Tea screening machine

A screening machine and tea technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of inability to connect, inability to block tea leaves, uneven vibration screening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

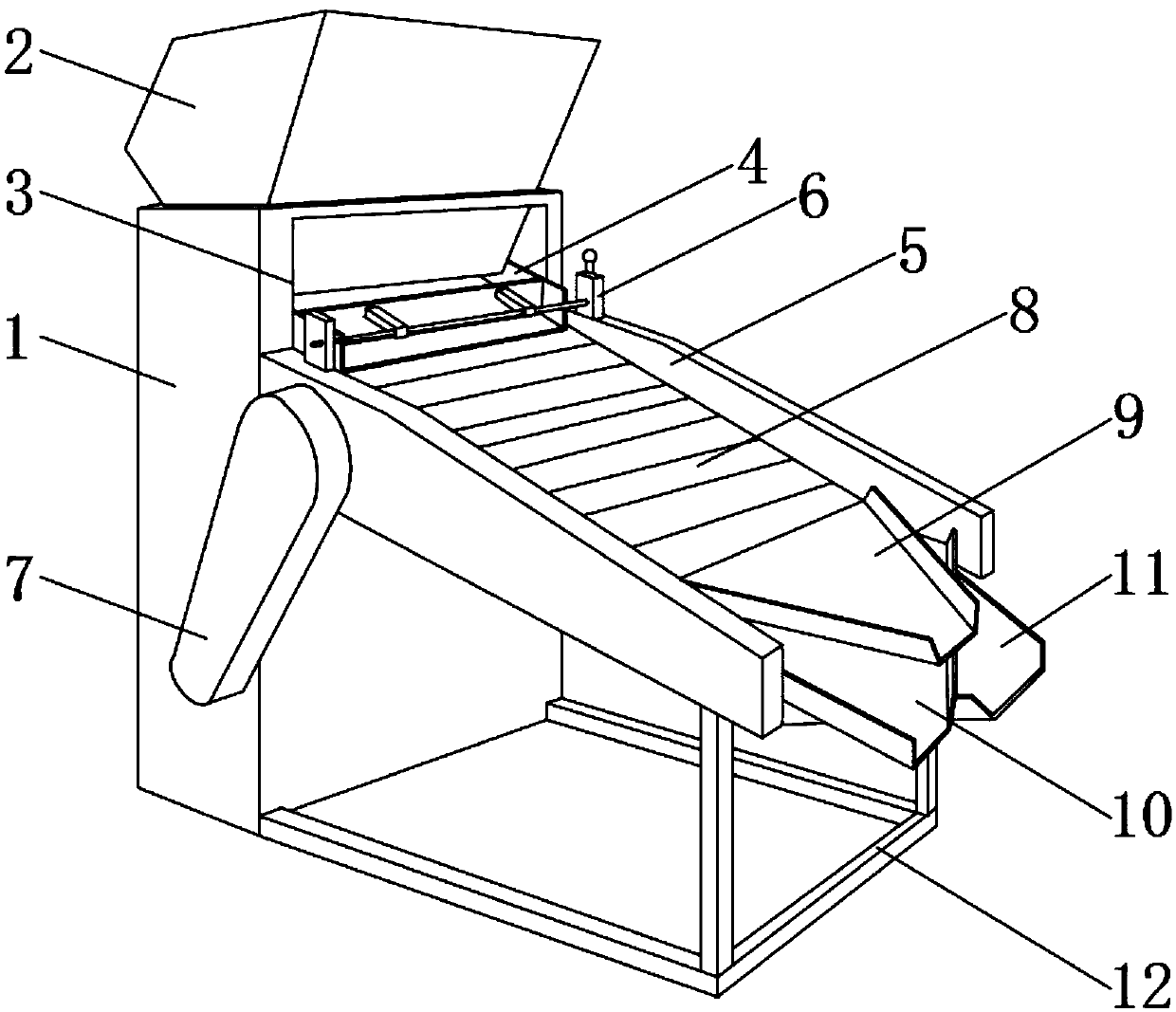

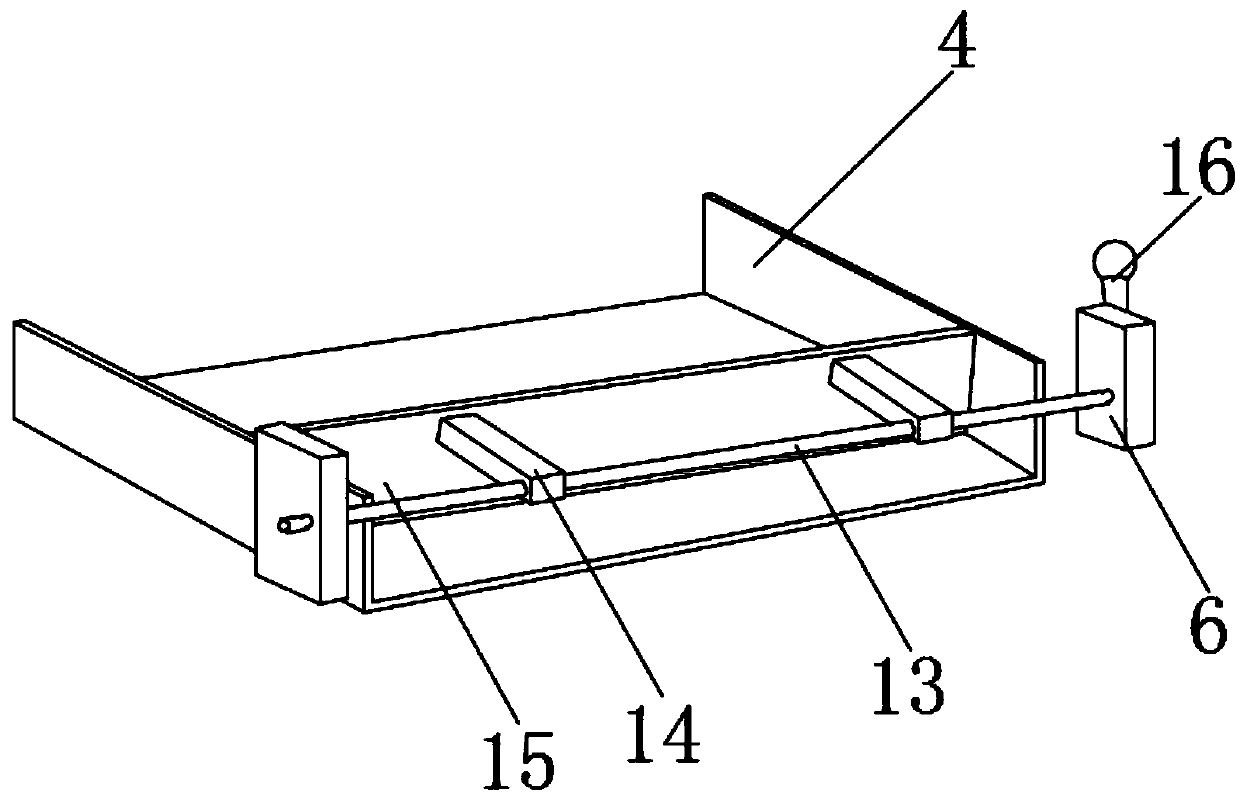

[0025] Such as Figure 1-4 As shown, a tea screening machine comprises a main frame 1 and a feed hopper 2, the feed hopper 2 is fixedly installed on the upper end of the main frame 1, and the upper end side of the main frame 1 is provided with a feeding port 3, and the feed hopper 2 The bottom end of the main box 1 runs through the upper end of the main box 1, the material receiving plate 4 runs through the inside of the feeding port 3, and the material receiving plate 4 is located at the bottom of the feeding hopper 2, and the bottom side of the feeding port 3 is fixed and installed There is a crossbeam plate 5, and an adjustment block 6 is fixedly installed on one side of the upper end of the crossbeam plate 5, and a transmission rod 13 is installed through the inside of the adjustment block 6, and two sets of installation rods 14 are fixedly installed on one side of the outer circumference of the transmission rod 13. One end of the group mounting rod 14 is fixedly equipped ...

Embodiment 2

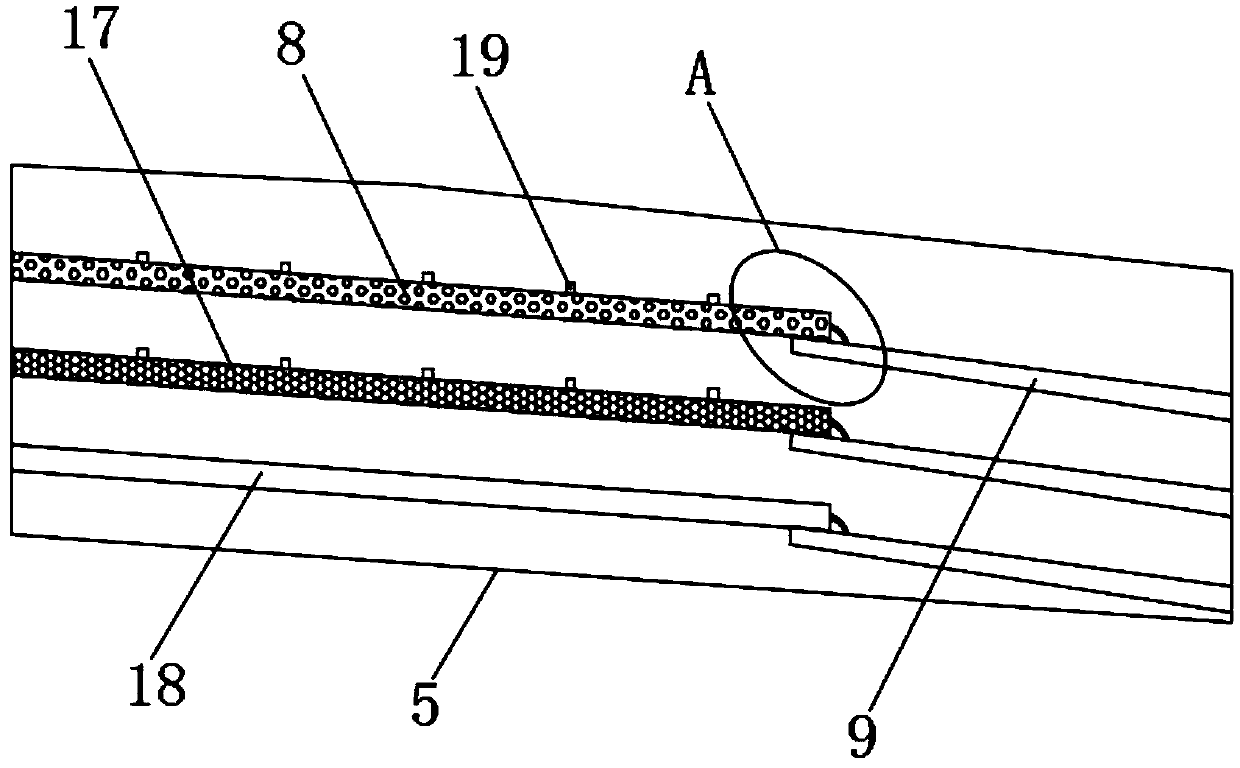

[0027] Such as Figure 1-4 As shown, the inside of the beam plate 5 is provided with a coarse sieve plate 8, a fine sieve plate 17 and a bottom plate 18, and the coarse sieve plate 8 is located at the upper end of the fine sieve plate 17, and the bottom plate 18 is located at the lower end of the fine sieve plate 17, and the coarse sieve plate 8 is located at the lower end of the fine sieve plate 17. The lower end of the bottom plate is provided with a No. 1 discharge port 9, the lower end of the fine sieve plate 17 is provided with a No. 2 discharge port 10, the lower end of the bottom plate 18 is provided with a No. 3 discharge port 11, and the No. 10 and No. 3 discharge port 11 are all fixedly installed on the inner wall of the beam plate 5, a belt cover 7 is fixedly installed on one side of the beam plate 5, and the bottom end of the belt cover 7 is fixedly installed on one side of the main box 1, and the belt cover The inside of 7 is provided with a transmission belt, the...

Embodiment 3

[0029] A tea screening machine, comprising a main box 1, the top of the main box 1 is provided with a feeding hopper 2, the upper end of one side of the main box 1 is provided with a feeding port 3 communicating with the opening at the bottom of the feeding hopper 2, and the bottom of the feeding hopper 2 is A receiving plate 4 is arranged below the opening, and the receiving plate 4 stretches out from the feeding port 3 of the main box 1, and the end of the receiving plate 4 protruding from the main box 1 is inclined downward, and the receiving plate 4 is used to catch the material from the feeder. The tea leaves added by the bucket 2; one end of the material receiving plate 4 protruding from the main box 1 is connected to one end of the coarse sieve plate 8, the bottom of the coarse sieve plate 8 is provided with a fine sieve plate 17, and the bottom of the fine sieve plate 17 is provided with a bottom plate 18; There are several groups of coarse sieve holes on the plate 8, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com