Experimental device and experimental method for measuring isotropic and reverse imbibed recovery

A technology of reverse imbibition and experimental equipment, which is applied in the direction of measuring equipment, permeability/surface area analysis, and weighing by removing certain components, and can solve the problem of not strictly distinguishing between isotropic imbibition and reverse imbibition. Quantity, measurement method is not strict, measurement method is inaccurate and other problems, to achieve the effect of eliminating oil droplets hanging on the wall, improving precision and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Further illustrate the present invention below in conjunction with accompanying drawing.

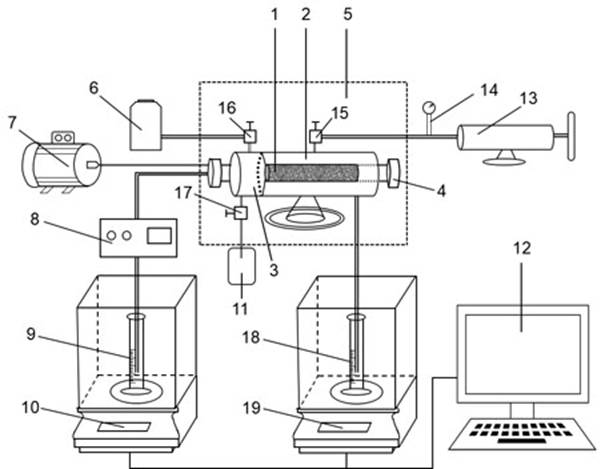

[0028] see figure 1 , figure 2 , image 3 .

[0029] The experimental device for measuring the output of isotropic imbibition and reverse imbibition consists of a core to be tested 1, a holder 2, a liquid storage container 3, a piston 4, a constant temperature box 5, a liquid storage tank 6, a motor 7, a self-priming It consists of pump 8, beaker 11, computer 12, confining pressure pump 13, and pressure gauge 14.

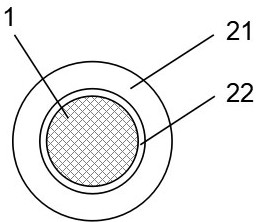

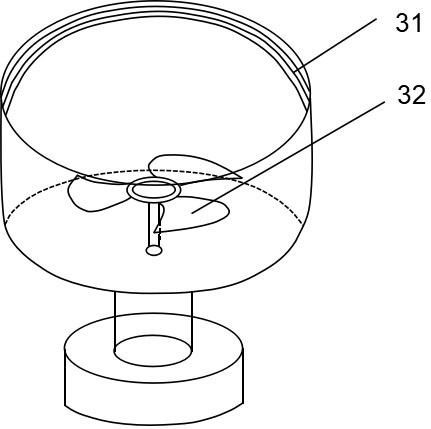

[0030] The rock core 1 to be tested is installed in the holder 2, and there is a sealing sleeve 22 on the outside of the rock core 1 to be tested and is close to the wall surface 21 of the holder; the left end of the holder is connected to the liquid storage container 3 through a thread 31, and the right end of the holder is connected to the piston 4. The rock core 1 to be tested is fixed at the leftmost end of the holder through the piston, and both the holder and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com