Reaction device used for producing polyoxyethylene and process thereof

A technology of polyethylene oxide and reaction devices, applied in pressure vessels used in chemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as insufficient contact of reaction materials, achieve narrow molecular weight distribution range, eliminate hanging Effect of wall phenomenon, increase in heat transfer rate and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

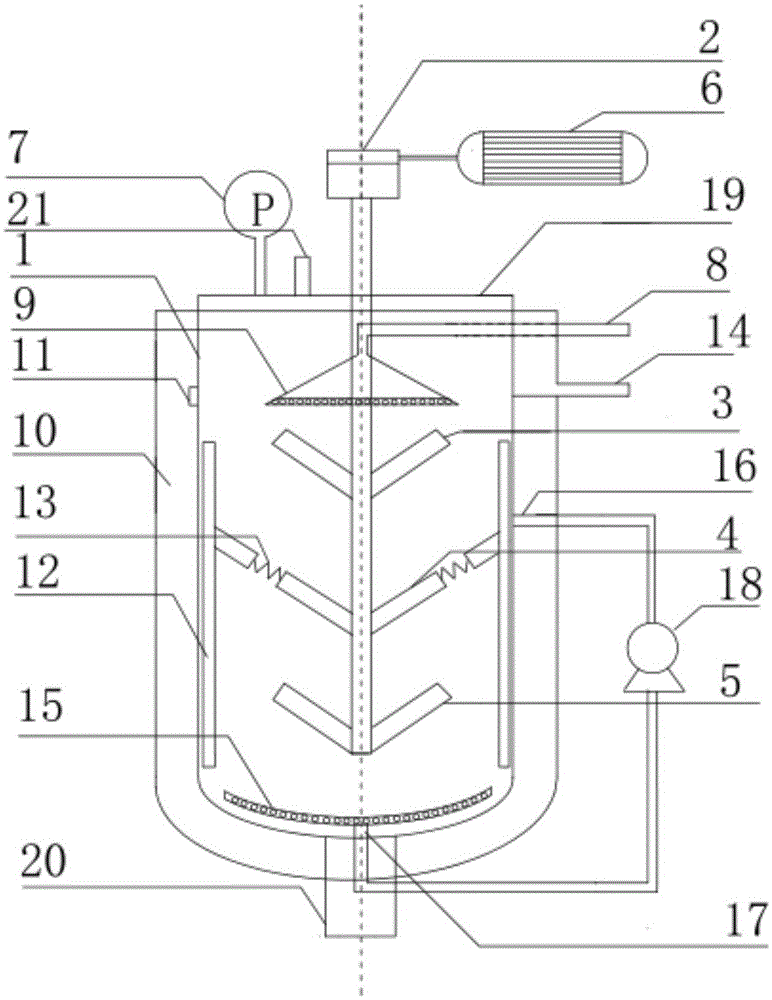

[0020] Such as figure 1 As shown, the reaction device for the production of polyethylene oxide involved in the present invention is composed of a kettle body 1, a stirrer 2, a motor 6, a nozzle 9, a jacket 10, a bubbling device 15 and a reaction kettle cover 19, wherein the stirrer 2 is set In the center of the kettle body 1, the uppermost end of the agitator 2 is connected to the motor 6 outside the kettle body 1, and the first stirring blade 3 and the second stirring blade are respectively placed on the upper, middle and lower parts of the agitator 2 inside the kettle body 1. 4 and the third stirring blade 5; every group of stirring blades is 6 pieces, trapezoidal, with a diameter of 20cm, and an angle of 20° with the vertical surface, and the wall scraper 12 is connected on the second stirring blade 4 by a spring 13, scraping The wall device 12 is closely attached to the inner wall of the kettle body 1, and two scrapers are arranged on the wall scraper 12; the nozzle 9 is a...

Embodiment 2

[0022]The reaction device of this embodiment is as embodiment 1: open reactor cover 19, add solid calcium, cover reactor cover 19 and seal, the reaction device is carried out vacuumize operation, vacuum time is 10min, and vacuum degree is 0.02MPa, The cooling medium ethanol is passed into the coil 11, the temperature in the kettle body 1 is reduced to -60°C, and the liquid ammonia is passed through the feed port 8, and the nozzle 9 can spray the liquid ammonia evenly on the calcium surface for reaction, and the motor 6 drives the agitator 2, and the agitating blades can fully stir the materials, wherein each group of agitating blades is 6 pieces, trapezoidal, 20 cm in diameter, and 20° with the vertical surface, and the wall scraper 12 is provided with 2 scrapers, 20 holes are set on the nozzle 9, the diameter of the holes is 2.0mm, the angle between each hole and the vertical direction is 30°, the mass ratio of liquid ammonia to calcium is 20:1, and the reaction time is 5h , ...

Embodiment 3

[0024] The reaction device of this embodiment is as embodiment 1: open reaction kettle cover 19, add solid calcium, cover reaction kettle cover 19 and seal, the reaction device is carried out vacuumize operation, vacuum time is 20min, and vacuum degree is 0MPa, in The cooling medium ethylene glycol is passed into the coil 11, the temperature in the kettle body 1 is lowered to -40°C, and the liquid ammonia is passed through the feed port 8, and the nozzle 9 can spray the liquid ammonia evenly on the calcium surface for reaction. The motor 6 drives the stirrer 2, and the stirring blades can fully stir the materials, wherein, each group of stirring blades is 8 pieces, trapezoidal, 30 cm in diameter, and 50° with the vertical surface, and the wall scraper 12 is set There are 6 scrapers, 60 holes are arranged on the nozzle 9, the diameter of the holes is 0.5mm, the angle between each hole and the vertical direction is 50°, the mass ratio of liquid ammonia to calcium is 40:1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com