MEMS microphone

A technology for microphone and sound detection, which is applied to sensor components, microelectronic microstructure devices, sensors, etc., and can solve problems such as mechanical load sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

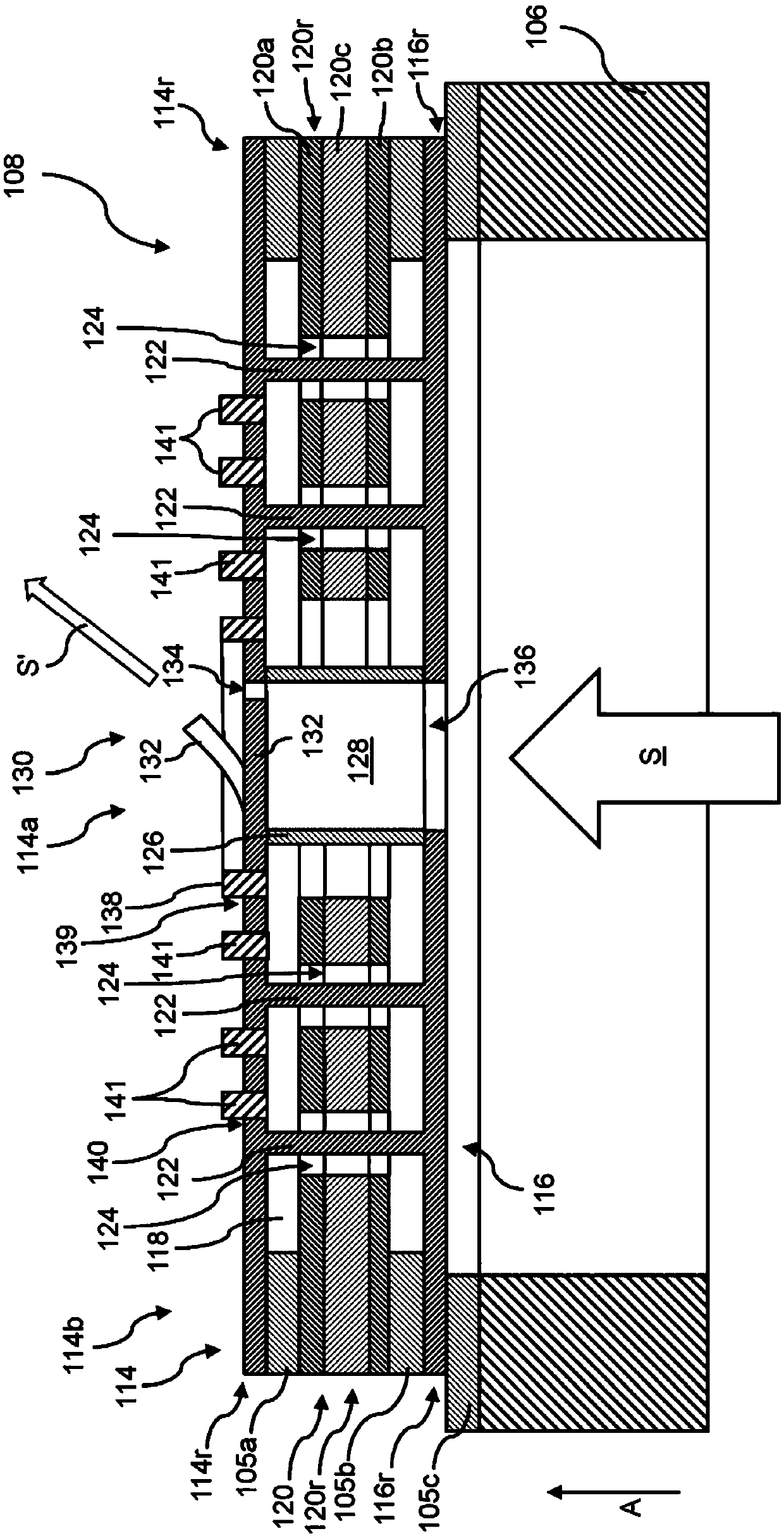

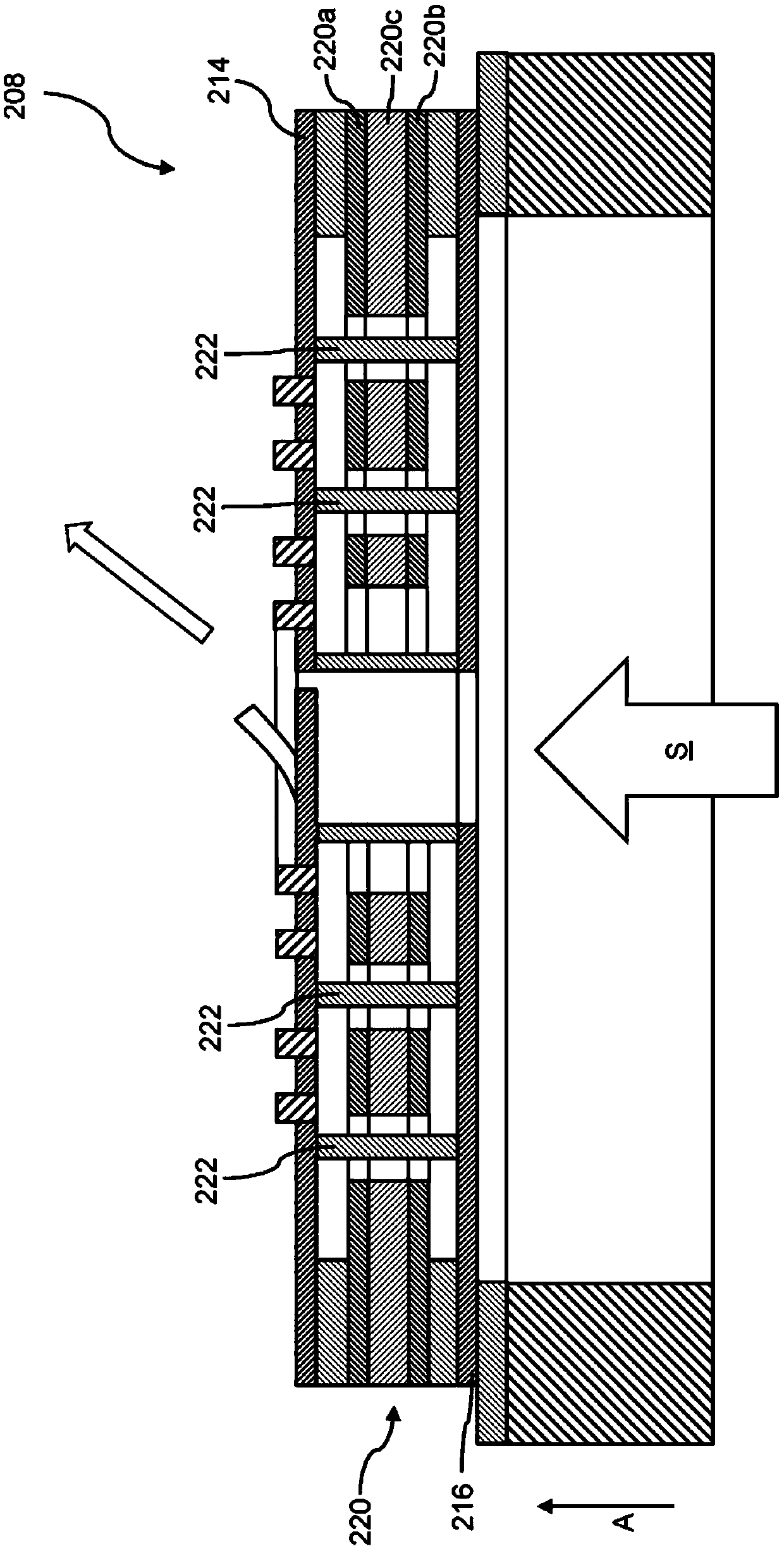

Embodiment Construction

[0009] The term "exemplary" is used herein to mean "serving as an example, as an example, or for illustration." Every implementation or configuration described herein as "example" is not necessarily to be construed as preferred or advantageous over other implementations or configurations.

[0010] In this application, "flat" means a geometric shape of a component that has an extension along a first spatial direction and a second spatial direction orthogonal to the first spatial direction compared to along the first and second spatial directions. The extension of the orthogonal third spatial direction is larger by more than one order of magnitude, optionally by more than two orders of magnitude, further optionally by more than three orders of magnitude. The third spatial direction can also be referred to as the thickness direction of the component.

[0011] The conductive material in the present application may have a conductivity greater than 10S / m, such as greater than 10 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap