Testing system and method for heat-transfer properties of engineering magnitude-order double-layered molten pool of nuclear reactor

A technology for a nuclear reactor and a test system, which is applied in the field of a nuclear reactor engineering-level double-layer molten pool heat transfer characteristic test system, can solve problems such as failure to obtain the natural convection heat transfer relationship of the molten pool, and inability to simulate the heat transfer characteristics of the double-layer molten pool.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

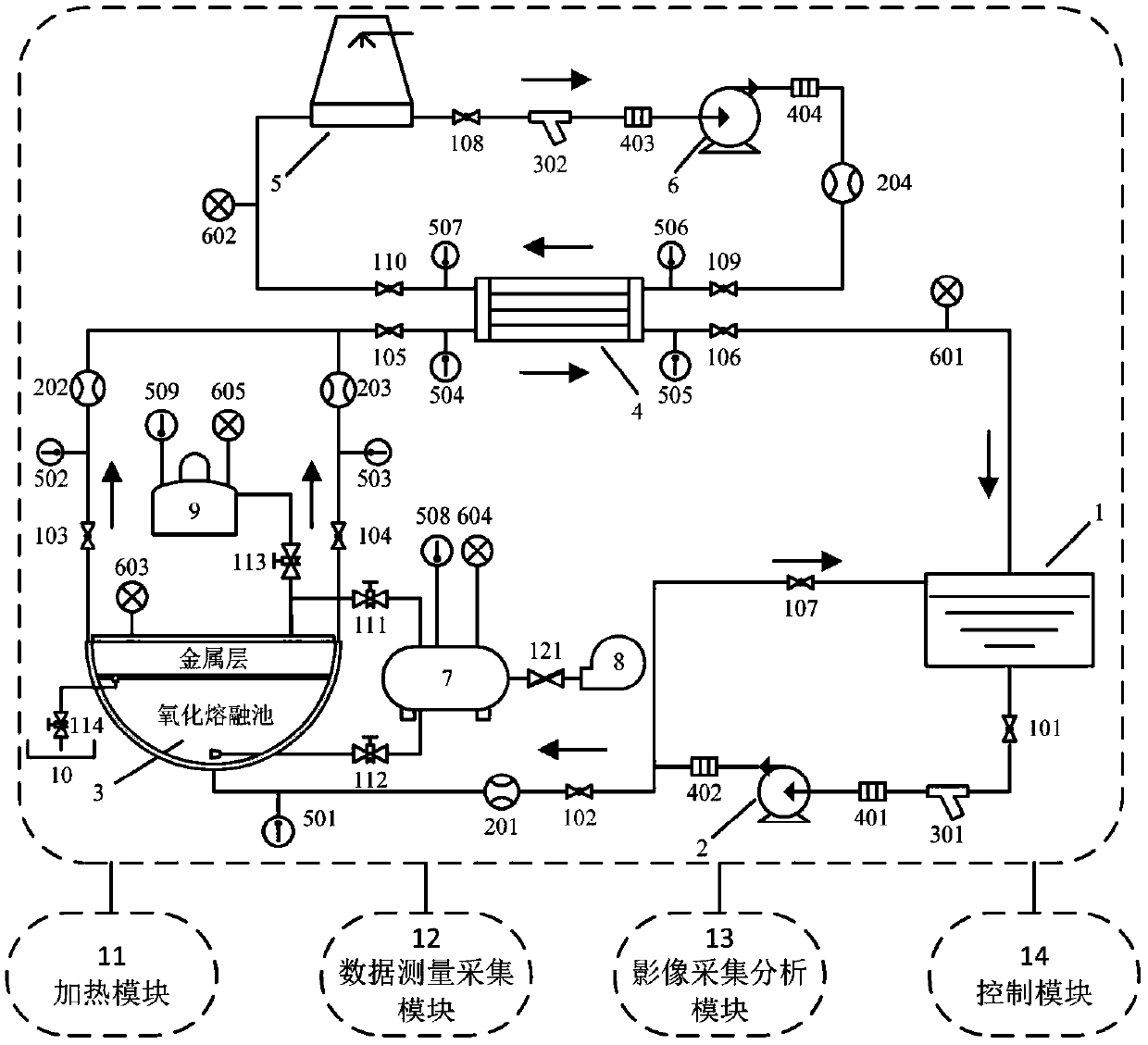

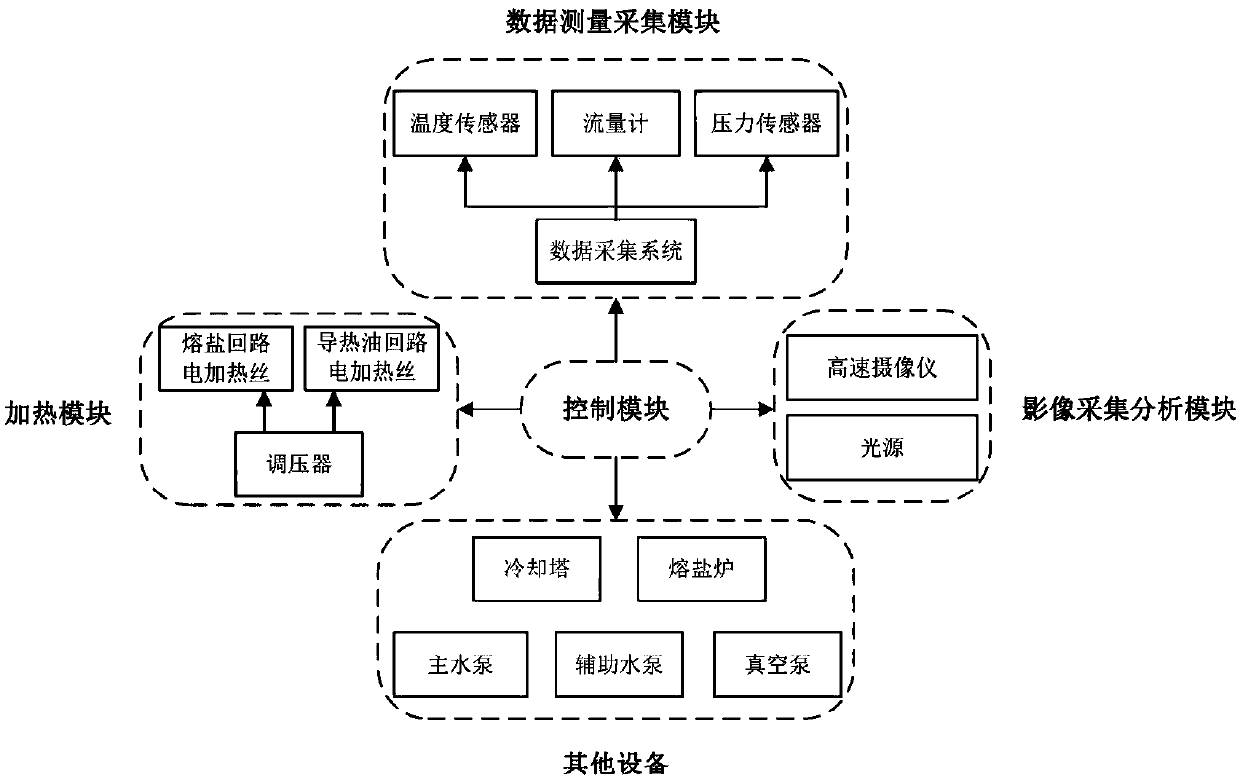

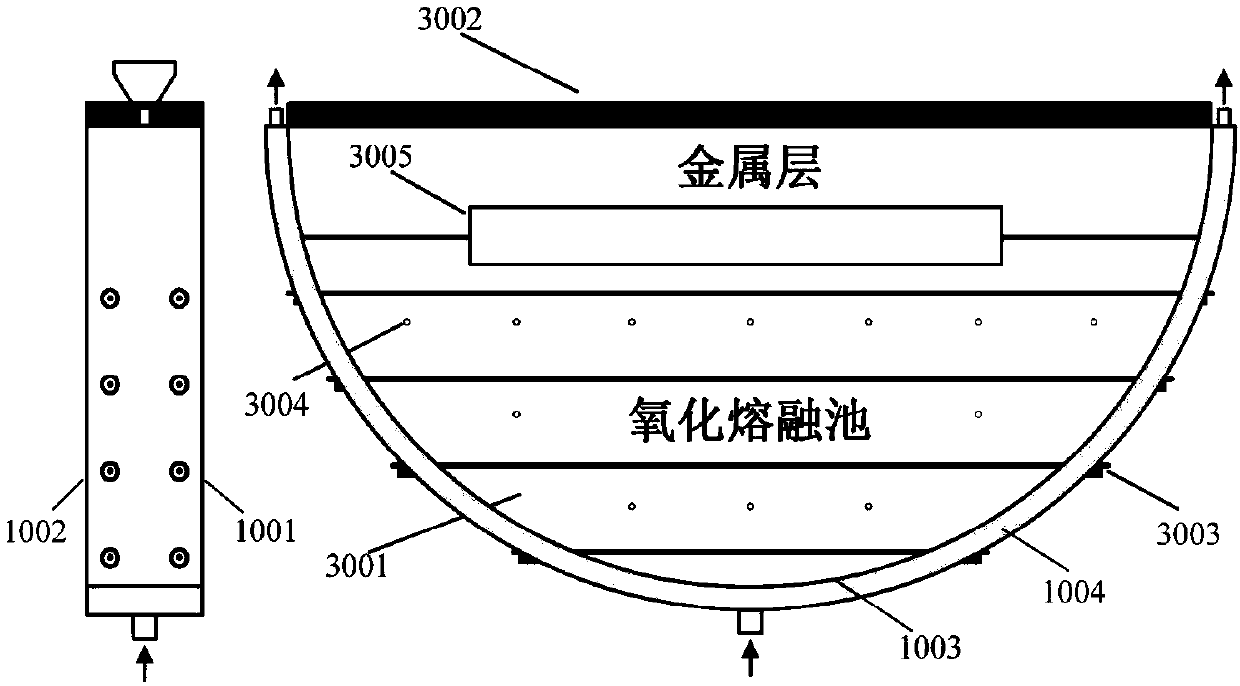

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

[0033] Such as figure 1 As shown, the present invention relates to a nuclear reactor engineering level double-layer molten pool heat transfer characteristic test system, including the main water pump 2 on the main circuit and the first soft joint 401 and the first Y-type filter on the upstream pipeline of the main water pump 2 301, the first valve 101 on the upstream pipeline of the first Y-type filter 301 and its upstream water storage tank 1; the downstream pipeline of the main water pump 2 is connected with a second flexible joint 402, through the first flexible joint 401 and the second flexible joint 402 The cooperation of the main water pump 2 to slow down the pipeline vibration caused by the fluid at the outlet of the main water pump 2; a tee joint is installed on the downstream pipeline of the second soft joint 402, and the two outlets of the tee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com