Axial surface polymerization degree checker for dental prosthodontic tooth preparatory body

A technology for dental restoration and preparation, which is applied in dentistry, angle/taper measurement, medical science, etc. It can solve the problems of time-consuming and labor-intensive use, inflexible inspection device structure, and low measurement accuracy, so as to shorten the adjustment time and facilitate observation and judgment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

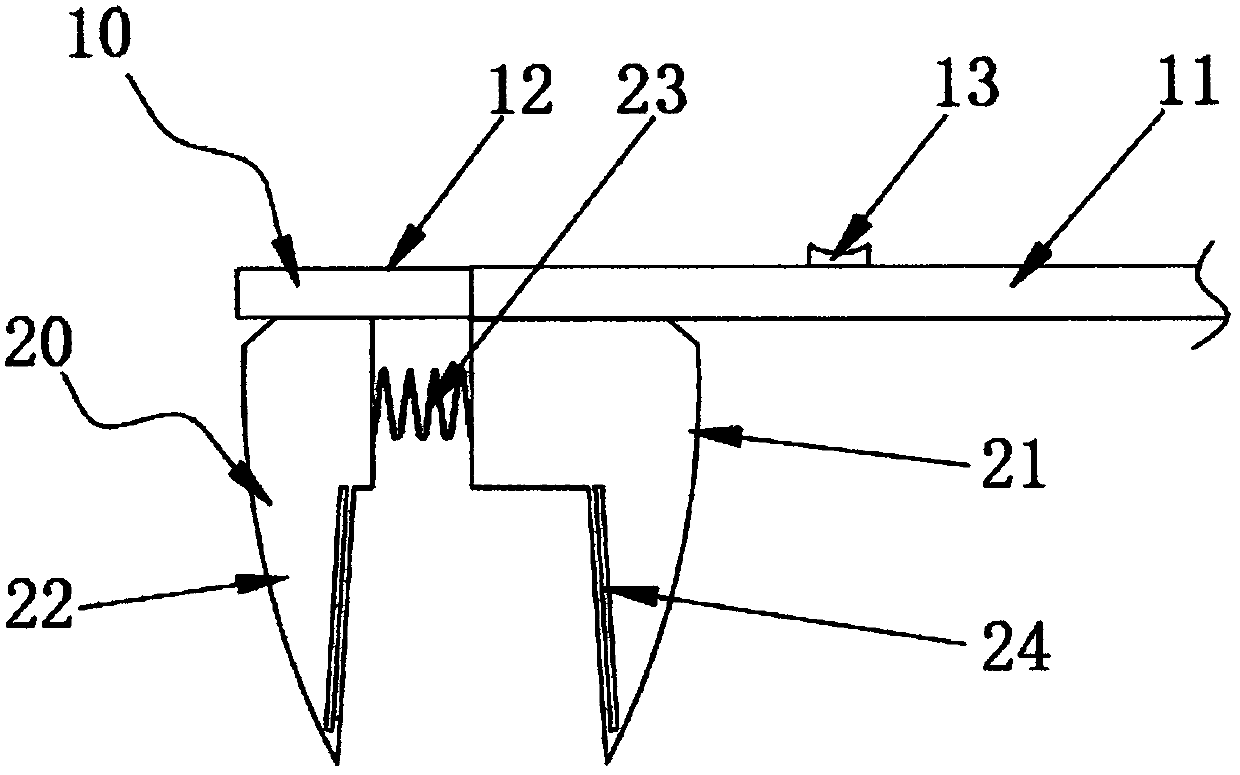

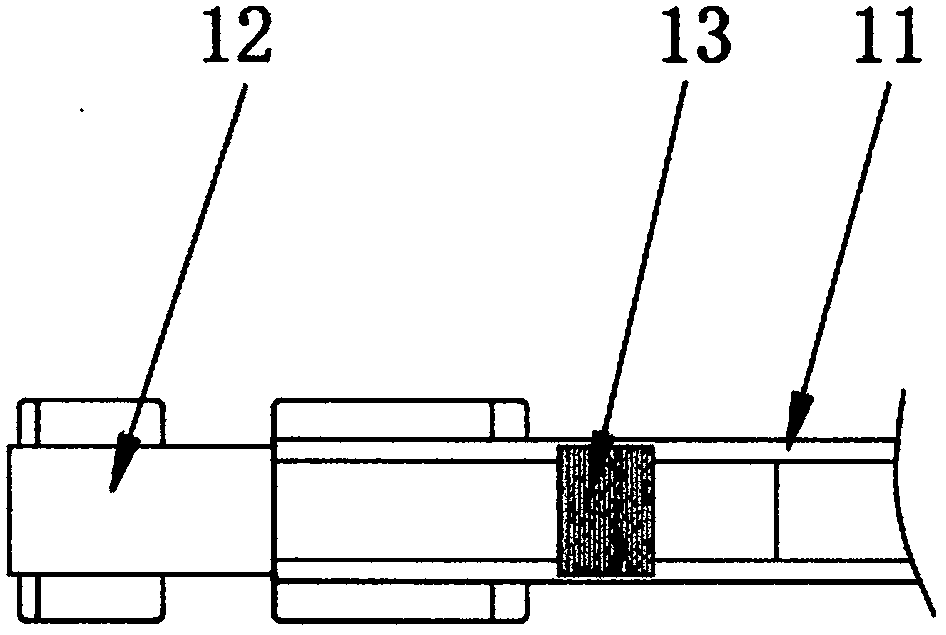

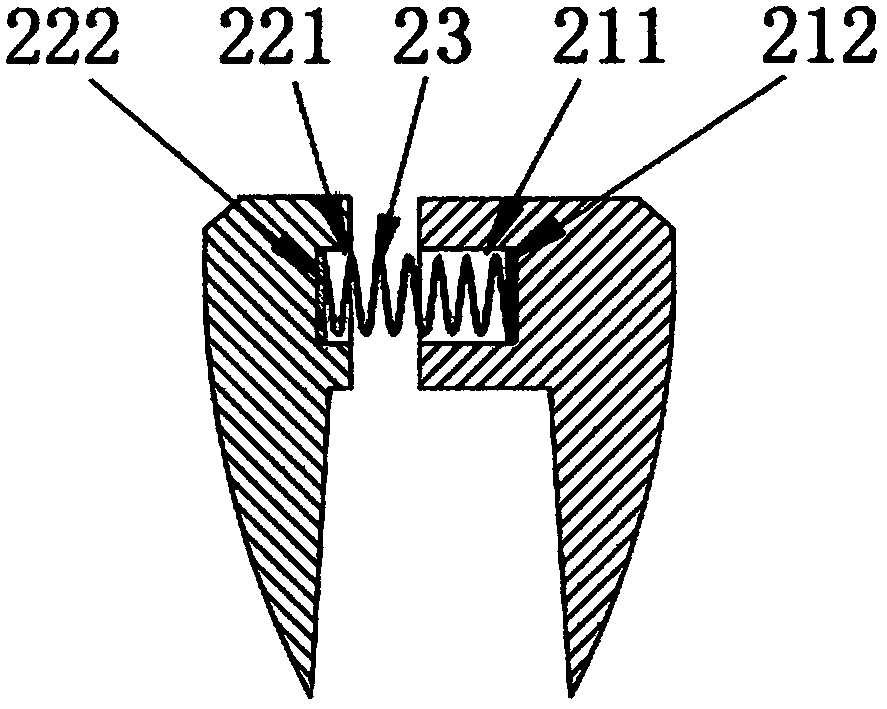

[0025] see Figure 1-4 , the present invention provides the following technical solutions: a dental prosthetic tooth preparation axial surface polymerization checker, comprising an adjustment assembly 10 and an inspection assembly 20, the adjustment assembly 10 includes a handle 11, a slider 12 and a button 13, the slider 12 and the handle 11 sliding connection, the button 13 is located on the top surface of the slider 12, and the button 13 is fixedly connected with the slider 12, the inspection assembly 20 includes a fixed arm 21, a moving arm 22, a spring 23 and a reflective strip 24, the fixed arm 21 is located on the handle 11 bottom surface, and the top surface of the fixed arm 21 is fixedly connected with the handle 11; the movable arm 22 is located at the bottom surface of the slider 12, and the top surface of the movable arm 22 is fixedly connected with the slider 12; The movable arm 22 is fixedly connected, and the fixed arm 21 and the front of the movable arm 22 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com