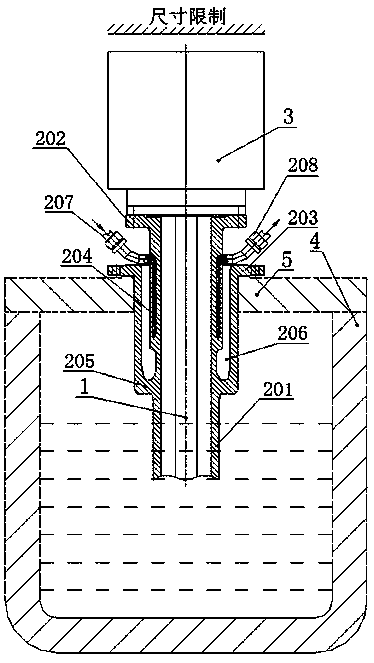

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] see figure 2 , a specific embodiment of a heat-insulating housing for a high-temperature pump, including a tubular housing body 201, the outer peripheral wall of the housing body 201 is respectively provided with a motor support platform 202 and a fixed platform 203 from high to low; it also includes a cooling The liquid passage 204 and the surrounding surface 205, the surrounding surface 205 is connected to the housing body 201 at the lower end and extends out of the wall surface of the housing body 201 periphery, the fixed platform 203 is arranged on the upper end of the surrounding surface 205, and the surrounding surface 205 and the housing body 201 An air-cooled and heat-insulated cavity 206 with a closed lower end and an open upper end is formed between the outer peripheral walls; the cooling liquid passage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com