Ultra-high temperature sterilization machine cleaning technology

A technology of ultra-high temperature sterilization and high-temperature sterilization, which is applied in food preservation, milk preparations, dairy products, etc. It can solve the problems that the softened water cannot be replenished in time, the cleaning effect is not ideal, and the alkali cleaning effect is not obvious, etc., and the cleaning effect is ideal. , Eliminate the effect of milk hanging on the wall and avoid quality hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

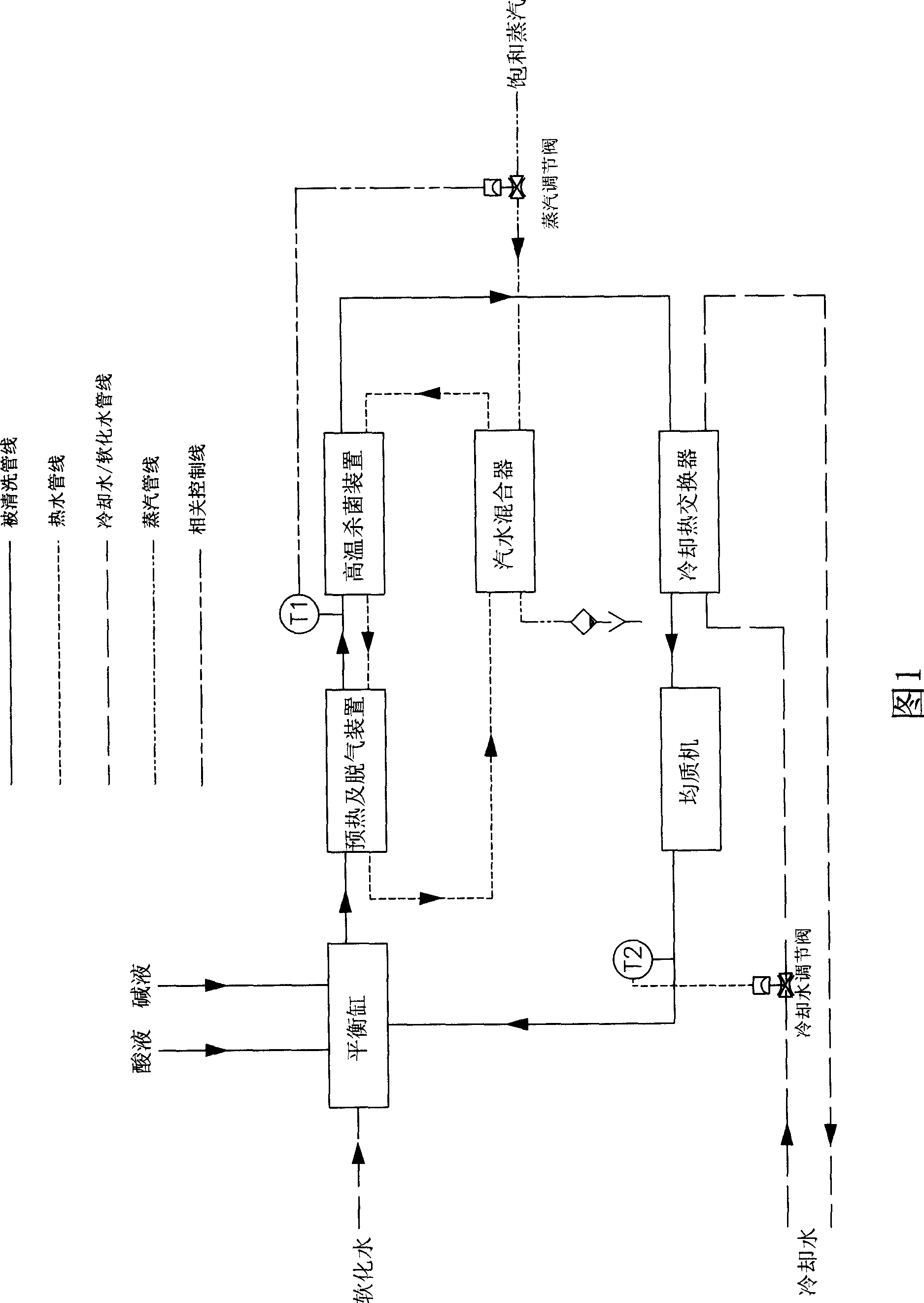

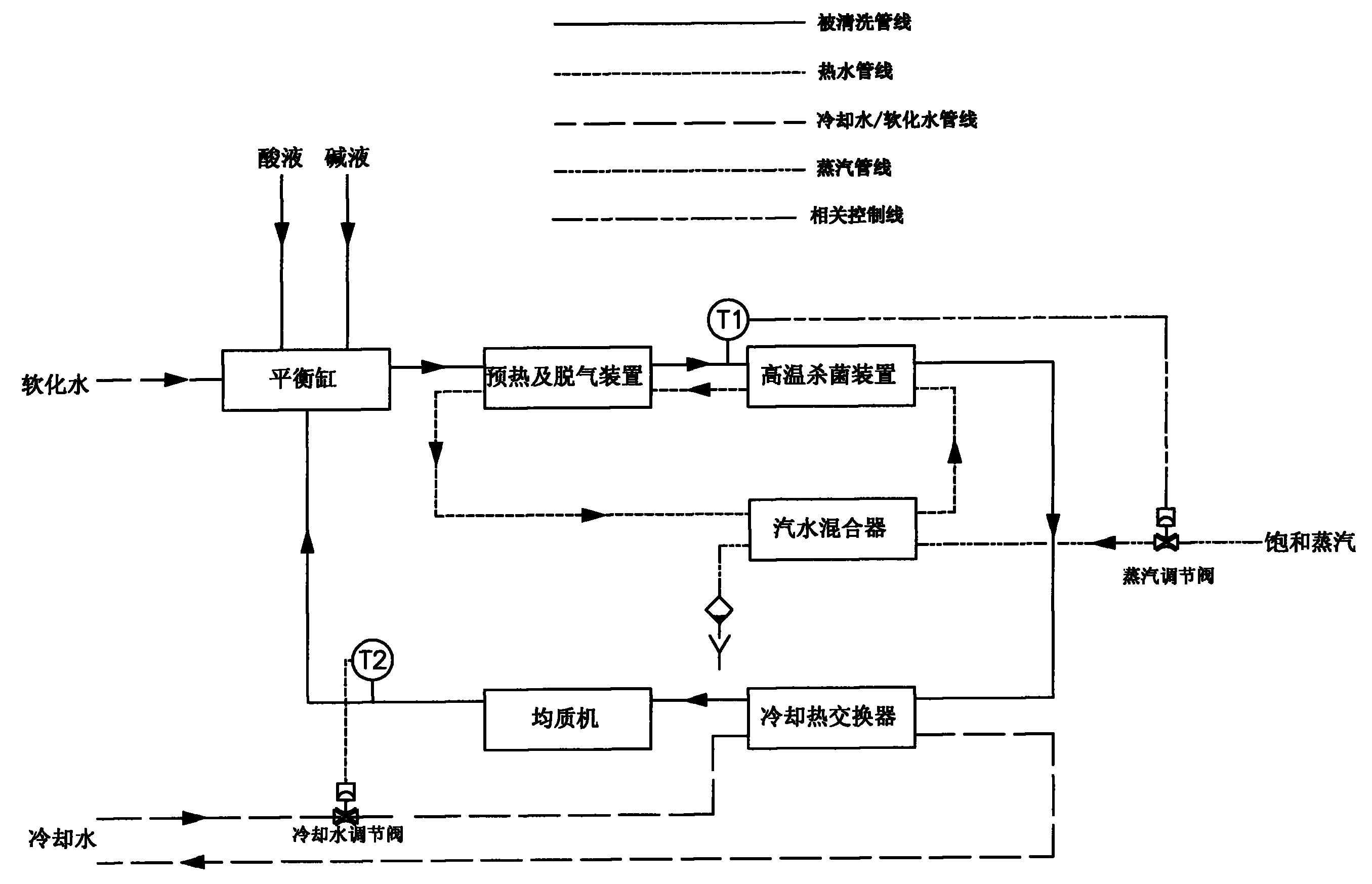

[0017] Embodiment 1: as shown in Figure 1, the ultra-high temperature sterilization machine cleaning process includes the following process steps,

[0018] (1) First, add the cleaning media: water, alkaline water, water, acid water, and water to the balance tank in sequence;

[0019] (2), each medium enters the balance cylinder, preheating degassing device, high temperature sterilization device, cooling heat exchanger, homogenizer, and finally returns to the balance cylinder through the pipeline;

[0020] (3) Steam enters the steam-water mixer to heat the water in the hot water circulation system. The hot water circulation system then heats the temperature of the high-temperature sterilization device and the preheating degassing device. The hot water in the hot water circulation system is heated in the high-temperature sterilization device, Continuous circulation between the preheating degassing device and the steam-water mixer; by controlling the opening of the steam control ...

Embodiment 2

[0022] Embodiment 2: as shown in Figure 1, the ultra-high temperature sterilization machine cleaning process includes the following process steps,

[0023] (1) First, add the cleaning media: water, alkaline water, water, acid water, and water to the balance tank in sequence;

[0024] (2), each of the mediums enters the balance cylinder, preheating degassing device, high temperature sterilization device, cooling heat exchanger, homogenizer, and finally returns to the balance cylinder through the pipeline;

[0025] (3) Steam enters the steam-water mixer to heat the water in the hot water circulation system. The hot water circulation system then heats the temperature of the high-temperature sterilization device and the preheating degassing device. The hot water in the hot water circulation system is heated in the high-temperature sterilization device, Continuous circulation between the preheating degassing device and the steam-water mixer; by controlling the opening of the steam ...

Embodiment 3

[0027] Embodiment 3: as shown in Figure 1, the ultra-high temperature sterilization machine cleaning process includes the following process steps,

[0028] (1) First, add the cleaning media: water, alkaline water, water, acid water, and water to the balance tank in sequence;

[0029] (2), each of the mediums enters the balance cylinder, preheating degassing device, high temperature sterilization device, cooling heat exchanger, homogenizer, and finally returns to the balance cylinder through the pipeline;

[0030] (3) Steam enters the steam-water mixer to heat the water in the hot water circulation system. The hot water circulation system then heats the temperature of the high-temperature sterilization device and the preheating degassing device. The hot water in the hot water circulation system is heated in the high-temperature sterilization device, Continuous circulation between the preheating degassing device and the steam-water mixer; by controlling the opening of the steam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com