Bottle blank counting device

A technology for counting devices and preforms, applied in packaging, packaging bottles, packaging protection, etc., can solve problems such as time-consuming and labor-intensive, and achieve a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

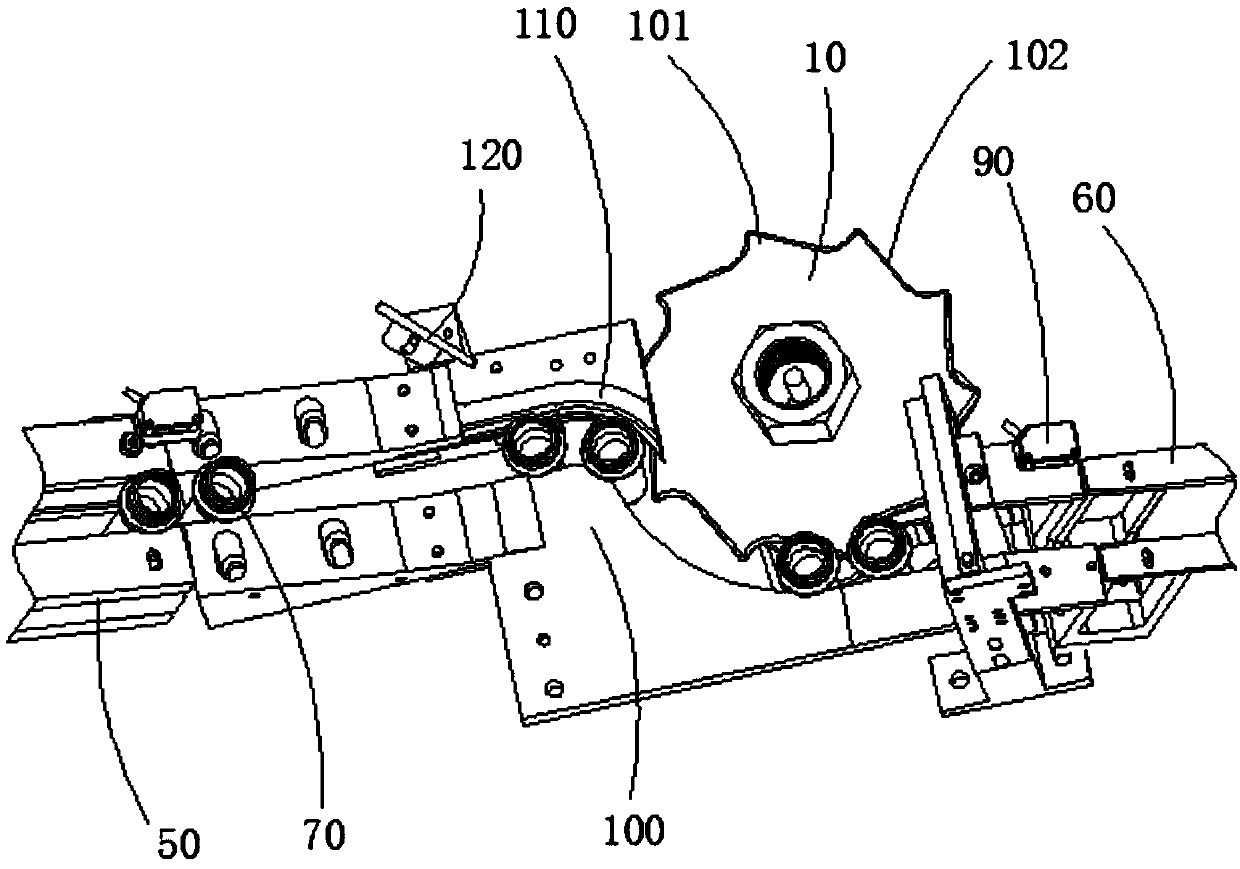

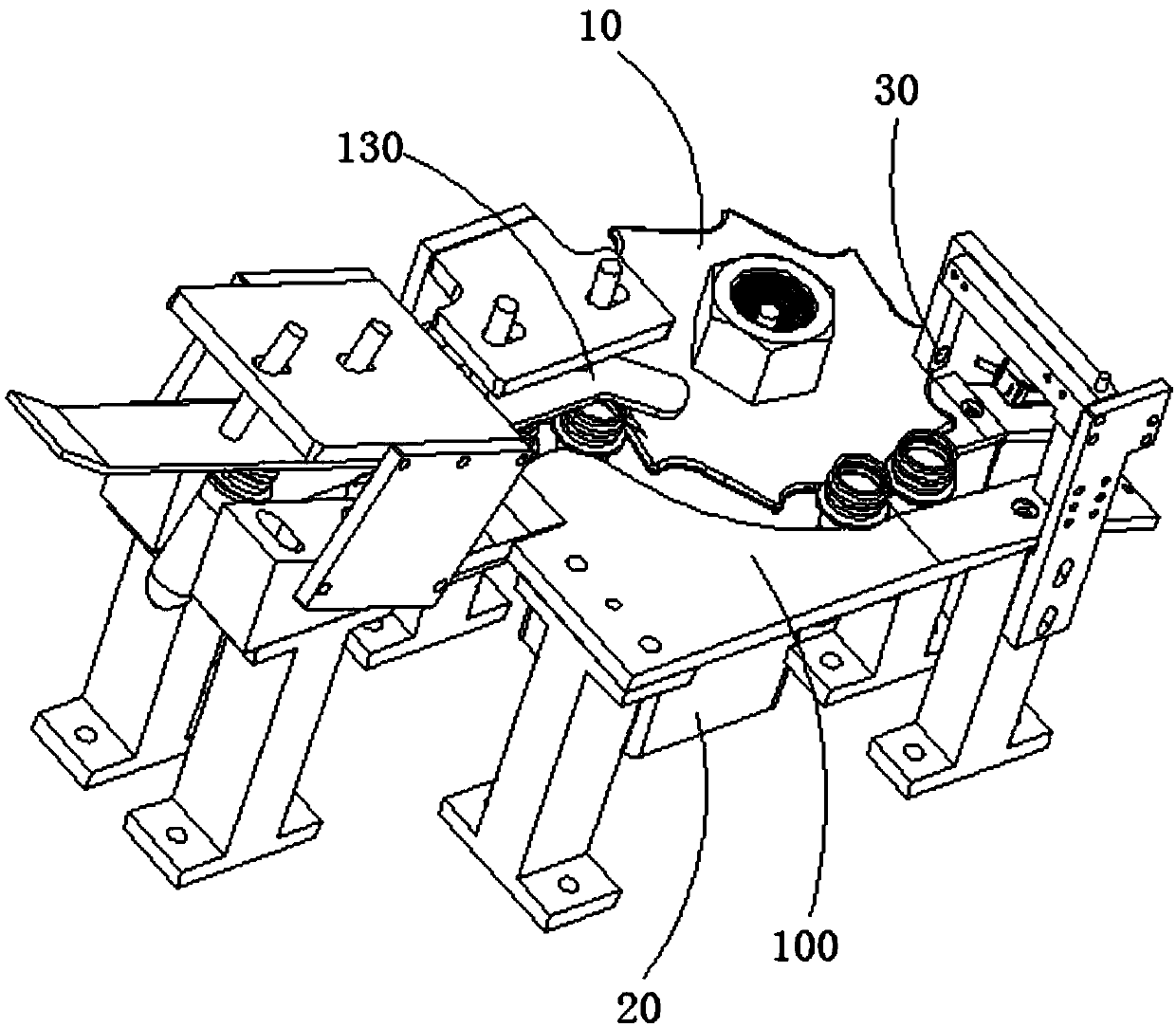

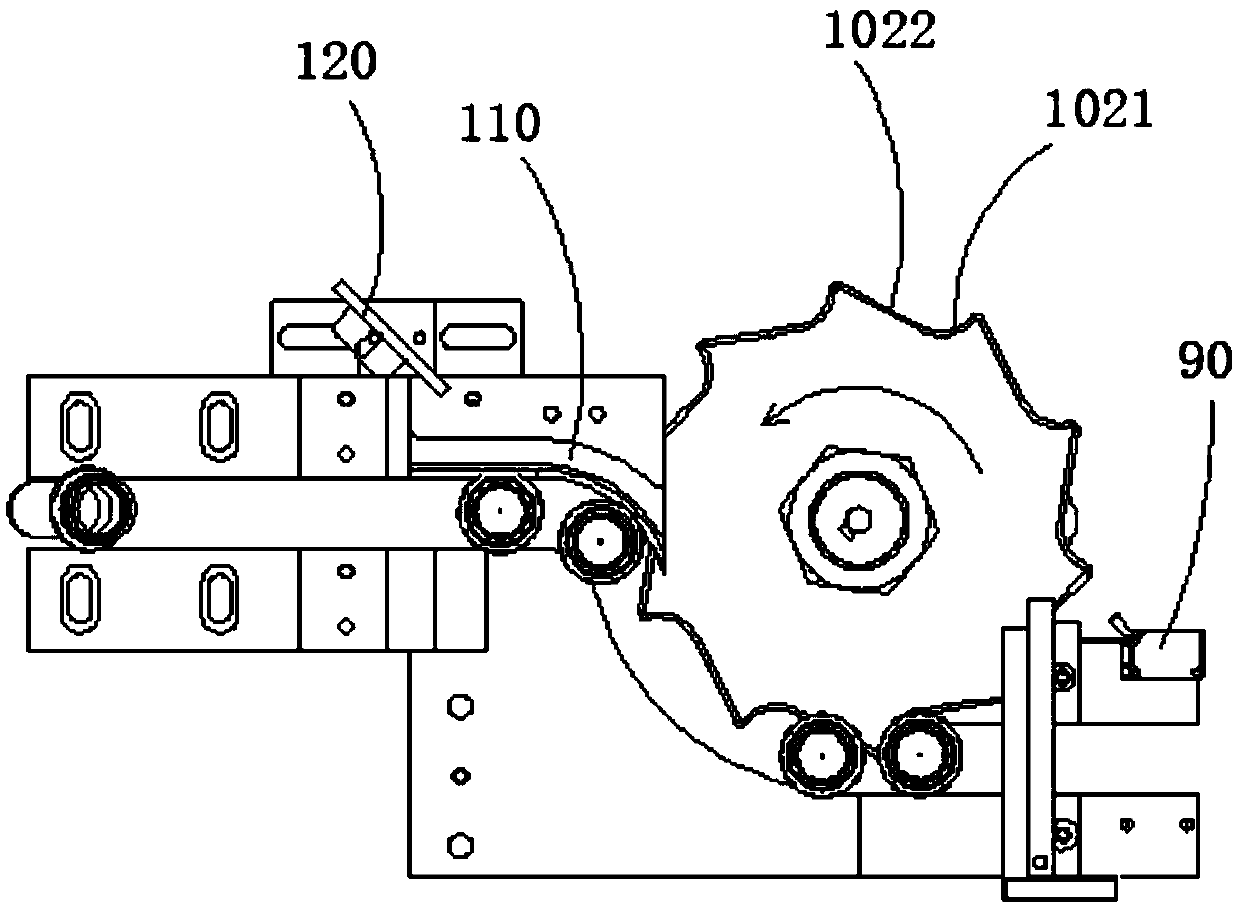

[0035] see figure 1 , figure 2 with Figure 4 , the first embodiment provides a preform counting device, including a turntable 10 , a first arc guide plate 100 , a driver 20 , a counter 30 and a controller 40 .

[0036] Wherein, the turntable 10 and the first arc-shaped guide plate 100 are installed between the feed channel 50 and the material channel 60, and the driver 20 is used to drive the turntable 10 to rotate; the edge of the turntable 10 is set There are a plurality of teeth 101 , and the inter-tooth grooves 102 of the turntable 10 cooperate with the first arc-shaped guide plate 100 to receive the preforms from the feed channel 50 and transport them to the material channel 60 .

[0037] The counter 30 is used to record the number of preforms 70 passing through the turntable 10, and the counter 30 is electrically connected to the driver 20 through the controller 40, and the controller 40 is used to 30 record times to judge whether the material channel 60 is full, an...

Embodiment 2

[0052] Correspondingly, see figure 1 , the present embodiment 2 provides a preform filling machine, which includes the preform counting device involved in the above embodiment 1 (the specific structure of the preform counting device will not be repeated one by one), and also includes a feed flow channel 50 and the forehearth 60 , the preform counting device in the first embodiment above is set between the feed channel 50 and the forehearth 60 .

[0053] The preform filling machine provided in the second embodiment has all the advantages of the above-mentioned preform counting device because it includes the above-mentioned preform counting device, and can judge whether the material path 60 is full, and automatically stop when the material path 60 is full. The conveyance of the preform 70 to the material channel 60 does not require manual observation and operation, and has a high degree of automation, saving time and effort.

[0054] In summary, the embodiment of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com